What you need to know about the VAZ 2106 oil pressure sensor: device, methods of verification and replacement

Content

The performance of the engine of any car depends on the presence of engine lubrication and the pressure created by the oil pump. In order for the driver to control these important parameters, a corresponding pointer and an emergency lamp flashing red are installed on the instrument panel of the “classic” VAZ 2106. Both indicators receive information from one element built into the engine - the oil pressure sensor. The part is simple and, if necessary, can be easily changed with your own hands.

Purpose of the oil pressure control sensor

All moving and rubbing parts of the power unit are constantly washed with liquid lubricant supplied by a gear pump from the engine oil pan. If, for various reasons, the supply of lubricant stops or its level drops to a critical level, a serious breakdown awaits the motor, or even more than one. The result is a major overhaul with the replacement of the crankshaft bearings, the cylinder-piston group, and so on.

To protect the owner of the car from these consequences, the classic Zhiguli models provide a two-level control over the engine lubrication system, which operates according to the following algorithm:

- After turning the key in the lock and turning on the ignition, the red control lamp lights up, signaling the absence of oil pressure. The pointer is at zero.

- In the first 1-2 seconds after starting the engine, the indicator continues to burn. If the oil supply is in normal mode, the lamp goes out. The arrow shows the actual pressure created by the pump immediately.

- When the engine is turned off, a large amount of lubricant is lost, or a malfunction occurs, the red indicator lights up instantly.

- If the pressure of the lubricant in the channels of the motor decreases to a critical level, the light starts flashing periodically.

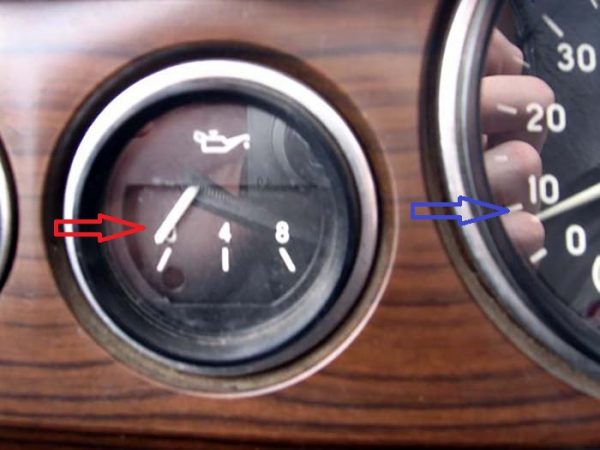

After starting the power unit, the arrow shows the pressure in the lubrication channels

After starting the power unit, the arrow shows the pressure in the lubrication channels

Malfunctions leading to a drop in pressure - breakdown or wear of the oil pump, complete exhaustion of the crankshaft liners or breakdown of the crankcase.

The main role in the operation of the system is played by a sensor - an element that fixes the oil pressure in one of the main channels of the engine. The indicator and pointer are just a means of displaying the information transmitted by the pressure meter.

