VAZ 2107 engine: device, main malfunctions, repair

Domestic "seven" was produced in the period 1982-2012. During this time, she won the name of the people's car due to the relative cheapness, reliability of components and assemblies and the ability to repair complex elements (up to the engine) almost “on the knee”.

The device of the VAZ 2107 engine

The power plant 2107 can be called revolutionary for the line of engines of cars of the Togliatti automobile plant. This is the first of the so-called classic cars to receive an advanced injection system.

The GXNUMX injection system operates in rather difficult conditions, with constant high loads, especially on our roads. For this reason, the engine requires good and timely maintenance. Even the slightest blockage will negatively affect the fuel supply, as a result of which the fuel fluid consumption will increase and the efficiency of the internal combustion engine will decrease.

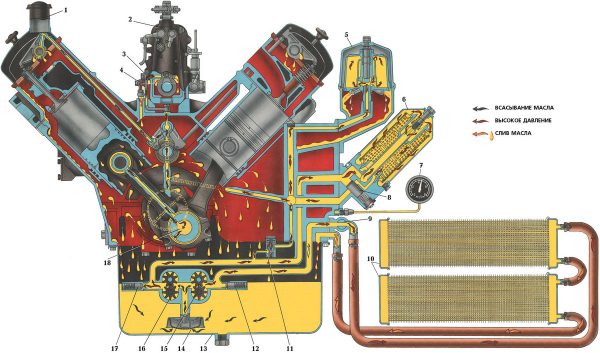

Lubrication system

One of the main areas of the VAZ 2107 engine is the lubrication system, which functions by supplying oil to the rubbing surfaces. Thanks to it, friction is reduced and the efficiency of the power plant increases. Filling with oil takes place through the oil filler neck, which is tightly closed with a lid. The old, no longer needed grease is drained from the system through another hole - it can be closed with a rubber plug.

Important characteristics of the lubrication system:

- the system holds exactly 3,75 liters of oil, the level of which can be monitored by the index gauge;

- the pressure on a heated internal combustion engine at an average crankshaft speed is 0,35–0,45 MPa;

- the lubrication system functions in combination - under pressure and by means of spraying.

It is customary to refer to the main problems of the lubrication system:

- clogged oil filter;

- crankcase ventilation problems;

- leakage of lubricant through loose connections;

- destruction of the crankshaft oil seals;

- problems with fluid pressure.

The causes of this problem are varied. It must be understood that the long-term operation of the engine is directly related to the lubrication system - it determines the durability of the power plant. Indeed, even a short-term interruption in the supply of lubricant to the rubbing internal parts of the motor can lead to overhaul and even the replacement of an expensive unit.

Find out which engine can be installed on the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/kakoy-dvigatel-mozhno-postavit-na-vaz-2107.html

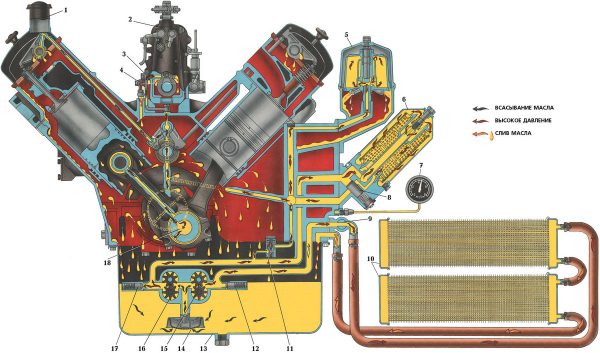

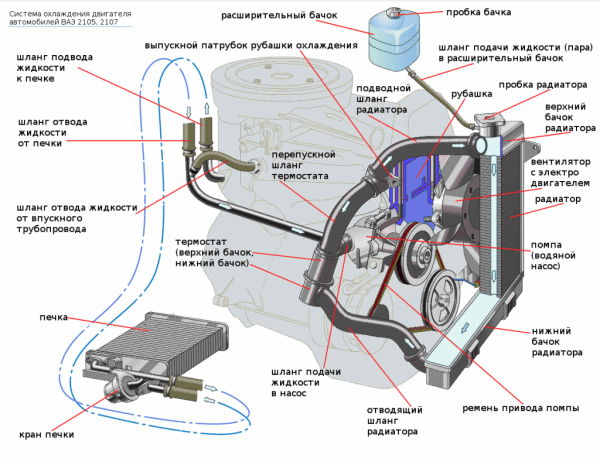

Cooling system VAZ 2107

It is designed to maintain the desired thermal regime of the engine installation by correlating heat removal from the most heated components and parts. On the "seven" there is a sealed liquid system with forced circulation. Some of its important components are a pump, an expansion tank, a heater radiator with an electric fan and a thermostat.

