How the Fuel Pressure Regulator Works (Checking and Replacing the RTD)

Content

In the control system of an automobile engine, a certain mathematical model is laid down, where the output values are calculated based on the measurement of the input ones. For example, the duration of the opening of the nozzles depends on the amount of air and many other variables. But besides them, there are also constants, that is, the characteristics of the fuel system, registered in memory and not subject to control. One of them is the fuel pressure in the rail, or rather, its difference between the inputs and outputs of the injectors.

What is a fuel pressure regulator for?

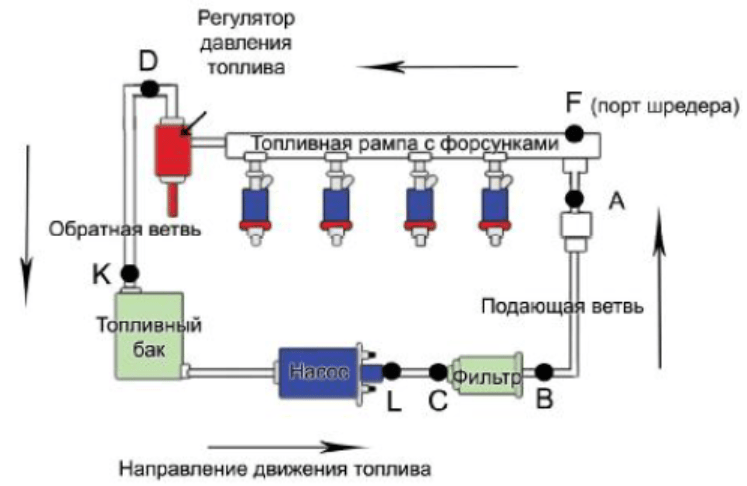

Fuel to the injectors comes from the tank by pumping it with an electric fuel pump located there. Its capabilities are redundant, that is, they are designed for maximum consumption in the most difficult mode, plus a significant margin for deterioration of performance over time during long-term operation.

But the pump cannot constantly pump with all the power of its changing capabilities, the pressure must be limited and stabilized. For this, fuel pressure regulators (RDTs) are used.

They can be installed both directly in the pump module and on the fuel rail that feeds the injection nozzles. In this case, you have to dump the excess through the drain line (return) back into the tank.

Устройство

The regulator can be mechanical or electronic. In the second case, this is a classic control system with a pressure sensor and feedback. But a simple mechanical one is no less reliable, while being cheaper.

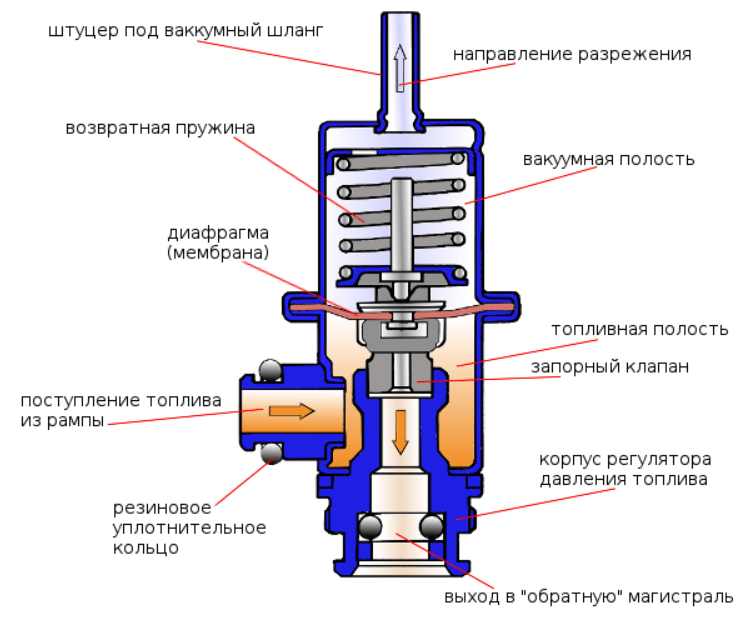

The rail-mounted regulator consists of:

- two cavities, one contains fuel, the other contains air depression from the intake manifold;

- elastic diaphragm separating the cavities;

- spring-loaded control valve connected to the diaphragm;

- housing with return fittings and a vacuum hose from the intake manifold.

