Do-it-yourself diagnostics, adjustment and repair of the VAZ 2106 carburetor

Content

- Purpose and device of the carburetor VAZ 2106

- Maintenance of the carburetor VAZ 2106

- Reasons for adjusting the carburetor VAZ 2106

- Troubleshooting the carburetor VAZ 2106

- Cleaning the jets

The VAZ 2106 carburetor is responsible for the formation and supply of the fuel-air mixture to the internal combustion engine. It is a rather complex device. However, in most cases, any car owner can determine the malfunction and adjust the carburetor with his own hands.

Purpose and device of the carburetor VAZ 2106

The VAZ 2106 car began production in 1976 and immediately gained great popularity among domestic motorists. A small engine needed air, fuel, a powerful spark and compression to run smoothly. The first two elements are mixed in a carburetor designed to prepare the fuel-air mixture of the optimal composition. On the VAZ 2106, the manufacturer installed an Ozone carburetor manufactured by the Dimitrovgrad Automotive Assembly Plant (DAAZ).

The operation of the device is based on the principle of jet thrust. A powerful jet of air through the nozzles located in the diffuser carries the fuel away from the float chamber. As a result, a fuel-air mixture is formed in the proportions required for its ignition in the combustion chamber.

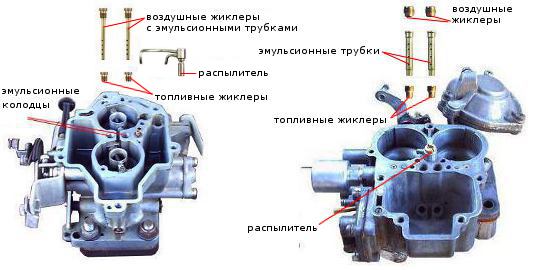

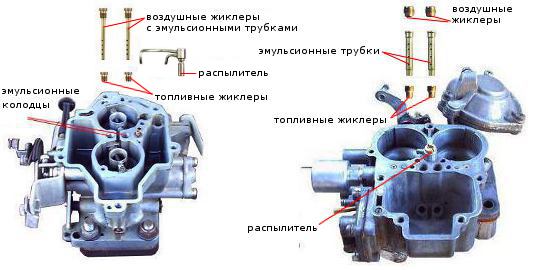

The carburetor consists of three main parts:

- The upper section is a cover with a damper to regulate the air flow to the combustion chambers. With the help of a channel system, it is connected to the throttle valve and the float chamber.

- The middle section consists of diffusers, fuel jets and a float chamber. The diameters of the nozzles are given in the table.

- The lower section includes two chamber throttle valves.

Table: calibration data of the Ozone carburetor

| Parameter | First camera | Second camera |

| Diameter, mm | ||

| diffuser | 22 | 25 |

| mixing chamber | 28 | 36 |

| main fuel jet | 1,12 | 1,5 |

| main air jet | 1,5 | 1,5 |

| idle fuel jet | 0,5 | 0,6 |

| idle air jet | 1,7 | 0,7 |

| econostat fuel jet | — | 1,5 |

| econostat air jet | — | 1,2 |

| econostat emulsion jet | — | 1,5 |

| starter air jet | 0,7 | — |

| throttle pneumatic actuator jet | 1,5 | 1,2 |

| accelerator pump spray holes | 0,4 | — |

| accelerator pump bypass jet | 0,4 | — |

| Delivery of the accelerating pump for 10 full strokes, cm3 | 7 ± 25% | — |

| Calibration number of the mixture sprayer | 3,5 | 4,5 |

| Emulsion tube calibration number | F15 | F15 |

Any deviation in the composition of the fuel-air mixture from the optimal one affects the operation of the engine. It is difficult to start a cold and warm engine, its operation at idle speed and in operating mode is disrupted, and acceleration dynamics deteriorates.

Maintenance of the carburetor VAZ 2106

During the operation of the carburetor, the narrow channels of the jets become clogged. This usually occurs when using low-quality fuel, untimely replacement of the air filter, etc. The composition of the fuel-air mixture is disturbed and its entry into the engine is difficult. As a result, the power unit begins to work intermittently, its dynamic characteristics are reduced. In such cases, it is necessary to rinse the contaminated jets with a special cleaning agent and then blow them with air.

In addition, it is recommended to periodically adjust the composition of the fuel-air mixture to the optimum using special adjusting screws. Otherwise, the engine will run unstable.

Reasons for adjusting the carburetor VAZ 2106

If the mixture from the carburetor to the engine is too rich in fuel, it can flood the spark plugs. If the mixture is too lean, the engine power will noticeably decrease. The main symptoms of a non-optimal mixture are:

- difficulty starting a cold engine;

- unstable engine idling;

- dips when pressing the accelerator pedal;

- loud bangs from the muffler.

