Automobile air conditioner compressor: diagram and device, principle of operation, diagnostics, malfunctions and replacement, TOP-3 models

Content

- The device and diagram of the air conditioner compressor

- Principle of operation

- The main characteristics of the compressor

- Types of Compressors

- How to check if it works

- Air Conditioning Compressor Malfunctions

- How to disassemble the air conditioning compressor

- How to replace

- Compressor recovery

- Flushing and cleaning the car air conditioner compressor

- The best car compressors

Auto compressors with electromagnetic clutch are very reliable. But the incessant rotation greatly wears out the rubbing parts, which distinguishes automotive equipment from household units. Models installed in machines are sensitive to depressurization; oil leaves the system along with freon.

Attempts to cool the interior of the car began as early as 1903. Today, not a single passenger car leaves the assembly line without climate control equipment. The main element of the system is the car air conditioner compressor. It is useful for every car owner to have an elementary idea of \uXNUMXb\uXNUMXbthe operation of the unit, characteristics, breakdowns and troubleshooting methods.

The device and diagram of the air conditioner compressor

The “heart” of an air conditioner is a complex structure in which the refrigerant (freon) is compressed and turns into a gas with a high temperature. The compressor pumps the refrigerant, drives it in a vicious circle.

The autocompressor divides the cooling system into two circuits: high and low pressure. The first includes all the elements up to the evaporator, the second - the line that connects the evaporator to the compressor.

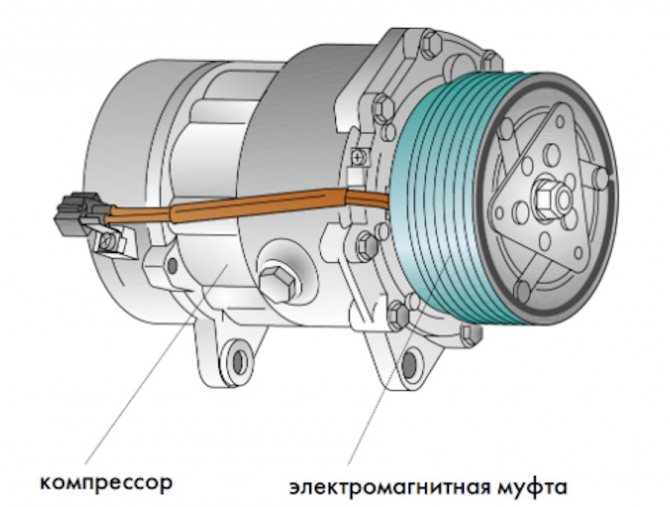

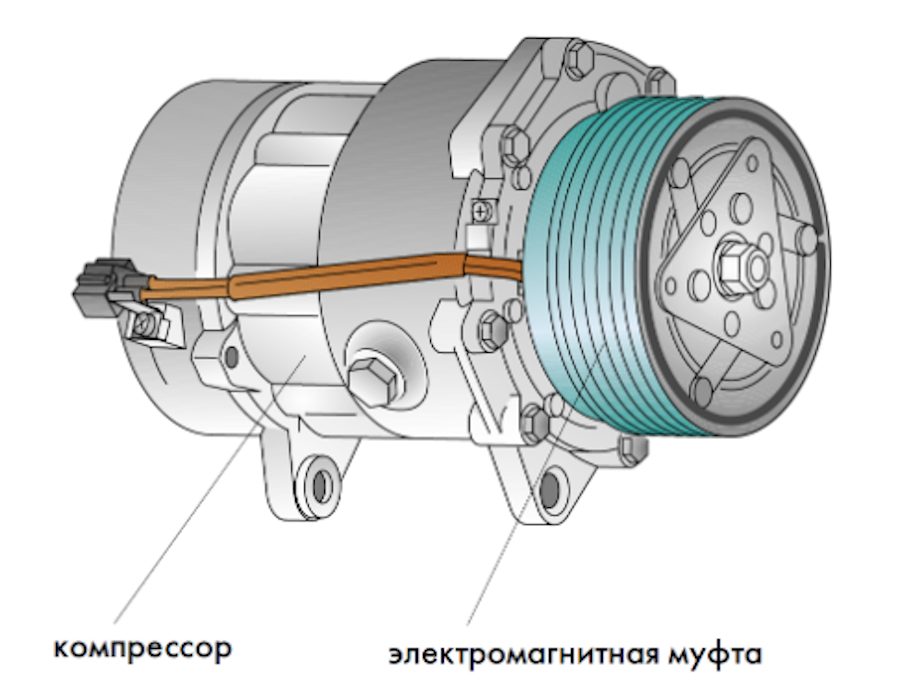

The main components of the car air conditioner compressor in the diagram:

Compressor units

Principle of operation

The electromagnetic clutch is equipped with a metal pulley. The principle of operation of the car air conditioner compressor is as follows. When the car engine is on, the pulley does not do any work: it rotates idle, the coolant is not affected. The car owner turns on the air conditioner with the button from the instrument panel, the clutch is magnetized, transmits torque to the pump. This starts the movement of the working substance (freon) in a vicious circle from the high pressure circuit to the low pressure circuit.

The main characteristics of the compressor

Performance is of interest to drivers when it is necessary to change a failed compressor for a new part. Consider the device of an automobile air conditioner compressor from your car, select an analogue according to external geometric parameters, design, and refrigerant used.

The weight

Weigh the old part. Do not trust the opinion "the harder the better." An automobile compressor for an air conditioner can have a mass of 5-7 kg and more. The heavier the unit, the more cold the air conditioner will produce, but it will also take more horsepower from the engine: your car may not be designed for this. Select a part in the car market not by weight, but by VIN code or body number of your car.

Power

This indicator is not indicated by all manufacturers: in addition, the data may be inaccurate. You should not arbitrarily choose the power of the device, since at the car factory the parameter is calculated exactly for the power unit and class of your car:

- class B and C cars lose 4 liters when the air conditioner is turned on. with., that is, the compressors have a capacity of 2,9 kW;

- cars of class D and E spend 5-6 liters. sec., which corresponds to the node power of 4-4,5 kW.

Maximum pressure

The unit of this parameter is kg/cm2. You can check the pressure of the car's air conditioner compressor yourself using pressure gauges with suitable connectors, or (more precisely) with a special pressure gauge block.

The indicator depends on the labeling of the refrigerant and the ambient temperature. So, for the refrigerant R134a at + 18-22 ° С on the thermometer in the low pressure circuit it will be 1,8-2,8 kg / cm2, high - 9,5-11 kg / cm2.

It is better to do a control check of the car's air conditioner compressor for working pressure in the service.

Types of Compressors

Although the device of the car air conditioner compressor is similar in principle of operation in different models, there are design features. There are the following types of pressure blowers:

- Piston. The design may contain one or from 2 to 10 pieces of differently spaced pistons driven by an inclined disk.

- Rotary blade. The blades (2-3 pieces) of the rotor rotate, change the volume of the circuits with the incoming working substance.

- Spiral. In the mechanism, two spirals are inserted one into the other. One rotates inside the second, motionless, spiral, compressing freon. Then the latter is discharged, goes further into the circuit.

