Checkpoint VAZ 2107: device, malfunctions, repair

Content

- Checkpoint VAZ 2107: what is it

- The main technical characteristics of the box VAZ 2107

- VAZ 2107 gearbox malfunctions

- Repair of the VAZ 2107 gearbox

- The role of oil seals in the operation of the gearbox, how to replace

- How to replace gears and synchronizers

- Oil in the gearbox VAZ 2107

- Backstage at the checkpoint - what is it for

Structurally, the seventh model in the VAZ line is recognized as one of the simplest and most affordable for self-maintenance and repair. However, the “seven” also has complex components, the repair of which is far from being possible for every driver to carry out with their own hands. One of these nodes is rightfully considered a gearbox.

Checkpoint VAZ 2107: what is it

What is a gearbox in a car design? The abbreviation "CAT" stands for "gearbox". This is the name of the unit, which is designed to change the frequency of torque.

It is curious that the first gearboxes were not invented for cars, but for machine tools in order to change the speed of rotation of the tool.

The purpose of the gearbox is to perform the function of converting the amount of torque that comes from the motor, with the transfer of this energy to the transmission. Only in this way is it possible to switch speeds in ascending order.

The checkpoint on the VAZ 2107 appeared in 1982 along with a new model in the AvtoVAZ line - the "seven". Structurally and practically, this box is still considered the most advanced unit among classic manual gearboxes.

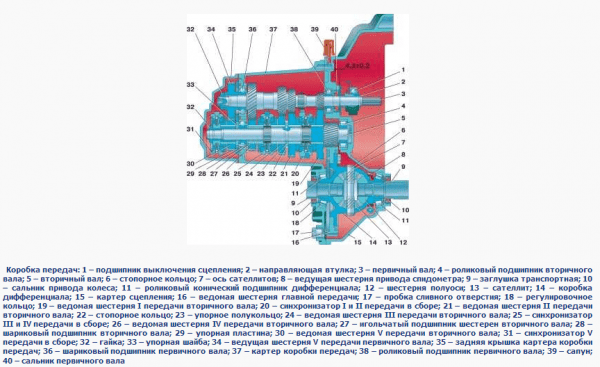

Transmission device

A five-speed gearbox is installed on the VAZ 2107, that is, changes in the torque frequency are possible in five positions. At the same time, five gears allow you to drive forward at different speeds, and the sixth is considered reverse and turns on at the moment when the driver needs to reverse.

The shift scheme for these gears is no different from the classic four-speed, which was installed on earlier VAZ models. The driver just needs to depress the clutch pedal and move the gearshift lever to the desired position.

It should be noted that structurally, the box on the "seven" is a rather complex device, so the diagnosis and repair of this device is usually trusted only by professionals. However, the “seven” gearbox adopted the main parameters from the “five”, since AvtoVAZ designers took the new gearbox from the VAZ 2105 as the basis.

Table: gear ratio ratios on the VAZ 2105 and VAZ 2107

Model | WHA 2105 | WHA 2107 |

|---|---|---|

Main couple | 4.3 | 4.1 / 3.9 |

1st gear | 3.667 | 3.667 |

2-I | 2.100 | 2.100 |

3-I | 1.361 | 1.361 |

4-I | 1.000 | 1.000 |

5-I | 0.801 | 0.820 |

Rear | 3.530 | 3.530 |

Speaking about the general design of the gearbox on the VAZ 2107, it should be borne in mind that outwardly it has the form of a closed case. At the same time, only three of its sides are completely closed (special durable covers are used for this), and the fourth side of the box “grows” into a gear shift knob. All lids fit tightly to the box, their joints are sealed.

The main elements of the gearshift are “hidden” in the gearbox housing:

- input shaft (four drive gears and synchronizers are installed on it);

- secondary shaft (ten gears are attached to its surface at once);

- intermediate shaft.

Let's consider each element separately in order to understand at least the general principle of the design and operation of the gearbox.

Primary shaft

Already by name, you can understand that the input shaft is a fundamental element of the box. Structurally, the shaft is one piece with four toothed gears and rotates with them on a bearing. The rotating bearing itself is fixed at the bottom of the box and sealed with an oil seal for a secure connection.

