What is Motronic System?

Content

For engine efficiency at different speeds and loads, it is necessary to correctly distribute the supply of fuel, air, and also to change the ignition timing. In older carburetor engines, this accuracy cannot be achieved. And in the case of a change in the ignition, a complex camshaft modernization procedure will be required (this system has been described earlier).

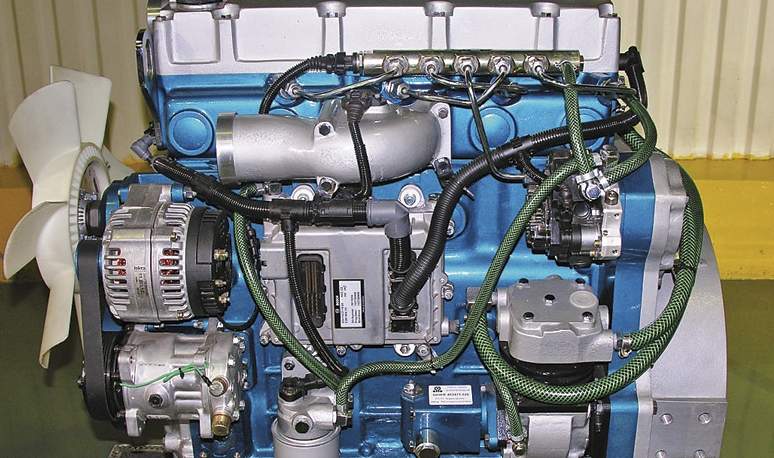

With the advent of electronic control systems, it became possible to fine-tune the operation of the internal combustion engine. One such system was developed by Bosch in 1979. Its name is Motronic. Consider what it is, by what principle it functions, and also what its pros and cons are.

Motronic device

Motronic is a modification of the fuel injection system, which is also capable of controlling the distribution of ignition at the same time. It is part of the fuel system, and has three main groups of elements:

- Sensors of the state of the internal combustion engine and systems that affect its operation;

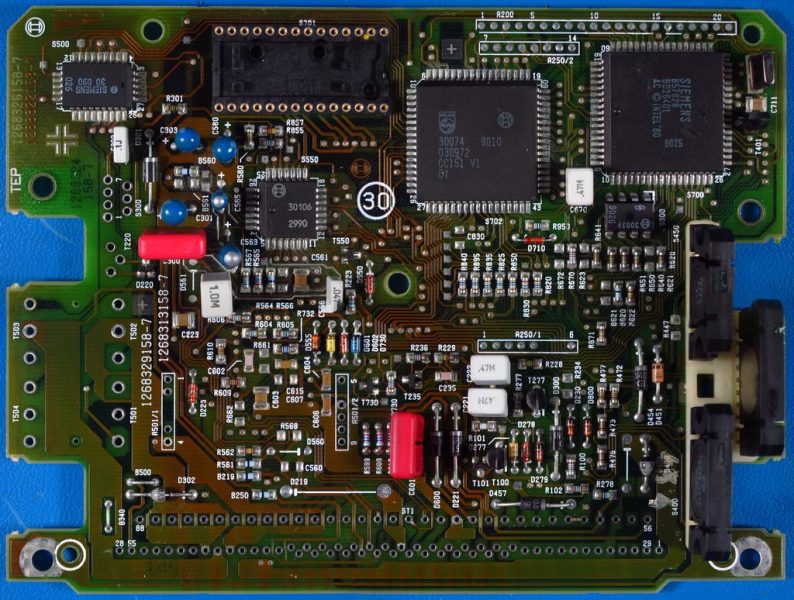

- Electronic controller;

- Executive mechanisms.

Sensors record the state of the motor and the nodes affecting its operation. This category includes the following sensors:

- DPKV;

- Detonation;

- Air consumption;

- Coolant temperature;

- Lambda probe;

- DPRV;

- Air temperature in the intake manifold;

- Throttle position.

The computer captures the signals from each sensor. Based on these data, he gives the appropriate commands to the execution elements to optimize the motor. An additional computer performs the following functions:

- Controls the dosage of fuel based on the amount of incoming air;

- It gives a signal to form a spark;

- Regulates boost;

- Changes the working phases of the gas distribution mechanism;

- Controls exhaust toxicity.

