What is a double clutch in a car (device and principle of operation)

Content

The transmission elements of any car are designed to ensure the transmission of engine torque to the drive wheels. At the dawn of the automotive industry, devices that provide this function were not very efficient due to the simplicity of the design. The modernization of the presented nodes led to the fact that it was possible to achieve a smooth gear change without loss of power and dynamic characteristics of the car.

The clutch plays a key role in the transmission of torque. This complex knot underwent a number of changes before becoming what we are used to seeing it now.

Many of the improvements that have found their way into the civilian automotive industry have been borrowed from racing cars. One of them can be attributed to the so-called double clutch, which we will talk about in this article.

What is the difference between a dual clutch transmission and an automatic transmission and a manual transmission

Let's try to figure out what this outlandish creation of engineering is. The very concept of double clutch suggests that such a design provides for the presence of 2 components.

So it is, this type of clutch is distinguished by the presence of two driven friction discs, but not everything is as simple as it might seem at first glance.

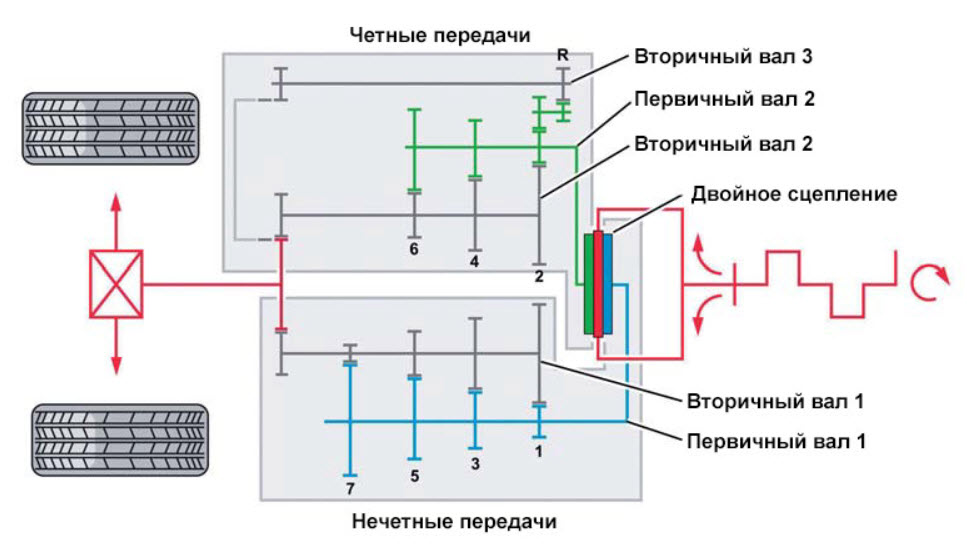

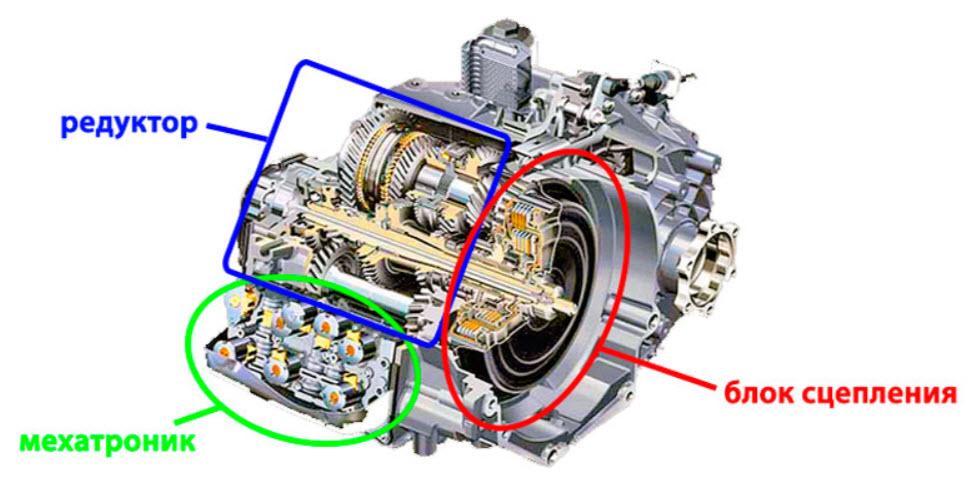

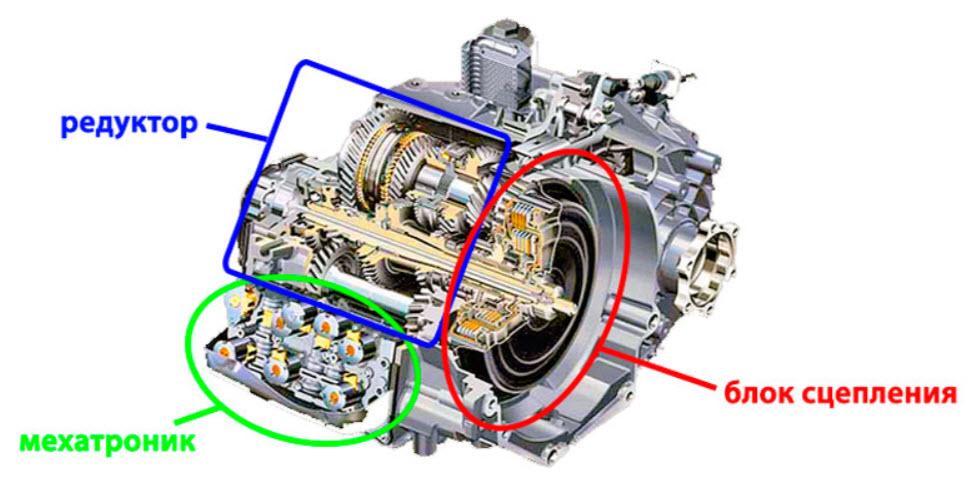

The presented type of mechanism is paired with robotic gearboxes. In this case, we are talking about paired gearboxes, which are responsible for turning on a certain set of speeds. One is responsible for odd gears, the other for even ones.

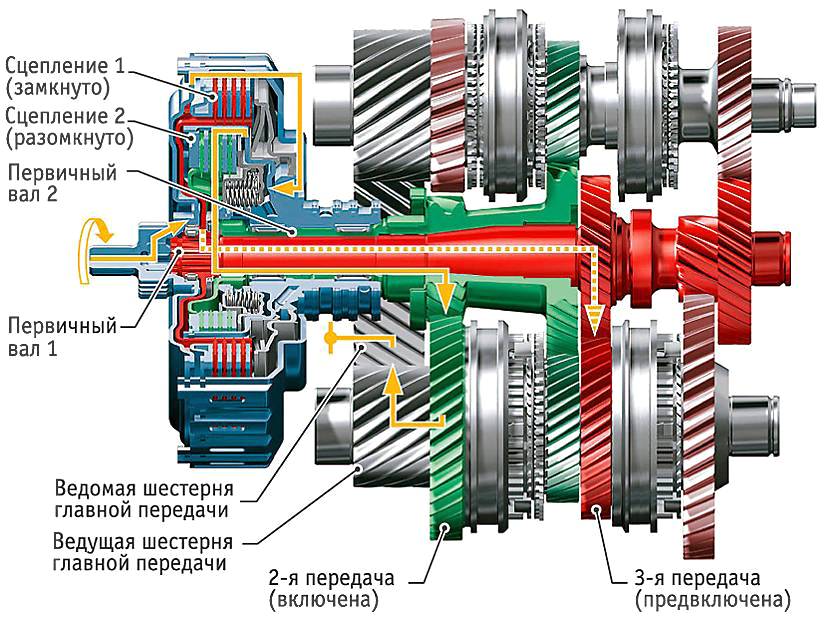

Perhaps the defining difference between a dual-clutch gearbox and all the others is the presence of a so-called double shaft. To some extent, it is the same gear block of a more complicated design.

The gears on the outer shaft of such a set of gears engage with the gears of even gears, and the gears of the so-called inner shaft interact with the gears of odd gears.

The control of the presented transmission units is carried out thanks to the system of hydraulic drives and automation. It is worth noting that the presented type of gearbox, unlike automatic transmission, is not equipped with a torque converter.