In most cases, the problem can be solved by timely adjustment of the mixture composition using the quality and quantity screws. By rotating these screws, it is possible to change the clearance of the emulsion channels, the fuel level in the float chamber and provide additional fuel supply, which compensates for the excess air. This procedure will only take a few minutes.

The car will not start

Difficulty starting a cold engine, when the crankshaft rotates, but the engine does not start, may be the ignition system and the carburetor. If the ignition is working properly, it is most likely that the nozzles, strainer or other elements are clogged, which impedes the supply of fuel to the float chamber. You can fix this problem as follows.

- It is necessary to clean the clogged channels and jets with a special aerosol carburetor flushing agent, and then blow them out with a jet of compressed air.

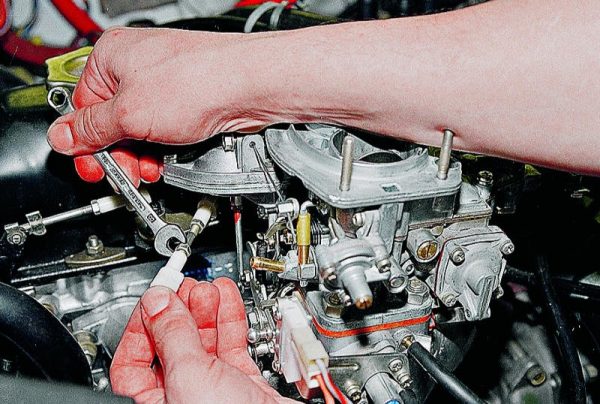

The use of aerosols for washing the carburetor will allow you to do without dismantling it

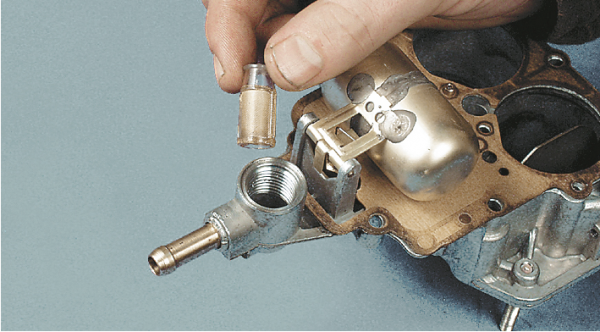

The use of aerosols for washing the carburetor will allow you to do without dismantling it - If there is no fuel in the float chamber, flush the strainer and needle valve. To do this, the filter will need to be removed from the carburetor.

Flushing the fuel filter eliminates the possibility of oil deposits preventing the penetration of fuel into the float chamber

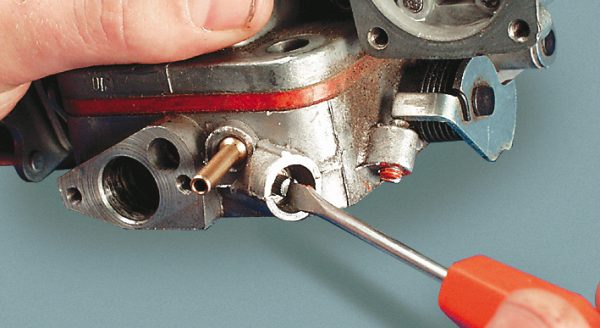

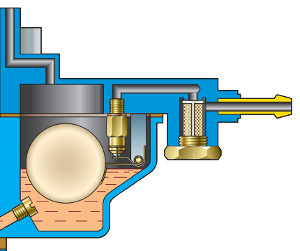

Flushing the fuel filter eliminates the possibility of oil deposits preventing the penetration of fuel into the float chamber - It is necessary to check the presence of gasoline in the float chamber using the accelerator pump (UH). With a sharp press on the accelerator lever, it should be visible how fuel is injected from the sprayer channel into the mixing chamber.

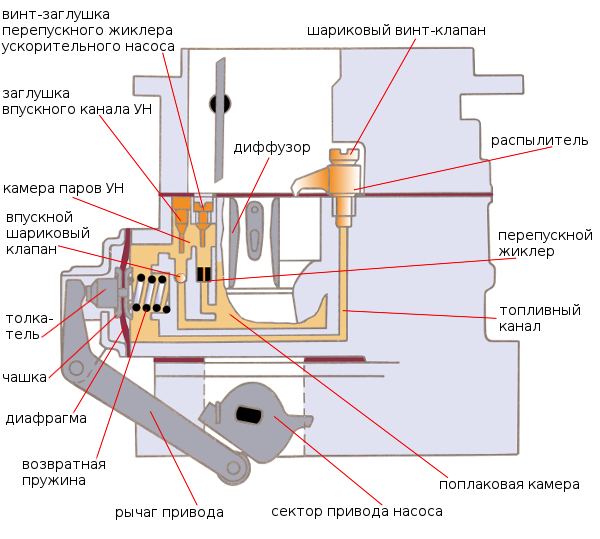

When the throttle is pressed, the lever through the drive sector acts on the diaphragm pusher, and there is an instant injection of fuel through the atomizer into the diffuser

