How to restore the heated rear window filaments

Content

To quickly eliminate fogging of the windshield and rear windows, conductive metal threads are applied to them. An electric current is passed through the grid formed by them, the threads are heated, and the condensate evaporates. Driving with defects in this system is dangerous, visibility is reduced, and repairing the heater is fairly easy in most cases.

The principle of operation of the heated rear window

When current passes through metals, the energy of electrons is converted into heat. The temperature of the conductors increases in proportion to the square of the current strength and electrical resistance.

The cross section of the filaments is calculated in such a way as to allocate sufficient thermal power to them with a limited applied voltage. A typical value of about 12 volts of the on-board network is used.

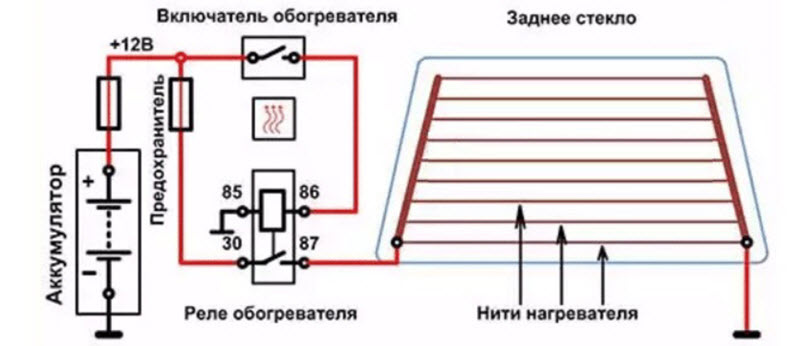

Voltage is supplied through a circuit that includes a protective fuse, a power relay and a switch that controls its winding.

A significant current flows through the relay contacts, ranging from a dozen amperes or more, depending on the area of \uXNUMXb\uXNUMXbglazing and the expected efficiency, that is, the speed of cleaning the fogged surface and the temperature of the glass and air.

The current is distributed evenly over the threads, for which they are performed as accurately as possible, with a calibrated cross section.

Why do heating elements fail?

A break can occur for mechanical or electrical reasons:

- the metal of the filament is gradually oxidized, the cross section decreases, and the released power increases, strong overheating causes the filament to evaporate and the contact to disappear;

- when cleaning glass, a thin strip of sprayed metal is easily damaged with the same consequences;

- even slight thermal deformations lead to a weakening of the structure of the conductive strip, which ends with the appearance of a microcrack and loss of electrical contact.

Most often, one or more threads break, and the entire mesh rarely fails completely. This can usually happen due to a power failure, blown fuse, relay or switch failure.

Sometimes switching is complicated by the introduction of an automatic electronic relay with a timer shutdown, which does not add reliability.

How to find a break in the glass heating filaments

Access to the conductive strips on the rear window is easy, so you can use a conventional multimeter, including an ohmmeter and a voltmeter, to troubleshoot. Both methods are suitable.

Visual inspection

In case of gross violations of the integrity, instrumental control may not be necessary, the breakage or disappearance of an entire section of the strip is noticeable to the eye. It is better to check what was found with a magnifying glass, under it the defect is visible in all details.