More about the input shaft VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/kpp/pervichnyiy-val-kpp-vaz-2107.html

Secondary shaft

We can say that the secondary shaft is, as it were, a logical continuation of the primary in the body space. It has gears of 1st, 2nd and 3rd gears (that is, all odd). All ten gears on this shaft have different dimensions, and therefore provide a transformation of the torque value.

The secondary shaft, like the primary shaft, rotates on bearings.

Intermediate shaft

The main task of this element is to serve as a kind of "layer" between the primary and secondary shafts. It also has gears that are one with the shaft, through which the transmission of torque is transmitted from one shaft to another.

Fork set

Ease of shifting gears while driving is provided by a set of forks. They are driven by a shift lever. The forks press on one or another gear of a certain shaft, forcing the mechanism to work.

Of course, there is a special hole in the housing through which lubricating fluid is poured into the gearbox. This hole is located on the left side of the gear shift knob and is closed with a plug. The volume of the gearbox on the VAZ 2107 is approximately 1 liters of oil.

The main technical characteristics of the box VAZ 2107

The gearbox of the "seven" works in conjunction with the clutch. A single-disk dry clutch is installed on the VAZ 2107, which has only one (central) pressure spring. This is quite enough for convenient control of vehicle speeds.

Gearbox - only mechanical, three-code, five-speed. On the VAZ 2107, synchronizers work for each forward gear.

The device weighs quite a lot - 26.9 kg without oil.

Video: the principle of operation of a mechanical box VAZ

What checkpoint can be put on the "seven"

The VAZ 2107 will be happy to work with both a four-speed and a five-speed gearbox, so only the driver decides which model to choose.

If we talk about domestic "VAZ" boxes, then initially the "seven" was equipped with a four-stage, so you can always buy and install this particular unit. The main advantage of such a box lies in its increased efficiency - the driver drives 200 - 300 thousand kilometers without ever investing in the repair of the device. In addition, the four-stage is more suitable for low-power 1.3-liter engines or for drivers who often carry heavy loads by car, since the box was originally designed for high traction.

Five-speed boxes allow you to develop a higher speed. Younger drivers like this, as you can squeeze the maximum power out of the car at the start and when overtaking. However, over time, such boxes began to be made from low-quality materials, so there is not always a clarity of switching.

Foreign checkpoints can also be installed on the VAZ 2107. Boxes from Fiat are most suitable, since it was this car that became the prototype of domestic models. Some motorists install boxes from old versions of BMW, but the installation procedure can take a long time, since the original design of the car does not provide for non-standard units.

VAZ 2107 gearbox malfunctions

VAZ 2107 is rightfully considered a "workhorse". But even this model cannot last forever. Sooner or later, but the car starts to "act up." If any malfunctions appear in the box, the owner must immediately take the necessary measures, since these defects directly affect the ability to operate the car.

Why the gears do not turn on or turn on randomly

This is a nightmare for any driver when the car does not obey his orders or performs actions in random order. To prevent this from happening in reality, you should, at the very first problems with gear shifting, find out the source of the origin of these problems:

- Strong wear of the moving parts of the box (hinges, spring) - it is best to overhaul the gearbox.

- The blocking rings on the synchronizers have worn out - it is recommended to simply replace them with new ones.

- The synchronizer spring has broken - a replacement will help.

- The teeth on the gears are worn out - it is recommended to replace the gear.

Why knocks out the transmission when it is turned on

It is not uncommon for a driver to be unable to engage a particular gear. Accordingly, the motor experiences increased loads, which negatively affects the ride. You need to figure out exactly what the problem is and take action:

- The clutch cannot fully disengage - the clutch mechanisms need to be adjusted.

- Jammed hinge on the shift lever - clean the hinge joints.

- Breakage of the lever itself - you need to replace it with a new one.

- Deformation of the forks in the box (usually happens after accidents) - it is better to immediately replace the whole set without trying to straighten it.

