Carburetor VAZ 2101: purpose, device, malfunctions and their elimination, adjustment of the assembly

Content

One of the main devices that ensure the stable operation of the carburetor engine in all modes is the carburetor. Not so long ago, domestic-made cars were equipped with a fuel supply system using this device. Therefore, almost every owner of the “classic” has to deal with the repair and adjustment of the carburetor, and for this it is not necessary to contact the service, since the necessary procedures are easy to do with your own hands.

Carburetor VAZ 2101

The VAZ 2101 car, or in the common people "penny", is equipped with a carburetor engine with a capacity of 59 liters. With. with a volume of 1,2 liters. A device such as a carburetor needs periodic maintenance and repair, otherwise the engine will be unstable, there may be problems with starting, and an increase in fuel consumption. Therefore, the design and adjustment of this node should be considered in more detail.

What is it for

The carburetor has two main functions:

- Mixing fuel with air and spraying the resulting mixture.

- The creation of a fuel-air mixture in a certain proportion, which is necessary for its efficient combustion.

A jet of air and fuel is simultaneously fed into the carburetor, and due to the difference in speeds, the fuel is sprayed. In order for the fuel to burn more efficiently, it must be mixed with air in certain proportions. In most cases, this ratio is 14,7:1 (air to fuel). Depending on the operating modes of the engine, the proportions may vary.

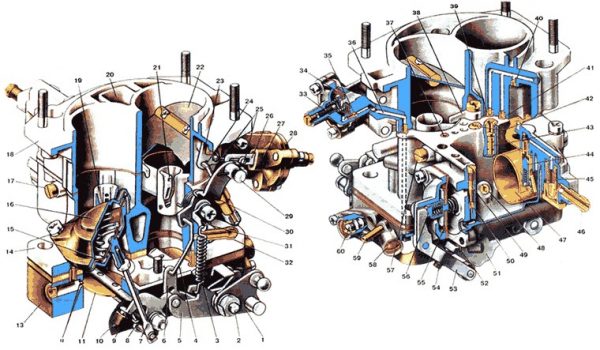

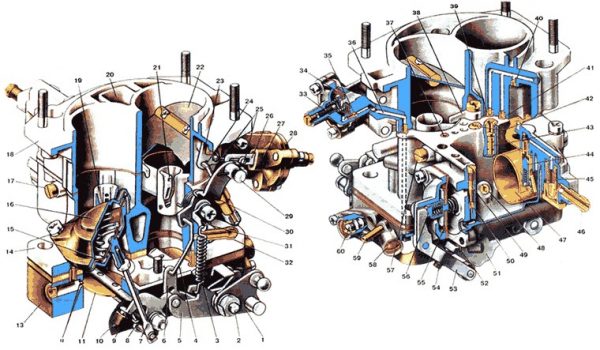

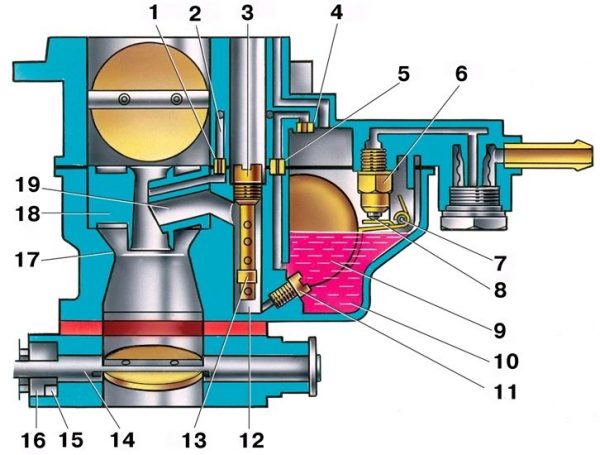

Carburetor device

Regardless of the modification of the carburetor, the devices differ little from each other and consist of several systems:

- systems for maintaining and adjusting the fuel level;

- engine start and warm-up systems;

- idle systems;

- accelerating pump;

- main dosing system;

- econostat and economizer.

Let's consider these systems in more detail in order to better understand the functioning of the node.

