How to check the generator for performance using a multimeter and other methods

Content

The vehicle's on-board network includes an energy source, consumers and a storage device. The required power is taken from the crankshaft through a belt drive to the generator. The storage battery (ACB) maintains the voltage in the network when there is no output from the generator or it is not enough to power the consumers.

For normal operation, it is necessary to replenish the lost charge, which may be prevented by malfunctions in the generator, regulator, switching or wiring.

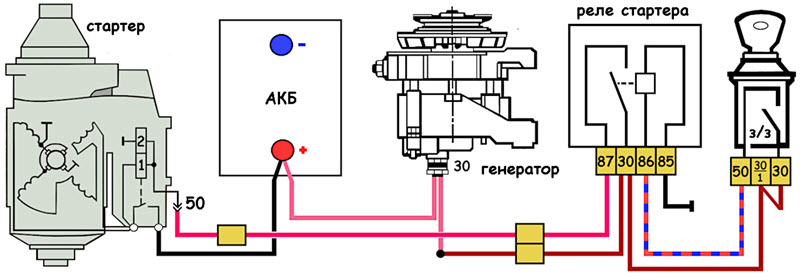

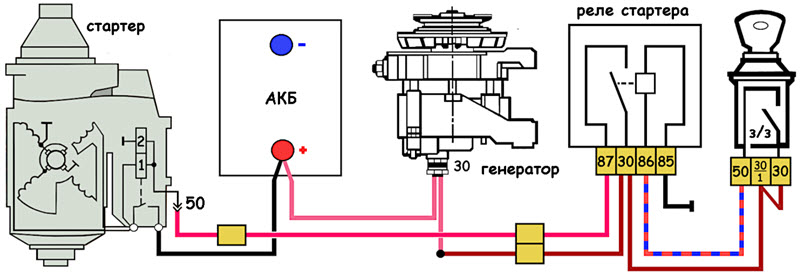

Scheme of connection of the battery with the generator and starter

The system is quite simple, representing a DC network with a nominal voltage of 12 volts, although during operation it is supported a little higher, about 14 volts, which is necessary to charge the battery.

The structure includes:

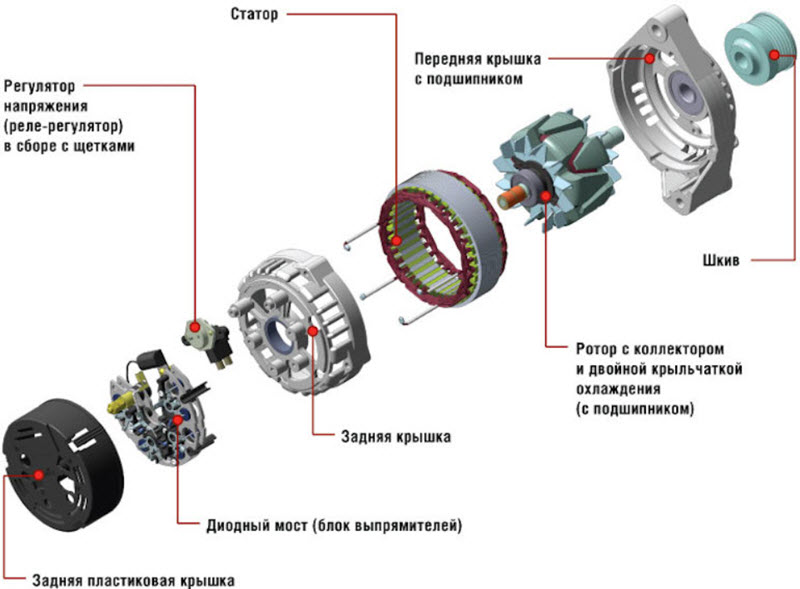

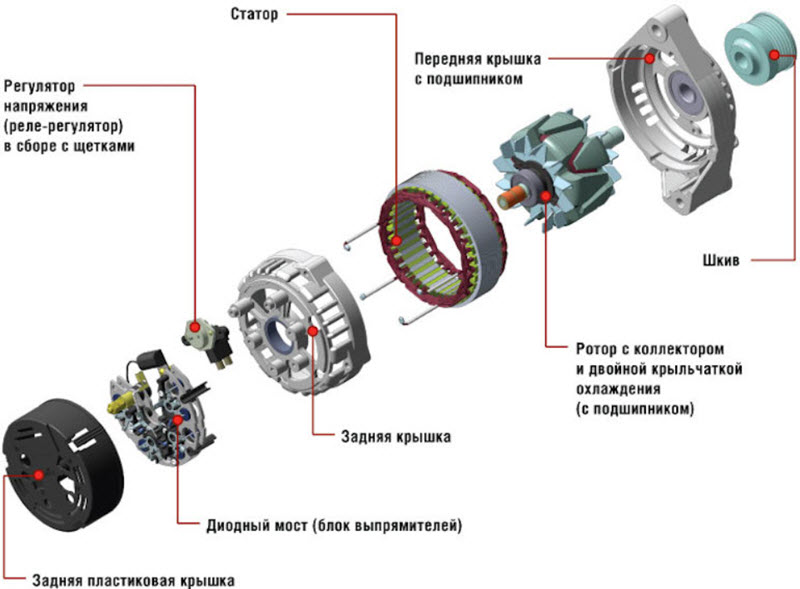

- an alternator, usually a three-phase dynamo with a built-in rectifier, relay-regulator, excitation windings in the rotor and power windings on the stator;

- a lead-acid starter type battery, consisting of six cells connected in series with a liquid, gley or electrolyte impregnating a porous structure;

- power and control wiring, relay and fuse boxes, a pilot lamp and a voltmeter, sometimes an ammeter.

The generator and battery are connected to the power supply circuit. The charge is regulated by stabilizing the voltage in the network at a level of 14-14,5 Volts, which ensures that the battery is recharged almost to the maximum, followed by the termination of the charging current due to the increase in the internal EMF of the battery as energy is accumulated.

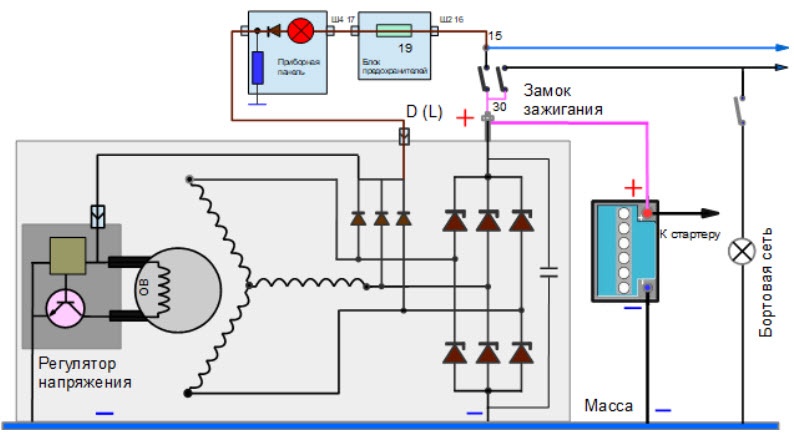

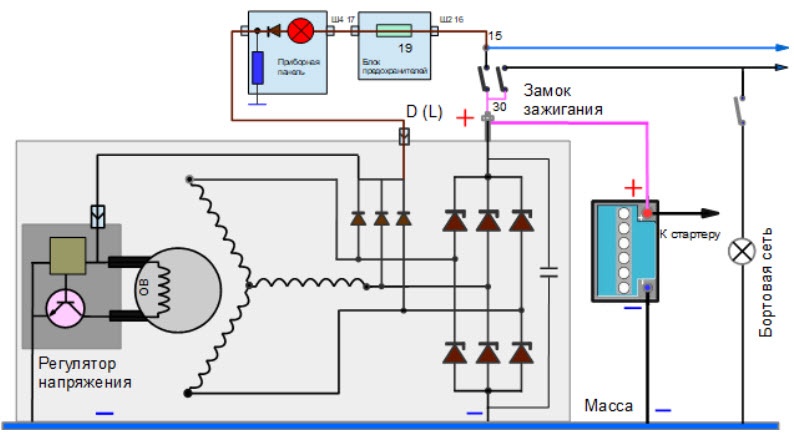

The stabilizer on modern generators is built into their design and is usually combined with a brush assembly. The built-in integrated circuit continuously measures the voltage in the network and, depending on its level, increases or decreases the generator excitation current through the rotor winding in the key mode.