The category of control mechanisms includes such elements:

- Fuel injectors;

- Ignition coils;

- Electric fuel pump;

- Exhaust system and timing valves.

Types of Motronic System

Today there are several varieties of the motronic system. Each of them has its own designation:

- Monkey;

- WITH;

- TO;

- M;

- ME.

Each variety works on its own principle. Here are the main differences.

Mono-Motronic

This modification works on the principle of single injection. This means that gasoline is supplied in the same way as in a carburetor engine to the intake manifold (there it mixes with air), and from there it is sucked into the desired cylinder. Unlike the carburetor version, the mono system delivers fuel under pressure.

MED-Motronic

This is a type of direct injection system. In this case, a portion of the fuel is fed directly into the working cylinder. This modification will have several injectors (depending on the number of cylinders). They are installed in the cylinder head near the spark plugs.

KE-Motronic

In such a system, nozzles are mounted on the intake manifold near each cylinder. In this case, the air-fuel mixture is formed not in the cylinder itself (as a modification of MED), but in front of the inlet valve.

M-Motronic

This is an improved type of multipoint injection. Its peculiarity lies in the fact that the controller determines the engine speed, and the air volume sensor records the motor load and sends a signal to the ECU. These indicators affect the amount of gasoline required at the moment. Thanks to such a system, minimum consumption is ensured with maximum efficiency of the internal combustion engine.

ME-Motronic

The latest system modification is equipped with an electric throttle. In fact, this is the same M-Motronic, only fully controlled by electronics. The gas pedal in such vehicles does not have a physical connection with the damper. Due to this, the position of each component of the system is more accurately verified.

How the Motronic system works

Each modification has its own principle of operation. Basically, the system operates as follows.

The parameters necessary for the effective operation of a particular engine are programmed in the controller's memory. Sensors record the position and speed of the crankshaft, the position of the air damper and the amount of incoming air. Based on this, the required fuel volume is determined. The remainder of unspent gasoline is returned through the return to the tank.

The car can be used in the following system:

- DME M1.1-1.3. such modifications combine not only the distribution of injection, but also a change in the ignition timing. Depending on the speed of the engine, the ignition may be set at a slightly late or early moment when the valves open. The fuel supply is regulated based on the volume and temperature of the incoming air, crankshaft speed, engine load, coolant temperature. If the machine is equipped with an automatic transmission, the amount of fuel is regulated depending on the speed included.

- DME M1.7 these systems have the action of a pulsed fuel supply. An air meter is located near the air filter (a flap that deviates depending on the volume of air), based on which the injection time and the volume of gasoline are determined.

- DME M3.1. This is a modification of the first kind of system. The difference is the presence of a mass flow meter (not volume) of air. Due to this, the motor operation adapts to the ambient temperature and air sparseness (the higher the sea level, the lower the oxygen concentration). Such modifications are installed on vehicles, which are often operated in mountainous areas. Based on changes in the degree of cooling of the heated coil (the glow current changes), motronic also determines the mass of air, and its temperature is determined by a sensor installed near the throttle.

In each case, when repairing, make sure that the part matches the model of the controller. Otherwise, the system will work inefficiently or failures at all.

Since the presence of finely tuned sensors can often lead to malfunctions (the sensor may fail at any time), the system control unit is also programmed to average values. For example, if the air mass meter fails, the computer switches to indicators of the throttle position and crankshaft speed.

Most of these emergency changes are not displayed on the instrument panel as an error. For this reason, it is necessary to carry out a complete diagnosis of the car's electronics. This will allow you to find the malfunction in time and eliminate it.

Troubleshooting Tips

Each modification of the Motronic system has its own characteristics, and at the same time its own methods of troubleshooting. Let's consider them in turn.

KE-Motronic

This system is installed on the Audi 80 model. To display the malfunction code on the on-board computer screen, you must take the contact located next to the gearshift lever and short it to ground. As a result, the error code will flash on the tidy.

Common malfunctions include:

- The engine does not start well;

- Due to the fact that the MTC is over-enriched, the motor began to work harder;

- At certain speeds, the engine stalls.

