What are hydraulic lifters for and how to install them on a VAZ 2107

Content

One of the options for improving the VAZ 2107 engine is the installation of hydraulic lifters. This part not only reduces the noise from the operation of the power unit, but also completely eliminates the need for periodic adjustment of valve clearances. Installation of hydraulic lifters is possible in garage conditions, for which you will need to prepare the elements of the system and the necessary tools.

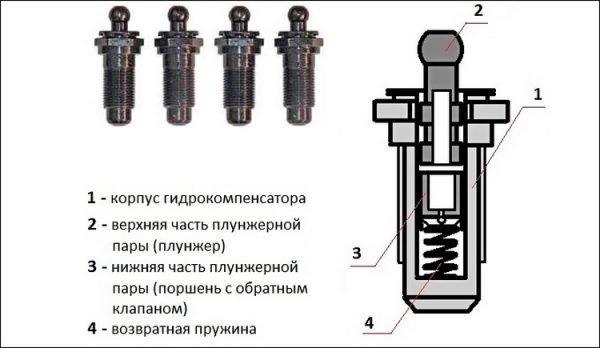

Hydraulic lifters VAZ 2107

Hydraulic lifters are devices that independently adjust the valve clearance. The part is a more advanced product than the mechanical type regulator used on older cars. On the VAZ 2107 and other "classics" hydraulic lifters (GKK) were not installed. As a result, every 10 thousand km. run had to adjust the thermal clearance of the valves. The adjustment procedure was carried out manually, that is, it was necessary to dismantle the valve cover and set the gaps using a special feeler gauge.

Description: why we need and the principle of operation of hydraulic lifters

The mechanical elements that are responsible for adjusting the gap wear out over time. If the gap is not adjusted in time, engine noise will appear, the dynamics will decrease, and gasoline consumption will increase. As a result, with a run of 40–50 thousand km. valves need to be changed. Speaking briefly about mechanical adjustment, this design is far from perfect.

Find out how you can regulate fuel consumption: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/rashod-fupliva-vaz-2107.html

When equipping the engine with hydraulic lifters, you do not need to think about the need to adjust the valves. The hydraulic support itself will set the required clearance, which has a positive effect on the resource of the power unit, increasing power, and reducing fuel consumption. In addition, the part is characterized by a rather long service life - about 120-150 thousand km. run. For a complete understanding of how hydraulic lifters work on the VAZ 2107 and any other car, it is worth considering their principle of operation.

Engine oil enters the hydraulic element through a special valve in the form of a ball. Lubrication pushes the GKK piston, changing its height. As a result, a position is reached in which the hydraulic component minimizes the valve clearance in the gas distribution mechanism. After that, no oil enters the hydraulic compensator, since there is a certain (maximum) pressing moment. When a wear is formed between the valve and the hydraulic element, the valve mechanism opens again and pumps oil. As a result, high pressure is always created in the GKK, providing maximum pressure.

Read about oil change in KKP: https://bumper.guru/klassicheskie-modeli-vaz/kpp/zamena-masla-v-korobke-peredach-vaz-2107.html

In addition to the advantages listed above, the hydraulic support also has negative aspects:

- the need to use high-quality oil;

- repairs are more difficult and expensive.

Signs of malfunction of hydraulic lifters and their causes

Like any other part of a car, hydraulic lifters fail over time and there are characteristic signs of this:

- the appearance of a knock (clatter);

- reduction in the power of the power unit.

Clunk under the valve cover

The main symptom that indicates a malfunction of the hydraulic support is an extraneous knock (clatter) after starting the engine, coming from under the valve cover. Since the noise and the reasons for its appearance may differ, you need to learn to distinguish the nature of the knocks and only then draw the appropriate conclusions.

- Knocking in the engine when starting. If the noise disappears a few seconds after starting the power unit, then this effect is not a sign of a problem.

- The appearance of a knock of hydraulic bearings on a cold and warm engine, while the noise disappears with an increase in speed. The probable cause is the wear of the check valve ball, which indicates the need to replace the GKK. The problem can also manifest itself when the hydraulic element is contaminated. To fix the problem, they resort to cleaning.

- The noise is only present when the engine is warm. This type of noise indicates wear of the elements of the hydraulic compensator. The part is to be replaced.

- Knocking when the power unit is running at high speeds. The problem can be either excessive or insufficient engine oil levels. In this case, it must be monitored and brought to normal. The reason may also be related to problems with the oil receiver, which will have to be fixed.

- The constant presence of a knock. The likely cause is the gap between the camshaft cam and the rocker. The problem is eliminated by cleaning or replacing worn parts.

Video: an example of the knock of hydraulic lifters on a VAZ 2112

Loss of engine power

In the event of malfunctions with hydraulic compensators, engine power is reduced, which, of course, affects the dynamic characteristics of the car. This phenomenon is due to a malfunction of the gas distribution mechanism: the valve opens and closes earlier or later than necessary. As a result, the engine is not able to develop its power performance.