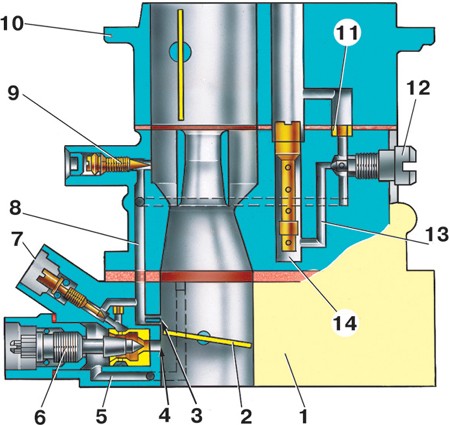

Fuel level maintenance system

Structurally, the carburetor has a float chamber, and the float located in it controls the fuel level. The design of this system is simple, but sometimes the level may not be correct due to a leak in the needle valve, which is due to the use of low-quality fuel. The problem is solved by cleaning or replacing the valve. In addition, the float needs to be adjusted periodically.

Starting system

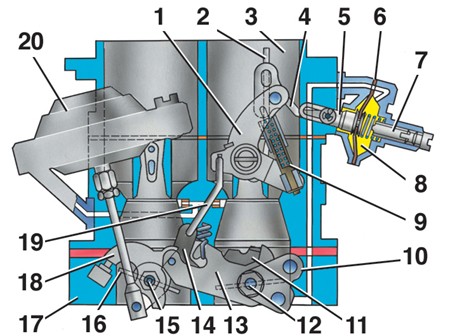

The starting system of the carburetor provides a cold start of the power unit. The carburetor has a special damper, which is located at the top of the mixing chamber. At the moment the damper closes, the vacuum in the chamber becomes large, which is what is required during a cold start. However, the air supply is not completely blocked. As the engine warms up, the shielding element opens: the driver controls this mechanism from the passenger compartment via a cable.

Idling system

In order for the engine to work stably at idle (XX), an idle system is provided in the carburetor. In XX mode, a large vacuum is created under the dampers, as a result of which gasoline is supplied to the XX system from a hole located below the level of the first chamber damper. Fuel passes through the idle jet and mixes with air. Thus, a fuel-air mixture is created, which is fed through the appropriate channels into the engine cylinders. Before the mixture enters the cylinder, it is additionally diluted with air.

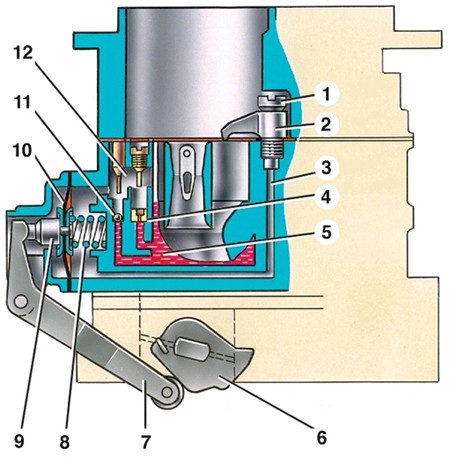

Accelerator pump

The accelerator pump is one of the integral systems of the carburetor, which supplies the fuel-air mixture at the moment the damper is opened. The pump operates independently of the airflow passing through the diffusers. When there is a sharp acceleration, the carburetor is not able to supply the required amount of gasoline to the cylinders. To eliminate this effect, a pump is provided that accelerates the supply of fuel to the engine cylinders. The design of the pump consists of the following elements:

- screw valve;

- fuel channel;

- bypass jet;

- float chamber;

- accelerator pump drive cam;

- drive lever;

- return spring;

- diaphragm cups;

- pump diaphragms;

- inlet ball valve;

- gasoline vapor chambers.

Main dosing system

The supply of the main volume of fuel when the engine is running in any mode, except for XX, is provided by the main dosing system. When the power plant is operating at medium loads, the system supplies the required amount of a leaner mixture in constant proportions. When the throttle valve opens, less air is used than the fuel coming from the atomizer. This results in a rich mixture. In order for the composition not to be over-enriched, it must be diluted with air, depending on the position of the damper. This compensation is exactly what the main dosing system performs.

Econostat and economizer

The econostat and the economizer in the carburetor are necessary to ensure the flow of fuel into the mixing chamber, as well as to supply a rich fuel-air mixture at a time of high vacuum, i.e. at high engine loads. The economizer can be controlled both mechanically and pneumatically. Econostat is a tube with different sections and emulsion channels located in the upper part of the mixing chamber. In this place, a vacuum occurs at maximum loads of the power plant.