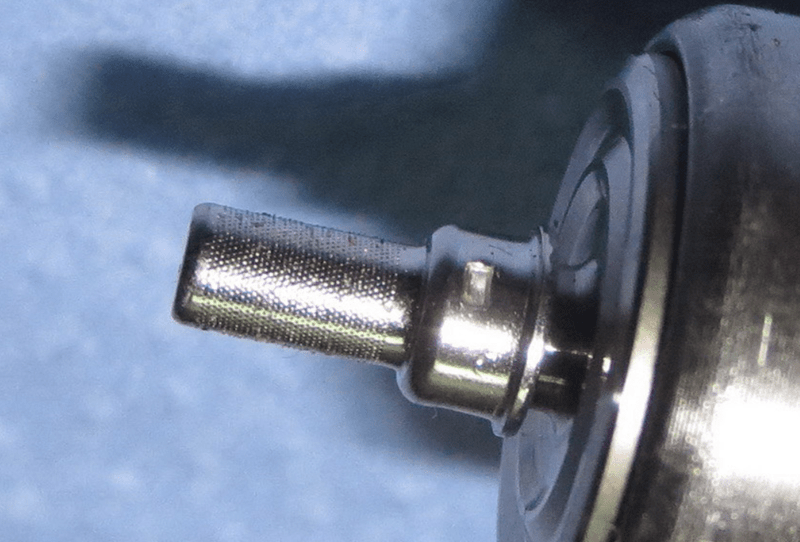

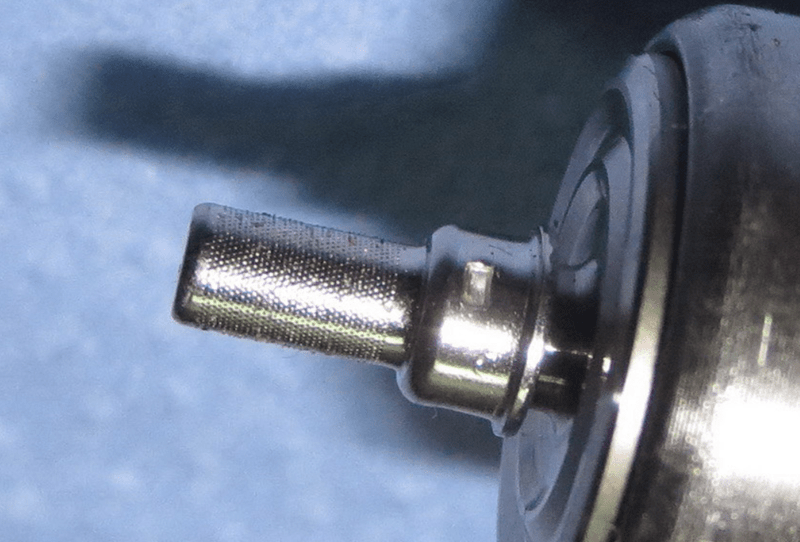

Sometimes the RTD contains a coarse mesh filter for passing gasoline. The entire regulator is mounted on the ramp and communicates with its internal cavity.

Principle of operation

In order to fix the pressure between the injectors' inlets and outlets, it is necessary to add to its value in the ramp a negative vacuum in the manifold, where the injector nozzles exit. And since the depth of the vacuum varies depending on the load and the degree of opening of the throttle, you need to monitor the difference continuously, stabilizing the difference.

Only then will the injectors work with the standard values of their performance, and the composition of the mixture will not require deep and frequent correction.

As the vacuum on the RTD vacuum pipe increases, the valve will open slightly, dumping additional portions of gasoline into the return line, stabilizing the dependence on the state of the atmosphere in the manifold. This is an additional correction.

The main regulation is due to the spring pressing the valve. According to its rigidity, the main characteristic of the RTD is normalized - the stabilized pressure. The work proceeds according to the same principle, if the pump presses with excess, then the hydraulic resistance of the valve decreases, more fuel is drained back into the tank.

