Do-it-yourself reverse hammer and spotter: detailed instructions for making a tool

Content

Homemade reverse hammer spotter must have a functional and aesthetically attractive body - it is a box made of plastic, metal, wood. The main thing is that it has a hinged cover for access to the internal contents: a transformer, a control unit, microcircuits, wires and contacts.

Straighteners in body repair use many ways of straightening metal. Concavities on large areas (hood, roof) are amenable to the simple impact of a rubber mallet on the reverse side of the defect. Another thing - bumps on the thresholds, wings, arches. Here other methods are used, one of which is a reverse hammer spotter. The finished tool is expensive, so the craftsmen design it on their own.

What is a spotter

This is a modern high-tech equipment focused on spot welding of thin metal. Bodybuilders use equipment to restore the original geometry of a bent car body.

Key features and specifications of the spotter

The device works without the usual electrodes: by touching the surface, the device produces the strongest current discharge. Under the action of an impulse, the metal melts. If a removable tip of the reverse hammer is put on the end of the equipment, then simultaneously with the discharge, the nozzle straightens the concavities. Warming up and cooling down at the point of contact occur simultaneously: the metal is immediately given its former rigidity, and the original shape is restored. So the reverse hammer and welding machine in tandem create the most efficient leveling fixture.

The device is characterized by two parameters:

- Current strength (A).

- Power, kWt).

The second indicator determines the functionality of the reverse hammer spotter:

- at standard power, the installation acts as a spotter;

- if you increase the indicator, this is already spot welding equipment.

Spotter for body repair

Depending on the type of electric current converter, inverter and transformer spotters are distinguished. If you are interested in the manufacture of the installation, take the second type of converter as a basis.

DIY instructions

The key advantage of the tool is the ease of leveling bent bodies. Correcting geometry in this way is cheaper than replacing and painting body parts.

The device looks like this: a case from which two electrical wires come out. The first is the mass, the second is attached to the gun, which the bodybuilder manipulates.

How the equipment works: they remove the battery from the car, bring the mass to the body. There is electricity going to the gun. By pressing the trigger, the master produces an electrical discharge. At the same time, small tubercles are knocked out on the panel with a reverse-action hammer - the discharge falls exactly on them. The metal becomes thicker, acquires its original shape, and the tubercles are cleaned after the procedure.

Knowing the principle of the installation, it is not difficult to assemble the equipment.

