How to replace a CV joint: inner, outer and anther

Content

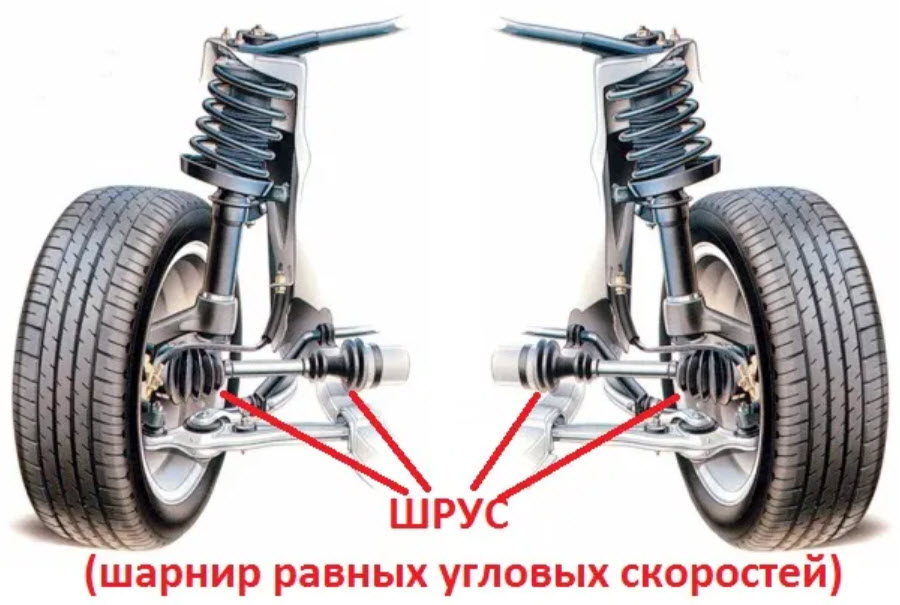

The drive of the front steered wheels, and often the rear wheels with independent suspension, is carried out by shafts with constant velocity joints (CV joints). These are fairly reliable units, but with ruthless operation, damage to protective anthers, and simply after a long service life, they may require replacement.

The operation is not extremely complex; with some skill and knowledge of the materiel, it may well be performed independently.

Types of CV joints

By location on the drive, the hinges are divided into external and internal. The division is not purely geometric, the nature of the work of these CV joints is very different, therefore they are structurally made in different ways.

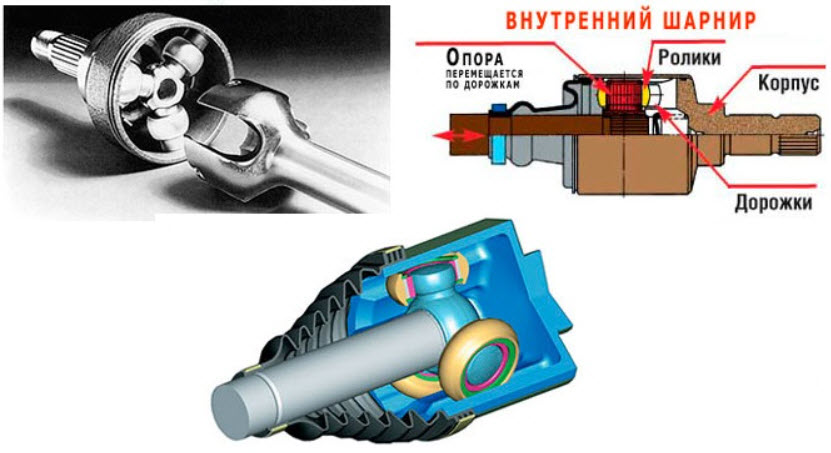

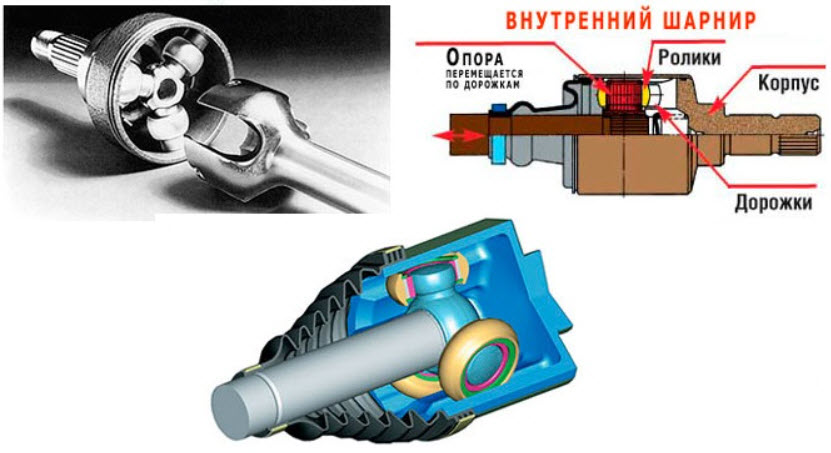

If the outer one is almost always a six-ball “grenade” of impressive size, then a three-pin tripoid-type hinge with needle bearings is often used as the inner one.

