What does the Knock Sensor affect and how to check it

Content

A knock detection sensor (DD) in the engine cylinders was not an obvious necessity in the first engine control systems, and in the days of simpler principles for organizing the power supply and ignition of gasoline ICEs, abnormal combustion of the mixture was not monitored at all. But then the engines became more complex, the requirements for efficiency and exhaust purity increased dramatically, which required an increase in the amount of control over their work at any given time.

Lean and super-poor mixtures, exorbitant compression ratios and other similar factors need to constantly work on the verge of detonation without going beyond this threshold.

Where is the knock sensor located and what does it affect

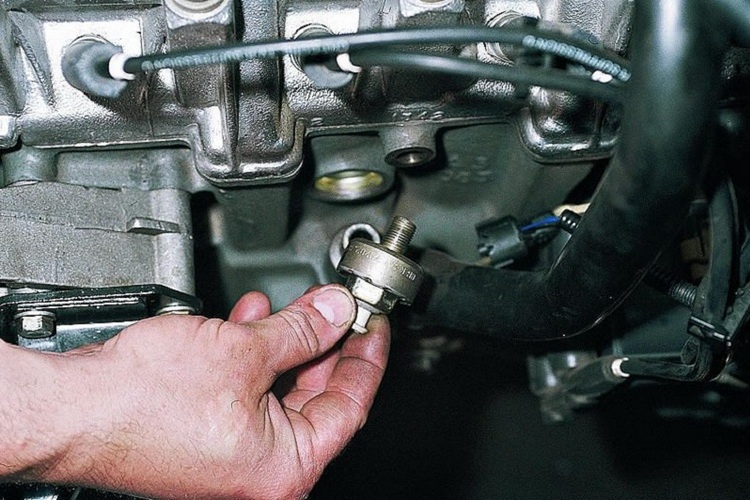

Usually DD is mounted on a threaded mount to the cylinder block, near the central cylinder closer to the combustion chambers. His location is determined by the tasks that he is called upon to perform.

Roughly speaking, the knock sensor is a microphone that picks up quite specific sounds made by a detonation wave hitting the walls of the combustion chambers.

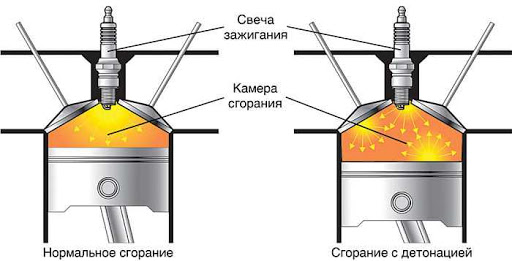

This wave itself is the result of abnormal combustion in cylinders at a very high speed. The difference between the regular process and the detonation process is the same as during the operation of a propelling powder charge in an artillery gun and a blasting-type explosive, which is filled with a projectile or grenade.

Gunpowder burns slowly and pushes, and the contents of a land mine crushes and destroys. The difference in the speed of propagation of the combustion boundary. When detonated, it is many times higher.

In order not to expose engine parts to breakdowns, the occurrence of detonation must be noticed and stopped in time. Once upon a time, it was possible to afford it at the cost of excessive fuel consumption and environmental pollution in order to avoid detonating the mixture in principle.

Gradually, motor technology reached such a level that all reserves were exhausted. It was necessary to force the engine to extinguish the resulting detonation on its own. And the motor was attached with an "ear" of acoustic control, which became the knock sensor.

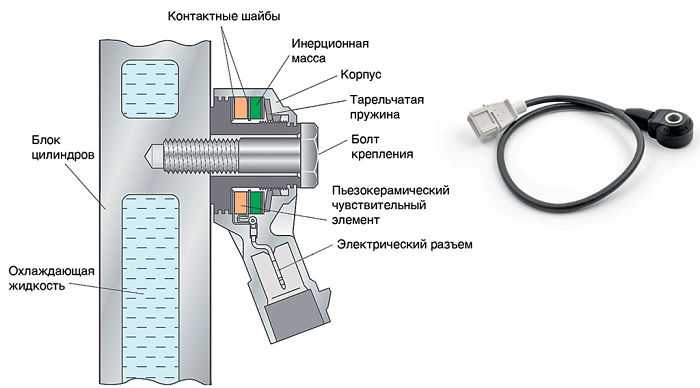

Inside the DD there is a piezoelectric element capable of converting acoustic signals of a certain spectrum and level into electrical ones.