When the throttle is pressed, the lever through the drive sector acts on the diaphragm pusher, and there is an instant injection of fuel through the atomizer into the diffuser

Learn more about the causes of engine failures: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/ne-zavoditsya-vaz-2106.html

The car stalls at idle

At idle, the dampers are closed. Under them, a vacuum is formed, which ensures the flow of fuel through the hole under the shutter of the first chamber. The cause of the situation in which the engine starts, but is unstable, is most often the carburetor. Depressurization of its body may occur. This will cause excess air to enter the carburetor, leaning the fuel-air mixture. Also, the settings of the quality and quantity screws that regulate the composition and quantity of the combustible mixture may also fail. In addition, the lack or absence of fuel in the float chamber leads to depletion of the mixture entering the engine.

The current situation will require the car owner to perform the following actions.

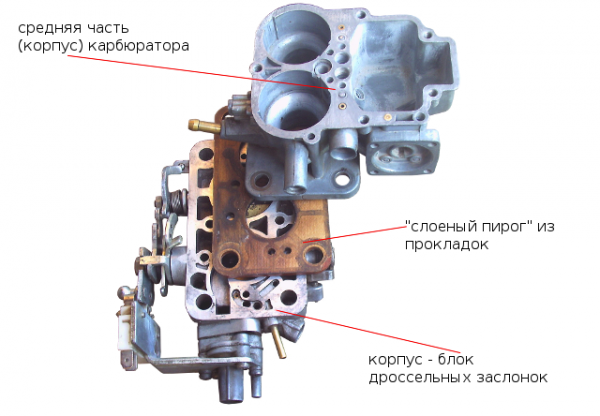

- To eliminate the depressurization of the housing, replace the sealing gaskets between its individual parts.

A heat-insulating gasket is used as a sealing element in the Ozone carburetor

A heat-insulating gasket is used as a sealing element in the Ozone carburetor - Tighten all bolted connections.

During operation, to prevent depressurization, periodically tighten the screw connections of the carburetor parts.

During operation, to prevent depressurization, periodically tighten the screw connections of the carburetor parts. - To prevent depressurization, replace the rubber ring of the solenoid valve and the quality screw.

- Check the condition of the vacuum ignition timing hose for wear and mechanical damage.

A loose connection in the vacuum ignition timing hose leads to excess air entering the carburetor