Spotter circuit

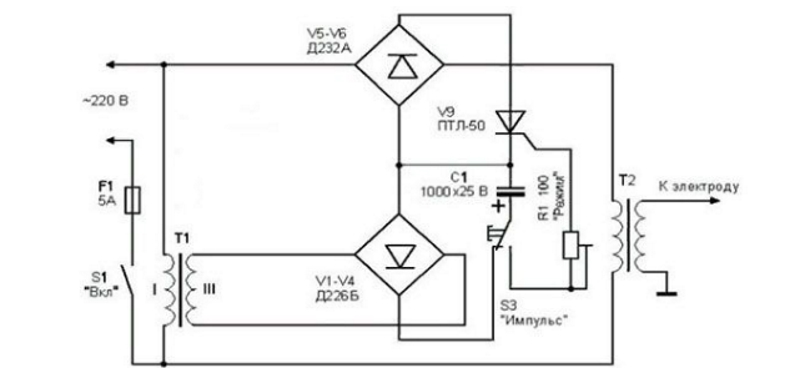

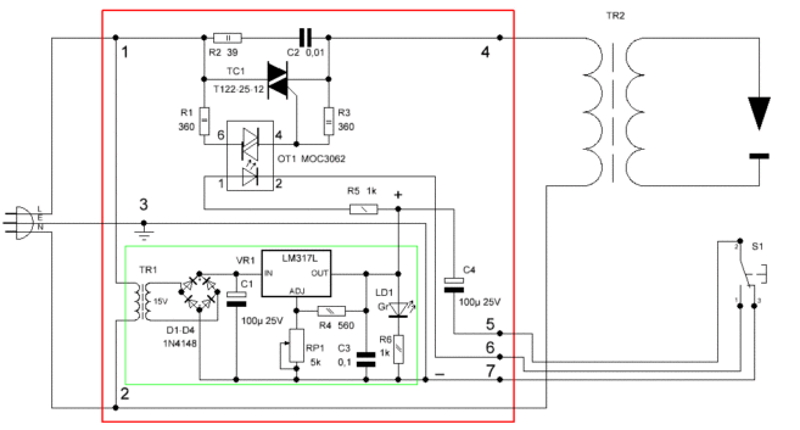

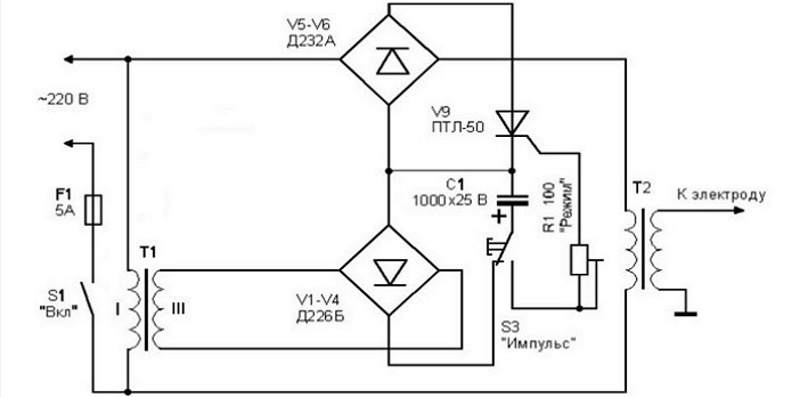

Review and work through the presented wiring diagrams.

The power supply in the diagram looks like this:

Power Supply Diagram

Spotter scheme:

Spotter circuit

You see two diagonals: the power of the current converter of one of them is higher than the second. Therefore, the converter (T1) receives voltage after the equipment is turned on. The current is converted and from the secondary winding enters the capacitor C1 through the diode bridge. The capacitor stores electricity. The voltage in the converter is passed because the thyristor is closed.

To start welding, you need to open the thyristor. By manipulating the switch, disconnect C1 from charging. Connect to thyristor circuit. The current generated by the discharge of the capacitor will go to its electrode and open the latter.

Accessories

Other necessary components to make a do-it-yourself reverse hammer for a spotter:

- pistol - the working part of the equipment;

- welding cables - 2 pcs.;

- reverse hammer;

- 30 amp relay;

- diode bridge (can be removed from an old car);

- two-position contractor;

- BU with thyristor.

Check the compatibility of the threaded connections of the components.

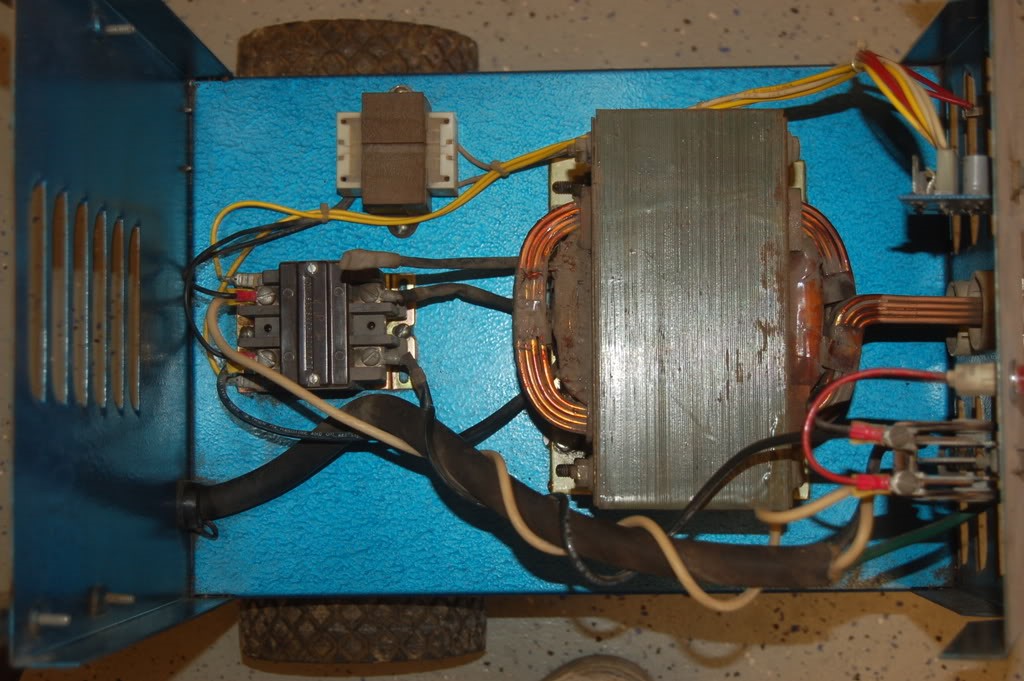

spotter transformer

Usually, the rewinding of the current converter is entrusted to electricians. But, having a copper magnetic circuit, unnecessary coils, you can do everything yourself:

- Cut off the sidewalls of the coils, glue the parts, wrap with a cloth, fill with varnish. To prevent the wire from bending, stick cardboard on the corners.

- Wind the magnetic circuit in rows, laying each with insulating material: this will protect the coil from interturn short circuits.

