Honing car engine

Content

Any motor sooner or later develops its resource, no matter how carefully it is operated. When a unit is overhauled, the foreman carries out many complex operations that require utmost precision. Among them is cylinder honing.

Let us consider in more detail what the essence of this procedure is, how it is performed, and whether there is any alternative for it.

What is engine cylinder honing

Honing the engine is the final procedure after the overhaul of the power unit. It is similar to lapping and polishing, only in comparison with them it has more efficiency.

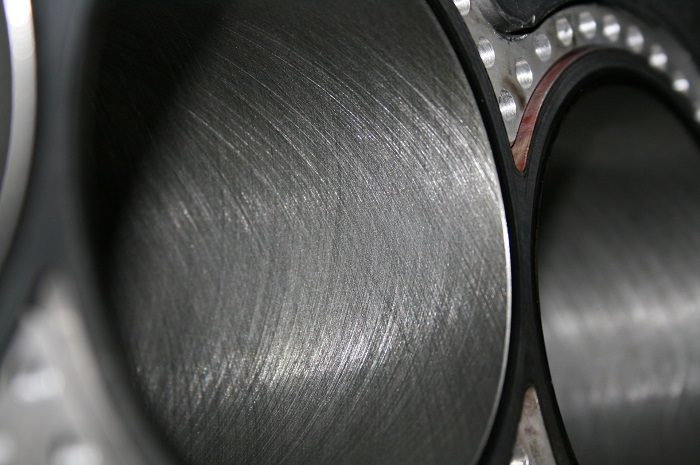

If you look at the surface of the cylinders after the procedure, then small risks in the form of a fine mesh will be clearly visible on it. Most modern internal combustion engines undergo this processing at the factory.

Honing should be done so that the direction, frequency and depth of the pattern are as accurate as possible. Since this is the final stage of engine repair, it is performed after basic work, for example, if cylinder bore is needed to install pistons with an increased diameter.

After major repairs, the cylinder has a beautiful, perfectly smooth surface. To apply the desired pattern, the master uses the same lathe as for boring with polishing, only he uses a hone - a special nozzle. It creates the required pattern structure with the required depth.

After honing, the piston-sleeve pair will require less grinding time than simply after repair boring. Here are the factors that may indicate the need for this procedure:

- Compression began to fall (how to measure it yourself, described separately);

- The engine began to consume more oil. In addition to the decreasing level in the sump, blue smoke will appear from the exhaust pipe (in addition, the reasons for this phenomenon are also described in separate review);

- Engine power has decreased markedly;

- Floating idle speed.

It is impossible to say with certainty at what point the engine of a particular car will require major overhaul (this issue is considered through the prism of capital, because it is not economically justified to hone the cylinder block separately). This is influenced by too many variables, such as driving style, what engine oil and fuel the vehicle owner uses, and other factors.

It is worth noting that all of these signs are indirect. Each of them may also indicate other malfunctions in the engine, fuel supply system, turbine, etc.

Most often, such problems with serviceable accompanying systems arise in cars with high mileage - at least 100 thousand. During this time, a certain development is formed in the cylinder-piston mechanism.

For example, the distance from the cylinder wall to the oil scraper ring increases so much that the oil is no longer able to create an oil wedge. For this reason, the lubricant remains on the surface, and upon contact with gasoline or diesel fuel it dissolves, due to which the air-fuel mixture contains foreign substances. When burned, they form a gray soot.

In addition to unpleasant exhaust emissions, a car with a similar problem significantly decreases in power due to low compression. During the exhaust stroke, part of the exhaust gases seep between the rings and the cylinder wall and enter the engine crankcase. Since the driver will force the power unit to work as usual, the fuel consumption will rise noticeably.

These are just some of the reasons why a major overhaul of the unit will be required. When the master has completed all the necessary procedures (cylinder bore to the appropriate repair size), you can ask to do the honing.

The main purpose of honing

The purpose of this operation is as follows. The micro-pattern creates a slight roughness on the cylinder mirror. It is needed to keep the lubricant on the surface.

Everyone knows that the oil in the cylinder-piston mechanism is needed in order to reduce friction between the rings and cylinder walls, as well as to provide the necessary cooling of the parts in the event of thermal loads.

In a power unit that has worked out its resource, the geometry of the cylinders changes, which reduces the performance of the motor. The inner part of the cylinders eventually gets scuffed and roughness that differs from the original parameter made at the factory.

