How to check a car engine pump without removing

Content

The water pump of the automotive engine cooling system, often referred to simply as a pump, plays a crucial role in maintaining the thermal regime, providing active circulation of the working fluid. If it fails, the motor under load boils almost instantly and collapses. Therefore, it is important to ensure maximum reliability, noticing the slightest signs of problems in time.

How to check the serviceability of a pump on a car

The best solution would be a preventive replacement of the pump with a run of 60-100 thousand kilometers, in the typical case, simultaneously with the timing belt, if the pump pulley is powered by it.

In other cases, the pump is changed simply according to the manufacturer's regulations, but this is not always the case:

- the resource of pumps from different manufacturers is very different;

- much depends on the properties of the liquid used, not all antifreezes retain their original properties for the same long time;

- bearing load depends on external factors, especially belt tension;

- the mode of operation, machine downtime and the frequency of temperature changes are strongly affected.

Hence the need to know the typical signs of the node degradation that has begun.

Extraneous noise

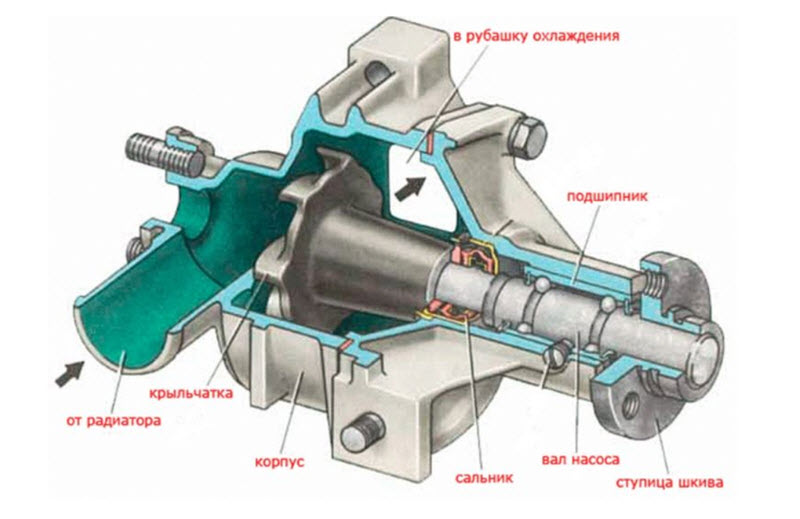

The pump consists of two wearing parts, on which its resource almost completely depends. It's a seal and a bearing. The wear of the stuffing box does not manifest itself in any way by ear, but the bearing, in the presence of wear, will not be able to work silently.

The sound can be different, it is screeching, buzzing and tapping, and sometimes with a crunch. Since it is difficult to get the pump out of rotation, it is necessary to exclude all other bearings from the side of the drive belts of the units, making sure that they are in good condition, leaving the pump under suspicion.

Then study her condition in more detail. The rotation of the pump rotor must be absolutely smooth, without the slightest sign of rolling of the bearing balls or backlash. And it’s better to change it right away, especially if the node has already worked a lot.

To mask the noise of the pump, the idler and circling rollers of the belt drive can. They also need to be checked, which is much easier, since when removing the belt it is easier to unwind them by hand and understand the presence of wear.

Pulley play

There are cases when the wear of a quality bearing occurs evenly and noise does not occur. Such a pump would still work, but the resulting backlash does not allow the stuffing box to work normally.

There is a danger of a leak, which will inevitably manifest itself. Thus, radial or axial clearances in the bearings, which are felt when rocking the pulley, are a signal for an immediate replacement of the pump assembly.

The appearance of a leak

An oil seal that has lost its tightness will not be able to hold the pressure of antifreeze in any way. The cooling system operates under excess pressure, which plays a positive role with a normal stuffing box, pressing its working edges.

After critical wear, there is nothing to tighten there, and the antifreeze under pressure begins to come out. This is noticeable visually.

The rapid drying of antifreeze on a hot engine makes it difficult to diagnose. But traces in the form of a characteristic coating remain, including on the drive belt.

When the leak is significant, it is already hard not to notice, the liquid level drops, the belt is constantly wet and does not have time to dry, antifreeze is scattered by rotating parts and even flows from the bottom of the casing.

You can not go further, you need an immediate replacement. Otherwise, wear and tear of the belt is possible, followed by a serious engine repair.

Antifreeze odor

Not all drivers are in the habit of often looking under the hood, especially since they know exactly where to look to assess the condition of the pump seal. But the engine compartment is rarely so tight that evaporating antifreeze will not find a way out, and even directly into the cabin.

The smell is very characteristic, anyone who has ever leaked a stove radiator will remember it. Further search for the source can lead to leaky pipes and radiators, as well as to a water pump.

Engine temperature rise

The most dangerous symptom of a pump malfunction. It can mean both the already described causes of the defect, and the relatively rare third - problems with the pump impeller.

A number of curved blades on the rotor shaft, forming an impeller, are directly responsible for mixing the liquid and creating its pressure. Previously, it was made by casting from cast iron, so its breakdowns were excluded. Unless there were rare cases of displacement of the casting from the shaft due to a violation of the technology of its press fit with the necessary tightness.

Now, for the manufacture of impellers, plastic of varying quality is mainly used.

Under conditions of rapid rotation in hot antifreeze at high speeds, causing cavitation, the blades may begin to collapse, the “bald” impeller will no longer be able to mix anything, the fluid circulation is disturbed, and the engine temperature begins to rise rapidly. In this case, the radiator will be relatively cold, the liquid from it simply will not get to the block and head.

Very dangerous mode, the engine should be turned off immediately and the problem should be looked for.

The same symptoms can occur with an intact impeller, but this will require significant fluid leakage, the formation of air pockets and the complete disappearance of the level in the expansion tank. This is fairly easy to spot when checking.

How to troubleshoot

Until the end of the last century, pumps on many machines could be repaired. The assembly was removed and pressed into separate parts, after which the bearing and seal were usually replaced. Now no one does it anymore.

Currently, the pump repair kit is a part of the body with an oil seal, bearing, shaft, pulley and the attached gasket. As a rule, the same standard size with a serial number known from the catalog is manufactured by many companies.

The quality here directly depends on the price. You should not hope that a part from an unknown manufacturer will be able to provide an acceptable resource. It is worth stopping at companies specializing in long-term supplies of proven pumps. Including on the conveyors of automakers.

Replacing the pump is not difficult. Therefore, it is usually changed as part of a timing belt kit. There are kits from the same manufacturer, both with and without the pump included.

The purchase of such a set is most appropriate, since a reputable company will not complete the belt and rollers with a low-quality pump, and with a complex replacement, the price of work is much lower, since most of the assembly and disassembly operations coincide, all that remains is to drain some of the antifreeze and unscrew the pump fasteners.

The new part is installed with the gasket in the repair kit, after which the coolant level is brought to normal.

The long service life of the parts will be ensured by the correct tension of the drive belt, which excludes overloading of the bearings. A torque wrench is usually used to avoid adjustment errors. You just need to set the desired force in accordance with the instructions.