Noise and crunch is heard from the box

It is very unpleasant when loud sounds and a heartbreaking crunch are heard during movement. It looks like the car is about to fall apart. However, the whole cause of a malfunction in the gearbox:

- The bearings on the shafts are noisy - it is necessary to change the broken parts.

- Strong wear of the teeth on the gears - replace.

- Not enough oil in the box - add fluid and find the leak to prevent subsequent malfunctions.

- The shafts began to move along their axis - it is necessary to replace the bearings.

Why is oil leaking out of the box

The full operation of the gearbox on the VAZ 2107 is impossible without good lubrication. Approximately 1.6 liters of oil are poured into the box, which usually changes completely only during a major overhaul. By itself, the oil cannot flow anywhere, since the body is sealed as much as possible.

However, if a puddle accumulates under the car during parking, and the internal parts under the hood are heavily oiled, it is urgent to look for the cause of the leak:

- The seals and gaskets are worn out - this is the reason for the depressurization of the box, you must immediately replace the rubber products and add oil.

- The crankcase fastenings have loosened - it is recommended to simply tighten all the nuts.

Note that some types of troubleshooting work are available to the average driver. However, serious and large-scale procedures (for example, gearbox overhaul) are best left to professionals.

Repair of the VAZ 2107 gearbox

Self-repair of the box is a task that only an experienced car owner who is accustomed to maintaining and repairing the car can handle on their own.

We remove the box

Repair of the box can only be carried out after it is dismantled from the car, so you have to drive the “seven” onto a flyover or inspection hole and get to work.

For work, it is better to prepare in advance:

- two screwdrivers with a thin flat blade;

- tweezers;

- a cross-blade screwdriver;

- socket wrench for 10;

- socket wrench 19.

The procedure for removing the checkpoint is carried out according to the following regulations:

- After the machine has been installed in the pit, you need to disconnect the wire from the negative terminal on the battery, and then drain the oil from the box.

- Remove the radio panel.

- Press the lever, insert a flat screwdriver into the hole of the locking sleeve of the box, pull the sleeve out.

- Remove the rod from the lever.

- Take the tweezers and remove the elastic rubber insert of the damper from the lever.

- Use two flat screwdrivers to open the damper insert petals and remove them from the lever.

- Remove the damper and all its bushings from the lever.

- Next, move the upholstery mat on the floor of the machine.

- Take a Phillips screwdriver and unscrew the four screws on the box cover.

- Remove the box cover from the lever.

- Remove the exhaust pipe from the muffler.

- Disconnect the clutch unit with a Phillips screwdriver.

- Remove wire harness.

- Remove cardan drive.

- Disconnect the flexible shaft from the speedometer.

- Take a 10 socket wrench and unscrew the two bolts securing the side cover of the box.

- A solid, stable support must be installed under the box.

- Take a socket wrench for 19 and unscrew the four bolted connections securing the crankcase to the cylinder block.

- Insert a flat screwdriver into the gap between the crankcase and the block and wring out both devices with it.

- Dismantling of KPP on VAZ 2107 is completed.

More about removing the checkpoint on the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/kpp/kak-snyat-korobku-na-vaz-2107.html

Video: dismantling instructions

Watch this video on YouTube

How to disassemble the checkpoint

The removed box must be installed on a flat and clean place. To disassemble the device for parts, you will need the following tools:

- adhesive composition;

- impact screwdriver;

- three-jaw bearing puller (you may also need a vice);

- new oil seals;

- complete set of gaskets;

- torque wrench.

The procedure for disassembling the box is one of the most difficult procedures when working on the VAZ 2107. The design of the gearbox has many small details, an inattentive attitude to any of them can lead to disastrous results. Therefore, it is recommended to disassemble the box yourself and replace worn-out elements only if you have extensive practical experience in this area.

Video: instructions for disassembling a mechanical box

Watch this video on YouTube

We change bearings

All three shafts in the gearbox rotate due to the bearing arrangement. However, experienced drivers know that it is the bearings that bring the main heap of problems, since sooner or later they begin to flow, knock or wear out during operation.