An example of the operation of an external CV joint.

How does an internal CV joint work.

But such differences have little effect on the replacement method, the insides of the CV joint will not affect the course of work. Unless the presence of balls will require more accuracy, they are easy to lose with careless handling.

When to replace

There is a set of typical symptoms that appear when the hinges are worn or broken, which is simultaneously used during the diagnosis and determination of the specific assembly to be replaced:

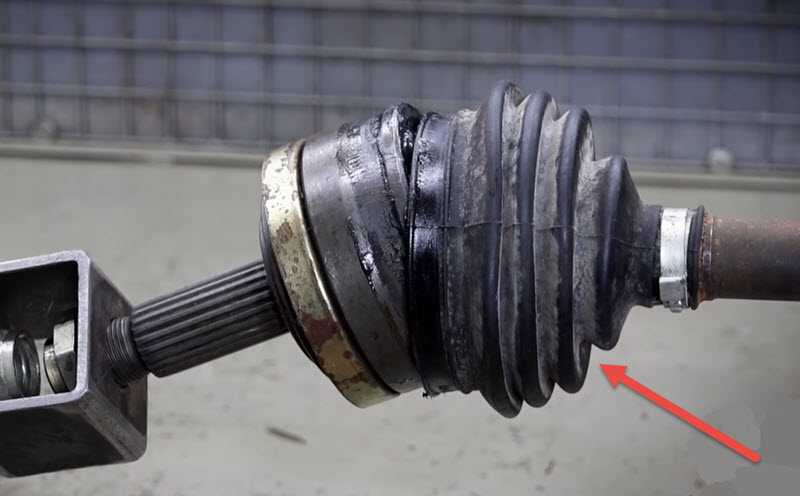

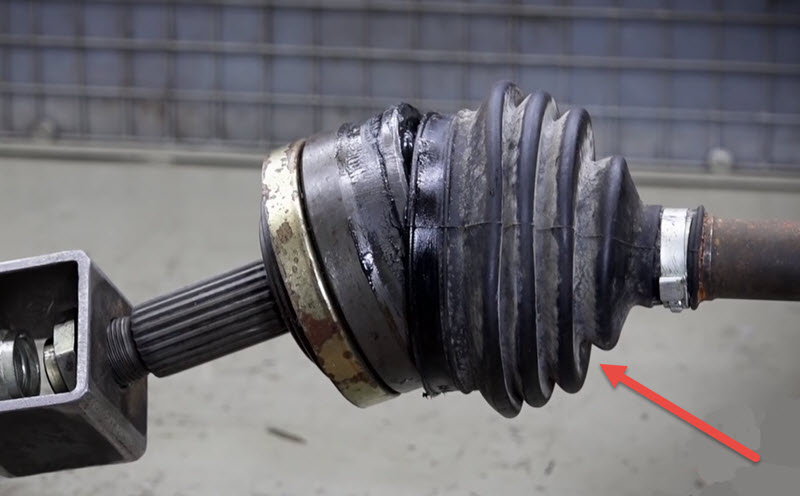

- during an external examination, a catastrophic damage to the cover was found with signs of old age, instead of lubrication, a mixture of wet dirt and rust has been working inside the hinge for a long time, there is no point in sorting out such a hinge, it needs to be changed;

- in turns under traction, a characteristic crunch or ringing beats are heard, which, after lifting the car, are clearly localized in the drives;

- when the car rolls, the sound is heard from the inside of the drive, and in the turn of the minimum radius, the outer hinge manifests itself;

- extreme case - the drive is cut off completely, the balls are destroyed, the car cannot even start moving, instead, a rattle is heard under the bottom.

Replacing a single hinge is advisable if you are sure that all others have not served long and are in good condition. Otherwise, it makes sense to listen to the manufacturer's instructions and replace the drive assembly.

The fact is that in addition to the CV joint there are two splined connections with the shaft, over time they work out and play appears. Such a drive will click or rattle even with new parts, and in advanced cases, vibrations or the complete destruction of the remnants of the spline connection may appear. This will also damage parts that have just been replaced.

Devices

Professionals do not use any specialized equipment when replacing a CV joint. However, in the absence of skills, a device for pulling a "grenade" from the shaft can help, at least psychologically. They can be of different designs, the common is a clamp fixed on the drive shaft and a screw puller that pulls the hinge off it.

Sometimes the existing shank of the outer cage with a regular hub nut screwed onto it is used as the working thread of this puller. The device is as inspiring confidence as it is inconvenient in practical work.

The bottom line is that the grenade is held on the shaft by a spring retaining ring, recessed into the groove of the splined part under pressure from the inner clip. The angle of attack of the chamfer of the clip on the ring is highly dependent on the deformation of the ring, the presence of grease and rust, and the configuration of the chamfer.