Signs and symptoms of a malfunctioning RTD

Depending on the nature of the malfunction, the pressure may either increase or decrease. Accordingly, the mixture entering the cylinders is enriched or depleted.

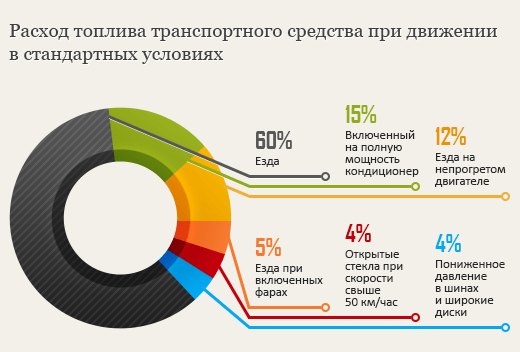

The control unit is trying to correct the composition, but its capabilities are limited. Combustion is disrupted, the motor starts to work intermittently, flashes disappear, traction deteriorates, and consumption increases. And in any case, the mixture is depleted, or enriched. At the same time, it burns equally badly.

How to check the device for operability

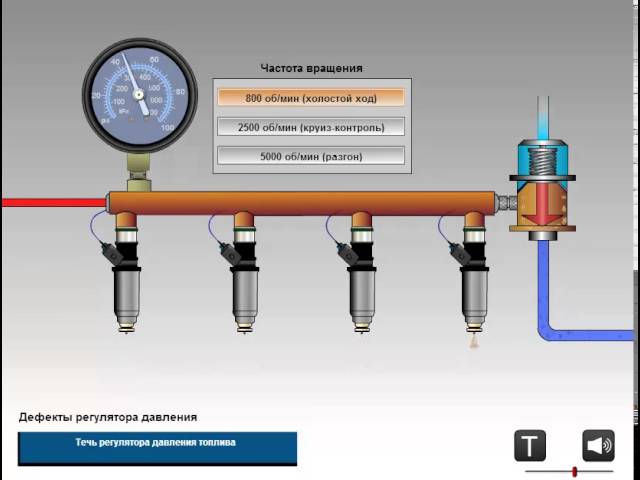

To check, the pressure in the ramp is measured. It is equipped with a valve to which a test pressure gauge can be connected. The device will show whether the value is within the norm or not. And the specific fault of the regulator will be indicated by the nature of the reaction of the readings to the opening of the throttle and turning off the return line, for which it is enough to pinch or plug its flexible hose.

Removing the vacuum hose from the RTD fitting will also demonstrate adequate pressure response. If the engine was running at minimum speed, that is, the vacuum was high, then the disappearance of the vacuum should cause an increase in pressure in the rail. If not, the regulator is not working properly.

Watch this video on YouTube

How to clean RTD

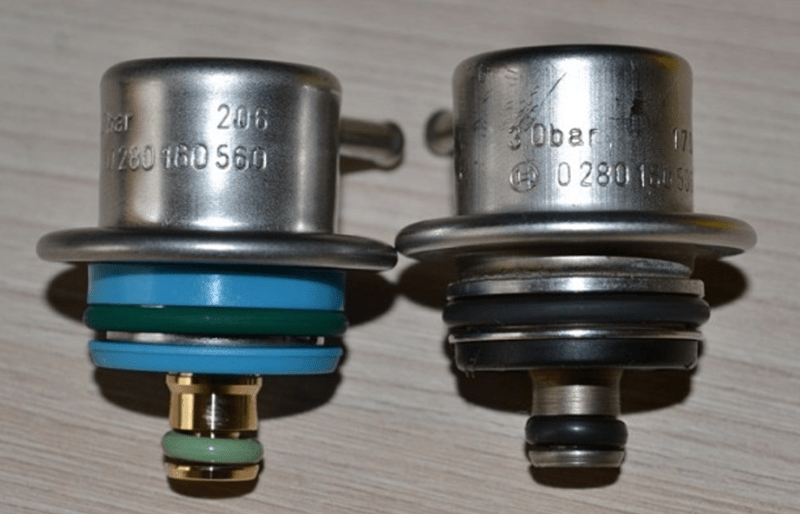

The regulator cannot be repaired, in case of a malfunction it is replaced with a new one, the price of the part is low. But sometimes it is possible to restore working capacity by cleaning the built-in filter mesh. To do this, the regulator is dismantled and washed with a carburetor cleaner, followed by purge.