What carburetors are installed on the VAZ 2101

Owners of the VAZ 2101 quite often want to increase the dynamics or reduce the fuel consumption of their car. Acceleration, as well as efficiency, depend on the installed carburetor and the correctness of its adjustment. Many Zhiguli models use the DAAZ 2101 device in various modifications. The devices differ from each other in the size of the jets, as well as the presence or absence of a vacuum corrector. The VAZ 2101 carburetor of any modification is designed to work only with the VAZ 2101 and 21011 engines, on which a distributor without a vacuum corrector is installed. If you make changes to the engine ignition system, you can put more modern carburetors on the “penny”. Consider the models of devices that are installed on the "classic".

DAAZ

Carburettors DAAZ 2101, 2103 and 2106 are Weber products, so they are called both DAAZ and Weber, meaning the same device. These models are characterized by a simple design and good overclocking performance. But it was not without drawbacks: the main disadvantage is the high fuel consumption, which ranges from 10–14 liters per 100 km. To date, a significant problem is also the difficulty of acquiring such a device in good condition. In order to assemble one normally functioning carburetor, you will need to purchase several pieces.

Ozone

On the Zhiguli of the fifth and seventh models, a more modern carburetor was installed, called Ozone. A properly adjusted mechanism allows you to reduce fuel consumption to 7-10 liters per 100 km, as well as provide good acceleration dynamics. Of the negative aspects of this device, it is worth highlighting the design itself. During active operation, problems arise with the secondary chamber, since it does not open mechanically, but with the help of a pneumatic valve.

With prolonged use, the Ozone carburetor becomes dirty, which leads to a violation of the adjustment. As a result, the secondary chamber opens with a delay or remains completely closed. If the unit does not work properly, the power output by the motor is lost, acceleration worsens, and the maximum speed decreases.

Solex

No less popular for the "classics" is DAAZ 21053, which is a product of Solex. The product is endowed with such advantages as good dynamics and fuel efficiency. Solex in its design differs from previous versions of DAAZ. It is equipped with a return system of fuel entering the tank. This solution made it possible to divert excess fuel into the fuel tank and save about 400–800 g of fuel per 100 km.

Some modifications of this carburetor are equipped with an XX system with adjustment by means of an electrovalve, an automatic cold start system. Export cars were equipped with carburetors of this configuration, and in the territory of the former CIS, the Solex with the XX solenoid valve was most widely used. However, this system during operation showed its shortcomings. Since in such a carburetor the channels for gasoline and air are rather narrow, therefore, if they are not serviced in time, they quickly become clogged, which leads to problems with idling. With this carburetor, fuel consumption on the "classic" is 6-10 liters per 100 km. In terms of dynamic characteristics, Solex loses only to Weber.

The listed carburetors are installed on all classic engines without modifications. The only thing to pay attention to is the selection of the device for the engine displacement. If the assembly is designed for a different volume, the jets are selected and replaced, the mechanism is adjusted on a specific motor.

Installation of two carburetors

Some owners of the "classics" are not satisfied with the operation of the power unit at high speeds. This is explained by the fact that a concentrated mixture of fuel and air is supplied to cylinders 2 and 3, and its concentration decreases in cylinders 1 and 4. In other words, air and gasoline do not enter the cylinders as they should. However, there is a solution to this problem - this is the installation of two carburetors, which will ensure a more uniform supply of fuel and the formation of a combustible mixture of the same saturation. Such modernization is reflected in the increase in power and torque of the motor.

The procedure for introducing two carburetors, at first glance, may seem rather complicated, but if you look, then such a refinement is within the power of anyone who is not satisfied with the operation of the engine. The main elements that will be required for such a procedure are 2 manifolds from Oka and 2 carburetors of the same model. In order to have a greater effect from installing two carburetors, you should think about installing an additional air filter. It is put on the second carburetor.

To install carburetors on the VAZ 2101, the old intake manifold is removed and the parts from the Oka are adjusted to fasten and fit to the block head. Experienced motorists recommend dismantling the cylinder head for the convenience of work. Particular attention is paid to the channels of the collectors: they should not have any protruding elements, otherwise, when the motor is running, a lot of resistance to the oncoming flow will be created. All that will interfere with the free passage of the fuel-air mixture into the cylinder must be removed using special cutters.