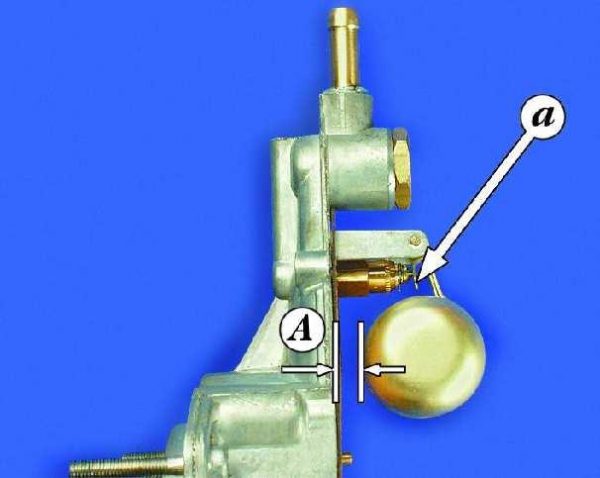

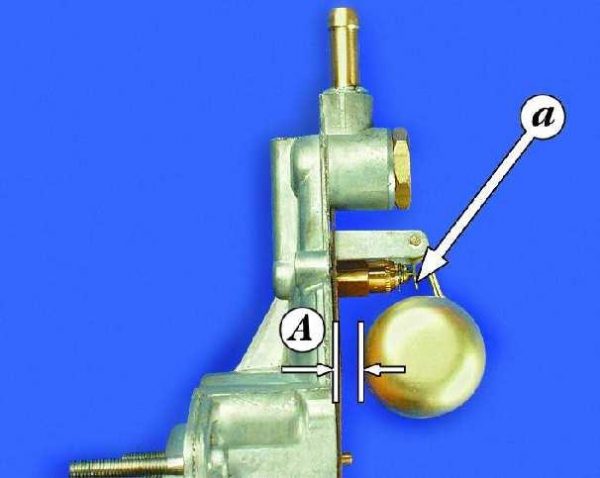

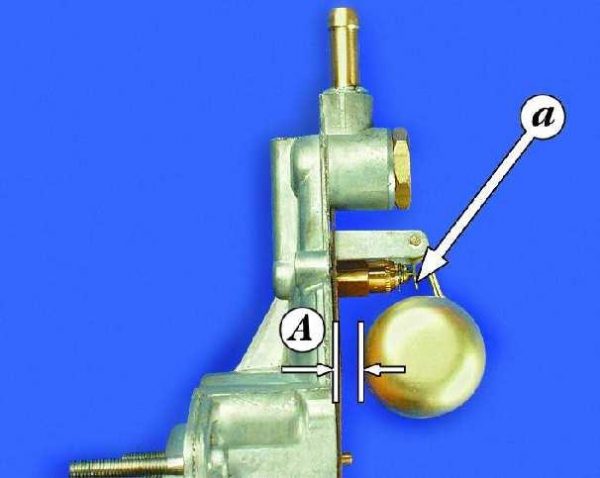

A loose connection in the vacuum ignition timing hose leads to excess air entering the carburetor - Set the optimal level of gasoline (in the Ozone carburetor it is located in the middle of the inclined wall of the float chamber), bending the float mounting tab. The float clearance (the distance between the float and the gasket adjacent to the carburetor cap) should be 6,5 ± 0,25 mm.

The optimal fuel level is in the middle of the inclined wall of the float chamber

The optimal fuel level is in the middle of the inclined wall of the float chamber - Use the quality screw to adjust the free movement of the fuel emulsion through the idle system, and the quantity screw to adjust the volume of the mixture supplied to the cylinders.

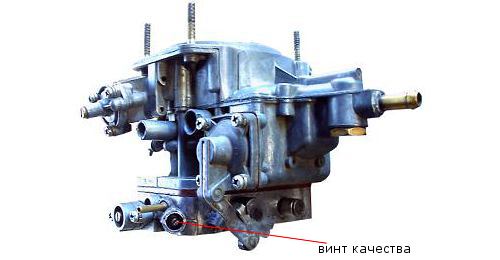

Turning the quality screw changes the size of the fuel channel, reducing or increasing the flow of the fuel emulsion

Turning the quality screw changes the size of the fuel channel, reducing or increasing the flow of the fuel emulsion

The smell of gasoline in the cabin

In any case, the appearance of the smell of fuel in the cabin is due to its excess in the float chamber or loose connection of the body elements as a result of wear or mechanical damage to the seals and rubber hoses.

The appearance of a smell in the cabin of the VAZ 2106 is a sign of a high fire hazard. In this situation, you should immediately turn off the engine and take all measures aimed at identifying the malfunction. The launch of the VAZ 2106 is possible only after the elimination of the causes that led to the penetration of gasoline vapors into the passenger compartment.

To eliminate the reasons for the ingress of gasoline vapors into the cabin, you should:

- Check fuel lines for leaks.

- Replace carburetor seals.

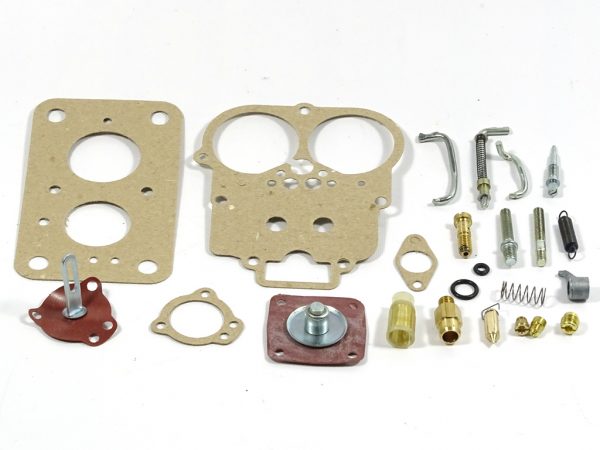

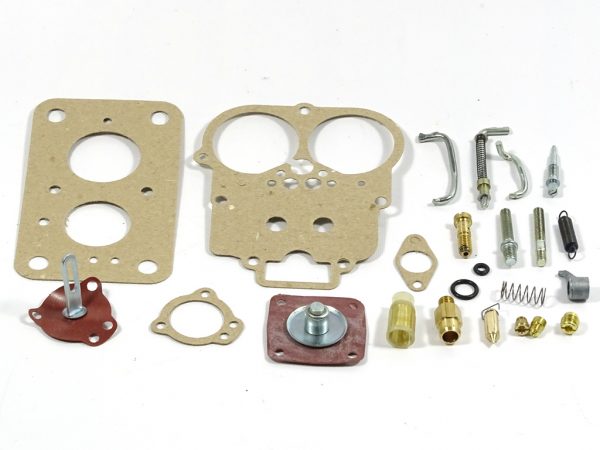

Periodic replacement of sealing elements to exclude malfunctions in the operation of the carburetor during long-term operation

Periodic replacement of sealing elements to exclude malfunctions in the operation of the carburetor during long-term operation - Measure with a vernier caliper and set the optimal height of the float position, ensuring full overlap of the needle valve (6,5 ± 0,25 mm).

