How to choose and make wires for lighting a car

Content

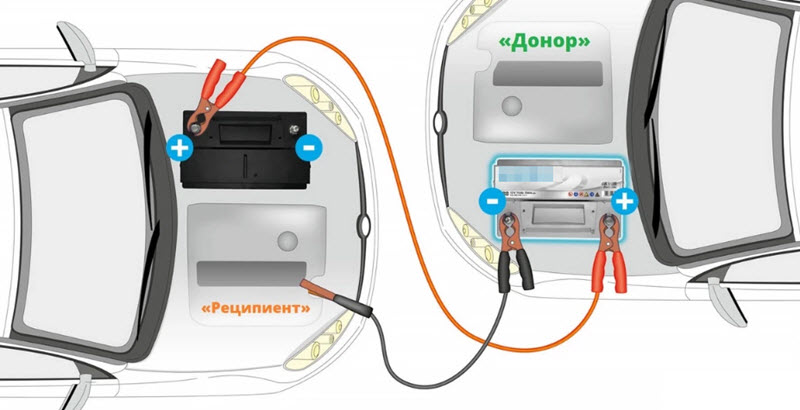

In the automotive sense of the word, cigarette light does not refer to the use of products that are harmful to health or to the popular “cigarette lighter” type connector in electrical equipment. This is a way to start a car with a dead or defective battery from a donor - another car.

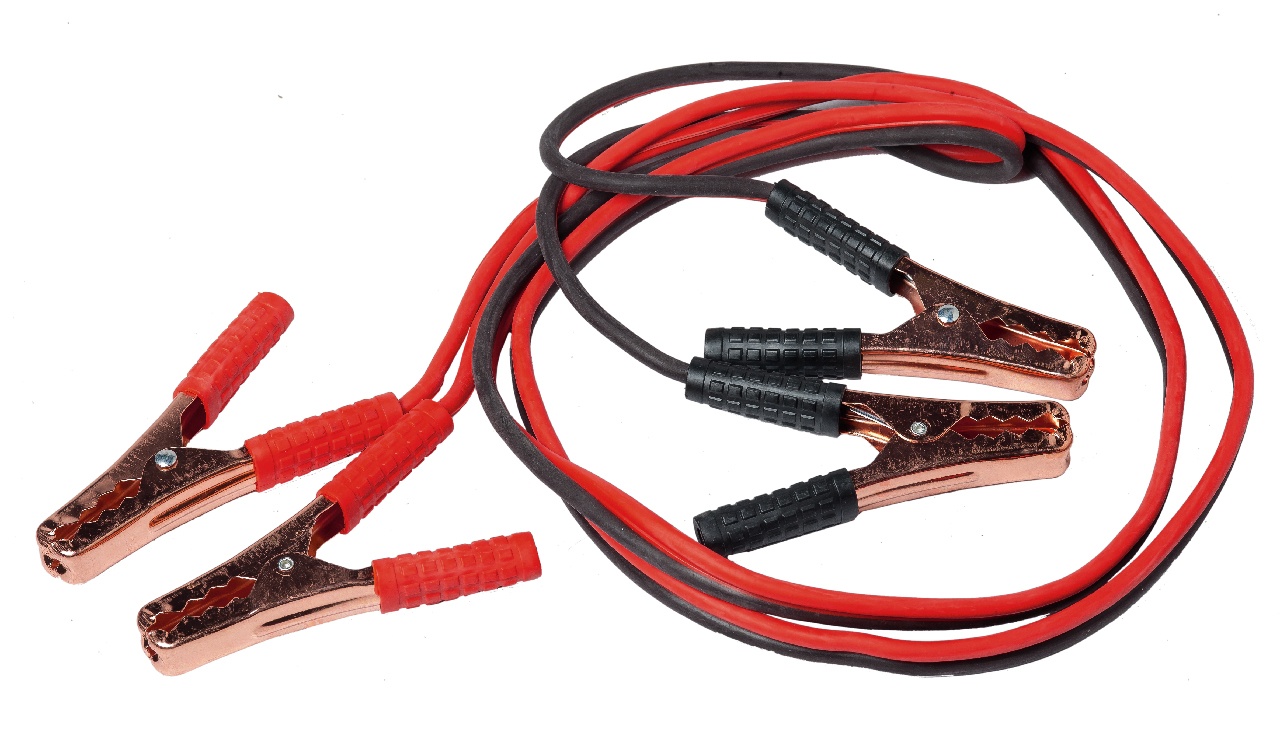

The on-board networks are interconnected by powerful cables with clamps, after which the current should be enough to operate the starter, but not always enough, a lot depends on the quality and properties of the wires with connectors.

