Cardan shaft in the automotive industry - where will the reliable clutch and cardan joint be?

Content

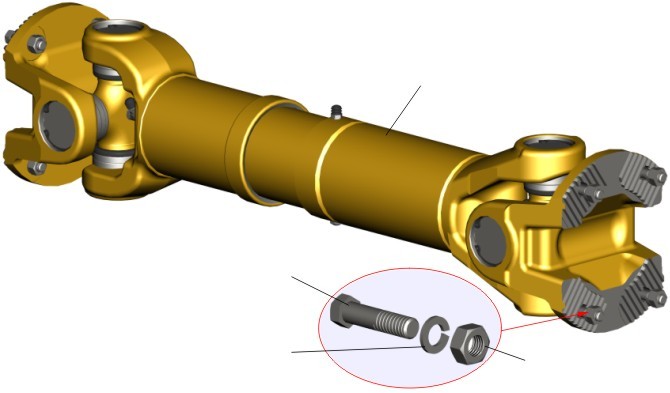

From the very beginning, we need to make one thing clear. The element that we will describe in the article is more correctly called a cardan coupling. However, for ease of naming and because of the generally accepted forms of definition, the term given in the title is usually used. The cardan shaft is designed to drive the rear axle or all axles of the vehicle. This is an extremely simple and reliable solution. How does a gimbal actually work? In what cars is this a great solution? Find out from our text!