The location of the float in the chamber must ensure that the needle valve is completely closed.

The location of the float in the chamber must ensure that the needle valve is completely closed.

Read about the VAZ 2106 fuel pump: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/priznaki-neispravnosti-benzonasosa-vaz-2106.html

Dips when pressing the accelerator pedal

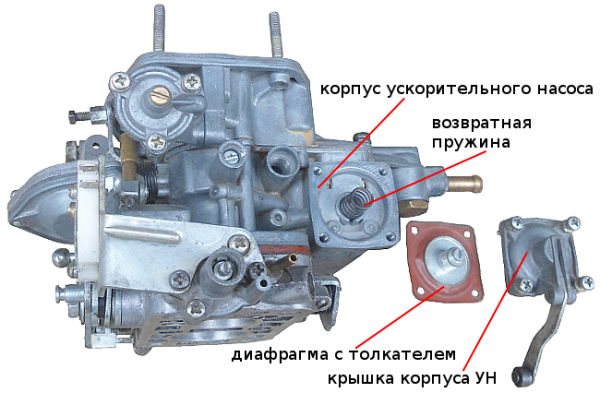

When you press the accelerator pedal, the throttle opens. Further, through the articulated lever, the accelerator pump comes into operation. If it is faulty, then pressing the pedal will lead to interruptions and stop the engine. This is most often manifested when starting off and a sharp increase in speed. When the accelerator lever is pressed sharply, a powerful jet of fuel should be observed from the atomizer channel into the emulsion chamber. A weak jet can be a consequence of:

- clogging of the inlet channels, spray nozzle and discharge valve;

- housing depressurization;

- jumped tube vacuum ignition timing.

To fix this problem, you need to:

- Replace carburetor seals.

- Tighten bolted connections.

- Replace the rubber o-ring on the solenoid valve.

- Check the tube of the vacuum ignition timing regulator for wear and mechanical damage.

- Repair the accelerator pump (flush the supply channels, clean the nozzle of the sprayer from deposits, replace the diaphragm).

Video: repair and maintenance of the VAZ 2106 accelerator pump

Pops in the exhaust system

The appearance of loud sounds in the exhaust system is the result of a too rich air-fuel mixture. Such a mixture with a high content of the liquid phase, not having time to burn out in the working cylinders and having heated up to maximum temperatures, ends the cycle with an explosion in the exhaust system. As a result, loud pops are heard in the muffler. In addition to the carburetor, which creates a mixture with an excessively high concentration of fuel, the causes of this situation may be:

- late ignition;

- loose fitting of exhaust valves;

- valve timing mismatch.

To eliminate the possible causes of this malfunction, you must:

- Remove the valve cover, measure the clearance of the exhaust valves and adjust if necessary.

Properly set thermal clearance of the exhaust valves eliminates the clamping of these valves and the release of unburned mixture into the muffler

Properly set thermal clearance of the exhaust valves eliminates the clamping of these valves and the release of unburned mixture into the muffler - Adjust the fuel supply to the carburetor by setting the required clearance of the shut-off valve in the float chamber. The distance from the float to the carburetor cover with gasket should be 6,5 ± 0,25 mm.

Properly set float clearance ensures optimal fuel level in the chamber

Properly set float clearance ensures optimal fuel level in the chamber - By rotating the quality screw and thereby changing the cross section of the fuel channel, to achieve free movement of the fuel emulsion along the idle circuit. Use the quantity screw to adjust the amount of mixture supplied to the cylinders.

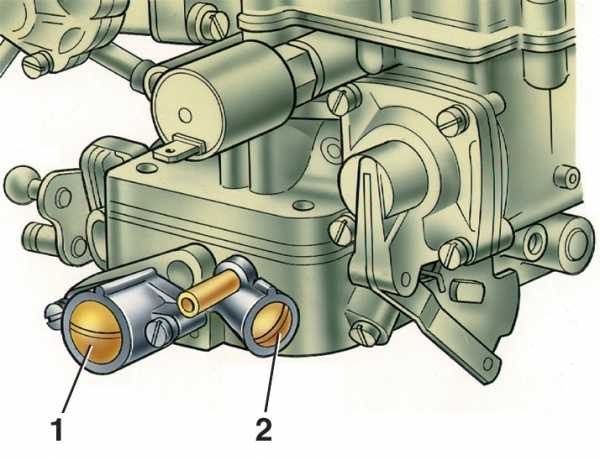

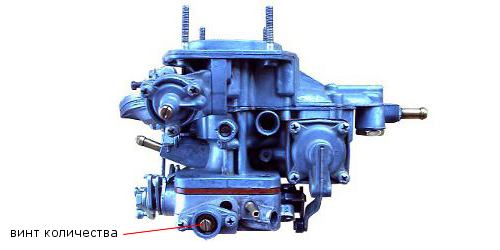

The composition and quantity of the mixture coming from the carburetor is regulated by quality and quantity screws: 1 - quality screw; 2 - quantity screw

The composition and quantity of the mixture coming from the carburetor is regulated by quality and quantity screws: 1 - quality screw; 2 - quantity screw - Set the ignition timing. To eliminate the possibility of late ignition, loosen the octane corrector fastening nut and turn the housing 0,5 divisions of the scale counterclockwise.