After amplifying the oscillations in the engine control unit (ECU), the information is converted into a digital format and submitted to the electronic brain for consideration.

A typical algorithm of operation consists in a short-term rejection of the angle by a fixed value, followed by a step-by-step return to the optimal lead. Any reserves are unacceptable here, since they reduce the efficiency of the engine, forcing it to work in a suboptimal mode.

Tracking occurs in real time at a high frequency, which allows you to quickly respond to the appearance of a "ringing", preventing it from causing local overheating and destruction.

By synchronizing the signals with the crankshaft and camshaft position sensors, you can even determine in which particular cylinder a dangerous situation occurs.

Types of sensors

According to the spectral characteristics, historically there are two of them - resonant и broadband.

In the first, a pronounced reaction to well-defined sound frequencies is used to increase sensitivity. It is known in advance which spectrum is given out by parts suffering from a shock wave, it is on them that the sensor is constructively tuned.

The broadband type sensor has less sensitivity, but it picks up fluctuations of different frequencies. This allows you to unify the devices and not select their characteristics for a specific engine, and a greater ability to capture weak signals is not very in demand, detonation has sufficient acoustic volume.

Comparison of sensors of both types led to the complete replacement of resonant DDs. Currently, only two-contact broadband toroidal sensors are used, fixed on the block with a central stud with a nut.

Symptoms of a malfunction

During normal engine operation, the knock sensor does not emit danger signals and does not participate in the operation of the control system in any way. The ECU program performs all actions according to its data cards sewn into the memory, regular modes provide detonation-free combustion of the air-fuel mixture.

But with significant temperature deviations in the combustion chambers, detonation can occur. The task of DD is to give a signal in time to parry the danger. If this does not happen, then characteristic sounds are heard from under the hood, which for some reason it is customary for drivers to call the sound of fingers.

Although in fact no fingers are knocking at the same time, and the main volume level comes from the vibration of the piston bottom, which is hit by a wave of explosive combustion. This is the main sign of abnormal operation of the knock control subsystem.

Indirect signs will be a noticeable loss of engine power, an increase in its temperature, up to the appearance of glow ignition, and the inability of the ECU to cope with the situation in normal mode. The reaction of the control program in such cases will be the ignition of the "Check Engine" light bulb.

Normally, the ECU directly monitors the activity of the knock sensor. The levels of its signals are known and stored in memory. The system compares the current information with the tolerance range and, if deviations are detected, simultaneously with the inclusion of the indication, it stores the error codes.

These are various types of excess or decrease in the levels of the DD signal, as well as a complete break in its circuit. Error codes can be read by the on-board computer or an external scanner through the diagnostic connector.

Error codes can be read by the on-board computer or an external scanner through the diagnostic connector.

If you do not have a diagnostic device, we recommend that you pay attention to a budget multi-brand autoscanner Scan Tool Pro Black Edition.

A feature of this Korean-made model is the diagnosis of not only the engine, as in most budget Chinese models, but also other components and assemblies of the car (gearbox, ABS auxiliary systems, transmission, ESP, etc.).

Also, this device is compatible with most cars since 1993, works stably without loss of connection with all popular diagnostic programs and has a fairly affordable price.

How to check the knock sensor

Knowing the device and the principle of operation of the DD, you can check it in fairly simple ways, both by removing it from the engine and in place, including directly on the running engine.

