How to determine which CV joint crunches

Content

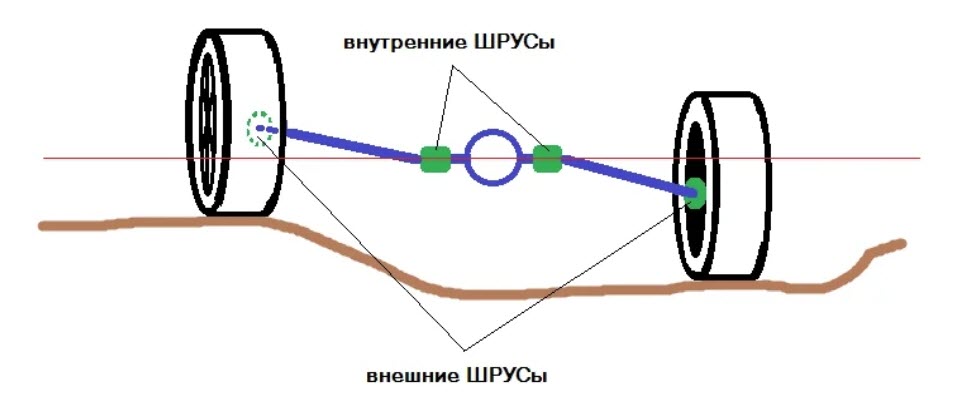

The drives of the steered wheels of a car are a combination of two constant velocity joints (CV joints) connected by a shaft with splined ends. Strictly speaking, a similar design is also found in the rear drive axle with a gearbox in a separate crankcase, but diagnostics are much more often required by the front-wheel drive, which operates in more severe conditions in terms of torque transfer angles.

The process of determining which of the four CV joints working there is worn out or has begun to collapse is usually difficult and requires adherence to an accurate methodology in order to avoid wasting time and money.

External and internal CV joint: differences and features

An external hinge is considered to be connected to the wheel hub, and an internal one is located on the side of the output of the gearbox or drive axle reducer.

Both of these nodes differ in design, which is associated with the requirements for them:

- during operation, the drive assembly must change its length during the displacement of the suspension from one extreme vertical position to another, this function is assigned to the internal hinge;

- the outer CV joint is engaged in ensuring the maximum angle of rotation of the front wheel, which is provided for in its design;

- the outer splines of the outer "grenade" end with a threaded part, onto which a nut is screwed, tightening the inner races of the wheel bearing;

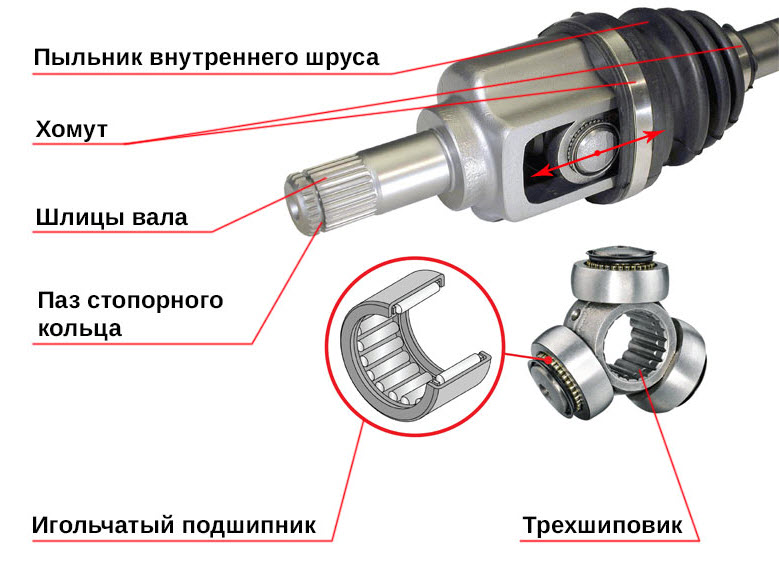

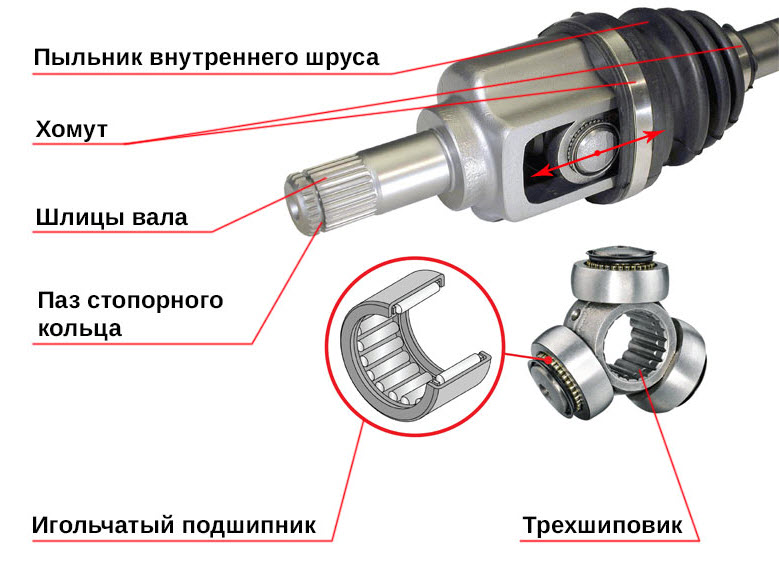

- the spline end on the inside of the drive may have an annular groove for the retaining ring, or have a loose fit, the shaft is held in the crankcase by other means;