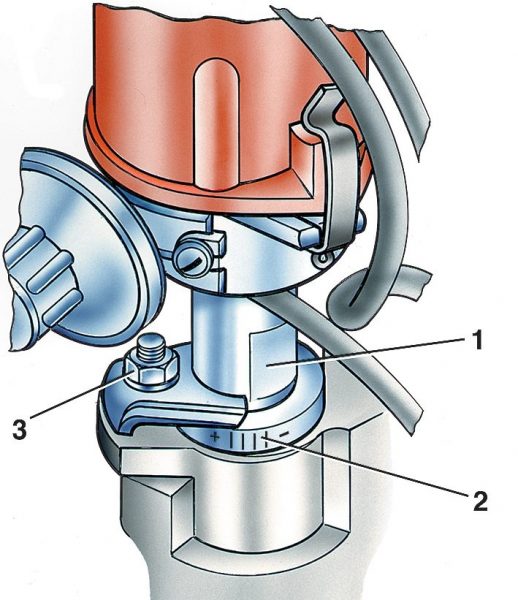

The ignition of the mixture is greatly influenced by the correctly set ignition timing: 1 - housing; 2 - scale; 3 - octane corrector fastening nut

The ignition of the mixture is greatly influenced by the correctly set ignition timing: 1 - housing; 2 - scale; 3 - octane corrector fastening nut

Troubleshooting the carburetor VAZ 2106

Before repairing the carburetor, you should make sure that other vehicle systems are working, which can cause problems. Troubleshooting will require:

- screwdriver for adjusting the carburetor;

To troubleshoot the carburetor, you will need a Phillips screwdriver

To troubleshoot the carburetor, you will need a Phillips screwdriver - a can of special aerosol for washing the carburetor channels from dirt and deposits;

When flushing the carburetor without dismantling, it is more convenient to use products in the form of an aerosol

When flushing the carburetor without dismantling, it is more convenient to use products in the form of an aerosol - a can of compressed air for purging channels and jets;

The use of compressed air (unlike rags) will not allow villi to enter the jets

The use of compressed air (unlike rags) will not allow villi to enter the jets - clean rags for external processing of the carburetor;

- fire extinguisher in case of emergency.

Since the fuel system is a source of increased fire hazard, you must have a fire extinguisher when performing work.

Since the fuel system is a source of increased fire hazard, you must have a fire extinguisher when performing work.

We begin troubleshooting work by disconnecting the negative terminal of the battery in order to protect ourselves from unforeseen situations.

Diagnosis of carburetor malfunctions does not require the use of any special instruments or devices. However, it is desirable to have some experience. A specialist can quickly adjust the device by ear, based on the readings of the tachometer. After making sure that the carburetor is the source of the problems, you can get to work.

Before adjustment, it is necessary to clean the channels and jets of dirt that makes it difficult for fuel to enter the emulsion chamber. Then, with a carburetor cleaner (preferably in the form of an aerosol), rinse the strainer and needle valve. As such a means, you can use both simple acetone and the compositions of LIQUI MOLY, FENOM, HG 3121, etc. In addition, dirt should be removed from the throttle and air damper drive rods, ensuring their free movement. After completing these procedures, the carburetor should be assembled.

The adjustment is made at a temperature warmed up to the operating temperature (at least 85оC) engine.

Never use wire or other foreign objects to clean the jets and channels from dirt. The use of improvised means will violate the geometry of the channels.

Adjusting the composition of the mixture using the quality screw

During operation, the supply channels, locking devices and adjusting screws wear out. It is recommended to replace worn elements with new ones before adjusting the carburetor. For this, commercially available repair kits are usually used.

The quality and quantity screws are on the front of the device. By turning these screws, you can achieve the optimal composition of the fuel-air mixture.

Idle adjustment

The idle setting sets the minimum stable crankshaft speed. This is done in the following way.

- We completely wrap the screws of quality and quantity, setting them in the starting position.

- We turn out the quality screw by two turns, and the quantity screw by three.

The composition and volume of the fuel-air mixture is regulated by quality and quantity screws

The composition and volume of the fuel-air mixture is regulated by quality and quantity screws - By turning the quality screw counterclockwise, we achieve maximum idle speed.