After installing the carburetors, the quality and quantity screws are unscrewed by the same number of revolutions. To simultaneously open the dampers on two devices, you will need to make a bracket to which the thrust from the gas pedal is supplied. The gas drive from carburetors is done using cables, for example, from Tavria.

Signs of a malfunctioning carburetor

The VAZ 2101 carburetor is a device that needs periodic cleaning and adjustment, due to the operating conditions and the fuel used. If problems arise with the mechanism in question, signs of malfunctions will be reflected in the operation of the power unit: it may twitch, stall, gain momentum poorly, etc. Being the owner of a car with a carburetor engine, it would be useful to understand the main nuances that may arise with a carburetor. Consider the symptoms of malfunctions and their causes.

Stalls at idle speed

A fairly common problem on a "penny" is a stalling engine at idle. The most likely reasons are:

- clogging of jets and XX channels;

- failure or incomplete wrapping of the solenoid valve;

- malfunctions of the EPHH block (forced idle economizer);

- damage to the quality screw seal.

The carburetor device is designed in such a way that the first chamber is combined with the XX system. Therefore, with problematic engine operation in idling mode, not only failures can be observed, but also a complete stop of the engine at the beginning of the car’s movement. The problem is solved quite simply: defective parts are replaced or the channels are flushed and purged, which will require partial disassembly of the assembly.

Video: idle recovery using the Solex carburetor as an example

Acceleration crashes

Sometimes when accelerating a car, so-called dips occur. A failure is when, after pressing the gas pedal, the power plant operates at the same speed for several seconds and only then begins to spin up. Failures are different and can lead not only to a later reaction of the engine to pressing the gas pedal, but also to its complete stop. The cause of this phenomenon may be a blockage of the main fuel jet. When the engine is running at low loads or at idle, it consumes a small amount of fuel. When you press the accelerator pedal, the engine switches to a higher load mode and fuel consumption increases sharply. In the event of a clogged fuel jet, the flow area becomes insufficient, which leads to failures in the operation of the power unit. The problem is eliminated by cleaning the jet.

Dips, as well as jerks, can be associated with a loose fit of the fuel pump valves or with clogged filter elements, that is, with everything that can create resistance when fuel is supplied. In addition, air leakage into the power system is possible. If the filter elements can be simply replaced, the filter (mesh) of the carburetor can be cleaned, then the fuel pump will have to be dealt with more seriously: disassemble, troubleshoot, install a repair kit, and possibly replace the assembly.

Fills the candles

One of the problems that can happen with a carbureted engine is when it floods the spark plugs. In this case, the candles are wet from a large amount of fuel, while the appearance of a spark becomes impossible. As a result, starting the engine will be problematic. If at this moment you unscrew the candles from the candle well, you can be sure that they will be wet. Such a problem in most cases is associated with the enrichment of the fuel mixture at the time of launch.

Filling candles can be for a number of reasons:

- the carburetor starter does not work;

- the needle valve failed;

- pumps the fuel pump;

- blockage of air jets.

Let's consider each of the reasons in more detail. In most cases, the problem of flooded candles on the VAZ 2101 and other "classics" is present during a cold start. First of all, starting clearances must be correctly set on the carburetor, i.e., the distance between the dampers and the walls of the chamber. In addition, the diaphragm of the launcher must be intact, and its housing sealed. Otherwise, the air damper of the carburetor, when starting the power unit to a cold one, will not be able to open slightly at the desired angle, which is the meaning of the operation of the starting device. As a result, the combustible mixture will be forcibly leaner by the air supply, and the absence of a small gap will contribute to the formation of a richer mixture, which will lead to the effect of "wet candles".

As for the needle valve, it may simply be leaky, resulting in the passage of excess fuel into the float chamber. This situation will also lead to the formation of an enriched mixture at the time of starting the power unit. In case of malfunctions with the needle valve, candles can be filled both cold and hot. In this case, it is best to replace the part.