In this case, it is customary to talk about two types of clutch: dry and wet. We will dwell on them in more detail below in the text.

Principle of operation

Having become acquainted with some design features of the presented node, let's try to understand the principle of its operation.

If you do not delve into technical subtleties, then the algorithm of work can be divided into several stages:

- After the start of movement in first gear, the system prepares to turn on the next one;

- Having reached a certain moment corresponding to the established speed characteristics, the first clutch is disconnected;

- The second clutch comes into operation, providing automatic engagement of the second gear gear;

- Analyzing the process of increasing the engine speed, the actuators that execute the commands coming from the control module are preparing to turn on the third gear.

The subsequent inclusion of speeds occurs according to the same principle. It is worth noting that the system of sensors installed in the presented form of the gearbox allows you to analyze a variety of parameters, including: wheel speed, gearshift lever location, intensity of pressing the accelerator/brake pedal.

Analyzing the received data, automation and selects the mode that is optimal for a particular situation.

Among other things, it is worth noting that in the presence of such a system, the clutch pedal is simply absent. Gear selection is carried out automatically, and if necessary, manually using the control buttons mounted in the steering wheel.

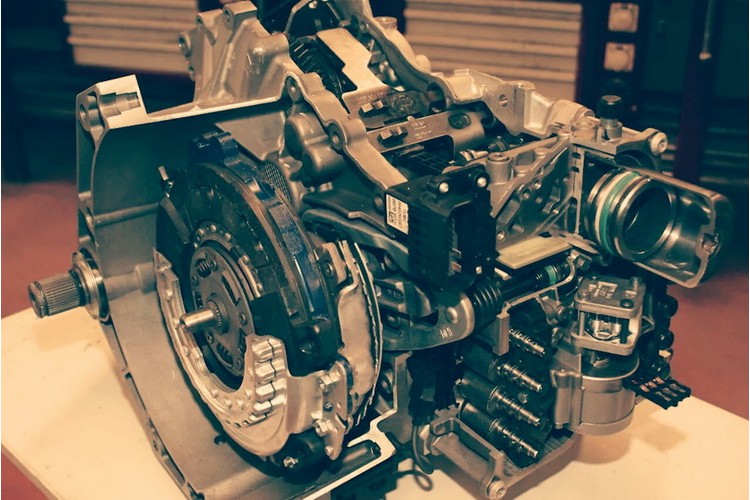

Mechanism device

In order to get acquainted with the presented node in more detail, it is necessary to study the device of the mechanism itself, which ensures smooth gear shifting.

Unlike all other types of clutch, this variety is distinguished by the presence of a number of unique nodes and elements.

So, this system includes the following key components:

- friction disc package;

- body with dry or oil sump;

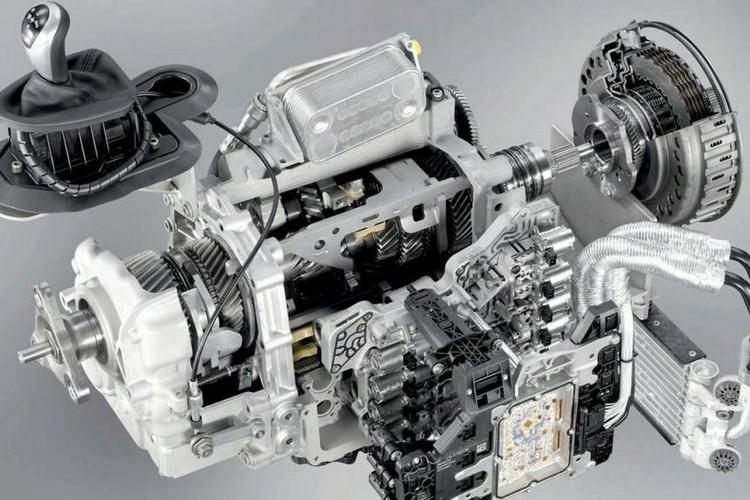

- mechatronic.

If the first two nodes are familiar enough to motorists, then the third gives the impression of something hitherto unknown.

So, mechatronics, this is a high-tech clutch unit that allows you to convert electrical signals into mechanical work of actuating units.

The mechatronics of a modern car, as a rule, includes two components: an electromagnetic unit and a control board.