When the quality screw is turned counterclockwise, the fuel-air mixture increases the fuel content

When the quality screw is turned counterclockwise, the fuel-air mixture increases the fuel content - By turning the quantity screw counterclockwise, we achieve a crankshaft speed of 90 rpm.

Turning the quantity screw counterclockwise increases the amount of mixture entering the cylinders

Turning the quantity screw counterclockwise increases the amount of mixture entering the cylinders - By turning the quality screw alternately one turn forward and backward, we check the maximum speed of the crankshaft.

- Using the quality screw, we reduce the crankshaft speed to 85–90 rpm.

Video: idle setting VAZ 2106

Watch this video on YouTube

Adjusting the level of carbon monoxide in the exhaust

Exhaust toxicity is determined by the content of carbon monoxide (CO) in it. Checking the concentration of CO in the exhaust gases is carried out using a gas analyzer. High levels of carbon monoxide are caused by excess fuel or lack of oxygen in the air/fuel mixture. Exhaust toxicity is adjusted by adjusting screws in a manner similar to the idle speed adjustment algorithm.

Adjustment of the float chamber VAZ 2106

An incorrectly set fuel level in the float chamber can make it difficult to start the engine and cause it to run unstable at idle. This level, with the carburetor cover removed, should correspond to the line of transition of the inclined part of the chamber wall to the vertical one.

Adjustment is carried out by bending the float tongue in the following order:

- Install the carburetor cover vertically with the fuel supply fitting up.

- At the moment the tongue on the bracket touches the needle valve float, we measure the distance from the gasket plane to the float (it should be 6,5 ± 0,25 mm).

- If the actual value of this distance does not correspond to the regulated values, we bend the float mounting bracket or tongue.

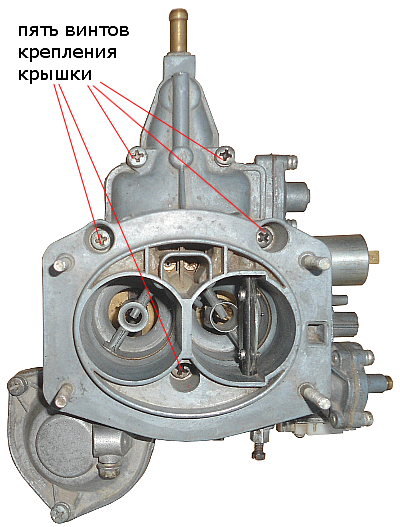

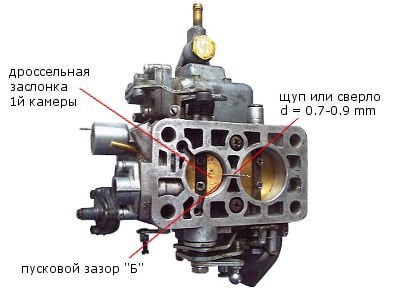

Throttle position adjustment of the first chamber

Loosely closed dampers cause an excess of fuel-air mixture in the engine intake manifold. Their incomplete opening, on the contrary, can lead to an insufficient amount of the mixture. Such situations are usually caused by an incorrect or misconfigured throttle actuator. The gap between the dampers and the walls of the mixing chamber should be 0,9 mm. This will avoid jamming of the damper and prevent the appearance of wear on the wall at the place of its contact with the damper. The gap is adjusted using the stop screw as follows.

- Disconnect the throttle link rod from the accelerator pedal.

The optimal gap size ensures the enrichment of the mixture at start-up, facilitating the process of its ignition

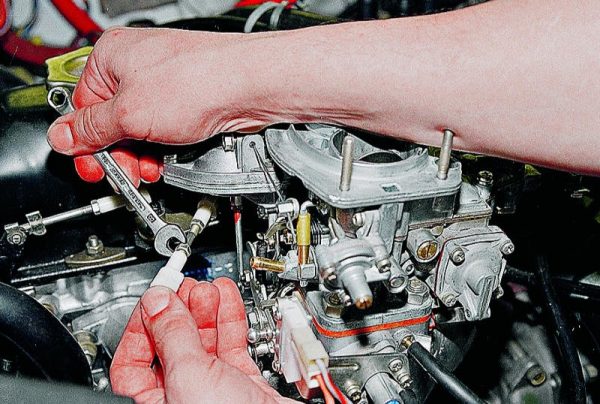

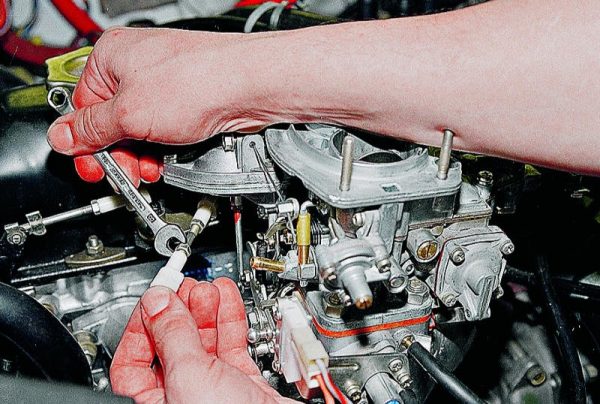

The optimal gap size ensures the enrichment of the mixture at start-up, facilitating the process of its ignition - By pressing the accelerator pedal, we determine the degree of opening of the damper. With the pedal fully depressed, the damper of the first chamber should be fully open. If this is not the case, adjust the drive. By rotating the plastic tip, we achieve the correct location of the damper.