Such malfunctions can be associated with the fact that the air flow meter plate is sticking. A common reason for this is incorrect installation of the air filter (its lower part clings to the plate, and does not allow it to move freely).

To get to this part, it is necessary to dismantle the rubber hoses that go over it and connect to the intake manifold. After that, you need to find out the reasons for blocking the free wheel of the plate (sometimes it is installed incorrectly, and it cannot open / close, adjusting the air flow), and eliminate them. It is also necessary to check if this part is deformed, as this can occur due to kickback, which sharply increased the back pressure in the intake system. This element must have a perfectly flat shape.

If the plate is deformed, it is removed (this will require great efforts, since the fasteners are fixed with special glue so that the pin does not twist out). After dismantling, the plate is leveled. To do this, you should use a mallet and a wooden block so as not to spill the product. If burrs have formed or the edges are damaged, they are processed with a file, but so that burrs do not form. Along the way, you should inspect and clean the throttle, idle valve.

Next, it is checked whether the ignition distributor is clean. It can collect dust and dirt, which disrupts the distribution of ignition timing in the corresponding cylinder. Rarely, but still there is a breakdown of high-voltage wires. If this fault is present, they must be replaced.

The next item to be checked is the junction of the intake air line and the dosing head in the injection system. If even the slightest loss of air occurs in this part, the system will malfunction.

Also, in engines equipped with this system, unstable idle speed is often observed. First of all, candles, high-voltage wires, and the cleanliness of the distributor cover are checked. Then you should pay attention to the performance of the injectors. The fact is that these devices operate on fuel pressure, and not at the expense of an electromagnetic valve. Standard cleaning of these nozzles will not help, as this requires special equipment. The cheapest way is to replace the elements with new ones.

Another malfunction that affects idle is contamination of the fuel system. This should always be avoided, as even minor contamination will adversely affect the operation of the fuel meter. To make sure that there is no dirt in the line, it is necessary to remove the pipe coming from the fuel rail and check if there are any deposits or foreign particles in it. The cleanliness of the line can be judged by the condition of the fuel filter. During a planned replacement, you can cut it and see the state of the filter element. If there is a lot of dirt in it, then there is a high probability that some particles still got into the fuel line. If contamination is detected, the fuel line is thoroughly flushed.

Often there are problems with cold or hot starting of the engine with this system. The main reason for such a malfunction is a set of malfunctions:

- Decrease in the efficiency of the fuel pump due to wear of its parts;

- Clogged or broken fuel injectors;

- Defective check valve.

If the valves do not work well, then, as an option, the element responsible for the cold start can be synchronized with the operation of the starter. To do this, you can connect the plus of the starter to the plus terminal of the valve, and ground the minus to the body. Thanks to this connection, the device will always be activated when the starter is turned on bypassing the control unit. But in this case there is a risk of fuel overflow. For this reason, you should not press the gas pedal hard, but turn the starter for a much shorter period of time.

M1.7 Motronic

Some BMW models, such as the 518L and 318i, are equipped with this fuel system. Since this modification of the fuel system is extremely reliable, failures in its operation are mainly associated with the failure of mechanical elements, and not with malfunctions with electronics.

The most common cause of breakdowns is clogged elements, as well as those devices that are exposed to excessive heat or water. Errors in the control unit appear for precisely these reasons. This will cause the engine to run unstable.

There are frequent failures in the operation of the motor, its vibration and interruptions, regardless of the operating mode of the unit. This is mainly due to contamination of the ignition distributor cap. It is covered by several plastic covers, where dust mixed with grease gets into over time. For this reason, there is a breakdown of the high voltage current to ground, and, as a result, interruptions in the supply of a spark. When this malfunction occurs, it is necessary to remove the distributor cover, and thoroughly clean it and the slider. As a rule, the casings themselves do not need to be changed. It is enough to keep them clean.

The high-voltage wires themselves in such cars are enclosed in special tunnels that protect the high-voltage line from dirt, moisture and exposure to high temperatures. Therefore, problems with the wires often relate to the incorrect fixing of the tips on the candles. If in the process of work the motorist damages the tip or the place of fixing the wires in the distributor cover, then the ignition system will work intermittently or stop functioning altogether.

