The principle of operation of the brake system on the VAZ 2107

Content

Any vehicle is equipped with a high-quality braking system - moreover, the operation of a car with faulty brakes is prohibited by traffic rules. The VAZ 2107 has a brake system that is outdated by modern standards, but it copes well with its main functions.

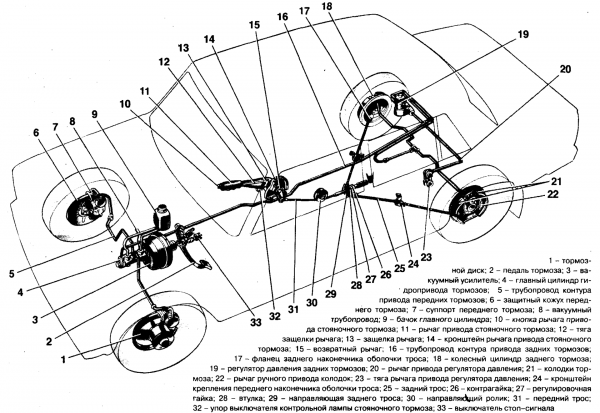

Brake system VAZ 2107

The braking system on the "seven" ensures safety when driving. And if the engine is needed for movement, then the brakes are for braking. At the same time, it is very important that braking is also safe - for this, brake mechanisms were installed on the VAZ 2107, using the friction forces of various materials. Why was it necessary? Only in this way in the 1970s-1980s it was possible to quickly and safely stop a car rushing at high speed.

Brake system elements

The braking system "seven" consists of two main units:

- service brake;

- parking brake.

The main task of the service brake is to quickly reduce the speed of the machine to a complete stop. Accordingly, the service brake is used in almost all cases of driving a car: in the city at traffic lights and parking lots, when the speed of movement in a traffic flow decreases, when passengers disembark, etc.

The service brake is assembled from two elements:

- Braking mechanisms are different parts and assemblies that have a stopping effect on the wheels, as a result of which braking is carried out.

- A drive system is a series of elements that the driver controls to brake.

The "seven" uses a dual-circuit braking system: disc brakes are installed on the front axle, and drum brakes on the rear axle.

The task of the parking brake is to completely block the wheels on the axle. Since the VAZ 2107 is a rear-wheel drive car, in this case the wheels of the rear axle are blocked. Blocking is necessary when the car is parked in order to exclude the possibility of arbitrary movement of the wheels.

The parking brake has a separate drive, which is not connected in any way with the drive part of the service brake.

How does it all work

You can briefly describe the principle of operation of the VAZ 2107 brake system as follows:

- The driver, while driving on the highway, decides to slow down or stop.

- To do this, he presses the brake pedal with his foot.

- This force is immediately applied to the valve train of the amplifier.

- The valve slightly opens the supply of atmospheric pressure to the diaphragm.

- The diaphragm acts on the stem through vibrations.

- Further, the rod itself exerts pressure on the piston element of the master cylinder.

- The brake fluid, in turn, under pressure begins to move the pistons of the working cylinders.

- The cylinders are expanded or pressed down due to pressure (depending on whether disc or drum brakes are on a given axle of the car). The mechanisms begin friction between the pads and discs (or drums), due to which the speed of movement is reset.

Features of braking on the VAZ 2107

Despite the fact that the VAZ 2107 is far from the most modern and safe car, the designers made sure that the brakes work flawlessly in emergency cases. Just due to the fact that the system on the "seven" is two-circuit (that is, the service brake is divided into two parts), braking is possible even with one part of the circuit, if the other is depressurized.

Therefore, if air has entered one of the circuits, then only it needs to be serviced - the second circuit is working properly and does not need additional maintenance or pumping.

Video: the brakes failed on the "seven"

Major faults

The most common malfunction of the VAZ 2107 brake system is the ineffectiveness of the braking itself. The driver himself can notice this malfunction by eye:

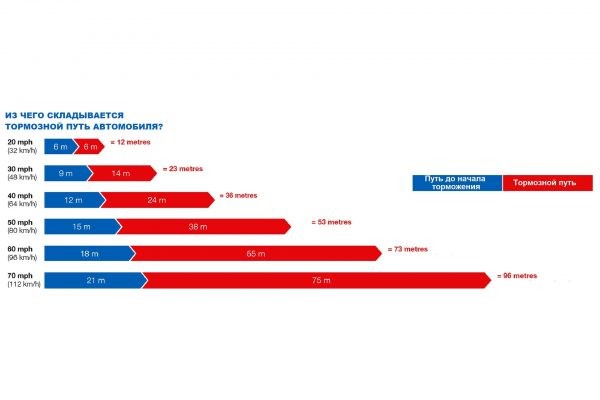

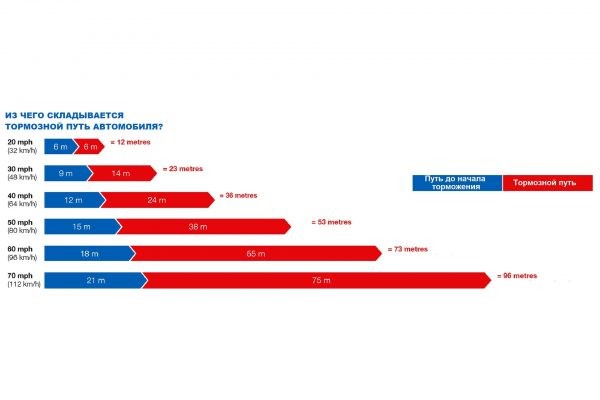

- when braking, the braking distance increases;

- the braking process itself takes longer than before.