- The centrifugal pump is driven by the crankshaft. It consists of a lid held on by four studs and a body connected to the lid through a sealing gasket. The pump also has a roller with an impeller rotating on a bearing.

- The expansion tank is integrated into the cooling system for a reason. The element accepts excess antifreeze, which, when expanded, creates high pressure that can break all hoses, pipes and radiator cells. The vacuum rarefaction formed during cooling (reduction) of the liquid has the same force. The expansion tank is designed to eliminate both phenomena. It is an element of a durable tank with a filler neck and fittings. A special role is played by the tank lid, equipped with valves to remove excess pressure.

- The heater radiator is a structural part with two reservoirs and an iron core. Mounted on rubber cushions, fixed to the body of the "seven" with two bolts. The element is connected to the expansion tank in a sealed circuit. It is equipped with an electric fan that is activated by a sensor. On the "sevens" of the early year of production, an electric fan was not installed, the blades rotated mechanically from the motor. In injection systems, the electric fan receives a command already from the computer through a relay and an antifreeze temperature sensor.

- The thermostat maintains the desired thermal regime of the power unit, helps it start quickly. Equipped with two valves: main and bypass. Thanks to the thermostat, the engine warms up quickly.

The principle of operation of engine cooling can be represented as follows: antifreeze circulates through all zones of the system, heats up, then enters the radiator and the pump.

More about the cooling radiator device: https://bumper.guru/klassicheskie-modeli-vaz/sistema-ohdazhdeniya/radiator-vaz-2107.html

Piston group

This includes 4 required elements.

- Pistons on the VAZ 2107 are sorted according to the diameter of the finger into 3 classes every 0,004 mm. In their manufacture, special attention is also paid to the mass, therefore, during the overhaul of the engine installation, it is not necessary to use pistons of the same group - it is enough that they are under the "seven" engine. There is a direction arrow on the piston crown.

- The piston pin is a structural element, seized by retaining rings.

- The connecting rods on the VAZ 2107 are used with a pressed bushing made of combined iron. They, like pistons, are also classified into 3 classes, depending on the diameter of the sleeve. Connecting rods are made of steel, forged.

- The rings in the piston group of the "seven" are cast iron. Two of them are barrel-shaped, semi-chrome and compression, one is oil scraper.

Cylinder block

The block is made of a special type of cast iron - high-strength. Sleeves for VAZ cylinders are not needed, as boring on the spot is implied. The cylinders are internally honed, making them highly accurate. They are divided into 5 classes, alternating by 0,01 mm.

Malfunctions of the standard engine VAZ 2107

It is customary to distinguish between the main malfunctions of the regular engine of the "seven". All of them require an early and mandatory permit in order to avoid major repairs.

Engine overheating

A frequent malfunction caused by various reasons and threatening a breakdown of the cylinder head gasket or a complex engine repair. Usually, when the engine overheats, an indicator on the dashboard signals. Unfortunately, many motorists do not react in time to the arrow approaching the red zone.

At the first symptoms of overheating, it is necessary to act already at the wheel:

- open the air damper;

- turn on the heater fan, setting it to the highest speed;

- put the gearbox in neutral mode, try to roll the car to the edge of the road due to inertia (be sure to turn on the emergency gang);

- leave the engine to idle for 2-3 minutes.

This will work if there are no puffs of steam coming out from under the hood, i.e., the superheat level is low. Remember that it is not recommended to immediately turn off the engine with such overheating. This is done only on the condition that the hose has burst, and there is a threat of depressurization of the cooling system.

After turning the key to the opposite position, the engine does not completely turn off, it works due to pseudo-ignition, so it must be turned off forcibly by putting the gearshift lever in any position other than neutral, and press the brake - then release the clutch.

