Why does the starter clicks, but does not turn the engine

Content

Often, starting a car is accompanied by pronounced malfunctions in the operation of the key starting device - the starter. Malfunctions of its operation can manifest themselves in the form of characteristic clicks at the moment the starter circuit is closed with the ignition key. Sometimes, after several persistent attempts, the engine can be brought to life. However, after a while, there may come a moment when the car simply will not start.

In order to exclude this possibility and restore the operation of the device, it is necessary to carry out a number of diagnostic measures and eliminate the breakdown. This will be discussed in the presented article.

How does the engine start with a starter

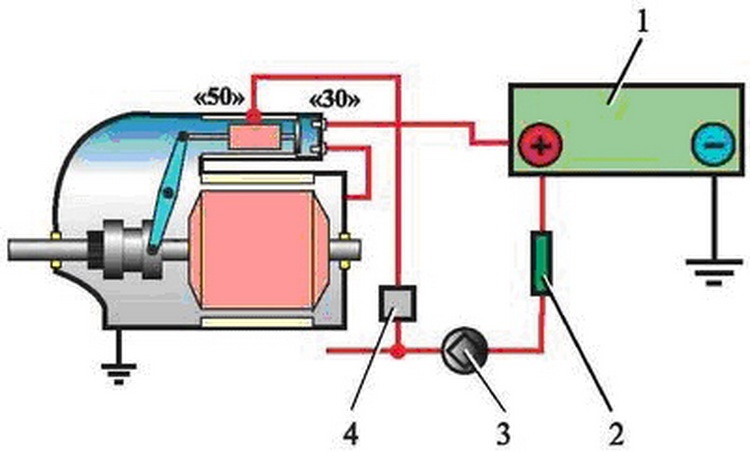

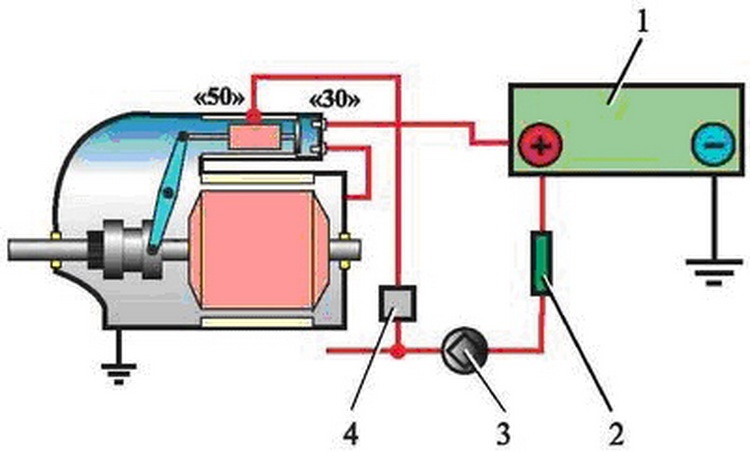

The starter is a DC electric motor. Thanks to the gear drive, which drives the engine flywheel, it gives the crankshaft the torque necessary to start the engine.

How does the starter engage with the flywheel, thereby starting the power plant?

To answer this question, for starters, it is necessary to get acquainted in general terms with the device of the engine start unit itself.

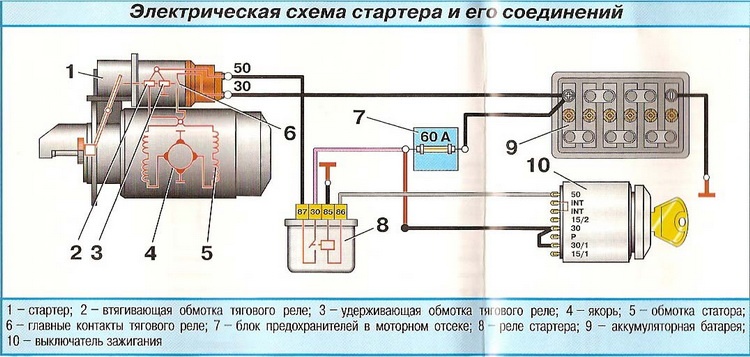

So, the main working elements of the starter include:

- DC motor;

- retractor relay;

- overrunning clutch (bendix).

The DC motor is powered by a battery. Voltage is removed from the starter windings using carbon-graphite brush elements.

The retractor relay is a mechanism inside which there is a solenoid with a pair of windings. One of them is holding, the second is retracting. A rod is fixed on the core of the electromagnet, the other end of which acts on the overrunning clutch. Two powerful underwater contacts are mounted on the relay case.

An overrunning clutch or bendix is located on the anchor of the electric motor. This knot owes such a tricky name to one American inventor. The freewheel device is designed in such a way that at the moment the engine is started, its drive gear disengages from the flywheel crown, remaining intact.

If the gear did not have a special clutch, it would have become unusable after a short operation. The fact is, at start-up, the overrunning clutch drive gear transmits rotation to the engine flywheel. As soon as the engine started, the flywheel rotation speed increased markedly, and the gear would have to experience heavy loads, but then the freewheel comes into play. With its help, the bendix gear rotates freely without experiencing any load.