Measuring voltage

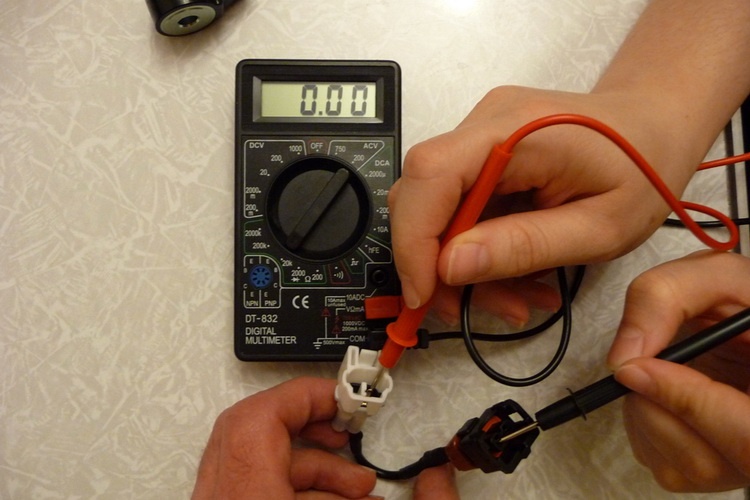

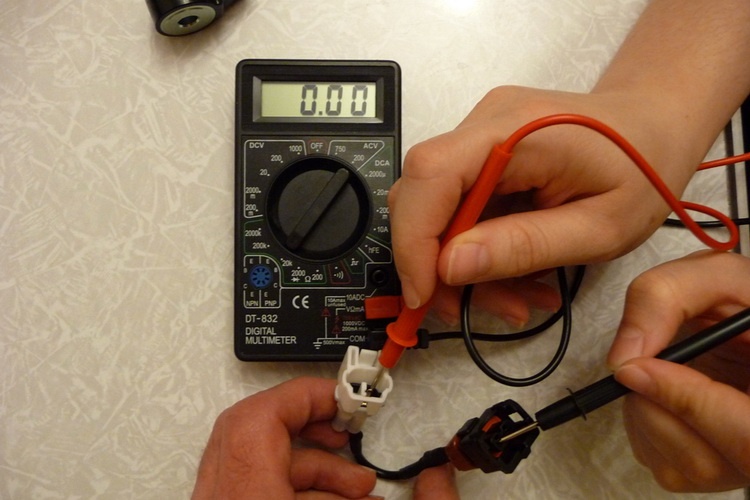

A multimeter is connected to the sensor removed from the cylinder block in voltage measurement mode. Gently bending the body of the DD through a screwdriver inserted into the hole of the sleeve, one can follow the reaction of the built-in piezoelectric crystal to the deforming force.

The appearance of voltage at the connector and its value of the order of two to three tens of millivolts approximately indicates the health of the device's piezoelectric generator and its ability to generate a signal in response to mechanical action.

Resistance measurement

Some sensors contain a built-in resistor connected as a shunt. Its value is on the order of tens or hundreds of kΩ. An open or short circuit inside the case can be fixed by connecting the same multimeter in resistance measurement mode.

The device should show the value of the shunt resistor, since the piezocrystal itself has an almost infinitely large resistance that cannot be measured with a conventional multimeter. In this case, the readings of the device will also depend on the mechanical effect on the crystal due to the generation of voltage, which distorts the readings of the ohmmeter.

Checking the sensor on the ECU connector

Having determined the desired contact of the ECU controller connector from the electrical circuit of the car, the state of the sensor can be checked more fully, with the inclusion of the supply wiring circuits.

On the removed connector, the same measurements are carried out as described above, the difference will be only a simultaneous check of the cable's health. Bending and twitching the wires make sure that there is no wandering fault when the contact appears and disappears from mechanical vibrations. This is especially affected by corroding places where wires are embedded in the lugs of the connectors.

With the computer connected and the ignition on, you can check the presence of a reference voltage on the sensor and the correctness of its division by external and built-in resistors, if this is provided for by the circuit of a particular car.

Usually, the +5 Volt support is roughly halved and an AC signal is generated against the background of this DC component.