After stopping the engine, the antifreeze continues to circulate, having the greatest effect on the joints of the engine parts. If the outcome is unfavorable, this threatens the formation of vapor locks. The phenomenon is called "heat stroke".

If overheating of the engine installation is accompanied by steam knocking out from under the hood of the car, the troubleshooting instructions look different.

- Open the hood, check the presence of antifreeze in the expansion tank, the integrity of the hoses, radiator and thermostat.

- Grasp the tank cap with a rag, carefully unscrew it 1 turn to release the pressure. Work extremely carefully so as not to scald with hot antifreeze!

- Restore the causes of overheating and depressurization of the cooling system: wrap the broken hose with electrical tape or replace it, close the crack formed due to corrosion on the radiator, fill in the required dose of refrigerant, etc.

In some cases, the overheating culprit is the sensor that turns on the fan motor. It is easy to check it: you need to throw off both wires from the sensor terminals and connect them together - if the fan works with the ignition on, you need to change the sensor, it does not work.

The thermostat, which regulates the flow of antifreeze through and around the radiator, may also fail. The cooling system assembly is checked as follows: on a warm engine, you should feel the upper and lower pipes connecting the motor to the radiator with your hand. A thermostat malfunction can be judged by a cold lower hose.

Engine knock

He is different.

- First of all, when it comes to knocking, we mean the connecting rod. If the element starts to knock, then the oil pressure immediately drops. As a rule, experienced motorists easily recognize the sound of a damaged connecting rod by a thud that increases as the car accelerates.

- Knocking also occurs in the crankshaft main journals, when pressure drops in the system and a dull metallic noise is heard. It is recognized at all engine speeds, and a malfunction can be diagnosed without disassembling the internal combustion engine.

- Knocking when cold is manifested on worn motors. There is nothing terrible in it. It's just that the gaps between the mating parts have exceeded the permissible limits, when the power plant heats up, everything returns to normal.

- Knocking is possible due to valve beating, which occurs due to poor adjustment of the “bed” of the camshaft or wear of the rocker.

- Finally, it can be caused by a loose chain drive. In this case, we can clearly distinguish the metallic ringing at idle. As the speed increases, the sound disappears partially or completely.

Smoke from the breather

When it comes to this, there is no smoke coming into the muffler, no steam, but the car starts to use liters of oil. At the same time, the first and fourth cylinders of the engine become clogged.

This malfunction has several causes: a change in engine compression, wear on the valve stem seals, or bursting rings.

Engine trophy

The VAZ family of cars equipped with old-generation injection systems often “sin” with such an effect as tripling. The causes of the malfunction, as a rule, should be sought in injection systems, fuel supply, etc.

There is only one way to eliminate tripping caused by a clogged fuel pump or filters - by replacing the elements or cleaning them. In some cases, the pump may not work correctly, then it will have to be disassembled and the cause found.

If the nozzles are clogged, then this happens more often due to poor-quality fuel. The elements themselves are also subject to wear. The injectors are checked using a special stand, which not only allows you to diagnose the condition of the injectors, but also cleans them.

Tripping can occur due to the loss of a spark. In this case, suspicion immediately falls on the spark plugs. They are recommended to be carefully checked, visually inspected for cracks or accumulated dirt. Doubtful elements should be replaced immediately. The engine of the "seven" can triple due to burnout of the valves.

Smoke from muffler

Many unknowingly ignore smoke, because it is almost invisible on a hot engine. However, if it does not stop, this is a sign of more or less serious problems in the engine installation.

According to experienced motorists, the smoke escalates at the factory of the engine installation. Special attention should be paid to it, in time to determine the malfunction.

Basically, excessively dense smoke hints at errors in the cooling and fuel supply systems. Malfunctions of the distribution mechanism or piston group are possible.

About the device of the exhaust system VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/muffler-vaz-2107.html

Throws oil on candles

Also one of the common malfunctions of the VAZ 2107 engine. The thread of the candle or the body is covered with oil, and in special cases, even the entire base. At the same time, the motor signals a deterioration in dynamic properties, increased smoke and high oil consumption.

Experts name the reason for throwing oil on candles, first of all, damage or wear of valve guides, valve stem seals, piston group elements or cylinder head gaskets.