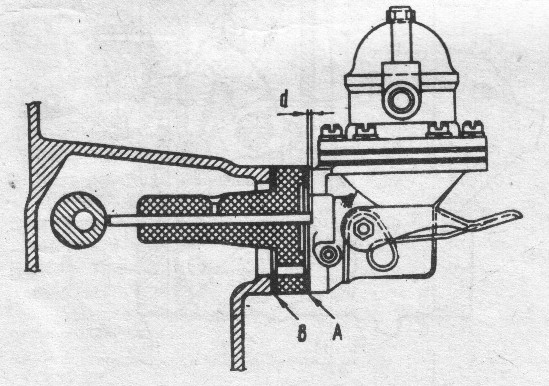

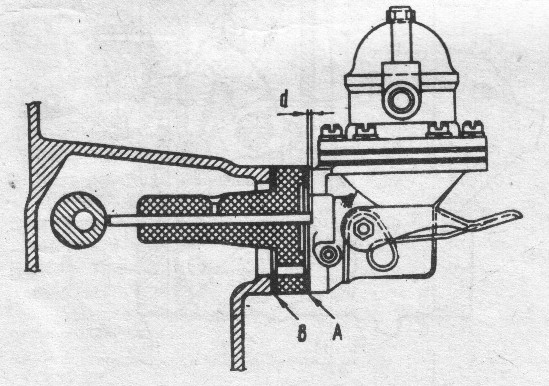

Candles can also be filled due to improper adjustment of the fuel pump drive, as a result of which the pump pumps fuel. In this situation, excessive pressure of gasoline is created on the needle-type valve, which leads to an overflow of fuel and an increase in its level in the float chamber. As a result, the fuel mixture becomes too rich. In order for the rod to protrude to the desired size, it is necessary to install the crankshaft in a position in which the drive will protrude minimally. Then measure the size d, which should be 0,8–1,3 mm. You can achieve the desired parameter by installing gaskets of different thicknesses under the fuel pump (A and B).

The air jets of the main metering chamber are responsible for supplying air to the fuel mixture: they create the necessary proportion of gasoline and air, which is necessary for the normal start of the engine. If the jets are clogged, the air supply is partially or completely stopped. As a result, the fuel mixture becomes too rich, which leads to flooding of the candles. The problem is solved by cleaning the jets.

The smell of gasoline in the cabin

Sometimes owners of the VAZ 2101 are faced with the problem of the presence of the smell of gasoline in the cabin. The situation is not the most pleasant and requires a quick search for the cause and its elimination. After all, fuel vapors are not only harmful to health, but are generally dangerous. One of the reasons for the smell may be the gas tank itself, i.e., a microcrack could appear in the tank. In this case, you will need to find the leak and close the hole.

In addition to the fuel tank, the fuel line itself can leak, especially when it comes to a “penny”, because the car is far from new. Fuel hoses and pipes need to be checked. In addition, attention should be paid to the fuel pump: if the membrane is damaged, the mechanism may leak, and the smell can penetrate into the cabin. Since the fuel supply by the carburetor is carried out mechanically, over time the device has to be adjusted. If this procedure is carried out incorrectly, the carburetor may overflow fuel, which will lead to a characteristic smell in the cabin.

Adjusting the carburetor VAZ 2101

After making sure that the “penny” carburetor needs to be adjusted, you first need to prepare the necessary tools and materials:

- spanners;

- rags;

- a set of screwdrivers (cross, flat);

- protective gloves;

- solvent;

- toothpicks;

- compressed air can or pump;

- repair kit.

After preparation, you can proceed to the adjustment work. The procedure requires not so much effort as precision and accuracy. Setting up the assembly involves cleaning the carburetor, for which the top, float and vacuum valve are removed. Inside, everything is cleaned of contaminants, especially if carburetor maintenance is carried out very rarely. Use a spray can or a compressor to clear clogs. Another mandatory step before starting the adjustment is to check the ignition system. To do this, evaluate the gap between the contacts of the distributor, the integrity of high-voltage wires, coils. After that, it remains to warm up the engine to an operating temperature of + 90 ° C, turn it off and set the car to the parking brake.

Throttle valve adjustment

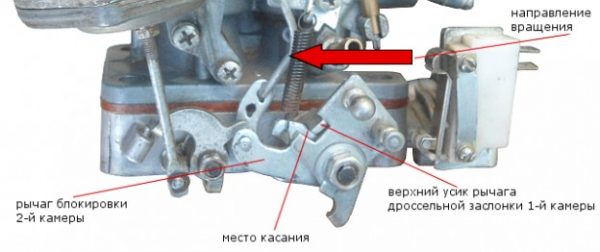

Setting up the carburetor begins with setting the correct throttle position, for which we dismantle the carburetor from the engine and perform the following steps:

- Turn the damper control lever counterclockwise until it is fully open.