Location and appearance of the device

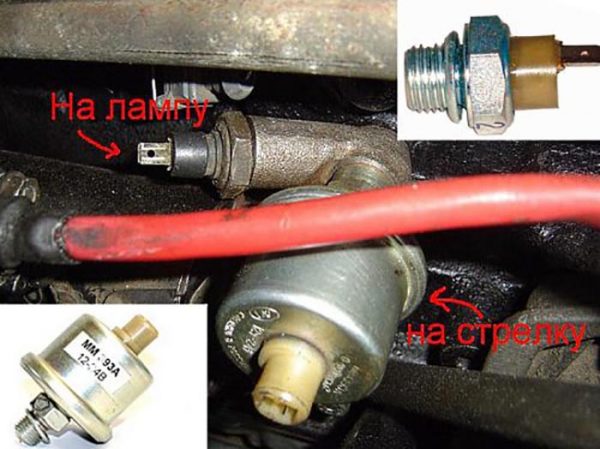

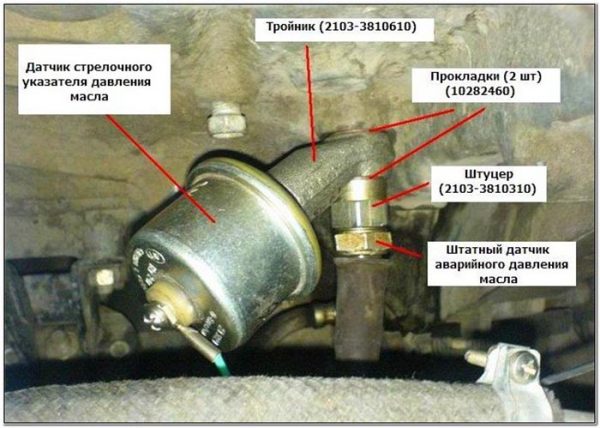

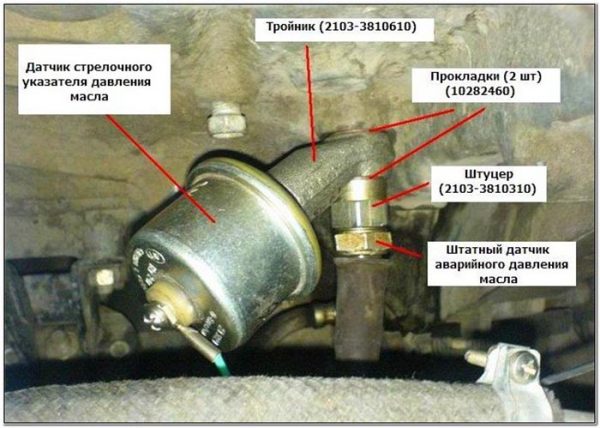

The sensor installed on the classic VAZ 2106 models consists of the following parts:

- an element in the form of a round metal barrel with one terminal for connecting a wire (factory name - MM393A);

- the second part is a membrane switch in the form of a nut with a contact at the end (designation - MM120);

- steel tee, where the above parts are screwed;

- sealing bronze washers.

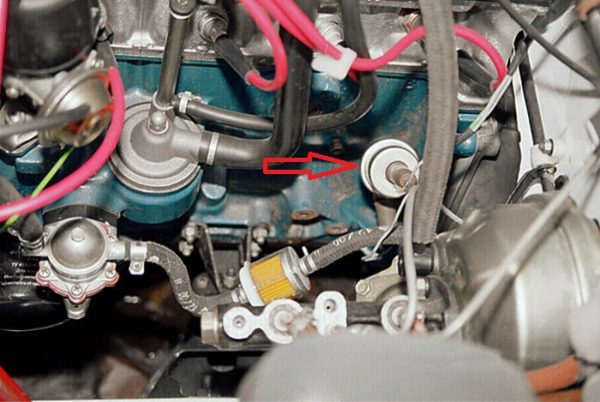

The large “barrel” MM393A is designed to measure the pressure value, the “nut” with the MM120 terminal fixes its absence, and the tee is a connecting element screwed into the engine. The location of the sensor is on the left wall of the cylinder block (when viewed in the direction of movement of the machine) under spark plug No. 4. Do not confuse the device with the temperature sensor installed above in the cylinder head. Wires leading inside the cabin, to the dashboard, are connected to both contacts.

In later models of the "classic" VAZ 2107, there is no indicator arrow on the dashboard, only a control lamp is left. Therefore, a stripped-down version of the sensor without a tee and a large barrel is used.