This damage is repaired by bored out the cylinders. If a similar procedure has already been carried out, then the size of the cylinder will no longer correspond to the first, but to the second repair value. After the operation has been completed, you need to make the appropriate notches with the help of a hone.

Besides improving the lubrication of the cylinder surface, honing has another purpose. This procedure removes the barrel or tapered shape if it has formed during the enlargement process.

Honing the motor ensures maximum roughness accuracy, which is more difficult to achieve with polishing or lapping. In order for such a repair of the internal combustion engine to have the necessary indicators later, the size of the cells and the depth of the notches must comply with factory standards. We will talk about how the procedure is performed correctly, as well as about the norms a little later.

What to do if there are seizures in the motor

Now we will focus on whether it is possible to remove the defect if a scuff has formed, but without disassembling the cylinder block. Of course, this problem is extremely difficult to diagnose without visual confirmation. The most common factor is loss of engine power and compression. As already mentioned, this symptom is also characteristic of burnout valves or a failure in the fuel system.

If all these reasons are eliminated, but the desired result was not obtained, then there is a high probability that a scuff has formed in the cylinder (with low compression). This malfunction cannot be ignored, because even a minor problem will very soon cause severe wear on the piston-cylinder pair.

If the bullies are still very small

The first thing you can try to do before proceeding with the disassembly of the internal combustion engine is to use a tool that has a tribotechnical composition. This is a substance that, under certain conditions, creates a strong film on a metal surface, preventing an increase in the friction force between damaged parts.

These are added to the engine oil. The additive begins to act depending on the characteristics of the composition. Today there is a wide variety of such funds. One of these formulations is Suprotec Active Plus, which is manufactured by a domestic company.

Additive Suprotec Active Plus in engine oil

The peculiarity of this product is that the tribo composition asset plus restores the surface if the cylinder wall is slightly damaged (wear should not exceed a few tenths of a millimeter).

For the composition of suprotek to have a positive effect, you need to follow the manufacturer's recommendations. If the restoration of the motor is carried out in violation of these requirements, the substance will not work.

The advantage of this additive is that exceeding the dosage will not harm the unit. True, there will be no effect from it either. For these reasons, this stage must be taken seriously. If all the manufacturer's requirements have been met, but the desired result is not observed, then the problem is more serious.

When additives don't help

No additive will help eliminate large seizures. In this case, you only need a complete disassembly of the power unit, cylinder boring and subsequent honing of their surface. The very stage of applying the appropriate notch is not laborious. More difficult to do other repairs. The only important condition is that the one who will carry out the repair must understand the intricacies of the especially the final stage of engine processing.

Knowledge of plumbing will be useful in order to accurately maintain the uniformity and angle of inclination of the resulting notches. In garage conditions, a special abrasive brush is used for this. On a more professional level, the hon looks like a rod, which on the one hand is inserted into the chuck of a lathe, and on the other hand is equipped with three blocks with the appropriate material that can leave behind microscopic scratches.

Process and equipment requirements

Smooth movement of the grinding attachment within the cylinder is required for a uniform cut. If a lathe is used, then you should get the hang of smoothly moving the pile of chuck. More often in a garage, a special brush is used. The speed, effort and smoothness of movements already depend on the physical abilities of the master. If he has repeatedly performed this procedure, it will be easier for him to create an accurate drawing. But it will still differ from the effect after the use of technical means.

To complete the procedure, you will need a level and a guide rail. These tools can help create a uniform pattern with the correct angle. If the master gets lost, he will ruin the pattern, because of which he will have to redo everything.

Another important prerequisite for honing a motor is stable surface lubrication. For this, kerosene or its mixture with oil is useful. This liquid will wash away small chips that interfere with the creation of a suitable roughness.

After completing the work, the unit must be washed with a soapy solution. This will remove all small particles, preventing them from appearing in the cavities of the unit after assembly. After that, the block must be dried and treated with anti-corrosion oil.

When the motor is assembled, before the usual load is given to it, the cylinder-piston group must be run-in. This will allow the details to rub against each other. During this period, the internal combustion engine will need a more scrupulous approach to changing the oil and using high-quality fuel.

For a more gentle lapping, you can use the same tribotechnical substance Suprotek plus. In some cases, honing can be performed without cylinder bore. If the damage is minor, and this operation alone is sufficient, the motor may not even be removed from the machine.