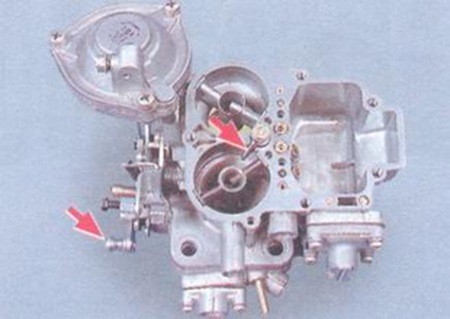

Carburetor tuning begins with throttle adjustment by rotating it counterclockwise until it stops.

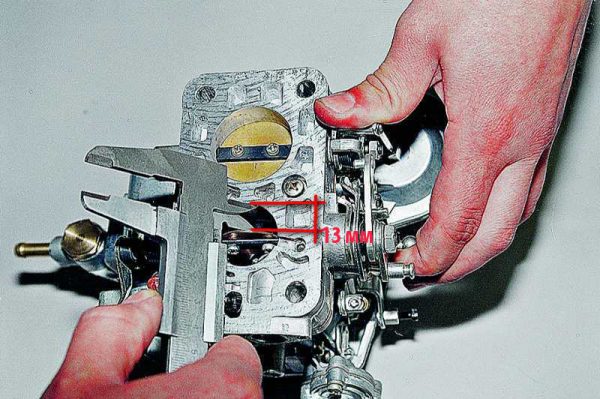

Carburetor tuning begins with throttle adjustment by rotating it counterclockwise until it stops. - We measure up to the primary chamber. The indicator should be about 12,5–13,5 mm. For other indications, the traction antennae are bent.

When checking the gap between the throttle valve and the wall of the primary chamber, the indicator should be 12,5–13,5 mm

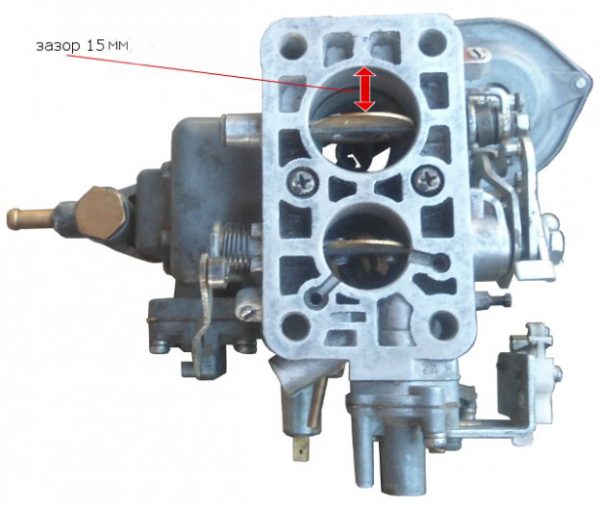

When checking the gap between the throttle valve and the wall of the primary chamber, the indicator should be 12,5–13,5 mm - Determine the opening value of the damper of the second chamber. A parameter of 14,5–15,5 mm is considered normal. To adjust, we twist the pneumatic drive rod.

The gap between the throttle and the wall of the secondary chamber should be 14,5–15,5 mm

The gap between the throttle and the wall of the secondary chamber should be 14,5–15,5 mm

Trigger adjustment

At the next stage, the starting device of the VAZ 2101 carburetor is subject to adjustment. To do this, perform the following actions:

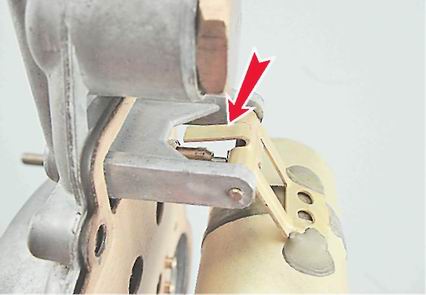

- We turn the throttle valve of the second chamber, which will lead to its closing.

- We check that the edge of the thrust lever fits snugly against the axis of the throttle valve of the primary chamber, and that the trigger rod is located at its tip. If adjustment is needed, the rod is bent.

If there is a need for such an adjustment, it must be carried out carefully, since there is a high probability of damage to the thrust.