- Make a branch wire.

- In the same way, carry out the secondary winding with a branch.

- Remove the magnetic circuit from the coil.

- Impregnate the structure with shellac.

spotter transformer

Connect the primary winding to the power supply of the device, the secondary to the output terminals. Given this circumstance, calculate the length of the outgoing wires.

Блок управления

Insert wires, contacts for the "start" key and other switches into the control unit: adjust the current strength, the time of the action of the electrical impulse on the surface to be straightened.

Chassis

Homemade reverse hammer spotter should have a functional and aesthetically attractive body - it is a box made of plastic, metal, wood. The main thing is that it has a hinged cover for access to the internal contents: a transformer, a control unit, microcircuits, wires and contacts. Outside, place the control buttons. Don't forget to treat your apparatus with a dielectric material.

A suitable option for the case is a system unit from a computer, but there are other ideas.

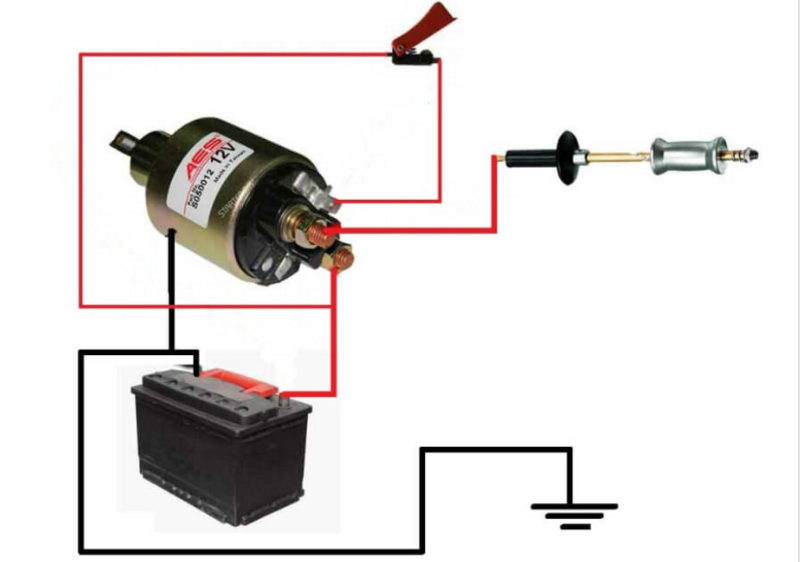

From battery

For the operation of such a device, mains voltage is not needed. You will need an old battery and a solenoid relay.

Connect as follows:

- On the "minus" connect the body of the current breaker and the welding wire. At the end of the latter, weld a contact designed for attachment to a defective area of \uXNUMXb\uXNUMXbthe car.

- There are two bolts on the relay. Attach the “plus” of the battery to one, to the other - an electrical wire that stretches to a hammer or gun. The length of this cable is up to 2,5 m.

- Also, from the positive terminal, run a wire to the on/off switch of the unit. The length of the wire is arbitrary.

Schematic representation of a battery spotter:

Battery spotter circuit

From a household microwave

Old microwave ovens will come in handy in the construction of a spotter. You will need transformers (2 pcs.) And the body of one furnace.

Wind new secondary windings on the current converters, otherwise the current will not be enough for a powerful discharge.

Assemble all components according to the scheme and fix on a dielectric sheet. Place the structure in the microwave body.

The electric circuit of the spotter from the microwave oven:

Electrical diagram of a microwave oven spotter

Manufacturing process

When the transformer, control unit and housing are ready, proceed to the manufacture of working elements of the equipment.

Welding gun

This component of the spotter is called the studder. Make it with a glue gun. Cut out two identical rectangles from thick (up to 14 mm) textolite. In one piece, create a niche for mounting the electrode (this is a copper rod with a cross section of 8-10 mm) and a switch that delivers a discharge. Make a bracket as a fastener.

The welding gun is attached to the spotter with an electric wire: thread the end of the latter into the hole in the bracket, strip, solder.

reverse hammer

Get a foam spray gun. Further step by step:

- Cut off the foam can.

- In its place, weld racks to the gun - 3 rods with a diameter of up to 10 mm.

- Bend a ring 100 mm in diameter from the rest of the same rod, weld it to the rods.

- Wrap the ring with electrical tape so that it does not weld to it during the process of leveling the surface.

- Cut off the curved part of the mounting gun, attach the electric wire.

Do-it-yourself reverse hammer with spot welding is ready.

Electrode

By electrode is meant a non-fusible element in its usual form. In a spotter, these are nozzles or tips of a cylindrical shape made of brass. Nozzles are used depending on the type of welding fasteners: washers, studs, nails.

The simplest forms can be made independently, complex ones can be ordered from a turner.