Planetary gearbox - a space solution for efficient operation? What is a planetary gear?

Content

Efficient torque transmission is associated with various operating conditions. Therefore, gears are used in a huge number of devices. They may have a different structure, but usually their principle of operation is very similar - they allow you to make translations. The simplest solution of this type is a single-speed transmission with one pair of wheels. As industrial and automotive technology developed, other inventions appeared. They are used in power tools, bicycles, combustion vehicles and industrial automation.

Planetary or planetary gear

A planetary gear is a fairly complex set of gears that is different from other mechanical gear options. Its other name is planetary gear. Why is that? It comes from the structure and how the system works. In most cases, other units of this type have gears permanently attached. Everything is different here. Worker mods inside do not have a fixed location and can dynamically move relative to each other.

Planetary gear - design and principle of operation

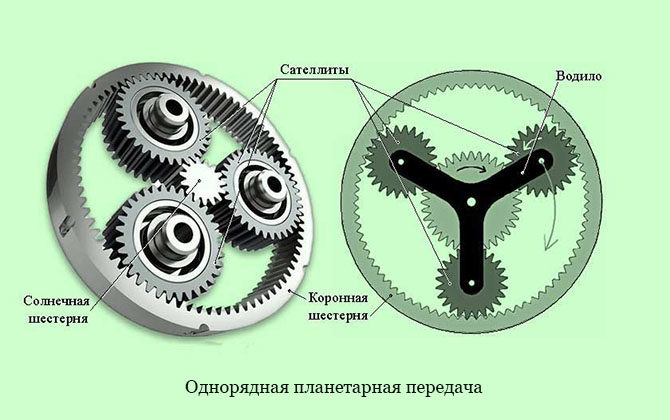

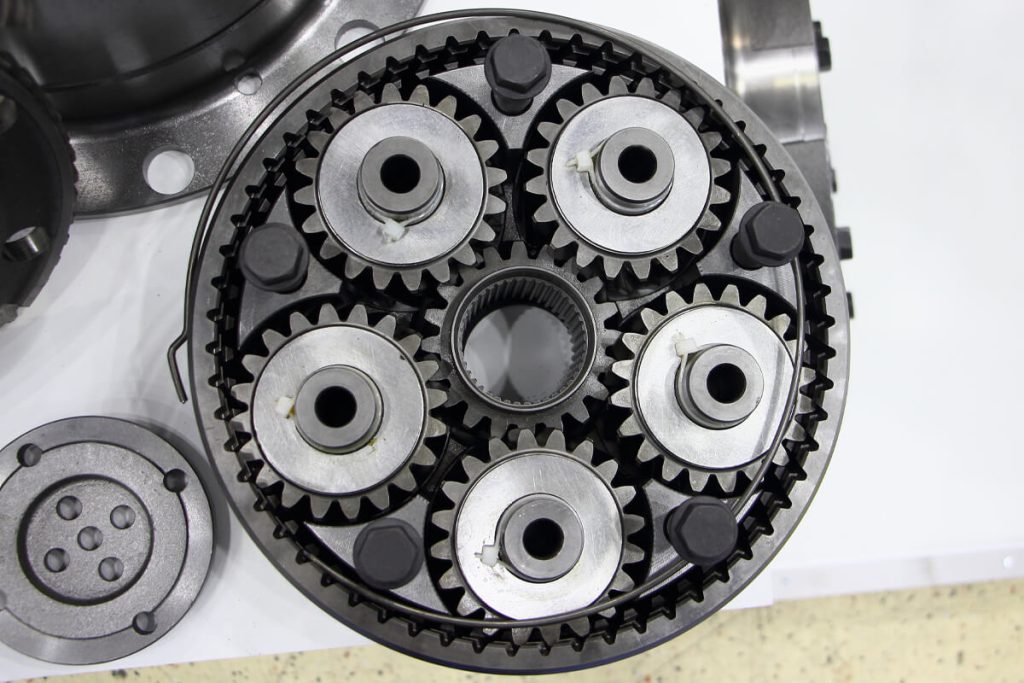

The first mandatory element of the design of the planetary gear is the ring gear. They are sometimes called the crown wheel. Its task is to cover the entire assembly and escape it. This part has teeth on the inside. Inside is the sun gear, which has teeth on the outside. Around it are satellites that provide indirect engagement of the sun gear with the ring gear. Planetary gears are characterized by the presence of several satellites, the number of which usually does not exceed 5. Their distribution is uniform and falls within a certain angular value.