What wires are suitable for lighting a car

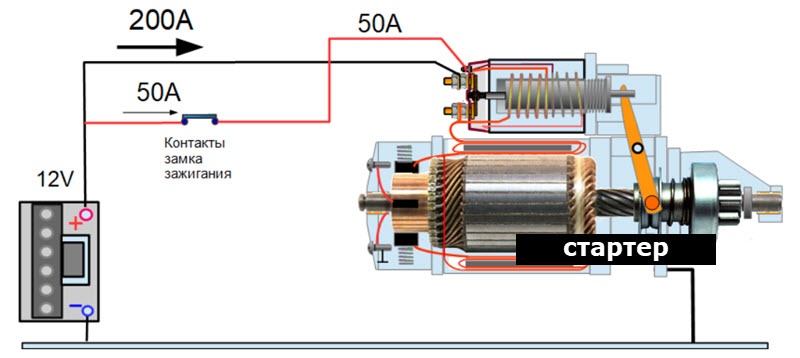

The starter draws a lot of current during operation. This is due to the need to transfer power of the order of 1-2 kilowatts at low voltage. The on-board network of a car has 12 volts, which is extremely small in power drive technology.

Power, as you know, is equal to the product of voltage and current, with a small value of one parameter, the second has to be brought to values that are inconvenient in practical use.

Of the common analogues, such cables can only be seen in electric arc welding machines. They are the best fit for all characteristics:

- sufficient cross-section of conductive wires;

- the use of materials with low resistivity, usually electrical copper;

- the flexibility of the conductor, which is a weave of many thin single components;

- electrical safety through the use of a reliable insulating sheath made of rubber or special types of plastic;

- a wide range of serially produced products.

But the direct use of such cables conflicts with the required market price of such products.

Therefore, really high-quality wires can only be found in home-made cigarette lighters, and the kits available for sale are significantly simplified with the loss of certain qualities.

Selection Criteria for Starter Leads

Both in the independent manufacture of lighting wires, and before buying, you need to pay attention to the performance of all characteristics, namely:

- cable resistance, determined by geometric dimensions, material and selection of connectors;

- the quality of the insulating coating affects the durability, safety and usability;

- type and size of clamps, their ergonomics, impact on contact reliability, including those with oxidized terminals;

- the flexibility of the resulting wires and their ability to withstand temperature changes over a wide range;

- cable length, it is not always possible to place the launched car and the donor close enough;

- acceptable cost of the product.

Each component of the product must be studied separately, sometimes any of them will interfere with effective use. These are conductor, insulator, clamps and workmanship.

Cores (material)

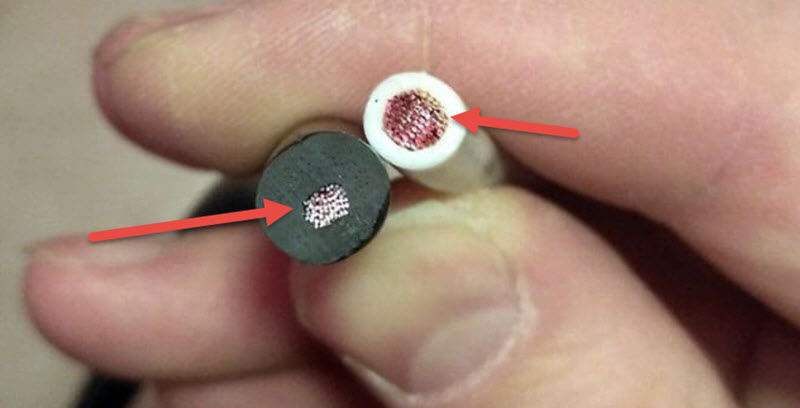

There should be no doubt about the material. Only copper, and pure, electrical. Massively there are cheap options with aluminum wires. The specific resistance of such conductors is three times worse; aluminum is unsuitable here without additional measures.

It can be added that there are cables that are commonly used in acoustics. They are made of aluminum, but each core in the package is covered with a thin layer of copper. This reduces the cost of the wire, and in the acoustic sense, the difference is insignificant.

The so-called skin effect helps out, when the high-frequency current density is distributed mainly to the outer layers of the conductor, where the copper is. But the starter is powered at zero frequency, at direct current.

The thinnest copper coating does not work here, such a cable can only be considered a hoax. Externally, the conductor looks quite copper, in fact, being 99% aluminum. And an increase in the number of individual cores in the cable does not always save.

section

You can not count the number of cores and multiply by the diameter using the number "pi", manufacturers are required to indicate the effective cross section of the conductive material in square millimeters.

Having understood the values of current consumption, linear resistance and efficiency, we can say that a good cable should have a minimum of 10-12 square meters. mm section for copper, and preferably all 16, which is the lower limit for the already mentioned welding cables of household appliances.

Anything less will waste energy on heating, causing a voltage drop across the payload.