How to identify a faulty hydraulic lifter

Having determined that the occurrence of a knock in the motor is associated with malfunctions of the hydraulic lifters, it remains to check which particular part has become unusable. Diagnostics is performed in the following sequence:

- The valve cover is removed from the engine immediately after the unit stops.

- Set the piston of the first cylinder to the top dead center (compression stroke), for which the crankshaft is turned with a special key.

- Apply force to the shoulder of the rocker (rocker) of the intake valve.

If, when pressed, the rocker moves easily, then this indicates a malfunction of the hydraulic compensator. Similarly, the remaining hydraulic elements are checked by turning the crankshaft to the appropriate position (similar to valve adjustment). VAZ 2107 car owners who have installed hydraulic lifters recommend checking the health of the hydraulic bearings by pressing the part with a screwdriver. If the element is out of order, there will be a significant stroke (more than 0,2 mm).

Video: how to identify non-working hydraulic lifters on the example of Chevrolet Niva

Watch this video on YouTube

Installation of hydraulic lifters on the VAZ 2107

Before proceeding with the installation of hydraulic lifters on the VAZ 2107, you will need to prepare the necessary parts, materials and tools. The list of elements that will be needed for work:

- one camshaft stud;

- camshaft assembly VAZ 21214;

- 8 hydraulic lifters from the same model;

- oil rail from VAZ 21214;

- 8 rockers.

If the old rockers are in good condition, then there is no need to replace them. Of the tools and materials you will need:

- torque wrench;

- standard set of wrenches;

- set of heads;

- flat screwdriver;

- wire;

- timing cover gasket;

- rags.

The process of installing hydraulic lifters on the "Zhiguli" of the seventh model is reduced to the following step-by-step actions:

- We provide access to the valve cover by dismantling the air filter housing, carburetor and distributor. The last two devices are removed for convenience only.

To access the timing mechanism, we dismantle the filter with the housing, the carburetor and the distributor, and then remove the valve cover

To access the timing mechanism, we dismantle the filter with the housing, the carburetor and the distributor, and then remove the valve cover - Turning the crankshaft with a key of 38, we set it to a position in which the mark on the camshaft coincides with the ebb on the bearing housing.

By turning the crankshaft, we set a position in which the mark on the camshaft gear will coincide with the protrusion on the bearing housing

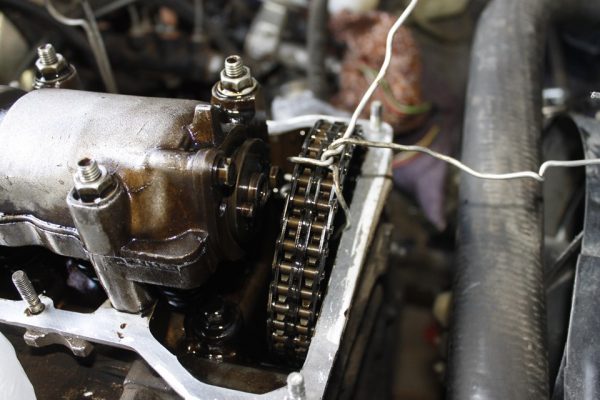

By turning the crankshaft, we set a position in which the mark on the camshaft gear will coincide with the protrusion on the bearing housing - Using a screwdriver, we bend the stopper of the camshaft gear bolt and unscrew the fasteners with a key of 17. We fix the chain on the sprocket with wire.

To avoid the chain falling inside the engine, we tie it with wire to the camshaft gear

To avoid the chain falling inside the engine, we tie it with wire to the camshaft gear - With a head of 13, we unscrew the fastening of the bearing housing and remove the camshaft completely.

We unscrew the camshaft mount with a 13 head and remove the mechanism

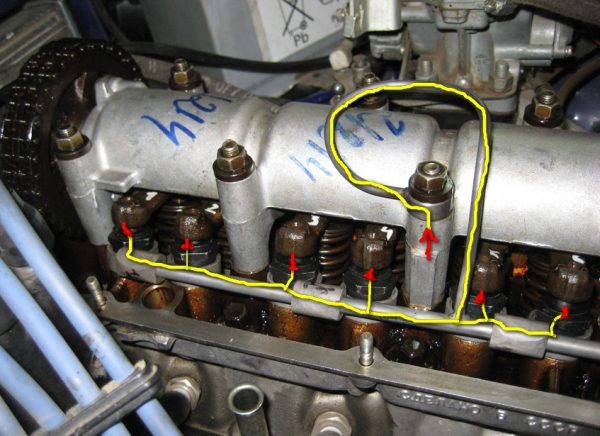

We unscrew the camshaft mount with a 13 head and remove the mechanism - We dismantle the rockers with springs. Each rocker will need to be installed in its place, therefore, when disassembling, we take this moment into account, for example, we number it.