In order for each of the gears to move relative to each other, the shafts on which they are mounted must be able to stop. Therefore, both the ring gear, and the sun gear shaft, and the pinion basket shaft are called central.

Planetary gear - features and applications

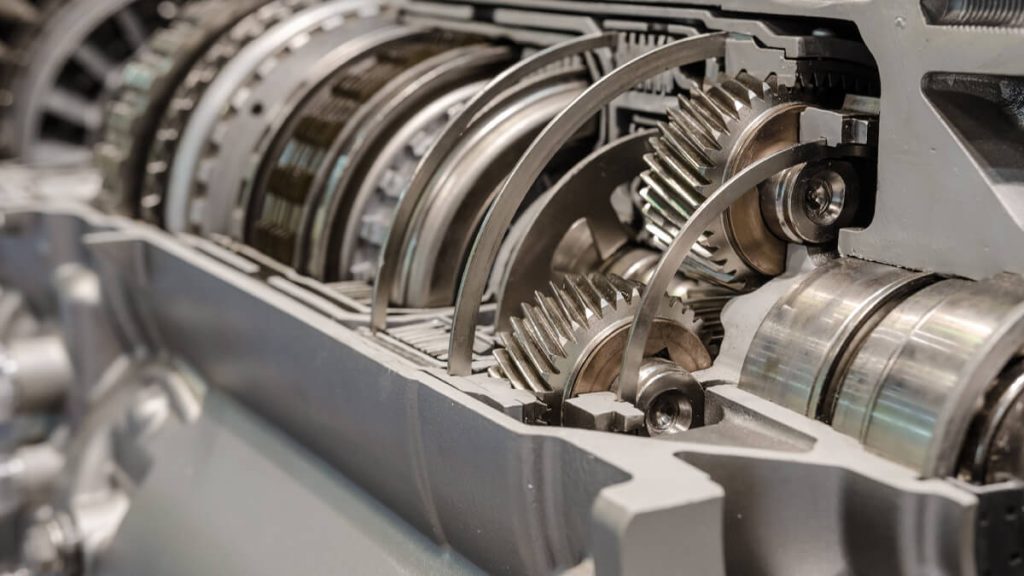

Due to their compact design and relatively low weight, each planetary gear can be used in a wide range of applications. Used to build gearboxes with large gears. This is due to the high kinematic capabilities of the device. They are used in the creation of automatic transmissions with variable speed transmission. The method of operation is to brake and connect cells under load without the need to block the flow of power.

Benefits of planetary gears

The big advantage of this solution is the realization of high torque coefficients. Gears are also characterized by low inertia. The visible advantages of planetary gearboxes also include a low percentage of failures due to a uniform power load on the satellites and gears. Due to this, all the torque is not transmitted to one mode, but is supplied to several interacting wheels. Using multiple gears also gives you the option to select any gear thanks to the multiple planetary gears.

It is worth noting that this unit is also distinguished by quiet operation. The gear ratio of the planetary gear allows it to be used in the gearboxes of many vehicles and 4×4 vehicles as differentials. In addition, they have a huge number of other applications in drives used in automation.

Defects in planetary gears

Such a compact and precise planetary gear design is unfortunately more expensive than competing applications of other types. This is due to high design requirements, the integration of individual gear elements with different diameters and number of teeth, as well as the need to use several planetary assemblies to achieve a certain number of gears. Changing them is also not easy and it is necessary to implement the appropriate number of videos. One planetary gear can provide 3 forward gears and one reverse gear, which limits its use in the automotive industry.

So, now you know how the mechanism works. Such a constructive solution determines its application in many industries, not only in the automotive industry. If you have such a device in your car, remember to use the device correctly. Despite its high strength, it can be destroyed.