What happens at the moment when the ignition key freezes in the “Starter” position? This causes current from the battery to be applied to the underwater contact of the solenoid relay. The movable core of the solenoid, under the influence of a magnetic field, overcoming the resistance of the spring, begins to move.

This causes the rod attached to it to push the overrunning clutch towards the flywheel crown. At the same time, the power contact of the retractor relay is connected to the positive contact of the electric motor. As soon as the contacts close, the electric motor starts.

The bendix gear transfers rotation to the flywheel crown, and the engine starts to work. After the key is released, the current supply to the solenoid stops, the core returns to its place, disengaging the overrunning clutch from the drive gear.

Why the starter does not rotate the engine, where to look

During prolonged use of the starter, problems may arise with its start. It happens, and so, that he does not show signs of life at all, or “turns idle”. In this case, it is necessary to carry out a series of diagnostic measures aimed at identifying the malfunction.

In the event that the armature of the electric motor of the device does not rotate, you should make sure that:

- ignition lock;

- Battery;

- mass wire;

- the solenoid relay.

It is advisable to start diagnostics with a contact pair of the ignition switch. Sometimes the oxide film on the contacts prevents the passage of current to the starter solenoid relay. To exclude this cause, it is enough to look at the ammeter readings at the moment the ignition key is turned. If the arrow deviates towards the discharge, then everything is in order with the lock. Otherwise, there is a reason to make sure it is working.

The starter motor is designed for high current consumption. In addition, a large value of current is spent on converting electrical energy into mechanical energy. Thus, the features of the starter operation impose certain requirements on the battery. It must provide the necessary current value for its efficient operation. If the battery charge does not correspond to the working value, starting the engine will be fraught with great difficulties.

Interruptions in the operation of the starter may be associated with a lack of mass with the body and engine of the car. The ground wire must be firmly fixed to the cleaned metal surface. You also need to make sure the wire is intact. It should not have visible damage and foci of sulphation at the attachment points.

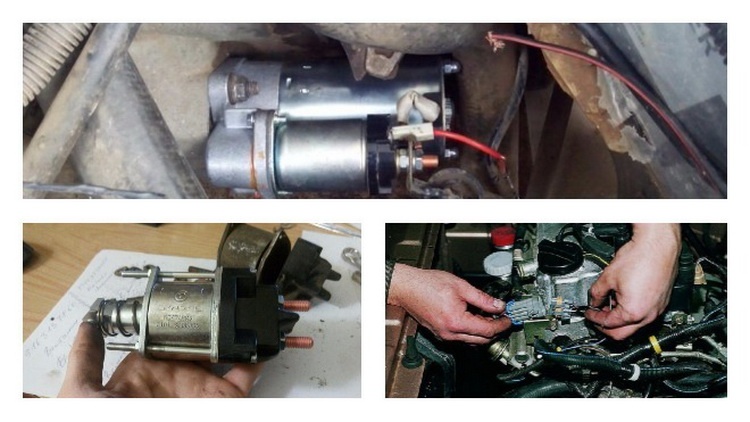

You should also check the operation of the solenoid relay. The most distinct sign of its malfunction is the characteristic clicking of the solenoid core at the moment of closing the contacts of the ignition switch. To repair it, you will have to remove the starter. But, don't jump to conclusions. For the most part, the malfunction of the "retractor" is associated with the burning of the contact group, the so-called "pyatakov". Therefore, first of all, you need to revise the contacts.

Low battery

A bad battery can cause your car's starter to fail. Most often, it manifests itself in the winter season, when the battery experiences the greatest load.

Diagnostic measures in this case are reduced to:

- checking the density of the battery electrolyte;

- checking the battery charge level.

Depending on the operating conditions, the density of the battery electrolyte should be the specified value. You can check the density with a hydrometer.

The value of the concentration of sulfuric acid for the middle band is 1,28 g/cm3. If, after charging the battery, the density in at least one jar turned out to be lower by 0,1 g / cm3 battery must be repaired or replaced.

In addition, it is necessary from time to time to monitor the level of electrolyte in banks. Failure to comply with this requirement may lead to the fact that the electrolyte concentration in the battery will become noticeably higher. This will lead to the fact that the battery will simply fail.

To check the battery level, just press the car horn. If the sound does not sit down, then everything is in order with him. This check can be backed up with a load fork. It should be connected to the battery terminals, and then apply the load for 5 - 6 seconds. If the "drawdown" of the voltage is not significant - up to 10,2 V, then there is no reason for concern. If it is below the specified value, then the battery is considered defective.

Malfunction in an electric chain of management of a starter

The starter refers to the electrical equipment of the car. There are frequent cases when interruptions in its operation are directly related to damage to the control circuit of this device.

To detect this kind of malfunction, you should:

- make sure that there is no damage to the power wire;

- check the performance of the contact pair;

- make sure the fuse is good.

To identify the problems presented, it is advisable to use a multimeter. For example, in order to audit the entire starter electrical circuit, it is advisable to ring all the connecting wires for a break. To do this, the tester should be set to ohmmeter mode.