Oscilloscope check

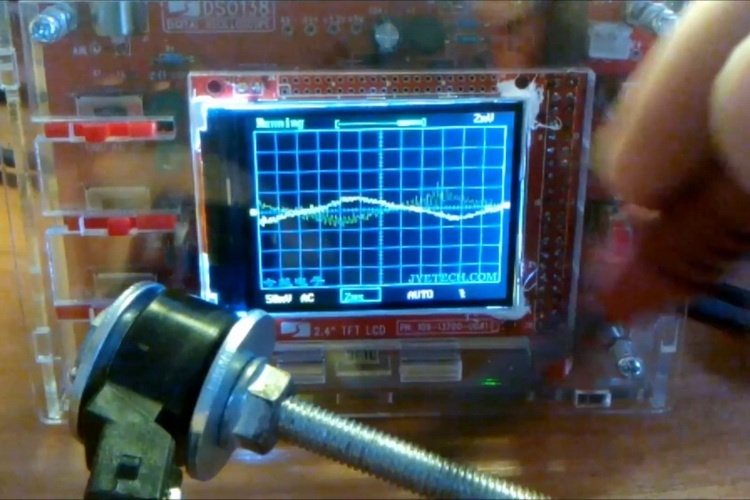

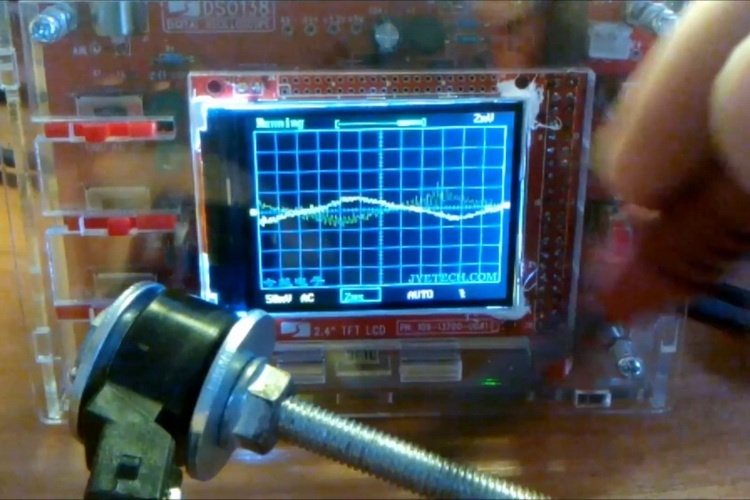

The most accurate and complete instrumentation method will require the use of an automotive digital storage oscilloscope or an oscilloscope attachment to the diagnostic computer.

When hitting the body of the DD, it will be seen on the screen how much the piezoelectric element is capable of generating steep fronts of the detonation signal, whether the seismic mass of the sensor works correctly, preventing extraneous damped oscillations, and whether the amplitude of the output signal is sufficient.

The technique requires sufficient experience in diagnostics and knowledge of typical signal patterns of a serviceable device.

Checking on a working engine

The simplest way to check does not even require the use of electrical measuring instruments. The engine starts and is displayed at a speed below average. When applying moderate blows to the knock sensor, you can observe the reaction of the computer to the appearance of its signals.

There should be a regular rebound of the ignition timing and the associated drop in the steady-state engine speed. The method requires a certain skill, since not all motors respond equally to such testing.

Some "notice" the knock signal only within a rather narrow phase of the rotation of the camshafts, which still needs to be reached. Indeed, according to the logic of the ECU, detonation cannot occur, for example, at the exhaust stroke or at the beginning of the compression stroke.

Watch this video on YouTube

Replacing the knock sensor

DD refers to attachments, the replacement of which does not present any difficulties. The body of the device is conveniently fixed on a stud and to remove it, it is enough to unscrew one nut and remove the electrical connector.

Sometimes, instead of a stud, a threaded bolt in the body of the block is used. Difficulties can arise only with corrosion of the threaded connection, since the device is very reliable and its removal is extremely rare.

An all-purpose penetrating lubricant, sometimes called a liquid wrench, will help.