Communication with the winding occurs through a rotating connection in the form of a lamellar or ring collector and metal-graphite brushes.

The rotating rotor creates an alternating magnetic field that induces current in the stator windings. These are powerful coils, divided by the angle of rotation into three phases. Each of them works on its shoulder of the diode rectifier bridge in a three-phase scheme.

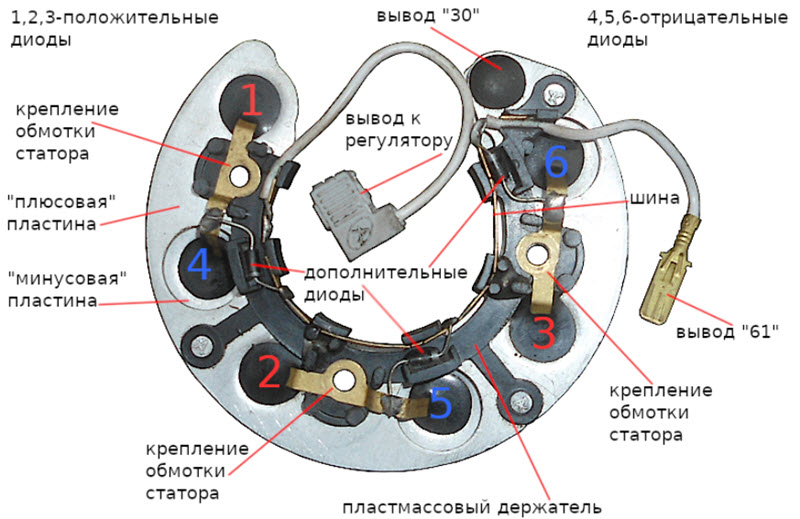

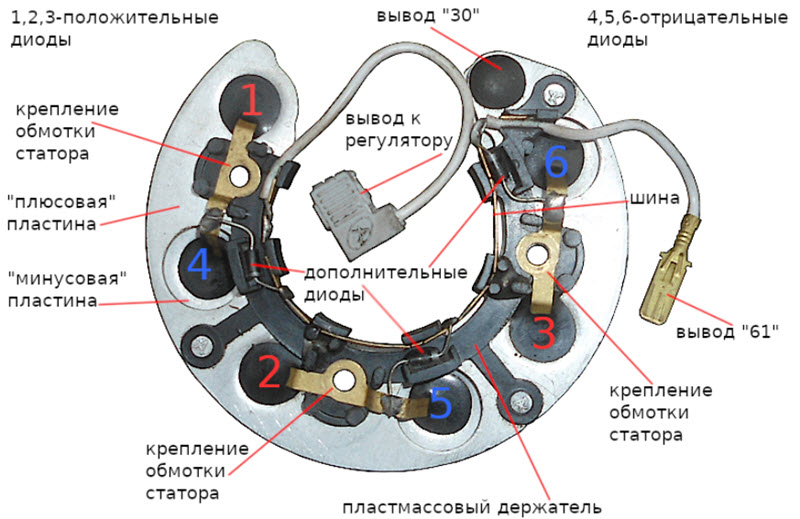

Usually, the bridge consists of three pairs of silicon diodes plus three additional low-power regulators for power supply, they also measure the output voltage for on-line control of the excitation current.

A small ripple of the rectified three-phase voltage is smoothed out by the battery, so the current in the network is almost constant and suitable for powering any consumer.

How to find out if the charge is going from the alternator to the battery

To indicate the absence of charging, the corresponding red light on the dashboard is intended. But she does not always provide information on time, there may be cases of partial failures. A voltmeter will present the situation more accurately.

Sometimes this device is available as standard equipment of the car. But you can also use a multimeter. The voltage in the on-board network, which is desirable to measure directly at the battery terminals, must be at least 14 volts with the engine running.

It may vary slightly downwards if the battery is partially discharged and takes on a large charging current. The generator power is limited and the voltage will drop.

Immediately after the starter is running, the battery EMF decreases, then gradually recovers. The inclusion of powerful consumers slows down the replenishment of the charge. Adding turns increases the level in the network.

If the voltage drops and does not increase, the generator does not work, the battery will gradually discharge, the engine will stop and it will not be possible to start it with a starter.