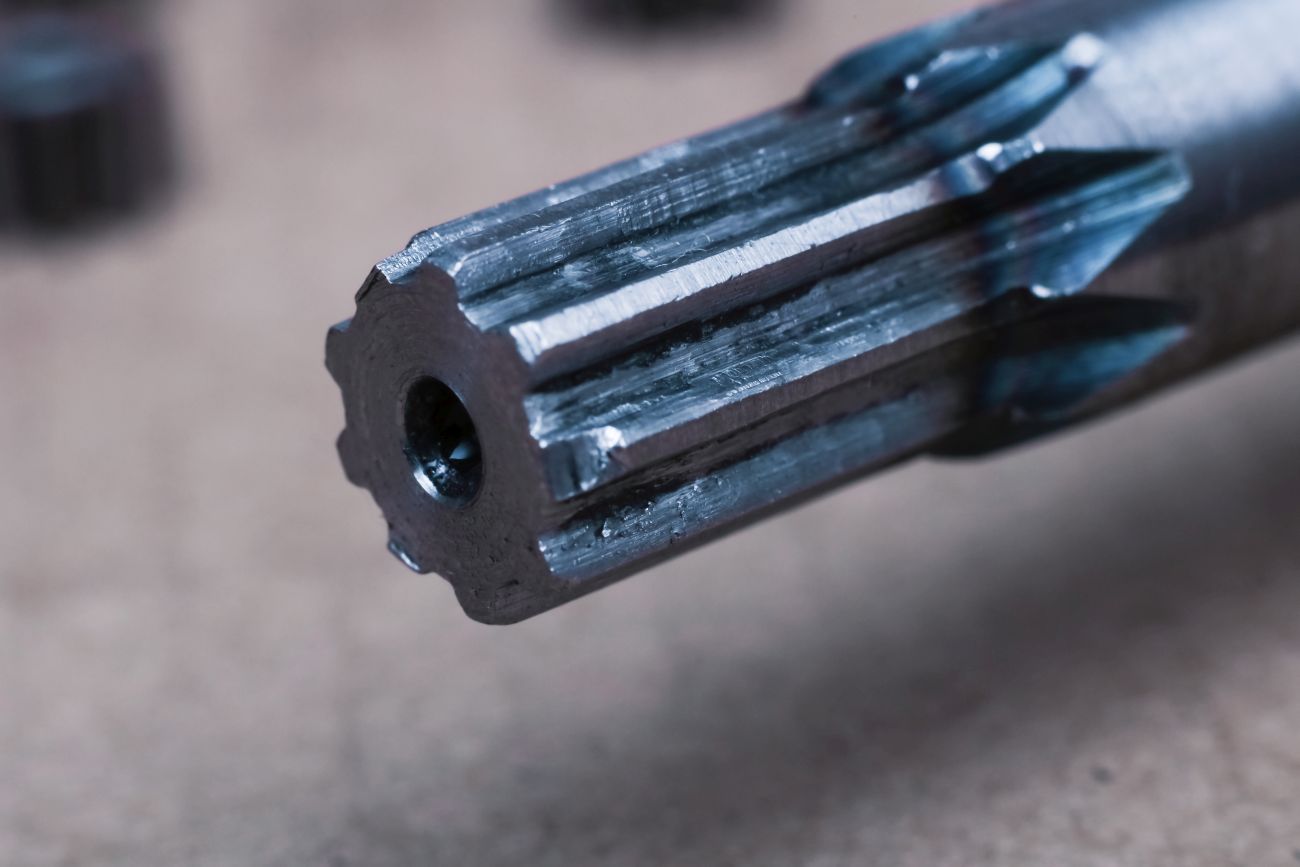

Cardan shaft - drive structure design

The cardan joint is very simple. On one side there is an active shaft, and on the other - a passive one. Between them there is a transverse connector that allows you to transfer torque between one element and another. Thanks to the connection in the form of a permanent coupling, the cardan shaft can transmit energy not only along the axis, but also at an angle. However, this is due to pulsation.

In addition to the listed elements, the rink also has:

- flange connection;

- pipe connection;

- shaft housing;

- sliding joints in the form of security.

Cardan shaft - the principle of operation of the coupling and cardan joint

On one side, the shaft is connected to a transmission that transmits power from the drive unit. The energy received by the flange connection goes to the shaft. Then, through the cross, the torque is transmitted to another part of the shaft. This part of the shaft initiates the rear axle drive. However, in older designs, the cardan shaft has a certain disadvantage. A single clutch with simultaneous angular deflection of the shafts caused a speed pulsation proportional to the angle. For this reason, newer models are equipped with a dual clutch, where this problem disappears.

Cardan shaft - what is it and what is it for?

The cardan shaft allows the use of center connections over long distances. Therefore, very often this type of design was used to supply torque to rear-wheel drive cars. There are no serious contraindications to the use of several such elements in multi-axle vehicles. When you need to transfer power at an angle, a universal joint is also very useful.

Cardan hinge - pluses and minuses

What are the benefits of a gimbal? Primarily:

- simplicity of design;

- cheap and easy repair.

In such a design, there are few elements that can break. Something else? In contrast to the ball joint, a cross member is used here, which does not require lubrication during rotation. Thus, repairing a damaged component is cheaper and less problematic.

Cardan joint and its disadvantages

The cardan shaft also has some disadvantages. As mentioned above, the disadvantage is, in particular, the speed ripple. With the constant operation of the hinge at an angle, the speed transmitted to the driven axle changes cyclically. The active shaft receiving torque from the motor has the same speed. Idle shaft problem.

The use of cardan shaft in the automotive industry.

Nowadays, the propeller shaft is often used to transmit drive in motorcycles and ATVs. Although the chain is more flexible and causes less energy loss, there are still many proponents of using a gimbal. The latter is usually installed on two-wheeled vehicles and ATVs that are not focused on minimizing weight. So it's about choppers, cruisers and tourist cars. The shaft is considered reliable, although, as you know, it is difficult to find ideal and trouble-free solutions in mechanics. Shaft damage can result from overuse or neglect.

Symptoms of a broken cardan shaft

The cardan shaft can be damaged due to careless maintenance and operation. And how to recognize the problem? The following symptoms indicate this:

- knocking and jerking when starting off;

- disturbing vibrations from the pendulum area;

- non-standard sounds coming from the vicinity of the embankment;

- noticeable vibration while driving.

Should I choose a car with a driveshaft? As for the bike, it's worth it. Of course, you have to consider that a two wheeler will have worse performance than a similar model with the same engine but with a chain. The engine will also be heavier. However, the reliability of the universal joint makes many reach for the car with just such a transmission.