The first is a set of solenoid valves, the so-called solenoids. Previously, instead of solenoids, hydraulic distribution mechanisms, the so-called hydroblocks, were used. But due to their low productivity, they were replaced by more advanced electromagnetic devices.

Consider the fundamental features of wet and dry clutches.

"Wet" double

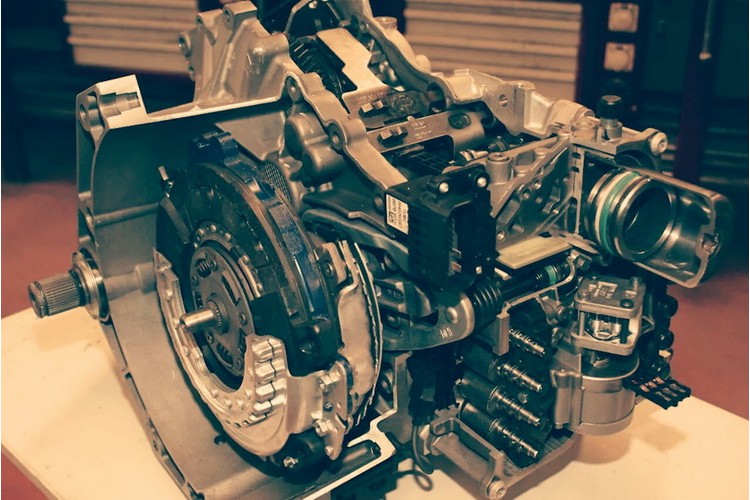

If we conduct an excursion into the history of the node in question, then the so-called “wet type” is considered to be the progenitor of the double.

It is a set of two sections of Ferodo discs immersed in an oil bath in the clutch housing housing.

Watch this video on YouTube

In this case, it is customary to distinguish between two types of "wet clutch" depending on the type of vehicle drive. So for front-wheel drive cars, a clutch with a concentric arrangement of Ferodo discs is used. For owners of rear-wheel drive cars, the peculiarity of this device is manifested in the parallel arrangement of the driven disks.

The components of both varieties of "wet clutch" are the same. These include:

- inlet flange;

- main flange;

- master drive;

- package of friction discs of the first and second order;

- diaphragm spring, auxiliary spring;

- plunger;

- hydraulic cylinders;

- primary shaft of the first and second order.

"Dry" double

In addition to the "wet" clutch, there is also the so-called "dry" clutch. It cannot be said that it is worse or better than the previous one. In this case, it will be appropriate to emphasize that each of them is effectively used in the operating conditions provided for them.

Watch this video on YouTube

Unlike the previous type, the design feature of the "dry" clutch does not involve the use of lubricants. The driven disks are directly engaged with the input shafts of each of the gearboxes.

The working elements of such a mechanism include:

- primary shafts;

- release bearings;

- friction discs;

- master drive;

- two auxiliary disks;

- flywheel;

- diaphragm springs.

This design is designed to transmit less (as opposed to "wet") torque, due to the low heat transfer coefficient.

However, due to the absence of the need to use an oil pump, which inevitably leads to power losses, the efficiency of this type of clutch is significantly superior to the previously considered variety.

Pros and cons of dual clutch

Like any other vehicle component, the dual clutch has both a number of positive qualities and a number of disadvantages. Let's start with the positives.

So, the introduction of such an improvement in the vehicle transmission system made it possible to achieve:

- significant fuel savings;

- high dynamic performance;

- smooth running;

- no loss of engine power.

Despite such significant advantages of the presented node, there are a number of negative points. These include:

- extremely limited resource of working elements;

- low maintenance;

- costly repairs.

Perhaps another equally significant drawback of this transmission is that in the event of increased wear of the working elements of the assembly, further operation of the vehicle becomes impossible.

Watch this video on YouTube

In other words, if the same “kicking” automatic transmission will allow you to get to the service and make repairs on your own, then in this case you will only have to rely on the help of a tow truck.

Nevertheless, progress does not stand still and manufacturers, focusing on the operating experience of their developments, introduce various innovations into the design of the “double clutch” units, designed to increase the resource of its mechanisms and improve maintainability.