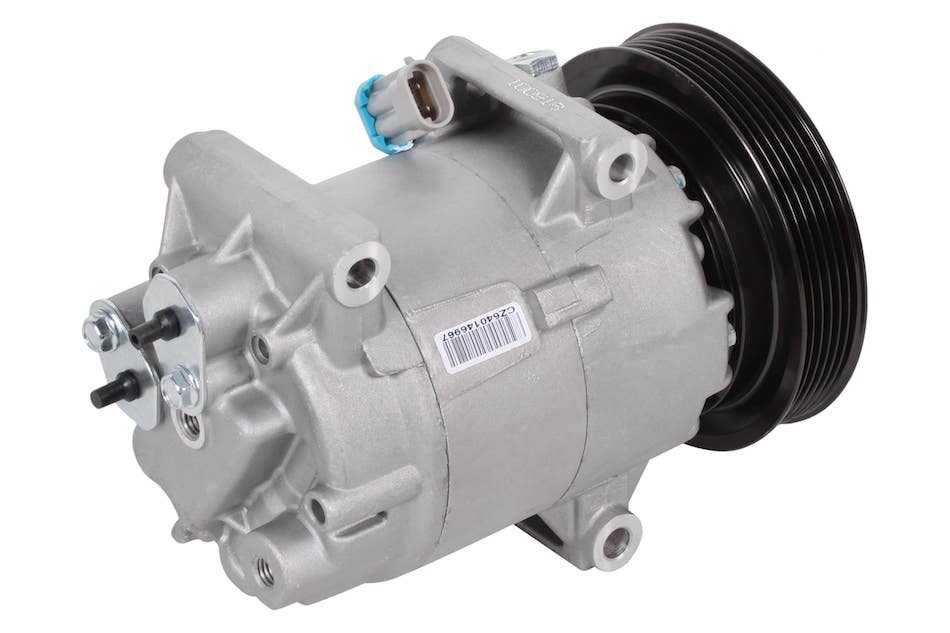

Appearance of an air conditioner compressor

Piston installation is the simplest and most common. Rotary types are installed mainly on Japanese cars. Scroll compressors have become widespread since 2012, they come with an electric drive.

How to check if it works

When a car is bought in the secondary market, you need to check the car's air conditioning compressor for performance.

Simple ways:

- Run the unit in normal mode: switch settings, watch how the temperature in the cabin changes.

- Examine the knot. Oil leakage, leakage can be seen visually.

- Listen to the operation of the system: it should not rattle, buzz, create extraneous noise.

- Independently or in the service, measure the pressure inside the system.

Air Conditioning Compressor Malfunctions

Regular maintenance, properly selected oil prevent breakdowns of climate control equipment. However, malfunctions of the car air conditioner compressor still happen often.

Warning signs:

- Noise is constantly heard from the node, even if the air conditioner is not turned on, but only the car engine is running. Check pulley bearing.

- The electromagnetic clutch does not turn on. There are many reasons to look for.

- The unit does not cool the air in the cabin well. Possible freon leak.

- Something in the compressor is cracking, rumbling. Check the pressure in the hot and cold state of the equipment.

One or more signs appeared - professional diagnostics of the car air conditioning compressor is needed.

Causes

Autocompressors are reliable units with a long working life. But failures happen, there are many reasons:

- Bearings worn out. The danger is that the load on the coil increases, the drive pulley warps, freon can come out completely.

- The system overheated, due to which the clutch failed.

- The body or pipes were deformed as a result of some mechanical impact, the sealing was broken.

- The valves responsible for the supply of the working substance are out of order.

- Clogged radiator.

Compressor device for car air conditioner

Deficiency or excess of freon also has a bad effect on the performance of the system.

Solutions

Refrigeration equipment is a complex installation that is difficult to restore in a garage environment.

You can do the following with your own hands:

- Weld cracks on the body and nozzles of the autocompressor.

- Replace the seals after removing the refrigerant and dismantling the unit.

- Change the failed drive pulley bearing, but only after removing the mechanism, and if you know how to press in the elements.

- Repair the electric clutch, which often needs to change parts: plate, coil, pulley.

It is risky to touch the piston group, since you need to completely remove the assembly, disassemble, and wash the parts. Before the procedure, freon is removed, oil is drained, so it is better to entrust service to servicemen.

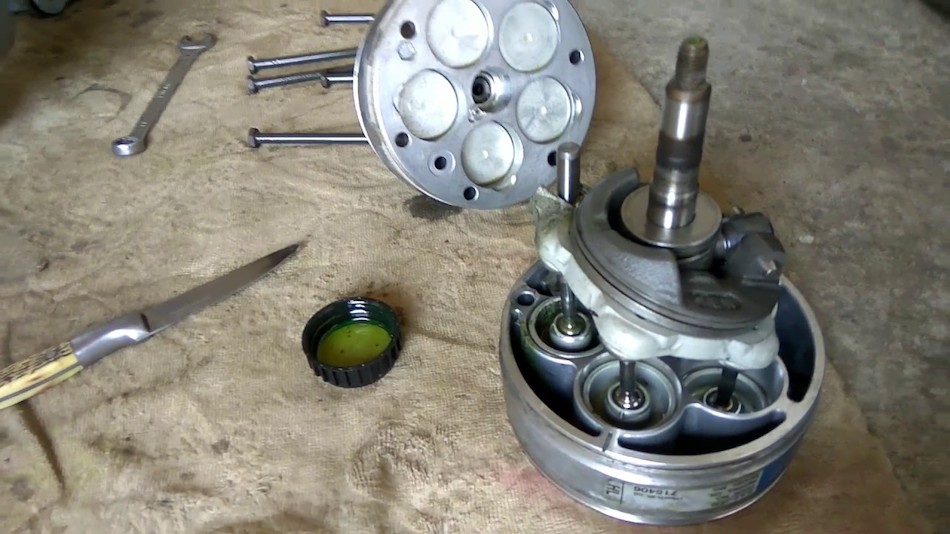

How to disassemble the air conditioning compressor

The dismantling of the compressor on different brands of machines takes place in a different order. But when the part is already on the workbench, do the bulkhead according to this scheme:

- Clean the assembly of dirt.