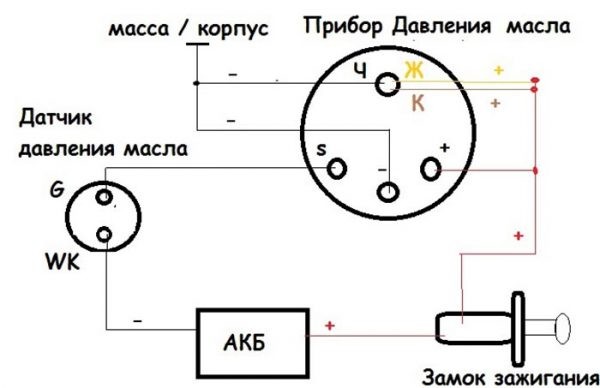

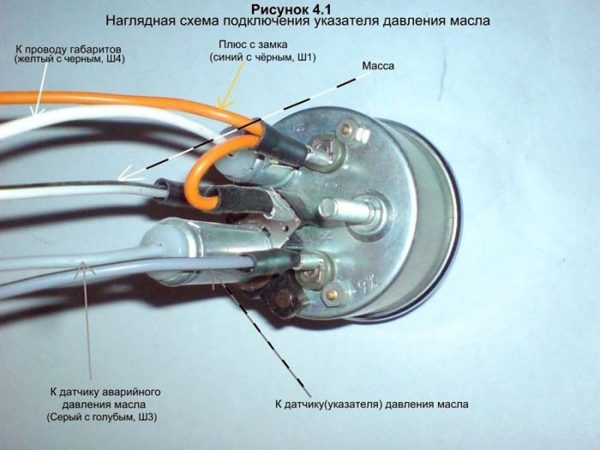

Device and connection diagram

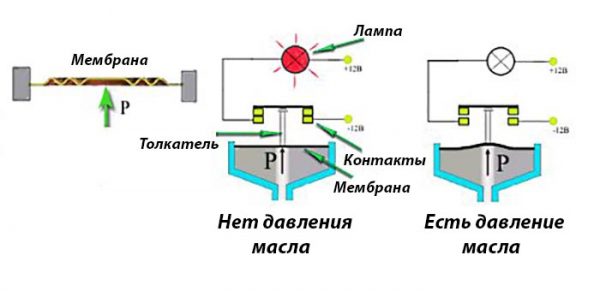

The task of the membrane switch, made in the form of a nut with a terminal, is to timely close the electrical circuit with the control lamp when the lubricant pressure drops. The device consists of the following parts:

- metal case in the form of a hexagon;

- contact Group;

- pusher;

- measuring membrane.

The element is included in the circuit according to the simplest scheme - in series with the indicator. The normal position of the contacts is “closed”, therefore, after the ignition is turned on, the light comes on. In the running engine, there is a pressure of oil flowing to the membrane through the tee. Under the pressure of the lubricant, the latter presses the pusher, which opens the contact group, as a result, the indicator goes out.

When one of the malfunctions occurs in the engine, causing a decrease in the pressure of the liquid lubricant, the elastic membrane returns to its original position and the electrical circuit closes. The driver immediately sees the problem by the flashing "control".

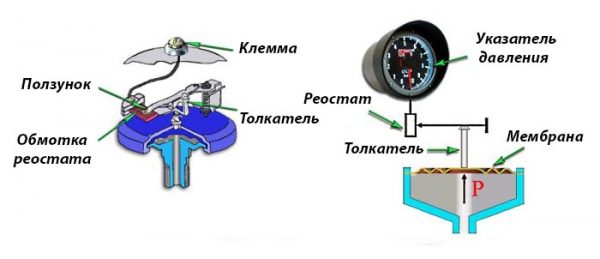

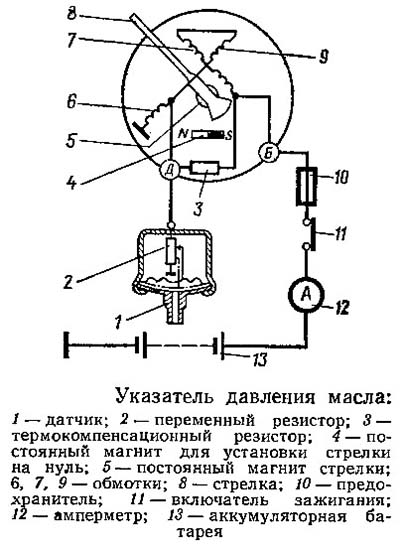

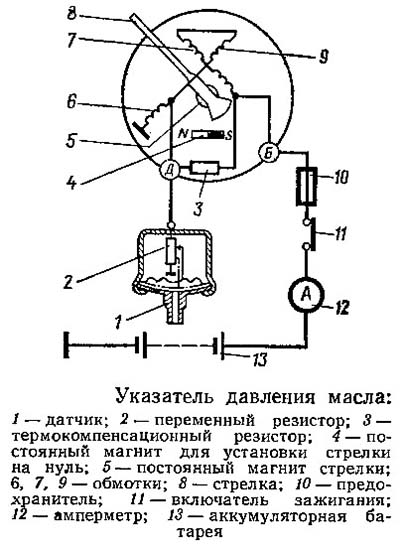

The device of the second element - a "barrel" called MM393A is somewhat more complicated. The main role here is also played by an elastic membrane connected to an actuator - a rheostat and a slider. The rheostat is a coil of high-resistance chromium-nickel wire, and the slider is a moving contact that moves along the turns.

