Why does a hiss sound when you press the brake and how to fix it

According to the existing stereotype, only air escaping under pressure from leaks in pneumatic devices can hiss. Indeed, the brakes of trucks and large buses hiss loudly because they use pneumatic actuators, but cars have hydraulic brakes. However, there are also sources of such a sound, they are connected with a vacuum amplifier.

Causes of hissing

The appearance of this sound can be both a sign of the regular normal operation of the vacuum brake booster (VUT), and a malfunction. The difference is in the nuances, and clarification requires diagnostics. It is quite simple, you can do it yourself.

Silent operation of the VUT is possible, but there is no need for developers to always strive for this. The most common measures are soundproofing the engine compartment where the amplifier is located, as well as finalizing its typical design to reduce the sound of air flowing under pressure.

All this increases the cost of the unit and the car as a whole, so budget cars have the right to hiss a little when you press the brakes.

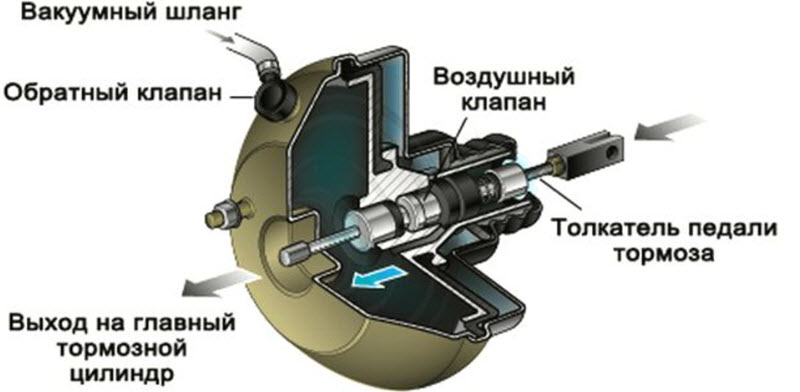

VUT has an elastic diaphragm dividing it into two chambers. One of them is under negative atmospheric pressure. For this, the vacuum that occurs in the throttle space of the intake manifold is used.

The second, when you press the pedal through the opening bypass valve, receives atmospheric air. The difference in pressure across the diaphragm and the stem connected to it creates an additional force that adds up to what is transmitted from the pedal.

As a result, an increased force will be applied to the piston of the main brake cylinder, which will facilitate pressing and accelerate the operation of the brakes both in service mode and in an emergency.

The rapid transfer of the air mass through the valve into the atmospheric chamber will create a hissing sound. It quickly stops as the volume fills up and is not a sign of a malfunction.

The effect is complemented by the “expenditure” of part of the vacuum in the amplifier and the associated slight drop in speed if the engine was running with a closed throttle. The mixture will be somewhat leaner due to the pumping of a small amount of air from the VUT into the intake manifold. This drop is immediately worked out by the idle speed controller.

But if the hiss is unusually long, loud, or even constant, then this will indicate the presence of a malfunction associated with depressurization of the volumes. There will be an abnormal air leak into the manifold, which will upset the balance of the engine control system.

This air is not taken into account by the flow sensors, and the readings of the absolute pressure sensor will go beyond the limits allowed for this mode. The reaction of the self-diagnosis system is possible with the emergency indicator flashing on the dashboard, and the engine speed will change randomly, interruptions and vibrations will occur.

How to find a malfunction in the brake system

The method for diagnosing the causes of abnormal hiss is to check the vacuum amplifier.

- The tightness of the VUT is such that it is able to work out several cycles of amplification (pressing the pedal) even with the engine turned off. This is what is being checked.

It is necessary to stop the engine and apply the brake several times. Then leave the pedal depressed and start the engine again. With a constant effort from the foot, the platform should drop a few millimeters, which indicates the help of a vacuum that has arisen in the intake manifold or a vacuum pump that has started working if it is used on engines where there is not enough vacuum due to the design.

- Listen for a hiss from the knot. If the pedal is not pressed, that is, the valve is not activated, there should be no sound, as well as air leaks into the manifold.

- Blow out the check valve installed in the vacuum pipeline from the manifold to the VUT body. It should only let air through in one direction. The same can be done without dismantling the fitting with the valve. Stop the engine with the brake pedal depressed. The valve should not let air out of the manifold, that is, the force on the pedals will not change.

- Other malfunctions, for example, a leaky VUT diaphragm (membrane) in modern cars, cannot be repaired and separately diagnosed. A defective amplifier must be replaced as an assembly.

The already mentioned engines with low manifold vacuum, such as diesel engines, have a separate vacuum pump. Its serviceability is checked by noise during operation or instrumentally, using a pressure gauge.

Troubleshoot problems

If the boost system fails, the brakes will work, but the operation of such a vehicle is prohibited, this is a very unsafe condition.

Unusually increased pedal resistance can disrupt the worked out reactions of even an experienced driver in a sudden potentially emergency situation, and beginners will not be able to fully use the full effectiveness of the braking system, because it will take a very large effort to work the mechanisms until the ABS is turned on.

As a result, the brake response time, as one of the components of the emergency deceleration process, will greatly affect the final stopping distance, where every meter to the obstacle is important.

Repair consists of replacing the parts that cause abnormal air leakage. There are few of them, this is a vacuum hose with fittings and a check valve, as well as directly assembled VUT. Other recovery methods are not allowed. Reliability is above all here, and only new standard parts can provide it.

If the problem is in the amplifier, then it must be removed and replaced without purchasing remanufactured components or cheap products from little-known manufacturers.

The unit is simple, but requires the use of high-quality materials and proven assembly technology, which cannot be achieved in terms of cost savings.

The same can be said about the rarefaction pipeline. The fitting on the manifold must be securely fixed according to the factory technology, and not glued in a garage after being disconnected from old age.

The valve and vacuum hose are used specifically designed for this car model, indicating compatibility by cross-numbers.

No universal repair hoses are suitable, a certain flexibility, chemical resistance to hydrocarbon vapors, external and thermal influences, and durability are needed. The valve and hose seals must also be replaced. What is needed is not sealant and electrical tape, but new parts.