Doesn't pull motor

Has the car lost its former traction? Almost every owner of the "seven" who has been operating the car for more than 5 years faces this phenomenon. She accelerates for a long time, cannot overcome climbs in high gears.

As you know, the VAZ 2107 comes with injection and carburetor engines. Depending on this, the causes of the malfunction are distinguished.

- On a carbureted internal combustion engine, the lack of traction is caused by the power system - there is not enough fuel or its supply is too large. Carburetors need to be properly adjusted, otherwise the engine will be unstable. The gas distribution mechanism also affects the engine power indicator, which is characterized by a decrease in pressure.

- If the engine with the injection system does not pull well, the reason is associated with the timing, filters, ignition systems and malfunctions in the piston group.

Engine repair

The following tools will be needed for this job:

- a puller that allows you to easily pull out the piston pin;

- adjustable support under the bottom, withstanding at least 1 ton;

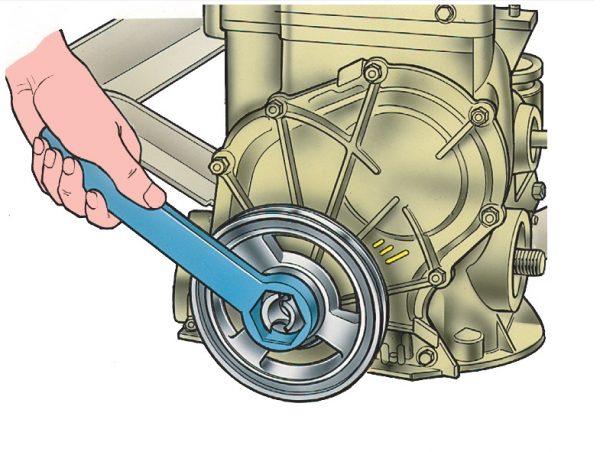

- crankshaft ratchet key;

The crankshaft ratchet wrench will allow you to easily hold the flywheel

The crankshaft ratchet wrench will allow you to easily hold the flywheel - wide flat probe 0,15 mm;

- a pressure gauge capable of measuring the pressure in the fuel rail;

- metal ruler;

- vice;

- compression gauge, etc.

The compression gauge will help determine the condition of the engine

The compression gauge will help determine the condition of the engine

How to remove the engine

The engine is removed for repair or replacement. There is nothing particularly complicated in the procedure if there is a special winch. The motor can be dismantled in this case as a whole, however, it is harder than removing it without a cylinder head.

The sequence of actions looks like this.

- The hood of the car is recommended to be removed to provide free access.

- Drain all coolant.

- Remove the air filter, disconnect the suction cable, throw off the accelerator lever, the carburetor gas hose - in a word, all the attachments that can be an obstacle to work.

- Unscrew the muffler, remove the hose from the heater.

You can unscrew the muffler VAZ 2107 with an ordinary wrench

You can unscrew the muffler VAZ 2107 with an ordinary wrench - Remove the distributor.

- Pull out the starter.

- Remove the radiator.

- Disconnect the fuel hose from the pump.

Now you can proceed to the direct work with the engine.

- Unscrew the nuts from the pillows.

The pillow of the VAZ 2107 engine rests on a nut

The pillow of the VAZ 2107 engine rests on a nut - Separate the gearbox from the engine.

- Pull the engine off the pillows, substitute a strong rope under them.

It will be more efficient to stick a metal pipe under the rope. Put the ends of the rope on the hydraulic equipment to lift the engine. Spin and pull out the motor.

Replacing crankshaft bearings

Engine removed, you can continue.

- Loosen the 14 bolts securing the sump to the cylinder head.

- Remove oil pump.

- Unscrew the connecting rod nuts, remove the covers.

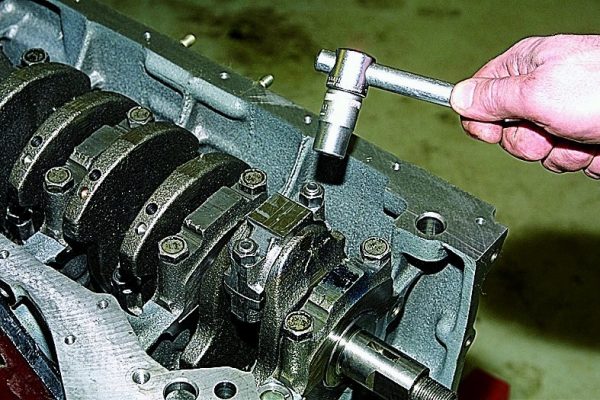

The connecting rod nuts must be removed.