The electrical circuit for connecting the sensor and the pointer is similar to the first one - the rheostat and the device are in series in the circuit. The algorithm of work is the following:

- When the driver turns on the ignition, the on-board network voltage is applied to the circuit. The slider is in its extreme position, and the winding resistance is at its maximum. The instrument pointer stays at zero.

- After starting the motor, oil appears in the channel, which enters the “barrel” through the tee and presses on the membrane. It stretches and the pusher moves the slider along the winding.

- The total resistance of the rheostat begins to decrease, the current in the circuit increases and causes the pointer to deviate. The higher the lubricant pressure, the more the membrane is stretched and the resistance of the coil is lower, and the device notes an increase in pressure.

The sensor responds to a decrease in oil pressure in the reverse order. The force on the membrane decreases, it is thrown back and pulls the slider along with it. He includes new turns of the rheostat winding in the circuit, the resistance increases, the arrow of the device drops to zero.

Video: what pressure should a working device show

How to check and replace an element

During long-term operation, the internal parts of the sensor wear out and periodically fail. The malfunction manifests itself in the form of false indications of the indication scale or a constantly burning emergency lamp. Before drawing conclusions about the breakdown of the power unit, it is highly desirable to check the performance of the sensor.

If the control light comes on while the engine is running, and the pointer drops to zero, your first action is to immediately turn off the engine and not start until a problem is found.

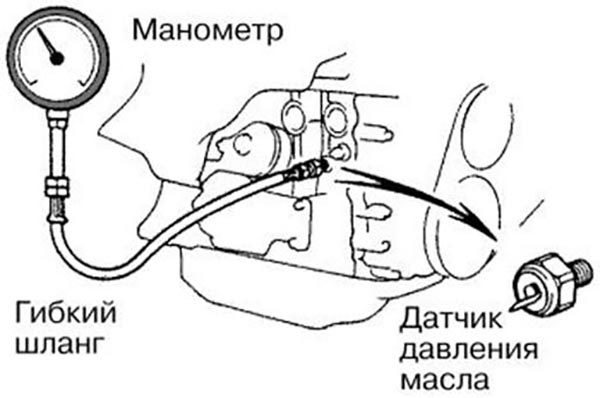

When the light turns on and goes out in a timely manner, and the arrow does not deviate, you should check the serviceability of the oil sensor - pressure gauge MM393A. You will need a 19 mm open-end wrench and a pressure gauge with a scale of up to 10 bar (1 MPa). To the pressure gauge you need to screw a flexible pipe with a threaded tip M14 x 1,5.

The check procedure is as follows:

- Turn off the engine and let it cool down to 50-60 ° C so that you do not have to burn your hands during operation.

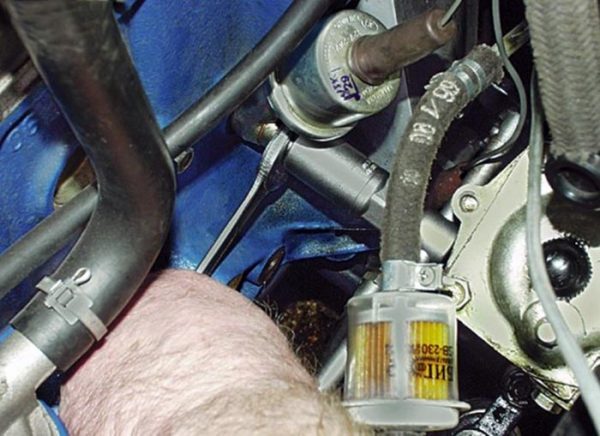

- Disconnect the wires from the sensors and unscrew them with a 19 mm wrench together with a tee. Please note that a small amount of oil may leak from the unit during disassembly.

The assembly is easily unscrewed with a regular open-end wrench

The assembly is easily unscrewed with a regular open-end wrench - Screw the threaded part of the pipe into the hole and carefully tighten. Start the engine and observe the pressure gauge.