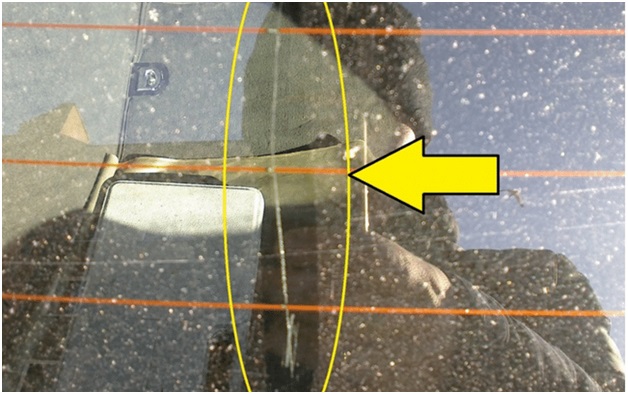

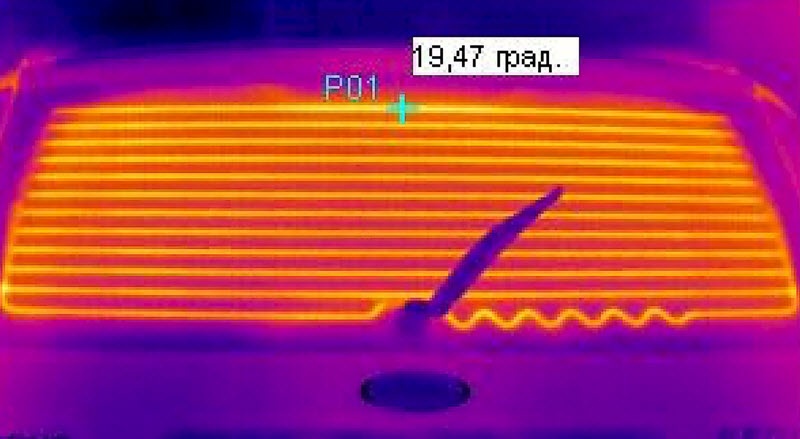

The primary localization of the malfunction is immediately visible when the heating is turned on on the misted glass. Whole filaments quickly form transparent sections of glass around themselves, and condensate remains for a long time around the torn filament.

Checking threads with a multimeter

You can go along the noticed faulty strip with a pointed probe of the device in voltmeter or ohmmeter mode.

Ohmmeter mode

When checking a suspicious place, the multimeter switches to the mode of measuring the smallest resistances. A working thread gives indications of small, almost zero resistance. The dangling one will show the resistance of the entire grid, which is noticeably greater.

By moving the probes along it, you can find the area where the readings of the device abruptly drop to zero. This means that the cliff has been passed, we must return, clarify the place of the cliff, and examine it through a magnifying glass. The defect is visually determined.

When working with an ohmmeter, be sure to turn off the ignition and heating. It is even better to remove the heating connector from the glass.

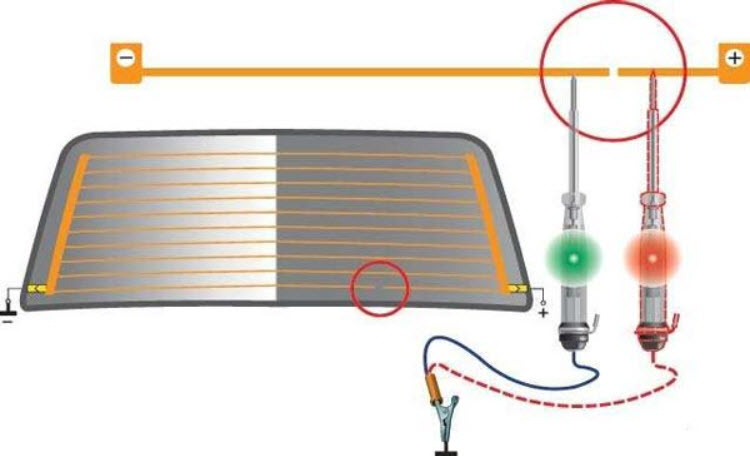

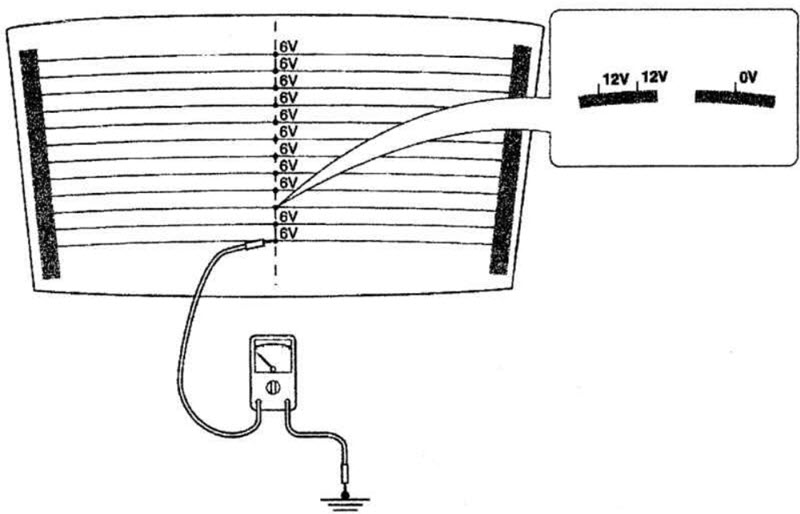

Voltmeter mode

A voltmeter, the probes of which are located at a small distance along a serviceable strip, shows a small voltage, approximately proportional to the distance between them. At the maximum distance, when connected to the edges of the grid, the device will show the mains voltage, about 12 volts.