Particular attention should be paid to the contacts of the ignition switch and the retractor relay. There are times when the return spring, as a result of wear, does not allow the contacts to touch properly.

If clicks of the retractor relay are traced, there is a possibility of burning the power contacts. To verify this, it is enough to close the positive terminal of the “retractor” with the terminal of the stator winding of the electric motor of the device. If the starter starts, the fault is the low current carrying capacity of the contact pair.

Starter problems

Problems with the starter can be caused by both mechanical damage to its working elements, and malfunctions in its electrical equipment.

Mechanical damage includes:

- slippage of the freewheel;

- jamming of the freewheel drive lever;

- increased wear of the armature bushings of the electric motor.

Signs indicating slipping of the overrunning clutch are expressed in the fact that when the key is turned to the “starter” position, only the electric motor of the unit starts, and the bendix refuses to come into contact with the flywheel crown.

The elimination of this problem will not do without removing the device and revising the overrunning clutch. It often happens that in the process of work, its components are simply contaminated. Therefore, sometimes to restore its performance, it is enough to wash it in gasoline.

The overrunning clutch lever is also subject to increased mechanical wear. The symptoms of this malfunction will be the same: the starter motor rotates, and the bendisk refuses to engage with the flywheel ring. Stem wear can be compensated for with repair sleeves. But, it is best to replace it. This will save time and nerves for the owner.

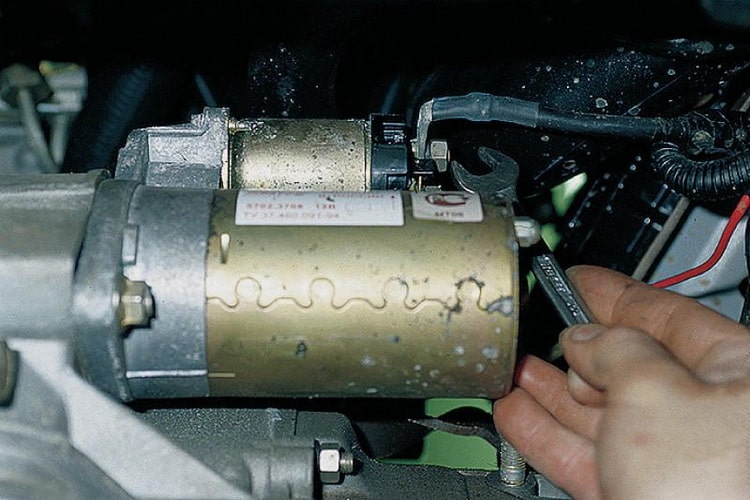

The starter armature rotates inside copper-graphite bushings. Like any other consumable, bushings wear out over time. Untimely replacement of such elements can lead to serious problems, up to replacing the starter.

As the wear of the anchor seats increases, the likelihood of contact of insulated parts increases. This leads to the destruction and burnout of the anchor winding. The first sign of such a malfunction is increased noise when starting the starter.

Starter electrical faults include:

- interturn circuit;

- increased collector wear;

- wear / loose brushes;

- breakage of wires in the winding.

If the insulation of the conductive elements of the starter is broken, it completely loses its performance. Turn-to-turn short circuit or breakage of the stator winding, as a rule, is not spontaneous. Such breakdowns can be caused by increased production of starter working units.

The brush-collector unit deserves special attention. During continuous operation, carbon-graphite sliding contacts wear out noticeably. Their untimely replacement can lead to damage to the collector plates. In order to visually know the performance of the brushes, in most cases it is necessary to dismantle the starter.

It would not be superfluous to say that some craftsmen, endowed with "colossal intelligence", change traditional graphite brushes to copper-graphite analogues, citing the high wear resistance of copper. The consequences of such innovation will not be long in coming. In less than a week, the collector will lose its function forever.

Solenoid relay

All malfunctions in the operation of the solenoid relay can be divided into four categories:

- operational wear of working elements;

- burnout of contact elements;

- mechanical damage to individual nodes;

- violation of the integrity of the electromagnet winding.

Brushes

During the operation of the device, the starter brush-collector assembly needs systematic diagnostics and timely maintenance, which involves the following actions:

- timely replacement of brushes;

- checking the collector assembly to detect burning and contamination;

- providing the necessary clamping force of the current-collecting elements.

Checking the performance of the brushes is done using a simple automotive 12 V light bulb. One end of the bulb should be pressed against the brush holder, and the other end should be attached to the ground. If the light is off, the brushes are fine. The light bulb emits light - the brushes are "run out".

Winding

As mentioned above, the starter winding itself rarely fails. Problems with it are often the result of mechanical wear of individual parts.

Nevertheless, in order to make sure of its integrity, in the event of a breakdown on the case, it is enough to check it with an ordinary ohmmeter. One end of the device is applied to the winding terminal, and the other to ground. The arrow deviates - the integrity of the wiring is broken. The arrow is rooted to the spot - there is no cause for concern.

Starter malfunctions, if we exclude factory defects, are mostly the result of its improper operation or improper maintenance. Timely replacement of consumables, careful attitude, and compliance with factory work standards will significantly increase its service life and save the owner from unnecessary expenses and nervous shocks.