To check the pressure gauge is screwed into place of the sensor

To check the pressure gauge is screwed into place of the sensor - Oil pressure at idle is from 1 to 2 bar, on worn engines it can drop to 0,5 bar. The maximum readings at high speeds are 7 bar. If the sensor gives other values or is at zero, you need to buy and install a new spare part.

When measuring, it is desirable to compare the readings of the pressure gauge and the pointer on the dashboard

When measuring, it is desirable to compare the readings of the pressure gauge and the pointer on the dashboard

On the road, the VAZ 2106 oil sensor is more difficult to check, since there is no pressure gauge at hand. To make sure there is lubricant in the motor passages, unscrew the element, disconnect the main ignition wire and rotate the crankshaft with the starter. With a good pump, oil will splash out of the hole.

If the arrow on the instrument scale shows normal pressure (in the range of 1-6 bar), but the red lamp is on, the small membrane sensor MM120 is clearly out of order.

When the light signal does not light up at all, consider 3 options:

- the light bulb is burnt out;

- broken wiring;

- the small sensor in the form of a hexagon has become unusable.

The first 2 versions are easy to check by dialing with a tester or multimeter. The serviceability of the membrane element is tested as follows: turn on the ignition, remove the wire from the terminal and short it to the vehicle ground. If the lamp lights up, feel free to change the sensor.

Replacement is done by unscrewing the large or small sensor with a wrench. It is important not to lose the sealing bronze washers, as they may not be included with the new part. Remove any leaks of engine grease from the hole with a rag.

Both meters cannot be repaired, only replaced. Their metal cases, able to withstand the pressure of the oil of a running engine, are hermetically sealed and cannot be disassembled. The second reason is the low price of VAZ 2106 spare parts, which makes such repairs pointless.

Video: how to check lubrication pressure with a pressure gauge

https://youtube.com/watch?v=dxg8lT3Rqds

Video: replacing the VAZ 2106 sensor

Watch this video on YouTube

Functions and operation of the pointer

The purpose of the device built into the dashboard to the left of the tachometer is to display the level of engine oil pressure, guided by the sensor. The principle of operation of the pointer resembles the operation of a conventional ammeter, which reacts to changes in the current strength in the circuit. When the mechanical rheostat inside the measuring element changes resistance, the current increases or decreases, deflecting the needle. The scale is graduated in pressure units corresponding to 1 bar (1 kgf/cm2).

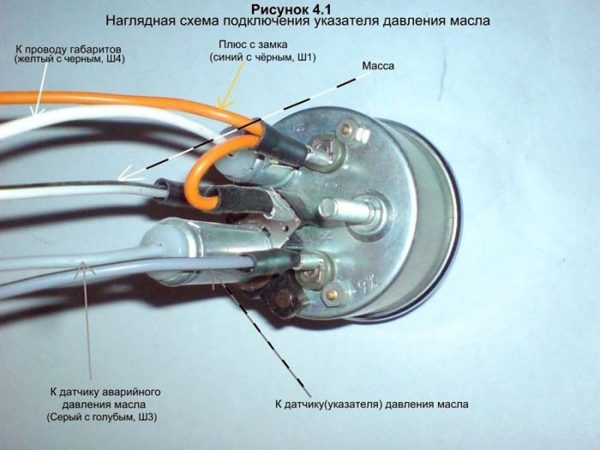

The device consists of the following main elements:

- round body;

- pointer mechanism with permanent magnet and windings;

- a control light connected to the corresponding sensor by a separate line;

- scale with backlight;

- compensation resistor;

- connector wires.

Zero readings of the device correspond to a circuit resistance of 320 ohms. When it drops to 100-130 ohms, the needle stays at 4 bar, 60-80 ohms - 6 bar.

The Zhiguli engine lubricant pressure indicator is a fairly reliable element that breaks very rarely. If the needle does not want to leave the zero mark, then the sensor is usually the culprit. When you doubt the performance of the indicating device, check it with a simple method: measure the voltage at the connection contacts of the MM393A oil sensor with the engine running. If the voltage is present, and the arrow is at zero, the device should be changed.

The VAZ 2106 oil pressure monitoring system with two sensors and a mechanical indicator is simple and reliable in operation. Despite the outdated design, motorists often buy and install these meters on other, more modern cars, equipped from the factory with only a control indicator. Examples are the updated VAZ "seven", Chevrolet Aveo and Niva.