Checking the mechanical part of the generator

With some knowledge and skills, the generator can be restored independently. Sometimes without even removing it from the car, but it’s better to dismantle it and partially disassemble it.

Difficulties can arise only with unscrewing the pulley nut. You will need an impact wrench or a large, padded vise. When working with a nut, it is possible to stop the rotor only by the pulley, the rest of the parts will be deformed.

Visual inspection

On the parts of the generator there should be no signs of burning, deformation of plastic parts and other signs of severe overheating.

The length of the brushes ensures their tight contact with the collector, and they must move under the action of pressure springs without jamming and wedging.

There are no traces of oxidation on the wires and terminals, all fasteners are securely tightened. The rotor rotates without noise, backlash and jamming.

Bearings (bushings)

The rotor bearings are heavily loaded by a tensioned drive belt. This is exacerbated by the high rotation speed, about twice as fast as that of the crankshaft.

Lubrication ages, balls and cages are subject to pitting - fatigue spalling of the metal. The bearing begins to make noise and vibrate, which is clearly noticeable when the pulley is rotated by hand. Such parts must be replaced immediately.

Checking the electrical part of the generator with a multimeter

Much can be found out by running the generator with a voltmeter, ammeter and loads on the stand, but in amateur conditions this is unrealistic. In most cases, a static test with an ohmmeter, which is part of an inexpensive multimeter, is sufficient.

Diode bridge (rectifier)

Bridge diodes are silicon gates that conduct current in the forward direction and are locked when the polarity is reversed.

That is, an ohmmeter in one direction will show a value of the order of 0,6-0,8 kOhm and a break, that is, infinity, in the opposite direction. It should only be ensured that one part is not shunted by another located in the same place.

As a rule, diodes are not supplied separately and are not replaceable. The purchase is subject to the entire bridge assembly, and this is justified, since overheated parts degrade their parameters and have poor heat dissipation to the cooling plate. Here the electrical contact is broken.