When dismantling the springs and rockers, the latter must be numbered to install in the same order.

When dismantling the springs and rockers, the latter must be numbered to install in the same order. - With a head of 21, we unscrew the bushings of the adjusting bolts.

We unscrew the adjusting bolts together with the bushings with a head of 21

We unscrew the adjusting bolts together with the bushings with a head of 21 - Before installing the oil rail, blow it with air using a compressor.

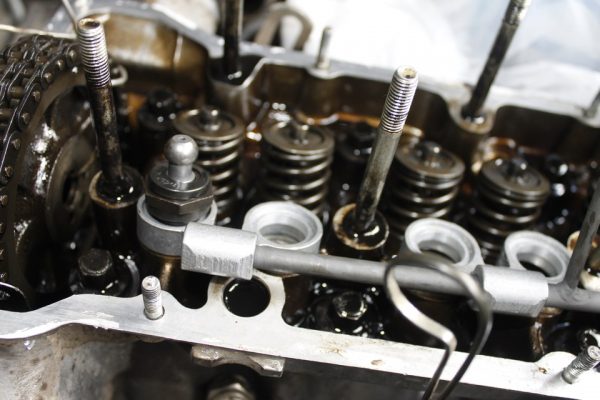

- We install hydraulic lifters through the ramp, having previously dismantled the stoppers. First, we tighten the GKK slightly, and then with a moment of 2–2,5 kg / m.

Before installing the hydraulic lifters, the locking elements are removed from them.

Before installing the hydraulic lifters, the locking elements are removed from them. - We mount the new camshaft and place the oil rail ring on the #1 stud.

When installing the camshaft on the cylinder head, place the oil rail ring on the stud No. 1

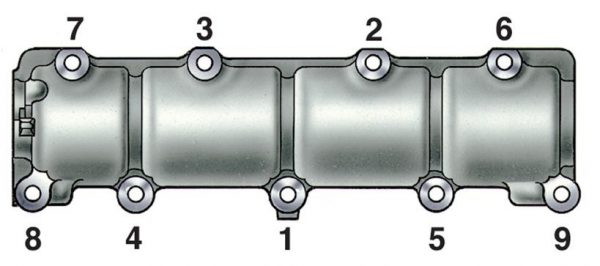

When installing the camshaft on the cylinder head, place the oil rail ring on the stud No. 1 - We tighten in a certain sequence.

The camshaft must be tightened in a certain sequence.

The camshaft must be tightened in a certain sequence. - We give the line a shape in which it will not interfere with the installation of the valve cover. Then install and fix the camshaft sprocket.

So that the oil line does not rest against the valve cover, it should be given a certain shape

So that the oil line does not rest against the valve cover, it should be given a certain shape - We reassemble all dismantled elements.

Details on choosing a carburetor for a VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/toplivnaya-sistema/kakoy-karbyurator-luchshe-postavit-na-vaz-2107.html

Replacing the rocker arms on the VAZ 2107

Rockers (rocker arms) are one of the elements of the gas distribution mechanism of the VAZ 2107 engine. The purpose of the part is to transfer energy from the camshaft cam to the valve stem. Since the rocker is constantly subjected to mechanical and thermal stress, wear occurs over time.

Determining the suitability of rocker arms

If during the operation of the "seven" a decrease in engine power is observed or a characteristic tapping is heard in the cylinder head, then the probable cause is a breakdown of the rocker arm. During repair work, it is necessary to clean the rockers from dirt, deposits and check them for wear and damage. If any defective parts are found, they are replaced with new ones. If the rocker arms are in good condition, the products are installed on the cylinder head.

Is it possible to align the rocker

When adjusting valves or repairing the cylinder head, you may notice that the rocker arms are somewhat skewed with respect to the camshaft, i.e. the distance between the rocker plane and the camshaft journal is not the same. To eliminate this nuance, some owners of the "classic" align or change the springs that press the rocker arms, replace the rocker itself, but the problem may still remain. In fact, on all classic Zhiguli models, including the VAZ 2107, skew is not as bad as an incorrect valve clearance. Therefore, it is the gap that should be paid attention to. The main thing is that the parameter is properly adjusted and is 0,15 mm cold.

How to replace rocker

If it becomes necessary to replace the rocker arms on the "seven", for example, 1 part in case of breakage, then it is not necessary to dismantle the camshaft. To do this, it will be enough to pry off the spring with a screwdriver, remove it, and then remove the rocker itself. The new part is installed in the reverse order. If all rocker arms are being replaced, then it is more reasonable to dismantle the camshaft.

Video: replacing the rocker with a "classic" one without disassembling the camshaft

Watch this video on YouTube

Equipping the VAZ 2107 engine with hydraulic lifters improves its operation and performance. Installing the mechanism will not take much time and effort, but will require material costs. Therefore, whether there is a need for such a modernization of the motor or not, each motorist decides for himself.