- the internal hinge, due to its small deviations in angle, is sometimes not made according to the classical six-ball design, but in the form of a tripoid, that is, three spikes and needle bearings on them with spherical outer races, this is stronger, more durable, but does not work well at significant angles.

Otherwise, the nodes are similar, both consist of a body with grooves for balls or spikes, an inner cage, splines sitting on the drive shaft and a separator that positions the balls when running in the working grooves.

Causes and symptoms of failure of constant velocity joints

The main reason for the failure of the hinge is the wear of the grooves of both clips, separator and balls. This can happen naturally, that is, in the presence of high-quality lubrication for a very long time, over hundreds of thousands of kilometers or accelerated.

Rapid wear begins with the ingress of abrasives or water into the protective elastic cover. With such an additive to the lubricant, the assembly lives a thousand kilometers or less. Then the first signs of problems begin to appear.

When the balls are running in, both cages are in exact interaction with minimal gaps. Rolling and sliding trajectories are precisely adjusted, often even by selective selection of parts. Such a hinge operates silently when transmitting any rated torque and at any angle from the assigned range.

As soon as the gaps increase due to wear or the geometry of the grooves is distorted, knocks appear in the hinge due to the choice of backlashes and crunches due to local wedging. The transmission of torque occurs with jerks of varying degrees of visibility.

How to check the outer CV joint

The most difficult condition for the outer part of the drive will be to transmit a large torque at a maximum angle. That is, if the hinge is worn out, then the maximum value of the backlash and acoustic accompaniment is achieved precisely in such modes.

Hence the method of detection:

- when driving at low speed, the wheels are turned all the way to the extreme position and a sharp acceleration is performed, a crunch will be heard from the faulty CV joint;

- by repeating the procedure in both directions, the conclusions are specified, while it is understood that the angle of rotation of the inner wheel relative to the trajectory of the wheel is greater than the outer one;

- in case of doubt, the car is hung on a lift, all these actions are repeated, and the diagnostician located under the car listens to specific nodes, the required load is simulated by simultaneously pressing the accelerator and brake pedals.

The final diagnosis is made after removing the drive from the machine and disconnecting the hinges from it. Backlash will be clearly visible when the outer cage is rocking relative to the inner one, groove wear is visible after disassembly and removal of grease, and cracks in the separator are clearly visible on its hardened surface.

Watch this video on YouTube

Checking the internal "grenade"

When checking on the move, the inner joint must also be created for it in the worst working conditions, that is, maximum angles. Nothing depends on turning the steering wheel here, so you will need to tilt the car as much as possible, moving in an arc at high speed under full traction.

A crunch from the inside of the car relative to the trajectory will mean wear on the inner joint on this particular drive. The opposite side, on the contrary, will reduce the angle of the break, so a crunch can appear there only from a node that is in a completely critical condition.

Watch this video on YouTube

The test on the lift can be built in much the same way, loading the drive with brakes, and changing the angles of inclination of the suspension arms using hydraulic props. At the same time, it is quite simple to assess the presence of backlashes and the condition of the covers. Long-torn anthers with dirt and rust inside will mean that the hinge must be replaced unambiguously.

Why is crunch dangerous?

A crunchy hinge won't last long, such impact loads will destroy it at an increasing rate. The metal gets tired, covered with a network of microcracks and pitting, that is, chipping of the working surfaces of the tracks.

A very hard but brittle cage will simply crack, the balls will behave randomly and the hinge will jam. The drive will be destroyed and further movement of the car will become possible only on a tow truck, and the loss of traction at high speed is also unsafe.

At the same time, there may be a malfunction of the gearbox, which has been hit by the drive shaft.

Is it possible to repair the CV joint or just a replacement

In practice, repair of the CV joint is impossible due to the high accuracy of its manufacture, which implies the selection of parts. The hinge assembled from disparate parts will be able to work somehow, but there is no need to talk about noiselessness and reliability.

A worn assembly will have to be replaced as an assembly, since the splined joints on the shaft also wear out, after which the assembly will knock even with new hinges. But it is quite expensive, so it is offered only by manufacturers of original spare parts.

Analogues can be supplied in the form of kits directly from the CV joint, anther, metal clamps and special grease in the right amount.