Types, device and principle of operation of the engine mount

Content

- What is an engine mount (pillow) and what is it for?

- Number and location of engine mounts

- The device and principle of operation of various types of engine mountings

- What you should know about the operation of pillows

- Diagnostics of pillows of the engine

- Replacing the engine mounts

- Selection of new engine mounts

- Hack and predictor Aviator

- Questions and answers:

Each modern internal combustion engine is mounted on pillows. Consider why this element is needed in a car device, what malfunctions are, as well as some tips for replacing a part.

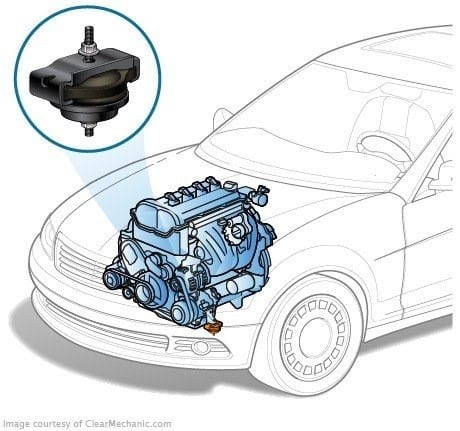

What is an engine mount (pillow) and what is it for?

During the operation of the motor, vibrations are formed in it. If you fix it on a support tightly, then there will be a terrible hum in the cabin, regardless of whether the car is standing or driving on an ideal road.

Depending on the design of the car chassis, the engine and gearbox are fixed to:

- Frame;

- Subframes;

- The body.

The engine mount primarily performs a damping function. In addition to the fact that the pillow protects against the spread of vibrations from the engine and gearbox throughout the body, it prevents the engine and transmission from swaying while the car is moving along bumps.

Number and location of engine mounts

The number of pillows depends on the brand of the engine, namely, on its weight and power (this factor affects the strength of vibrations). Also, depending on the type of bodywork or chassis design, the number of engine mounts varies. Another factor on which the number of these parts depends is the location of the internal combustion engine in the compartment.

Most often there are three-point mounts. Less often - four-point. These elements are not so easy to see - for this you need to look under the car (if it does not have crankcase protection). Under the hood, you can see only the top cushion (and even then not in all cars).

It is also worth noting that for the gearbox and for the motor, its own dampers are used.

The device and principle of operation of various types of engine mountings

Although the main purpose of pillows is to dampen motor vibrations, today there are several varieties of them. They all cope with their function. They differ only in design, principle of operation and cost.

There are two types of supports:

- Rubber-metal;

- Hydro support.

Each of them works on its own principle. Some work to compress rubber, others to twist. The second category is considered the most innovative among this type of damper parts.

Rubber metal

Such parts are also called simply rubber. Their design is the simplest - a rubber insert with a metal eye in the center, into which a mounting pin is inserted, is placed in a metal support (attached to the body).

Most often, this type of support is used in older engines. Sometimes there are modifications not with rubber, but with a polyurethane insert. Such varieties of supports are more hardy.

Hydro Bearings

This kind of dampers works on the principle of a shock absorber in the suspension. They have a more complex design. In addition to rubber seals, they also have a cavity filled with air or damping fluid.

The most common option is two-chamber supports. In them, both planes are connected to each other by a thin channel through which, under load, the fluid moves.

The types of hydrosupport include:

- Mechanical pillows. They are made for each modification of the motor separately. The force of vibrations, the mass of the motor and its dimensions are taken into account.

- Electronic pylons. In addition to the presence of working chambers, a solenoid valve is included in the device of the part, which regulates the rigidity of the support. The damper operation is automatically adjusted by commands from the computer.

- Dynamic supports. In such parts, metal particles are part of the working fluid. Due to the influence of a magnetic field, the structure of the liquid in the pillow changes (it changes the degree of viscosity).

Naturally, the cost of rubber supports is much lower than hydraulic counterparts.

What you should know about the operation of pillows

Like any part in a car, the engine mount also has its own resource. Although basically for such elements the regulation on replacement is established within 100 thousand km, the replacement period can be increased or decreased depending on the operating conditions of the machine.

The maximum load on the supports is when the unit starts, at the beginning of movement and deceleration of the car. For this reason, it is difficult to establish strict regulations for the replacement of pillows. If the driver uses the car to get to work and back, then in this case the parts will need less replacement.