If the convergence of the probes along one strip does not lead to a decrease in voltage, then it is in this strip that there is a break. After passing through it, the voltmeter readings will drop abruptly.

The principle is the same as with an ohmmeter. The difference is that a defect is searched for with a voltmeter when the heating is turned on, and with an ohmmeter, it is turned off.

Do-it-yourself rear window heating repair

Replacing heated glass is too expensive. Meanwhile, torn strips can be repaired, for which the corresponding formulations and kits are sold.

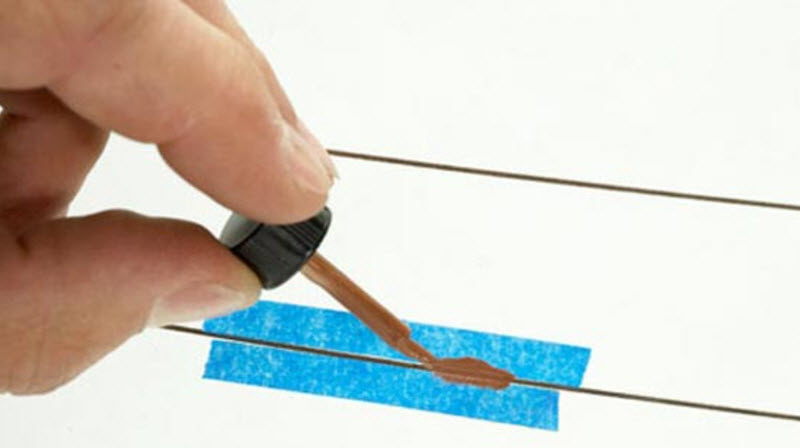

Sticky track

For repair by gluing, a special electrically conductive adhesive is used. It contains a binder and fine metal powder or small chips. When applied to the track, contact is restored.

It is important to maintain the characteristics of the linear resistance of the thread (strip). To do this, the glass is pasted over with masking tape, between the strips of which there is a distance equal to the width of the restored thread. The resistance of a conductor depends on its width and thickness. Therefore, it remains to give the repair layer the desired height relative to the glass.

The required information on the number of application layers is determined by the density of a particular commercial adhesive and is indicated on the label. All repair technology is also described there.

After the drying of the last layer is completed, the adhesive near the adhesive tape must be cut with a clerical knife so that when removing the protection, the entire sticker is not torn off the glass. The repaired place is checked visually, by the rate of condensate removal or by the device, using the methods indicated above.

Copper plating

There is a method of applying a thin layer of metal to the place of the break by electrochemical method. It is quite difficult, but quite affordable for fans of electroplating. You will need reagents - copper sulfate and a weak solution of sulfuric acid, not more than 1%.

- A galvanized brush is being made. This is a bundle of stranded wires of the smallest section of individual threads. They are crimped inside a thin metal tube.

- The place of repair is pasted over with electrical tape, there is a gap for the width of the strip. The mesh is grounded to the body of the car, and the brush is connected to the positive terminal of the battery through a bulb from the exterior lighting of the car.

- To prepare a galvanic solution for 100 ml of water, a few grams of vitriol and a solution of battery sulfuric acid are added. Wetting the brush, they lead it from the beginning of a serviceable strip to the place of the break, gradually depositing copper on the glass.

- A few minutes later, a copper-plated area appears, covering the place of the cliff. It is necessary to achieve approximately the same metal density as that of the original mesh.

If repair kits are available for sale, the method is not very relevant, but it is quite efficient. The resulting conductor after some training will be no worse than a new one.

In what cases is it useless to repair heating elements

With a large area of damage, when almost all the threads are broken and over a large area, it is unlikely that the grid can be restored to the nominal efficiency. There is no need to rely on the reliability of the result. Such glass must be replaced complete with a heating element.

In extreme cases, you can use an external heater installed under the glass, but this is a temporary measure, it works slowly, unevenly, consumes a lot of energy, and if the glass is very frozen, it can cause cracks and even spillage of tempered glass.