How to glue an aluminum car radiator and its plastic parts

Content

Modern radiators in the vast majority are made of aluminum and plastic. This is the perfect combination for the main task - heat dissipation. But due to its location, a small obstacle or a flown stone can disable such an important element of the system.

What to do in this case, consider below.

How to find a crack or a malfunctioning radiator

When the crack is very small, you can detect the place of antifreeze leakage by an elementary inspection for the source of the leaks. Severe damage is also easily detected by eye.

If the initial inspection fails to identify the place of leakage, experienced craftsmen do the following:

- Clamps are removed from the nozzles and the radiator is dismantled.

- They take a camera from a bicycle or car, cut a piece so that the nipple is in the middle.

- The pipes are tightly packed with rags.

- Then water is poured through the neck and closed with a cut-out chamber so that the nipple is in the middle. For convenience, you can wear a collar.

- The pump is connected and air is pumped.

- The pressure created inside will begin to displace water from the crack.

If the leak is very small, it is better to additionally mark it with a marker. After that, pull out the rags and drain the water. It remains only to decide on the method of repair.

Internal repair of the radiator with a chemical agent

Most experts do not recommend resorting to this method. Nevertheless, when you need to urgently go, and the antifreeze flows on the asphalt, there is not much choice left.

By the way, the method will work only with minor cracks. If a stone sticks out in the radiator, then all cases will have to be canceled.

Considering that all chemicals work on the principle of a long-proven old-fashioned method, it will be easier to turn to the original source.

Back in Soviet times, when the Chinese chemical industry did not pay attention to the problems of motorists, mustard powder came to the rescue. It falls asleep in the neck (when the engine is on). Since the liquid in the radiator is hot, it swells and fills the crack.

If mustard does not inspire confidence, you can buy a tool special for this purpose in the car shop.

They are called differently: powder reducing agent, radiator sealant, etc. But, as already mentioned, it is better to use other methods, because it is not exactly predictable how and where the powder will settle, but it can easily clog several tubes.

How and how to seal the plastic parts of the radiator in a car

Let's go back to the removed radiator. If a leak has formed in the plastic part, then consider half the work done. It remains to prepare the surface, run to the store for special glue or cold welding.

Surface preparation

No space technology is needed here. You just need to remove all the dirt and wipe the top with alcohol. Vodka is fine too. The main thing to remember is that the plastic here is very thin and you should not apply a lot of force, otherwise the crack may go further.

Use of adhesive

There are a lot of materials for working with plastic in stores. All of them are approximately the same, so you should not bother with the choice, the only thing worth paying attention to is that it says on it that the glue is resistant to aggressive chemical compounds.

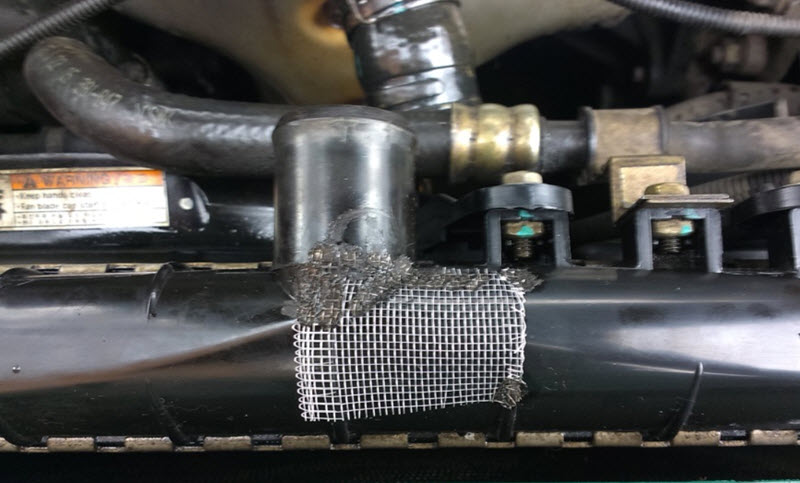

The technology of work is also described in the instructions for the tool as detailed as possible. However, it is worth noting that if the hole is large enough or a piece of the body is lost somewhere, additional manipulations will be required. For example, some people apply glue in several stages, slowly building up the lost part.

Most experts do not recommend doing this. It is better to find a piece of soft plastic and try to put it inside the crack or attach it from above and then glue this thing on all sides. A kind of patchwork.

Typically, such compositions cost at least 1000 rubles, so it’s worth considering whether such a repair is advisable or is it easier to change the part completely.

How to use cold welding

Most often, for these purposes, of course, cold welding is taken. It is much easier to work with it and outwardly the result inspires more confidence.

It is enough to squeeze a thick paste onto the crack and evenly distribute it with any flat object (some use cotton swabs).

If the crack is large. It is better to first apply the adhesive base, built up in stages, and fix the result on top with cold welding.

How to solder an aluminum radiator

If anyone can cope with a crack in plastic, then the situation with soldering is more complicated. First of all, the problem is the availability of the necessary tools.

For soldering, you need a strong soldering iron that works at temperatures of 250 degrees. Plus, you need a blowtorch to preheat the metal and a special flux for working with aluminum. Therefore, for such an operation, it is better to involve a specialist.

Пайка

If such a soldering iron and a lamp are at hand, it remains to get a flux that will not allow aluminum to interact with oxygen. For these purposes, it is better to contact the radio amateur store. They have it already prepared, it remains only to apply.

If you want to save money, you can make it yourself from rosin and metal filings (sharpen an unnecessary piece of iron with a file). Proportion 1:2.

You also need to additionally prepare solder from copper, zinc and silicon, pliers, fine-grained sandpaper, acetone.

The radiator must be thoroughly washed and dried. After, the procedure is as follows:

- Clean up the cracked area with sandpaper.

- Then degrease (without fanaticism).

- It is good to warm up the place of soldering. At the same time, turn on the soldering iron so that it is immediately ready for use.

- Gently and evenly apply the flux to the crack.

- Warm it up a little more.

- Introduce solder into the flux zone and solder in a circular motion, while it is better to lead the soldering iron away from you.

According to the masters, the use of the flux indicated above makes the soldering zone much harder than the aluminum itself.

Watch this video on YouTube

Safety Precautions

Do not forget that the materials used for soldering emit toxic compounds when heated, so repair work must be done under a hood or on the street. Gloves are strictly required.

Experts do not recommend soldering the radiator at the connection point of the pipes, because due to the load during operation, such repairs will not be durable.

Summarizing the above, it turns out that you can fix the radiator leak yourself, using adhesives and cold welding for cracks on plastic elements and soldering, in case of breakdown of aluminum parts.

Before starting the repair, you should estimate the material costs, in case the purchase of all the necessary materials will be a significant cost of a new part.