Video: how to visually determine the wear of bearings on shafts

Watch this video on YouTube

The VAZ 2107 gearbox contains bearings of different sizes, but none of them provides for a repair and restoration procedure. Therefore, during repairs, it will be necessary to knock out the shafts from the bearings and install new hinge devices.

Video: instructions for replacing the bearings of the primary and secondary shafts

Watch this video on YouTube

The role of oil seals in the operation of the gearbox, how to replace

An oil seal is a dense rubber gasket, the main task of which is to seal the joints between different parts in the box. Accordingly, if the stuffing box is badly worn, the sealing of the device is broken, oil leaks can be observed.

To prevent loss of lubricating fluid and restore the tightness of the device, it will be necessary to change the stuffing box. This will require simple tools that the driver always has at hand:

- nut heads;

- hammer;

- flat screwdriver;

- knife (it is most convenient for them to remove the old gasket);

- new oil seal;

- sealant.

Input shaft oil seal

This product is made from a CGS/NBR composite for maximum durability. The oil seal in working condition is completely immersed in gear oil, due to which its elasticity is maintained for a long time.

The input shaft oil seal is designed to operate in the temperature range from -45 to +130 degrees Celsius. Weighs 0.020 kg and measures 28.0x47.0x8.0 mm

The input shaft seal of the VAZ 2107 box is located in the clutch housing. Therefore, to replace it, you will need to dismantle the casing. And for this it is necessary to drive the car onto a flyover or a viewing hole.

Replacing the input shaft gasket is carried out as follows:

- Remove the gearbox from the car (you can also get the oil seal on the box that has not been removed, but the procedure will take a lot of time).

- Remove the fork and release bearing from the gearbox (this will require a hammer, puller and vice).

- Remove the six nuts from the casing.

- Remove the casing itself (it has the shape of a bell).

- Now access to the stuffing box is open: remove the old gasket with a knife, carefully clean the junction and install a new stuffing box.

- Then assemble the cover in reverse order.

Learn how to replace gearbox oil seals on a VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/kpp/zamena-salnika-pervichnogo-vala-kpp-vaz-2107.html

Photo gallery: replacement procedure

-

- The bearing is difficult to pull out, you have to use a special puller

-

- The casing can be easily removed immediately after unscrewing the fixing nuts.

-

- New products are installed in place of old ones

Output shaft oil seal

The product is also made of high quality composite materials. According to the technical characteristics, the output shaft seal is not much different from the primary shaft seal.

However, it weighs a little more - 0.028 kg and has larger dimensions - 55x55x10 mm.

The location of the oil seal explains some of the difficulties of removing and replacing it:

- Fix the box flange by inserting a bolt of the required diameter into its hole.

- Turn the flange nut with a wrench.

- Pry off the centering metal ring with a screwdriver and pull it out of the secondary shaft.

- Remove the bolt from the hole.

- Place a puller on the end of the output shaft.

- Remove flange with washer.

- Using screwdrivers or pliers, remove the old oil seal from the box.

- Clean the joint, install a new seal.

Photo gallery: working procedure

-

- You need to work with the shaft carefully so as not to damage its surface.

-

- A vice can also be used if necessary.

-

- New seals are easy to fit into place

How to replace gears and synchronizers

As mentioned above, independent work with a gearbox, and even more so with shafts and their elements, is fraught with many errors. Therefore, it is better to entrust the replacement of gears and synchronizers to car repair specialists.

Experienced owners of the VAZ 2107 can watch a special video that explains all the nuances of working to change these parts.

Video: a unique video for removing gear from fifth gear

Watch this video on YouTube

Oil in the gearbox VAZ 2107

A special gear oil is poured into the VAZ gearbox. It is necessary for the lubrication of gears, as it prolongs their service life.

The choice of gear oil depends on many parameters: the driver's finances, manufacturer's recommendations and the preferences of the owner of a particular brand. In the box of the "seven" you can without a doubt fill in the gear oil of the following companies:

- UFALUB UNITRANS 85W-90;

- LUKOIL TM-5 85W-90;

- SAMOIL 4404 80W-90 or 85W-90;

- FAIR SUPER E-80W-90 or T-85W-90;

- TNK TRANS GIPOID 85W-90 or 80W-90;

- AGIP ROTRA MP 80W-90 or 80W-95;

- NORSI TRANS 80W-90 or 85W-90;

- NOVOIL SUPER T 80W-90;

- SPECTROL FORWARD 80W-90;

- MP GEAR LUBE-LS 80W-90 or 85W-140 (GL-5).