To reduce the load on the damper bearings, experts recommend not using an aggressive riding style with frequent sharp accelerations and braking of the vehicle. Also, for the safety of pillows, you should ride smoothly on rough roads.

Diagnostics of pillows of the engine

In the case of rubber-metal pads, the diagnosis is as simple as possible - it is enough to conduct a visual inspection for the presence of delamination or rupture of the rubber part. If a type of hydraulic support is installed in the machine, then a visual inspection is unlikely to help.

The hydraulic support can be checked as follows. First, open the hood and start the engine. The first speed starts, drive a couple of meters and stop. We engage reverse gear, drive the same distance. We stop the engine.

During the procedure, unnatural knocks and clicks should not be heard from the engine compartment. If there is still extraneous noise, this indicates a malfunction of one of the supports (or maybe several). It also does not hurt to drive along the highway at high speed (permissible by law). If jerking is felt when switching speeds, then the problem is definitely with the supports.

Hydraulic pads can also be checked for fluid leaks. This can be done with a visual inspection.

Signs of wear on engine mountings

This is what causes engine mount failures:

- The engine vibrates strongly at idle (it is also important to make sure that the ignition and fuel system are working, and the valves are correctly adjusted);

- When driving (especially during gear changes), knocks are heard and jerks are felt, as if the motor is swinging;

- When the engine starts, knocks from under the hood are clearly audible;

- Difficulty switching gears.

If the machine is equipped with hydraulic supports, the motorist can determine their malfunction in case of loss of dynamism of the vehicle.

Replacing the engine mounts

Before unscrewing the motor mounts, it must be jacked up or hung up so that the damper is unloaded. The procedure can be performed independently. But even in the service center it is not very expensive - about $ 5 for one part.

However, it all depends on the condition of the car, for example, if the thread on the mount is broken, the procedure will be delayed, and the masters will take an additional fee for replacing the problem unit. In this case, the entire engine is dismantled so that it is possible to drill holes of a larger diameter and cut the threads into them.

The replacement procedure itself is very simple. The main thing is to find a viewing hole or flyover. To hang the motor, you need to take a thick board and put it across the pit. A jack is installed in the center of the motor and the ICE is raised so that the support can be unscrewed and a new one installed. Tightening must be done during the operation of the motor - this way there will be less vibration in the future, and also the fasteners will not loosen.

Selection of new engine mounts

Since the engine mounts are made taking into account the specific features of a specific internal combustion engine, ideally, one that is designed for this unit should be used. Some pillows are suitable for different machines (mounting holes are the same), but the motor parameters may not correspond to the characteristics of this part.

If a more advanced modification is selected, for example, instead of a rubber part, the motorist decides to use a hydraulic analog, then a check by the VIN code will help him determine whether the part can be installed on a specific motor or not.

After you have decided on the modification of the element, you should pay attention to the manufacturer. Do not choose products of dubious firms. Most often, the resource of such parts is extremely low. If the original parts are too expensive, you can look at the products, for example, TRW, Fenox, Boge, Sasic Ruville. These are European manufacturers who have established themselves as quality products.

As for the Chinese and Turkish counterparts, it is better not to risk it. Even with careful driving, it sometimes happens that they do not take care of their resources.

Hack and predictor Aviator

The engine mount not only protects the engine and transmission from premature wear, but also provides greater ride comfort. A scheduled inspection and simple diagnostics will allow you to pre-determine the malfunction, without waiting for an unpleasant vibration to appear throughout the body. The appearance of additional noise distracts the driver from the road and increases the risk of an emergency. For this reason, each driver must be attentive to the "behavior" of his car and respond in a timely manner.

Questions and answers:

How long do the engine mounts go? Engine mountings last from 80 to 100 thousand kilometers, depending on the condition of the roads on which the car drives. Therefore, motorists rarely pay attention to their condition.

Where are the engine mounts? The classic option for installing engine mounts: three points at the bottom of the engine and two points at the bottom of the gearbox. The connection between the units is rigid for the clutch to work.

What is the correct name for the engine mountings? The engine mount means the support of the power unit - a rubber part with a metal sleeve. Since the part not only secures the motor, but also smooths out vibrations, it is called a pillow.

What are the types of engine mountings? Most of the engine mounts are part metal, part rubber. In the models of the premium and executive segments, hydraulic cushions can be used.