It often happens that the ring does not sink, but rather jams, and the greater the force, the more it resists. In this case, a sharp blow works much more efficiently than even significant pressure developed by the thread of the puller.

And the whole procedure for installing a device in a limited space takes a lot of time. But sometimes it really works, along the way preventing the transfer of loads to an adjacent hinge.

Outer joint replacement procedure

It is much more convenient to work with the drive (half shaft) when it is removed and fixed on the workbench in a vice. But you can not perform unnecessary operations to dismantle and drain the oil from the gearbox by removing the outer grenade directly under the car, working from below or in the wing arch.

Without axle removal

The complexity of the task lies in the fact that when knocking down the outer CV joint, it is important not to transfer unnecessary forces through the shaft to the inner one. It can sort itself out or jump out of the box. Therefore, you need to act carefully, preferably together with an assistant:

- the wheel bolts or nuts are loosened, as well as the nut tightening the wheel bearing;

- the machine is lifted from the desired side with a jack and fixed on a reliable stand;

- the wheel is removed, the hub nut is unscrewed;

- further actions may differ depending on the car model, but in the most common case of a MacPherson type suspension, it is necessary to disconnect the steering knuckle from the ball joint with the lever or extensions, for which the ball joint pin is undocked or its body is unscrewed from the lever;

- the rack is retracted to the side, while the shank of the outer CV joint comes out of the spline connection of the hub;

- clamps and a cover are removed from the anther of the grenade, excess grease is removed, which interferes with working with the inner clip;

- the most crucial moment - while holding the shaft, apply a sharp blow with a heavy hammer through the spacer to the end of the inner cage, if done correctly, the grenade will move along the slots or even separate from the drive;

- the boot, clamps, nut, CV joint assembly and locking spring ring are subject to replacement, usually all this is available in the repair kit along with a tube of special grease, the usual multi-purpose one is not suitable here;

- first of all, a new anther is installed on the shaft;

- a new lubricated hinge is put on the shaft and moves with a sharp movement until the snap ring clicks, sometimes it is necessary to apply a light blow to the end of the shank, protecting it from deformation with the old nut;

- the suspension is assembled in the reverse order, the hub nut is tightened according to the repair documentation for a particular machine.

Watch this video on YouTube

It will be useful at the same time to change the boot of the inner CV joint while the outer one is removed. The resource of the node fundamentally depends on the condition of the covers.

Watch this video on YouTube

With axle removal

Removing the actuator assembly is useful for greater ease of operation, especially in severe cases of a jammed retaining ring. Usually, this will require draining the oil or part of it from the gearbox, remembering to fill it back in, or even better, combine the procedure with an oil change.

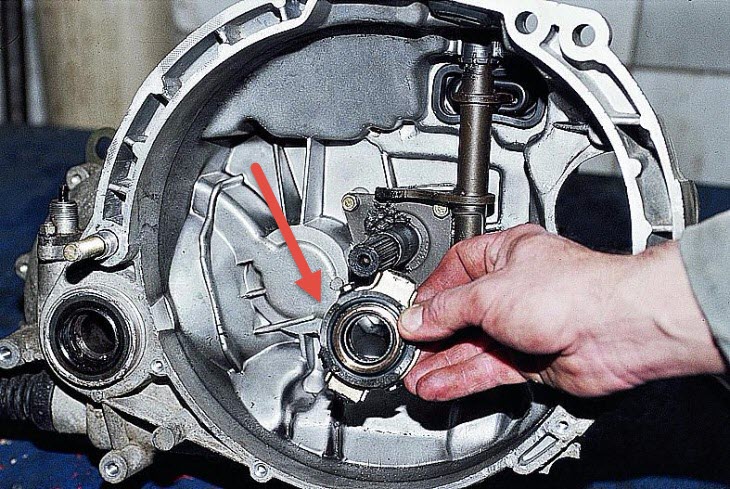

The drive in the box is held by a similar locking o-ring, which is compressed after a sharp blow to the outer race of the hinge through the spacer.

Sometimes it is possible to wring out the drive with a mount. The removal of the hinges from the shaft is carried out in a vice similar to the procedure already described.

Do not try to pull the axle shaft by the shaft. This will end with self-disassembly of the internal hinge, the thrust ring available there will not withstand.

Watch this video on YouTube

Replacing the inner CV joint

The operation is completely similar to the removal of the outer hinge, but here it is impossible to do without removing the axle shaft. There are designs where the drive is bolted to the box flange, for example, as in the Audi A6 C5. In this case, the oil does not need to be drained.

Unlike the outer one, the tripoid inner CV joint is easily disassembled, which gives access to the retaining ring. But it still compresses in the same way, with sharp blows to the inner clip with the drive fixed in a vice.

There are differences in the installation of the anther - the internal hinge allows longitudinal movement, therefore, it is necessary to fix its cover, taking into account the distance recommended by the factory from the end of the shaft. This is necessary for the correct operation of the anther when moving the hinge between the extreme positions along the length.