Video: how to adjust the carburetor starter

Watch this video on YouTube

Accelerator pump adjustment

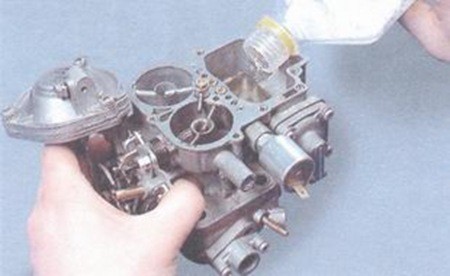

In order to assess the correct operation of the VAZ 2101 carburetor accelerator pump, it is necessary to check its performance. To do this, you need a small container, for example, a cut plastic bottle. Then we perform the following steps:

- We dismantle the upper part of the carburetor and half fill the float chamber with gasoline.

To adjust the accelerator pump, you will need to fill the float chamber with fuel

To adjust the accelerator pump, you will need to fill the float chamber with fuel - We substitute a container under the carburetor, move the throttle lever 10 times until it stops.

We check the performance of the accelerator pump by moving the throttle lever counterclockwise

We check the performance of the accelerator pump by moving the throttle lever counterclockwise - Having collected the flowing liquid from the sprayer, we measure its volume with a syringe or beaker. The normal indicator is 5,25–8,75 cm³ for 10 damper strokes.

In the process of diagnosis, you need to pay attention to the shape and direction of the fuel jet from the pump nozzle: it must be even, continuous, and fall clearly between the diffuser wall and the open damper. If this is not the case, clean the nozzle opening by blowing with compressed air. If it is impossible to adjust the quality and direction of the jet, the accelerator pump sprayer must be replaced.

If the accelerator pump is assembled correctly, normal fuel supply is ensured by the characteristics and size ratio of the pump. From the factory, a screw is provided in the carburetor that allows you to change the fuel supply by the pump: they can only reduce the supply of gasoline, which is almost never required. Therefore, once again the screw should not be touched.

Float chamber adjustment

The need to adjust the fuel level in the float chamber arises when replacing its main elements: a float or a valve. These parts ensure the supply of fuel and its maintenance at a certain level, which is necessary for the normal operation of the carburetor. In addition, adjustment is required when repairing the carburetor. To understand whether adjustment of these elements is necessary, you will need to perform a check. To do this, take a thick cardboard and cut out two strips 6,5 mm and 14 mm wide, which will serve as a template. Then we perform the following steps:

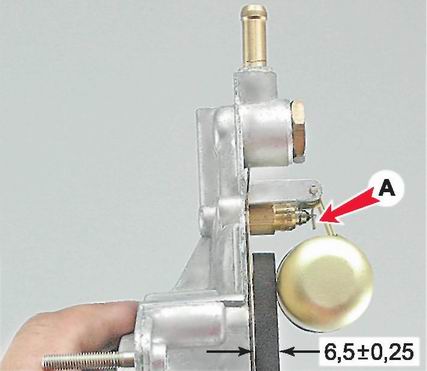

- Having dismantled the top cover from the carburetor, we position it vertically so that the float tongue leans against the valve ball, but at the same time, the spring does not compress.

- Using a narrower template, check the distance between the top cover seal and the float. The indicator should be about 6,5 mm. If the parameter does not match, we bend the tongue A, which is the fastening of the needle valve.

To check the maximum fuel level in the float chamber, between the float and the gasket of the upper part of the carburetor, we lean a template 6,5 mm wide

To check the maximum fuel level in the float chamber, between the float and the gasket of the upper part of the carburetor, we lean a template 6,5 mm wide - How far the needle valve opens depends on the stroke of the float. We retract the float as much as possible and, using the second template, check the gap between the gasket and the float. The indicator should be within 14 mm.

We retract the float as much as possible and use the template to check the distance between the gasket and the float. The indicator should be 14 mm

We retract the float as much as possible and use the template to check the distance between the gasket and the float. The indicator should be 14 mm - If there is a need for adjustment, we bend the stop located on the float bracket.

If there is a need to adjust the fuel level, we bend the stop located on the float bracket

If there is a need to adjust the fuel level, we bend the stop located on the float bracket

If the float is adjusted correctly, its stroke should be 8 mm.

Idle adjustment

The final step in adjusting the carburetor is to set the engine idle speed. The procedure is as follows:

- On a preheated engine, we completely wrap the quality and quantity screws.