The connecting rod nuts must be removed. - Push the pistons out of the cylinders.

- Loosen the crankshaft main bearing cap bolts.

- Remove crankshaft.

In order to be able to remove and replace the liners, it is necessary to remove the thrust bearing half rings from the grooves of the fifth main bed. After disassembling the crankshaft, you can remove the old liners and replace them. New items must match the desired category.

The inserts can only be replaced. They are not subject to repair, as they are made to exact dimensions. Over time, parts wear out, you have to put new ones. In fact, the liners are plain bearings for the connecting rods that act on the crankshaft.

Replacing the piston rings

In many cases, this procedure is required due to the fault of the car owner himself, who fills in something unclear instead of high-quality oil. In addition, the frequency of lubrication renewal is of great importance. The first symptom that indicates the failure of the rings is a sharp increase in fuel consumption.

Replacement on a removed but not yet disassembled engine.

- The crankshaft rotates so that the required piston is in the desired position - at the bottom dead center.

- The connecting rod cover is removed, all the pistons are pushed up by the cylinders.

- Carbon deposits are removed from the pistons.

- Old rings are replaced with new ones.

It is imperative to first install the oil scraper ring, and finally tighten both elements with a special mandrel.

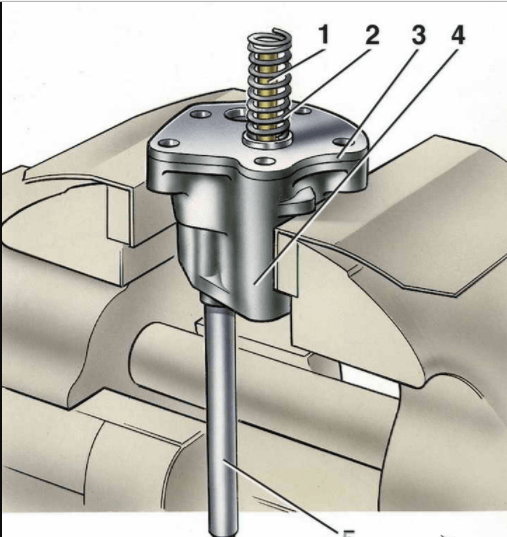

Oil pump repair

The oil pump on the VAZ 2107 is the most important element of the lubrication system, which allows the supply of lubricant under pressure. Repair of an element implies the presence of tools such as flat probes measuring 0,15–0,25 mm, rulers and a vise.

Algorithm for carrying out restoration work with an oil pump.

- Remove the pump and place it in a vise.

The oil pump VAZ 2107 is clamped in a vise

The oil pump VAZ 2107 is clamped in a vise - Loosen the bolts securing the intake pipe to the housing.

- Disconnect the pipe from the body, doing it carefully. The main thing is not to lose the washer of the pressure reducing valve.

- Remove spring and relief valve.

- Take out the cover.

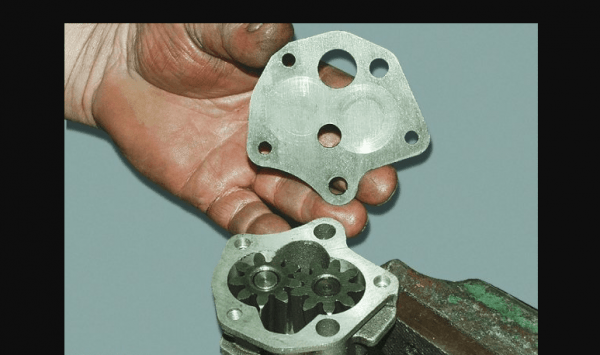

The oil pump cover is removed, then the gears are removed

The oil pump cover is removed, then the gears are removed - Then remove the gears.

Each removed part should be inspected for cracks and deformations. If they are found, the element must be replaced. At the end, be sure to rinse all parts with kerosene and dry with compressed air. After that, put everything back together.

The VAZ 2107 engine only looks like a complex device. In fact, if you follow the instructions and carefully, you can safely disassemble and assemble it.