How and how to paint car rims yourself

Content

Fundamentally, the process of imparting decorative properties to discs does not differ from any other painting work on a car. There are some features, but in general the technology is the same: surface preparation, priming, painting, preferably polishing. Home technology differs significantly from industrial production, where typically discs are hot cured powder coated.

What paint to choose for wheels

In terms of chemical composition, cost, durability and decorative properties, all paints are somewhat different.

Each has advantages and disadvantages, otherwise they would have ceased to be produced long ago.

- Nitroenamels. They dry very quickly, are cheap, but that's where their virtues end. Now few people use them to repair cars, although not so long ago they even painted Rolls-Royces. True, according to an extremely complex technology in two dozen layers with intermediate processing of each.

- Alkyd enamels. They are also easy to use and dry easily outdoors at normal temperatures. And they are inexpensive. A good property for an inexperienced master is that they quickly form a film, which helps to fight streaks. But the quality of the coating and durability leave much to be desired.

- Acrylic paints. The most popular means in body repair. They provide a high-quality coating with high decorative and protective properties. They can be used with natural drying and polymerization from heating. In combination with varnish, they give deep, rich metallic effects.

- Powder enamels. Few are used in amateur work, because they require sophisticated equipment for application. But the coating is very stable and provides a beautiful appearance.

- Liquid rubber. Strictly speaking, it does not apply to paints, it has a controversial reputation and a difficult technology. Material, as they say, for an amateur.

Most often, an acrylic coating is chosen for self-application. It is comfortable, durable and usually pleases with the result.

Pros and cons of spray painting and stamping

The use of paint in aerosol cans attracts with its simplicity. You do not need a paint gun, which few people know how to work properly, prepared and dehydrated air under strictly the right pressure, bringing the paint to the desired consistency. It is enough to shake up an inexpensively purchased spray can.

This is precisely the first shortcoming. Not all balloons are the same. Cheap good to paint the disk will not work.

The right spray should be from a reputable manufacturer, and not only contain good acrylic paint inside, but also provide an effective spray with a limited spot, inside which the paint should lay down evenly. This is the only way to get rid of unevenness and smudges.

You will have to apply several layers with intermediate drying. This will manifest the second drawback - low spray pressure. A high-quality torch, which gives a professional pistol, is not able to issue a can. In addition, the pressure changes as you spend, you will also have to adapt to this.

Painting four discs will require a lot of cylinders, which can negate all the savings. And the result is unpredictable. At least not without proper training.

How to paint wheels yourself without removing the rubber

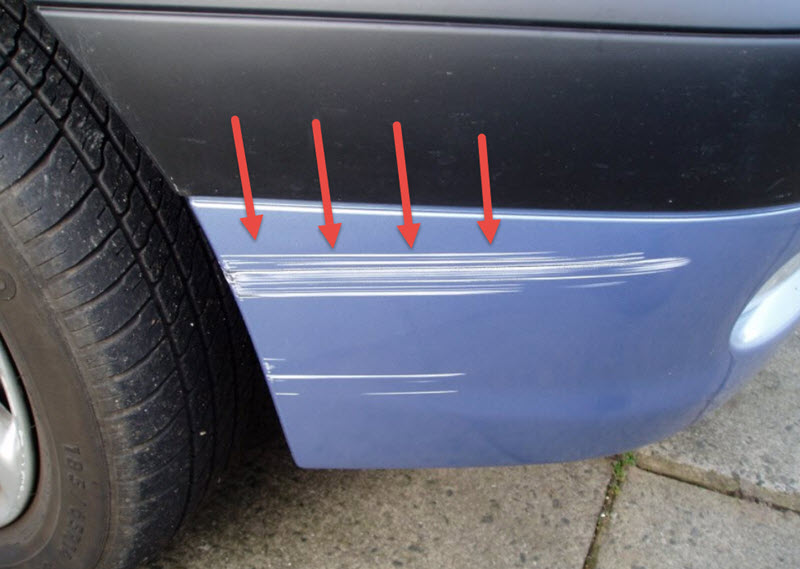

It's better to take it off, of course. But you can do without this costly operation, in which, moreover, it is easy to damage the results of labor. Repair paint does not have sufficient resistance to scratches and impacts.

Equipment and technology

To protect the rubber, you can use ordinary masking tape. Or use special cardboard shields that are inserted between the rim and tire with some overlap.

Watch this video on YouTube

Of the tools, it is desirable to have a grinder with low adjustable working speeds, or at least a good electric drill with nozzles, a compressor, a spray gun, spatulas, hand and respiratory protection. Consumables - sandpaper of different grain sizes, solvent, putty, primer, paint, varnish.

The wheel is glued to save the tire, after which it is processed to remove ill-fitting old paint and degreased. All irregularities are carefully filled with putty and sanded until a perfect surface is obtained. Paint and primer will not hide anything, on the contrary, a layer of paint is applied to reveal imperceptible flaws.

After preparation, the first layer of primary soil, the so-called filler, is applied. It will allow, after fine grinding, to remove traces of the skin on the putty surface. A finishing primer is applied over the polished filler.

As the primer dries, the first coat of paint can be applied. In total, it is desirable to perform two of them. In accordance with the description of the technology of a particular complex of materials, varnish is sprayed over the paint. Possible streaks are cut, sanded and polished.

It should be remembered that few people manage to get a mirror surface, but this is easy to fix by polishing with special pastes and a nozzle on a grinder.

How to paint casting

With the tire removed, you can paint the disc much better. With this technology, the border between the treated areas and the covered tires will be excluded. It is from there that the processes of destruction of the coating begin.

Otherwise, the technology does not differ from that described. But on the removed disk, powder coating can also be applied. It will be necessary to build an oven for hot polymerization of the applied coating. This is not such a complex structure, if you have enough space and powerful electrical wiring. But the coating will be no worse than the factory one.

You can even make a special electrostatic gun if you have experience with high voltage equipment.

How to paint stamping

Forged steel discs are less resistant to localized damage. Therefore, it is better to pre-roll them, which will restore their original shape, as well as roughly straighten possible irregularities.

Watch this video on YouTube

The rest will be done by putty, first strong, with fiberglass, and then finishing, which, when sanded with fine abrasives, will provide the desired smoothness.

What should be done so that the disks do not rust

When processing stamped steel discs, special attention must be paid to removing rust. It has the property of a catalytic effect on the destruction of the metal, even when under a layer of paintwork, the so-called under-film corrosion. Especially in hard-to-reach places where the disc connects to the rim.

Saves only sandblasting. Chemical rust removers should not be used on steel rims.

They perform their role poorly, while they themselves can become centers of corrosion, since they are difficult to remove from the resulting porous surface. Only mechanical rust removal followed by a primer should be used.