- Disconnect the electrical wires.

- After unscrewing the central nut, remove the drive pulley (you need a holding special wrench).

- Remove the clutch disc (use a universal puller).

- Remove the circlip holding the pulley bearing.

- Use a three-finger puller to pull the bearing pulley off the compressor.

- Remove the retaining ring that holds the clutch solenoid.

- Remove the electromagnet.

- You have the compressor in front of you. Unscrew the bolts of the front cover - it will move away from the body.

- Remove the cover with the shaft, take out the support bearing and its lower race.

- Remove the piston group, thrust bearing and seat.

- Remove the spring and key.

- Turn the part over, unscrew the fasteners of the compressor rear cover.

- Throw out the gasket you find: it will need to be replaced.

- Remove the valve disc and seal underneath.

How to disassemble the air conditioning compressor

Now you have to disassemble the cover with the shaft. Pull out in order: dust and retaining rings, key, shaft with bearing. Now it is important not to lose details.

How to replace

Disassembling the assembly shows how many special expensive tools need to be purchased. If you are not a professional car mechanic, then think about whether it was worth buying special tools for a one-time repair. Entrust the replacement of the car air conditioner compressor to specialists.

Compressor recovery

Auto compressors with electromagnetic clutch are very reliable. But the incessant rotation greatly wears out the rubbing parts, which distinguishes automotive equipment from household units. Models installed in machines are sensitive to depressurization; oil leaves the system along with freon.

Flushing and cleaning the car air conditioner compressor

Dust and moisture do not penetrate into the closed system. But this happens:

- the air conditioner can depressurize, then dirt gets inside;

- the pistons wear out, the chips begin to circulate along the contour;

- the owner refilled the wrong oil, it reacted with the working fluid, flakes formed.

In these cases, it is necessary to rinse and clean the climate equipment.

A simple motorist should not do this for several reasons:

- there is no necessary equipment;

- not everyone knows the most complicated technology for cleaning the node;

- you can be poisoned by toxic substances of the decomposition of freon.

Assess your capabilities, drive the car to a car repair shop.

The best car compressors

Experts, having evaluated the performance characteristics of different brands of car air conditioner compressors, ranked the best units.

3 position - Compressor Sanden 5H14 A2 12V

The five-piston apparatus weighs 7,2 kg, dimensions - 285x210x205 mm. Capacity 138 cm³/rev. Piston group rings are made of high-quality steel, which ensures a long working life of the equipment.

Compressor Sanden 5H14 A2 12V

Powerful compressor designed for refrigerators and air conditioners, works with liquids R134a, R404a, R50. Sanden 5H14 A2 12V is supplied with transport oil, which must be replaced with PAG SP-20 or equivalent before installation. The amount of lubricant - 180 g.

Price Sanden 5H14 A2 12V - from 8800 rubles.

2 position - SAILING Air Conditioning Compressor 2.5 Altima 07

The purpose of the compressor is air conditioners for passenger cars of domestic and foreign manufacturers. The 2 kW piston unit operates with HFC-134a refrigerant, the type of oil used is PAG46. One filling requires 135 g of lubricant.

SAILING Air Conditioning Compressor 2.5 Altima 07

Drive pulley type - 6PK, diameter - 125 mm.

The price of the product is from 12800 rubles.

1 position - Luzar LCAC air conditioner compressor

This popular and sought-after equipment is not easy to find commercially. A compact unit in a sturdy case weighs 5,365 g, dimensions - 205x190x280 mm, which allows you to install an autocompressor under the hood of any passenger car. Applied refrigerants - R134a, R404a, car oil - PAG46 and analogues. Lubricant volume – 150±10 ml.

Air conditioning compressor Luzar LCAC

The power of the device is 2 kW, the diameter of the pulley type 6PK is 113 mm.

The price starts from 16600 rubles.