The volume of liquid to be poured is usually 1.5 - 1.6 liters. Filling is done through a special hole in the left side of the box body.

How to check the oil level in the gearbox

If you suspect an oil leak, check the level in the box. To do this, you will have to put the VAZ 2107 on the inspection hole and start working:

- Clean the drain plug and filler hole on the box body from dirt.

- Take a 17 wrench and unscrew the filler plug with it.

- Any suitable object (you can even use a screwdriver) to check the oil level inside. The liquid should reach the bottom edge of the hole.

- If the level is lower, you can add the required amount of oil through the syringe.

How to change the oil in a box VAZ 2107

To change the oil in the car, you will need to prepare in advance:

- capacity for draining the spent fluid (at least 2 liters);

- key on 17;

- hexagon;

- screwdriver;

- rags.

It is recommended to replace it immediately after driving a car, as hot oil will drain faster from the box. The replacement procedure is relevant every 50 - 60 thousand kilometers.

Operating procedure

So that the work does not bring trouble, it is best to immediately cover the space around the box with rags. Follow the next diagram:

- Unscrew the oil fill plug on the box body.

- Place the drain container under the plug and open it with a hex wrench.

- Wait until the oil has completely drained out of the box.

- Clean the drain plug from the old oil and install it in place.

- Carefully pour fresh oil in a volume of 1.5 liters through the filler hole.

- After 10 minutes, check the level, if necessary, add more lubricant and close the plug.

Photo gallery: do-it-yourself oil change in a box

-

- It is better to clean the drain container under the cork in advance

-

- Old oil will flow out faster with a warm box after driving

-

- It is better to pour a smear through a funnel

Backstage at the checkpoint - what is it for

The backstage in the language of service station specialists is called “the thrust of the gearbox control drive”. The shift lever itself is mistakenly taken behind the scenes when the scene is a multi-component element:

- gear shift lever;

- traction;

- fork;

- packing gland fastener.

As part of the gearbox, the rocker plays the role of a connecting link between the lever and the cardan shaft. Being a mechanical device, it can wear out, so the driver will immediately begin to notice problems in driving. Current breakdowns are usually associated with the development of the backstage resource, less often with a drop in the oil level in the gearbox.

Self-adjusting backstage

If you have the first problems with gear shifting, you can first try to adjust the backstage. It is possible that some connections are loose and a little intervention can fix this problem:

- Drive the car onto the overpass.

- Move the lever to the left to the maximum.

- Tighten the clamp under the machine between the yoke and the shaft.

- Lubricate the parts with special grease through the joints in the box body.

Usually these actions are quite enough to return the car to its original controllability.

Video: instructions for adjusting work

Watch this video on YouTube

How to remove and put backstage on VAZ 2107

In fact, the process of dismantling the old backstage and installing a new one is quite simple. Motorists in an accessible language themselves explain on the forums how to conduct work.

As Raimon7 correctly wrote, this can be done from the salon. It's quite simple to unscrew the 3 lower nuts (see photo), pull out the entire mechanism. If you have 5st then there are no problems at all, but if 4x then you will need to disconnect the “gear shift lever” from the spring (see photo) (this is what you broke off). The spring will need to be pulled out so that it does not accidentally fall down, we have a friend here who rides with this spring, it’s not clear where. Then you just disassemble everything: the gear selection mechanism, throw out the broken lever, insert a new one, assemble it, screw the selection mechanism back and everything is fine drive

Thus, the gearbox on the VAZ 2107 is not in vain considered one of the most complex design elements of the model. The owner can do some of the operation, inspection and repair work with his own hands, but do not overestimate your strength in case of serious large-scale problems with the checkpoint - it is better to pay for the services of specialists.