- We unscrew the quantity screw by 3 turns, the quality screw by 5 turns.

- We start the engine and achieve the amount of screw so that the engine runs at 800 rpm. min.

- Slowly turn the second adjusting screw, achieving a drop in speed.

- We unscrew the quality screw half a turn and leave it in this position.

Video: Weber carburetor adjustment

Watch this video on YouTube

Cleaning and replacing jets

So that your “penny” does not cause problems regarding the operation of the engine, periodic maintenance of the power system and especially the carburetor is required. Every 10 thousand kilometers, it is recommended to blow through all the carburetor jets with compressed air, while it is not necessary to remove the assembly from the motor. The mesh filter located at the inlet to the carburetor also needs to be cleaned. Every 20 thousand kilometers, all parts of the mechanism need to be flushed. To do this, you can use benzene or gasoline. If there are contaminants that these fluids cannot remove, then a solvent is used.

When cleaning the “classic” jets, do not use metal objects (wire, needles, etc.). For these purposes, a wooden or plastic stick is suitable. You can also use a rag that does not leave a lint. After all the jets are cleaned and washed, they check whether these parts are sized for a particular carburetor model. Holes can be assessed with a sewing needle of a suitable diameter. If jets are replaced, then parts with similar parameters are used. Jets are marked with certain numbers indicating the throughput of their holes.

Each jet marking has its own throughput.

Table: correspondence of marking and throughput of Solex and Ozone carburetor jets

| Nozzle marking | Throughput |

| 45 | 35 |

| 50 | 44 |

| 55 | 53 |

| 60 | 63 |

| 65 | 73 |

| 70 | 84 |

| 75 | 96 |

| 80 | 110 |

| 85 | 126 |

| 90 | 143 |

| 95 | 161 |

| 100 | 180 |

| 105 | 202 |

| 110 | 225 |

| 115 | 245 |

| 120 | 267 |

| 125 | 290 |

| 130 | 315 |

| 135 | 340 |

| 140 | 365 |

| 145 | 390 |

| 150 | 417 |

| 155 | 444 |

| 160 | 472 |

| 165 | 500 |

| 170 | 530 |

| 175 | 562 |

| 180 | 594 |

| 185 | 627 |

| 190 | 660 |

| 195 | 695 |

| 200 | 730 |

The capacity of the holes is expressed in cm³/min.

Table: marking of carburetor jets for VAZ 2101

| Carburetor designation | Fuel jet of the main system | Main system air jet | Idle fuel jet | Idle air jet | Accelerator pump jet | |||||

| 1 room | 2 room | 1 room | 2 room | 1 room | 2 room | 1 room | 2 room | fuel | bypass | |

| 2101 – 1107010 Feet | 135 | 135 | 170 | 190 | 45 | 60 | 180 | 70 | 40 | 40 |

| 2101 – 1107010 – 02 | 130 | 130 | 150 | 190 | 50 | 45 | 170 | 170 | 50 | 40 |

| 2101-1107010-03; 2101 – 1107010 – 30 | 130 | 130 | 150 | 200 | 45 | 60 | 170 | 70 | 40 | 40 |

| 2103 – 1107010 Feet | 135 | 140 | 170 | 190 | 50 | 80 | 170 | 70 | 40 | 40 |

| 2103-1107010-01; 2106 – 1107010 Feet | 130 | 140 | 150 | 150 | 45 | 60 | 170 | 70 | 40 | 40 |

| 2105 – 1107010 – 10 | 109 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2105-110711010; 2105-1107010; 2105 – 1107010 – 20 | 107 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 |

| 21053 | 100 | 115 | 150 | 135 | 35 – 45 Feet | 50 | 140 | 150 | 45 | 40 |

| 2107-1107010; 2107 – 1107010 – 20 | 112 | 150 | 150 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2107 – 1107010 – 10 | 125 | 150 | 190 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2108 – 1107010 Feet | 97,5 | 97,5 | 165 | 125 | 42±3 | 50 | 170 | 120 | 30/40 | — |

Despite the fact that cars with carburetor engines are not produced today, there are quite a lot of cars with such power units, including among the Zhiguli family. With proper and timely maintenance of the carburetor, the unit will work for a long time without any complaints. If problems arise, it is better not to delay the repair, since the correct operation of the engine is disrupted, which leads to an increase in fuel consumption and a deterioration in dynamics.