Cylinder honing technology

The whole process takes place in two phases. During the first, a larger abrasive is used. This stage is called roughing. The finishing stage already requires a fine-grained tool. It simultaneously brings the surface of the cylinders to the ideal balance of smoothness and roughness.

In the past, this process used ceramic abrasives attached to bars. To date, diamond analogues have proven themselves. The reason for this is the high resistance of the material to prolonged mechanical stress.

Modern equipment is equipped with hons that can change the diameter. This technology avoids cylinder boring on lathes. After machining, the cylinder diameter may change slightly, but within the acceptable repair limits.

Little attention should be paid to handling two different types of motors. The repair of sleeve modifications is slightly different from the identical procedure for sleeveless analogs.

Sleeveless motors

The easiest way to hone classic caseless motors. For this, the block is dismantled and installed on the machine. The body is clamped, the required parameter is set on the hone and the coolant is supplied.

Depending on which tool is used, as well as to what extent the machining needs to be performed, the operation time will differ. It is important for the master to make sure that the cartridge will move in a strictly vertical direction, and the block is fixed as firmly as possible so that it does not wobble.

The honing result is controlled by an internal gage (a tool that measures the internal diameter along the entire length of the product). In more serious workshops, devices are even used to determine the level of roughness of the finished surface.

Sleeve motors

The peculiarity of such motors is that the overhaul in them is slightly simplified. The car owner purchases a set of liners for a specific power unit block. It is important to ensure that these parts have gone through the honing process. Otherwise, the product will not serve for a long time.

When such products are purchased, the manufacturer can assure that the product is ready for installation and does not need to undergo additional processing. Since the capital of the engine is an expensive procedure, it is better to see for yourself. You need to ask the wizard to check whether all the parameters for this type of product were really observed at the manufacturer.

For the processing of liners in the workshop, there must be a special clamp resembling a cylinder block body. It is fixed on the machine bed with the appropriate bolt tightening force so as not to damage the sleeves themselves, but at the same time not allow them to move.

New sleeves are processed in four stages:

- The rough metal layer is removed (in some cases, they are bored);

- Honing with 150 grit abrasive;

- Similar operation with smaller grain (300 to 500);

- Cleaning the surface from metal dust with nylon brushes using a paste containing silicon crystals.

Consequences of bullies and solutions

Here are the main consequences if the engine is seized:

| Malfunction: | Symptom: | Possible solution: |

| Heavy oil burnout is formed due to the fact that the oil scraper rings do not remove excess grease | The car began to take a lot of oil (in the neglected version, up to a liter per 1 km.) | Use an additive from Suprotek Active Plus; If the tool does not help, you will have to start a major overhaul of the internal combustion engine |

| Grease burnout has increased even more due to the fact that it mixes with the air-fuel mixture and burns out in the cylinder | In addition to increasing the consumption of lubricant, blue smoke will be abundantly emitted from the exhaust pipe. | Pour the tribo-composition into the oil; With minor scuffs, honing will change the situation without dismantling the unit |

| The density of the piston and cylinder pair is broken | Idle turns "float" | If the fuel system is in good working order, ignition and there are no errors in the control unit, this is a clear sign of seizures. At the initial stages, the Active Plus additive will help, in more advanced stages, boring and subsequent honing will be required |

| Exhaust gases burst into the crankcase | Increased fuel consumption (to maintain power at the same level, you will need to press the gas pedal harder and spin the crankshaft) | In some cases, means with a tribotechnical composition can help. However, accompanying malfunctions (for example, piston burnout) will require complete or partial disassembly of the motor. There is no other way to pinpoint the exact cause of the power loss. |

Although motor honing can be done at home using a drill and homemade machine tools, the quality of such a procedure will be poor. After such treatment, scuffs form in the motor faster, which will shorten the interval between overhaul of the power unit.

Since the capital of the internal combustion engine also has its own limitations on the number of identical works, it is better to entrust honing to specialists working on modern equipment. The electronics will perform finer processing than the "by eye" method.

For comparison, see how the process of direct honing of cylinders to oversize on modern equipment goes:

Questions and answers:

What is honing for? This is to reduce the roughness on the cylinder walls. It is also needed to speed up the running-in of the piston rings. Honingovka increases the service life of the internal combustion engine after capital.

What is Block Honing? This is a procedure in which a fine mesh is applied to the walls of the cylinders. It provides engine oil retention, which improves piston ring lubrication and stabilizes the oil mounts.