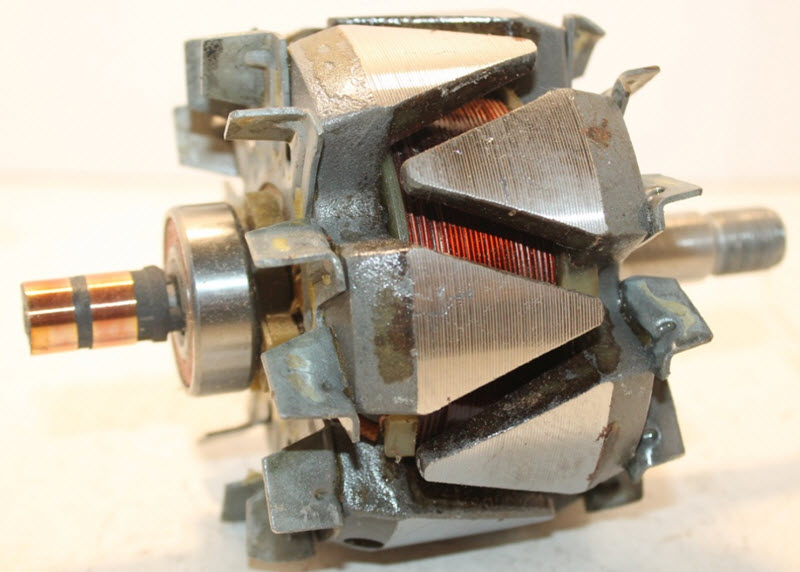

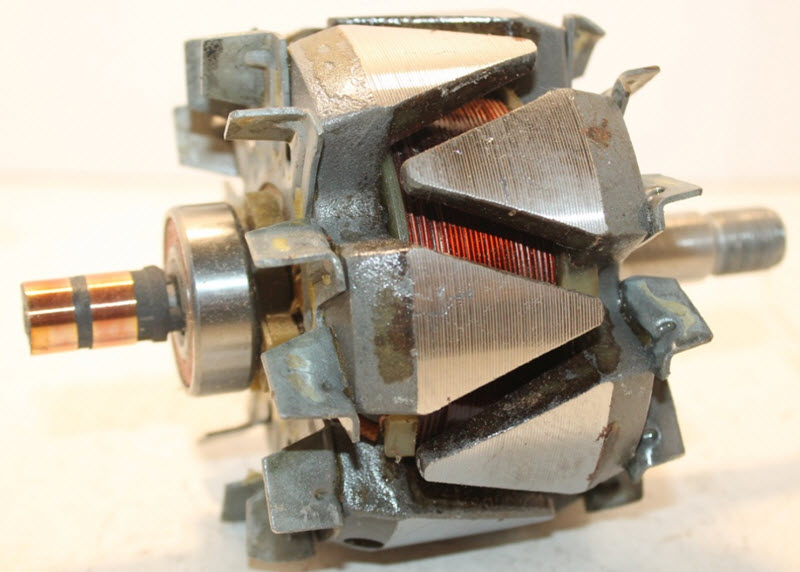

Rotor

The rotor is checked for resistance (by ringing). The winding has a rating of several ohms, usually 3-4. It should not have short circuits to the case, that is, the ohmmeter will show infinity.

There is a possibility of short-circuited turns, but this cannot be checked with a multimeter.

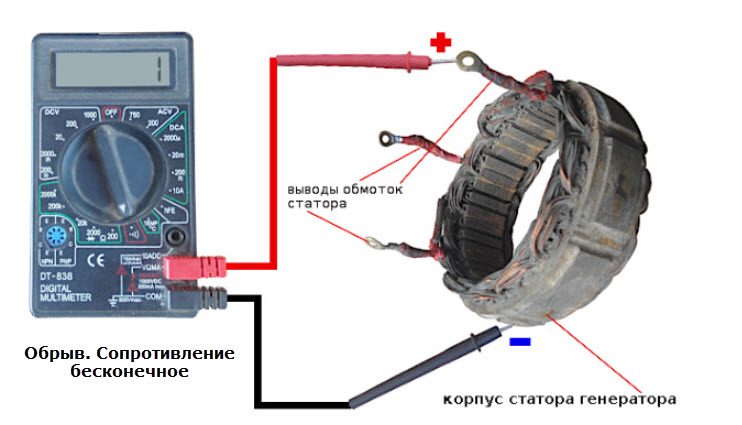

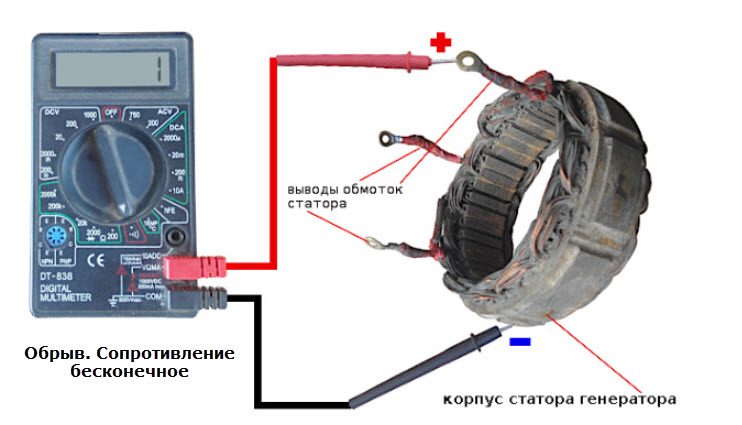

Stator

The stator windings ring out in the same way, here the resistance is even lower. Therefore, you can only make sure that there are no breaks and short circuits to the case, often this is enough, but not always.

More complex cases require testing at the stand or by replacing it with a known-good part.

Battery charging voltage regulator relay

An ohmmeter is practically useless here, but you can assemble a circuit from an adjustable power supply, a multimeter voltmeter and a light bulb.

The lamp connected to the brushes should light up when the supply voltage on the regulator chip drops below 14 volts and go out in excess, that is, switch the excitation winding when the threshold value is crossed.

Brushes and slip rings

The brushes are controlled by the remainder of the length and freedom of movement. With a short length, in any case, they must be replaced with new ones along with an integral relay-regulator, this is inexpensive, and spare parts are available.

The rotor manifold must not have burns or deep wear marks. Minor contamination is removed with sandpaper, and with deep development, the collector can in most cases be replaced.

The presence of contact of the rings with the winding is checked by ohmmeters, as indicated in the rotor test. If slip rings are not supplied, then the rotor assembly is replaced.