Clamps and their fastening

For cigarette lighters, crocodile clips with sharp teeth on the working edge are used. A powerful spring allows you to destroy the oxide film on the terminals, effectively contacting the metal. Losses are kept to a minimum.

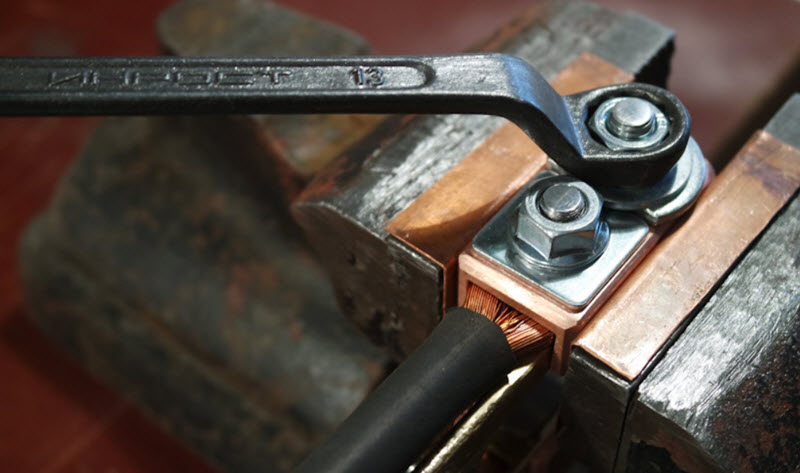

It is especially important to correctly connect the cable to the clamp. Ideally, soldering is used, but crimping the terminals under a press is also quite suitable. This is quite reliable when done without breaking the technology.

That is, not just tapping with a hammer on the anvil, but using a matrix and a punch. Only a press will allow you to crimp all the cable cores, eliminate the oxide transition and ensure long-term stability of the contact. Naturally, the crimping point is well insulated, protected from the atmosphere and moisture.

Wire length

Long wires are convenient, but remember that resistance is linear with length. That is, if you increase the distance between the machines, you will have to use a more expensive cable with a significant copper cross section.

It is for metal, since thick wires are often found, most of the section of which is occupied by plastic insulation.

Insulation type

Rubber works best, which is used in welding. But here the choice is small, most cigarette lighters are insulated with plastic. Polymers are also different, some are quite good. The question is the price.

How to make wires to start a car with your own hands

There is nothing complicated here, work is within the power of anyone with a minimum of electrical skills.

Cable selection

A welding cable in rubber insulation with a copper cross section of at least 16 square meters is suitable. mm. Saving here is not worth it, you will have to work with the cigarette lighter in the cold, when unnecessary problems are not needed.

Clips (crocodile)

Large copper crocodiles with a powerful spring and a sharp tooth are used. Cheap crafts won't work. Crimping points for the cable must be designed for the selected copper section. Deviations are unacceptable, losses will increase and durability will decrease.

Assembly

If it is supposed to solder the connections, then an ordinary soldering iron is indispensable, even a powerful one. The cable and mating part are stripped and tinned. For tinning, baths with molten flux and solder are used.

Copper is soldered with acid-free fluxes based on alcohol rosin. The connection of the tinned tips is heated by a gas burner. The solder should cover each strand in the cable.

If there is a crimping tool and a press, soldering can be omitted. But the effort must be significant, the impact technology cannot connect the parts correctly.

The wires should be brightly colored, red plus, black minus. The color of the insulation on the clamps matches the cable. It is better to purchase crocodiles with stamped large plus and minus signs.

Popular manufacturers

Most of the goods can be considered a maximum of souvenirs. But there are also serious producers.

Airline SA-1000-06E

Long wires with a large cross section. The declared characteristics, and they are even focused on launching trucks, are not quite met, but this is the trouble with all such products.

However, they have minimal resistance and are able to serve the most powerful car. The disadvantage is clear - a very high price.

Autoprofi AP / BC 7000 Pro

The cross section is slightly smaller, the same copper-plated aluminum is used, as in most similar products. But they will work, the resistance is quite satisfactory.

Another proof that only those products that are designed for diesels and trucks can be used for cars. You can't count on margins.

Heyner 404700

Very expensive and high quality wires made of 100% copper. Large section, European manufacturer. It can be considered an elite product, among the shortcomings, in addition to the price, are not quite powerful clamps and the average length of cables.

How to avoid becoming a victim of low-quality products

The basis of the right choice is the study of the declared properties, followed by verification by independent tests. Pay attention to the cross section of the metal in the wires and the linear resistance.

Even if copper-plated aluminum is used, this can be partially compensated by the increase in the thickness of the core and the quality of the termination in the clamps.

It is always worth remembering that buying the cheapest products will be a waste of money. At the right time, there will not be enough starting current, and the cables will simply melt.

Such products are suitable only for recharging a standard battery from a donor, but not for powering a starter.