Clogged injector (fuel injectors) is another reason for the unstable operation of the internal combustion engine (vibration). According to the experience of many motorists, the power units of the BMW brand are distinguished by the fact that the gradual wear of the fuel injectors leads to a greater depletion of the BTC. Usually this problem is corrected by using special washes for nozzles.

All motors equipped with the Motronic system are characterized by unstable idle speed when a malfunction occurs. One of the reasons for this is poor throttle retention. First, the device needs to be cleaned well. In addition, you should pay attention to the position of the damper travel stop. You can increase the speed by changing the position of the limiter. But this is only a temporary measure and does not fix the problem. The reason is that increased idle speed negatively affects the operation of the potentiometer.

The reason for the uneven operation of the engine at idle speed may be clogging of the XX valve (it is installed on the back of the engine). It is easy to clean. Along the way, malfunctions in the operation of the air flow meter may appear. The contact track wears out in it, which can cause voltage surges at the output of the device. The voltage growth in this node should be as smooth as possible. Otherwise, it will affect the operation of the control unit. This can result in misfiring and excessive enrichment of the air / fuel mixture. As a result, the engine loses power and the car has poor dynamics.

Diagnostics of the flow meter serviceability is carried out using a multimeter set to the voltage measurement mode. The device itself is activated when a current of 5V is applied. With the engine off and the ignition on, the multimeter contacts are connected to the flow meter contacts. It is necessary to manually rotate the flowmeter. With a working device on the voltmeter, the arrow will deviate within 0.5-4.5V. This check should be carried out on both cold and hot internal combustion engines.

To make sure that the potentiometer contact track is intact, you must gently wipe it with an alcohol wipe. The movable contact must not be touched so as not to bend it, and thereby not knock off the settings for adjusting the composition of the air and fuel mixture.

Difficulty starting a motor equipped with a Motronic M1.7 system may still be associated with malfunctions of the standard anti-theft system. The immobilizer is connected to the control unit, and its defect may be incorrectly recognized by the microprocessor, which will cause the Motronic system to malfunction. You can check this malfunction as follows. The immobilizer is disconnected from the control unit (contact 31) and the power unit is started. If the ICE has started successfully, then you need to look for faults in the anti-theft system electronics.

Advantages and disadvantages

Among the advantages of an advanced injection system, the following can be noted:

- A perfect balance is achieved between engine performance and economy;

- The control unit does not need to be reflashed, since the system itself corrects errors;

- Despite the presence of many finely tuned sensors, the system is quite reliable;

- The driver does not need to worry about increasing fuel consumption under identical operating conditions - the system adjusts the injection according to the features of worn parts.

Although the Motronic system has few shortcomings, they are significant:

- The system device includes a large number of sensors. To find the fault, it is imperative to conduct a deep computer diagnosis, even if the computer does not show an error.

- Due to the complexity of the system, its repair is quite expensive.

- Today, there are not many specialists who understand the intricacies of each modification, so you will have to visit an official service center for repairs. Their services are much more expensive than conventional workshops.

Be that as it may, advanced technologies are designed to make life easier for the motorist, increase comfort in driving, increase traffic safety and reduce environmental pollution.

Additionally, we suggest watching a short video about the operation of the Motronic system:

Questions and answers:

Why do you need the Motronic system. This is a system that simultaneously performs two functions that are important for the operation of the power unit. First, it controls the formation and distribution of ignition in a gasoline power unit. Secondly, Motronic controls the timing of the fuel injection. There are several modifications of this system, which include both mono injection and multipoint injection.

What are the advantages of the Motronic system. First, the electronics are able to more accurately control the timing of ignition and fuel delivery. Thanks to this, the internal combustion engine can consume a minimum amount of gasoline without losing power. Secondly, due to the complete combustion of BTC, the car emits less harmful substances contained in unburned fuel. Thirdly, the system has an algorithm that is able to adjust the actuators to the emerging failures in the electronics. Fourthly, in some cases, the control unit of the system is able to independently eliminate some errors, so that the system does not need to be reflashed.