By rotating the plastic tip, it is necessary to achieve the correct position of the throttle valve and the required clearance

By rotating the plastic tip, it is necessary to achieve the correct position of the throttle valve and the required clearance

Table: operating parameters of float and damper clearances

| Parameter | Value |

| Distance from float to carburetor cover with gasket, mm | 6,5±0,25 |

| Gaps at the dampers for adjusting the starting device, mm | |

| air | 5,5±0,25 |

| throttle | 0,9 – 0,1 Feet |

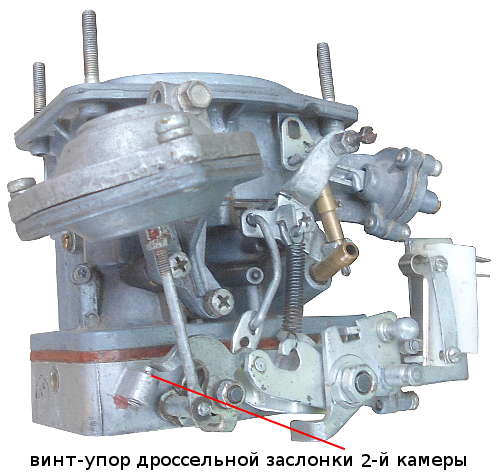

Second chamber throttle position adjustment

With a significant change in the parameters of atmospheric rarefaction with the damper of the first chamber open, the pneumatic actuator of the second chamber is activated. Its verification is carried out as follows:

- Fully open the shutter of the first chamber.

- Having drowned the rod of the pneumatic actuator of the second chamber, we fully open the second damper.

- By changing the length of the stem, we adjust the degree of opening of the damper. After loosening the locknut on the stem, rotate it until the damper is in the correct position.

The rotation of the stop screw ensures complete closure of the throttle valve of the second chamber of the carburetor and prevents air leakage

The rotation of the stop screw ensures complete closure of the throttle valve of the second chamber of the carburetor and prevents air leakage

Accelerator pump adjustment

The accelerator pump provides additional fuel supply at the time of acceleration, enriching the mixture. In normal mode, it does not require additional adjustment. If the pump supply adjusting screw adjusted by the manufacturer was turned out, after assembling the carburetor, the fuel supply from the atomizer should be adjusted. This is done in the following order.

- To fill the channels of the accelerator pump with fuel, turn the throttle drive lever ten times.

- We substitute a container under the nozzle of the sprayer.

- With an interval of three seconds, turn the throttle drive lever all the way ten more times.

- Medical syringe with a volume of 10 cm3 collect gasoline from the container. For ten full strokes of the pump diaphragm, the collected amount of fuel should be about 7 cm.3.

- We observe the shape and direction of the jet from the atomizer. In case of uneven and intermittent jet, clean the sprayer or change it to a new one.

- If necessary, we adjust the supply of fuel by the accelerator pump with a screw.

Adjustment of drafts of "gas" and "suction"

The length of the “suction” cables and the “gas” thrust must ensure complete closing and opening of the dampers in all engine operating modes. The order in which these nodes are checked is as follows:

- with the “suction” handle sunk to the stop, the air damper must be fully open, that is, it must be in a vertical position;

- with the “suction” handle extended to the stop, the air damper must be completely closed, blocking the cross section of the first chamber without gaps;

- to adjust, it is necessary to loosen the fixing screw of the “suction” drive rod end;

- adjustment of the “gas” thrust drive is carried out by rotating the plastic tip until the damper is in the desired position.

Cleaning the jets

Before adjusting the carburetor, it is necessary to clean the channels and jets from dirt and deposits. For this you need:

- unscrew the fuel and air jets;

- soak them in acetone or some other carburetor cleaner for ten minutes;

- blow the jets with compressed air;

- install the cleaned and dried jets in the carburetor.

Working with a carburetor is associated with an increased source of fire hazard. All precautions must be taken before starting work.

The VAZ 2106 carburetor is a rather complex device, consisting of many small elements. Nevertheless, any car owner can wash the jets and the strainer, as well as adjust the supply of the fuel-air mixture. To do this, you only need to consistently follow the instructions of specialists.