How an injection engine works, principle of operation and advantages

Instead of the recently ubiquitous carbureted engines, injection or injection engines are now mainly used. The principle of their operation is relatively simple and extremely economical. However, in order to appreciate the advantage of the injector, you must first understand why they replaced carburetors.

The carburetor serves to supply fuel to the intake manifold, where it is already mixed with air, and from there it is distributed to the combustion chambers of the pistons. The supply and mixing of fuel with air will consume engine power - up to ten percent. Gasoline is sucked into the manifold due to the difference in pressure in the atmosphere and the manifold, and in order to maintain the desired pressure level, engine resources are expended.

In addition, the carburetor has a lot of other disadvantages, for example, when too much fuel passes through the carburetor, it simply does not physically have time to direct it through a narrow neck into the manifold, as a result of which the carburetor begins to smoke. If the fuel is below a certain level, then the engine simply does not pull and stalls - a situation familiar to many.

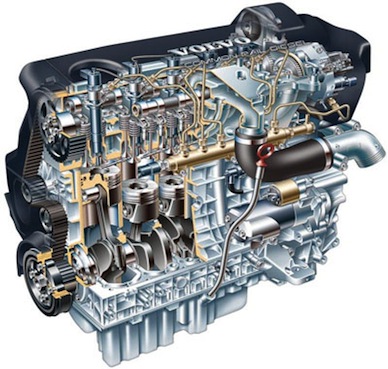

How the injector works

The injector, in principle, performs the same work in the engine as the carburetor - it supplies fuel to the combustion chambers of the pistons. However, this is not due to the suction of gasoline into the manifold, but by injecting fuel through nozzles directly into the combustion chambers or into the manifold, and here the fuel is mixed with air.

The power of injection engines is on average 10 percent higher than that of carburetor engines.

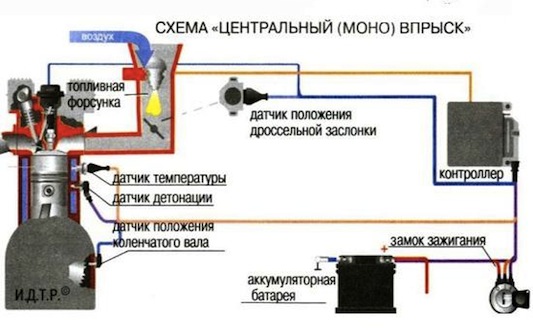

Injectors are divided into two main types:

- mono-injection - fuel is supplied through nozzles in the manifold, and then distributed directly to the combustion chambers;

- distributed injection - in the cylinder head there is a nozzle for each piston and the fuel-air mixture occurs in the combustion chamber.

Injection engines with distributed injection are the most economical and powerful. Gasoline is supplied when the intake valve opens.

Injector advantages

The injection system responds immediately to any change in engine load, as soon as the speed increases, injection is performed more frequently.

Cars with an injection system are easier to start, the dynamic moment of the engine increases. The injector reacts less to weather conditions, it does not require long-term heating at sub-zero air temperatures.

Injectors are more "friendly" to the environment, the level of emissions of harmful substances is 50-70 percent lower than that of a carburetor.

They are also more economical, since fuel is consumed exactly as much as is needed for the smooth operation of the engine at the moment.

Disadvantages of injection systems

The disadvantages include the fact that the normal operation of the engine requires the coordinated work of several electronic sensors that control different parameters and transmit them to the main processor of the on-board computer.

High requirements for fuel cleanliness - the narrow necks of the injectors will clog very quickly if low-quality gasoline is used.

Repairs are very expensive, and some elements cannot be restored at all.

As you can see, not a single system is without drawbacks, however, the injector has much more advantages, and it is because of this that injection engines have come to replace carburetor ones.

A very visual video, in 3D, about the principle of operation of an injection engine.

In this video you will learn about the principle of operation of the injection engine power system.

Loading…