The operation can be repeated for better results. It is also possible to use an ultrasonic solvent bath, which is used to clean injectors where similar problems arise due to dirty fuel.

There is no particular point in these procedures, especially if the part has already served a lot. The cost of time and money is quite comparable to the price of a new RTD, despite the fact that the old valve is already worn out, the diaphragm has aged, and caustic cleaning compounds can cause final failure.

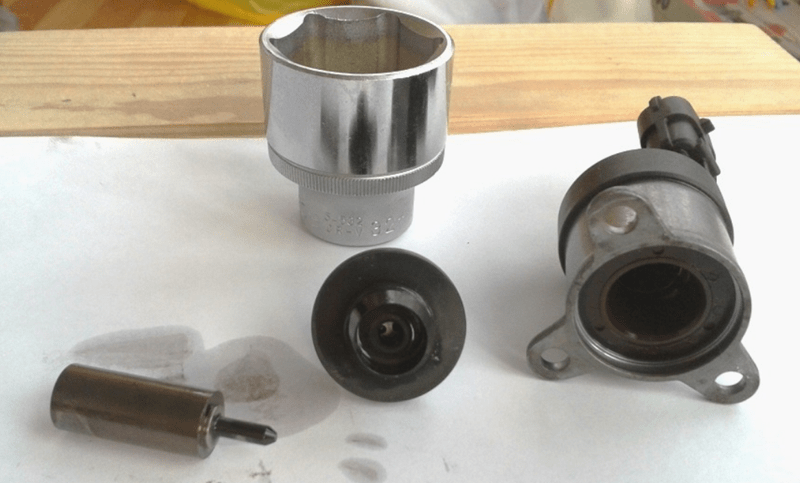

Instructions for replacing the fuel pressure regulator using the example of the Audi A6 C5

Access to the regulator on these machines is easy, it is installed on the fuel rail of the injectors.

- Remove the decorative plastic cover from the top of the motor by unscrewing the twist latches counterclockwise.

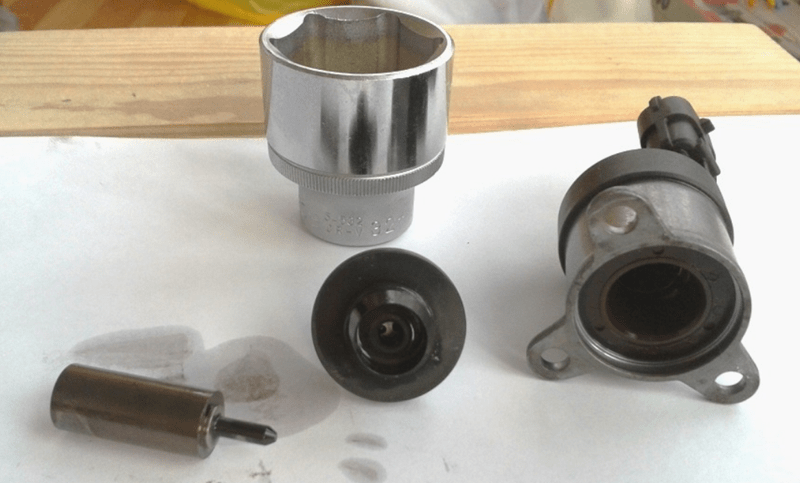

- A screwdriver is used to pry off and remove the fixing spring clip on the regulator body.

- Disconnect the vacuum hose from the regulator fitting.

- Residual pressure in the rail can be relieved in various ways by letting the engine run with the fuel pump turned off, pressing on the spool of the pressure gauge valve on the rail, or simply disconnecting the halves of the regulator housing. In the last two cases, you need to use a rag to absorb the outgoing gasoline.

- With the latch removed, the regulator is simply removed from the case, after which it can be washed, replaced with a new one, and assembled in the reverse order.

Watch this video on YouTube

Before installation, it is recommended to lubricate the sealing rubber rings so as not to damage them when immersed in the socket.