This malfunction can be caused by a number of breakdowns:

- there are air locks in the system;

- leakage of brake fluid;

- severe wear of the pads;

- breakage of cylinders.

The braking distance was determined for the VAZ 2107: at a speed of 40 km / h on a flat and dry road, the braking distance should not exceed 12.2 meters until the car comes to a complete stop. If the path length is longer, then it is necessary to diagnose the performance of the braking system.

In addition to ineffective braking, other malfunctions can also be observed:

- strong grinding (noise) when depressing the brake pedal;

- dodging the car to the sides when slowing down;

- the relaxed brake pedal lowered down;

- vibrations and jerks when pressing the pedal.

The device of the VAZ 2107 brake system: the main mechanisms

The braking system of the "seven" includes many small parts. Each of them serves a single purpose - to protect the driver and people in the cabin during braking or parking. The main mechanisms on which the quality and efficiency of braking depend are:

- master cylinder;

- amplifier;

- regulator;

- pads;

- disks;

- drums;

- pedal;

- highways.

Master cylinder

The master cylinder body works in direct communication with the amplifier. Structurally, this element is a cylindrical mechanism to which the brake fluid supply and return hoses are connected. Also from the surface of the master cylinder there are three pipelines leading to the wheels.

There are piston mechanisms inside the master cylinder. It is the pistons that are pushed out under the pressure of the fluid and create braking.

The use of brake fluid in the VAZ 2107 system can be explained simply: there is no need for complex drive units and the path of the fluid to the pads is maximally facilitated.

Vacuum booster

At the moment of pressing the brake by the driver, the amplification initially falls on the amplifier device. A vacuum amplifier is installed on the VAZ 2107, which looks like a container with two chambers.

There is a very sensitive layer between the chambers - a membrane. It is the initial effort - pressing the pedal by the driver - that makes the membrane vibrate and perform vacuum and pressure build-up of the brake fluid in the reservoir.

The design of the amplifier also has a valve mechanism that performs the main work of the device: it opens and closes the cavities of the chambers, creating the necessary pressure in the system.

Brake force regulator

The pressure (or brake force) regulator is mounted on the rear wheel drive. Its main task is to evenly distribute the brake fluid to the components and prevent the car from skidding. The regulator functions by reducing the available fluid pressure.

The drive part of the regulator is connected to the traction, while one end of the cable is fixed on the rear axle of the car, and the other - directly on the body. As soon as the load on the rear axle increases, the body begins to change position relative to the axle (skid), therefore the regulator thrust cable immediately presses on the piston. This is how the braking forces and the course of the machine are adjusted.

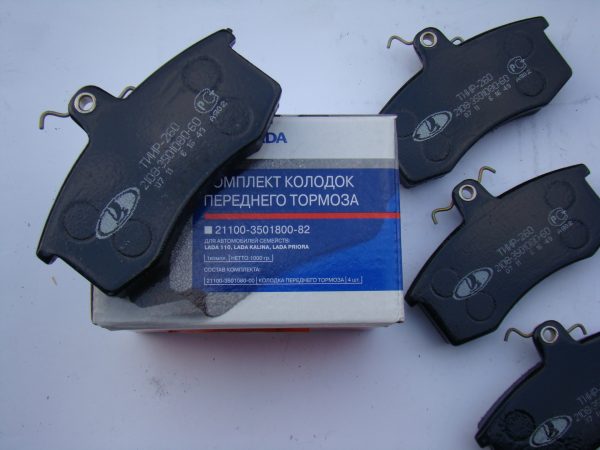

Brake pads

Pads on the VAZ 2107 are of two types:

- for front axle wheels for disc brakes;

- for rear axle wheels for drum brakes.

Read about ways to replace front brake pads: https://bumper.guru/klassicheskie-modeli-vaz/tormoza/zamena-perednih-tormoznyh-kolodok-na-vaz-2107.html

The pads are made of high-strength steel, a friction lining is attached to the base of the frame. Modern pads for the "seven" can also be bought in a ceramic version.

The block is attached to the disc or drum using a special hot melt adhesive, since when braking, the surfaces of the mechanisms can heat up to a temperature of 300 degrees Celsius.

Front axle disc brakes

The principle of operation of disc brakes on the VAZ 2107 is that pads with special linings, when you press the brake pedal, fix the brake disc in one position - that is, stop it. Disc brakes have several advantages over drum brakes:

- braking efficiency is not reduced due to overheating;

- high resistance when braking on snow, ice and water;

- unpretentious maintenance;

- large area of friction.

The disk is made of cast iron, so it weighs quite a lot, although it is very durable. The pressure on the disc is through the working cylinder of the disc brakes.

Rear axle drum brakes

The essence of the operation of the drum brake is identical to the disc brake, with the only difference being that the drum with pads is mounted on the wheel hub. When the brake pedal is depressed, the pads clamp very tightly onto the rotating drum, which in turn stops the rear wheels. The piston of the working cylinder of the drum brake also functions by using the pressure of the brake fluid.

More about replacing the brake drum: https://bumper.guru/klassicheskie-modeli-vaz/tormoza/kak-snyat-tormoznoy-baraban-na-vaz-2107.html

Brake pedal for VAZ 2107

The brake pedal is located in the cabin in its lower part. Strictly speaking, the pedal can have only one state provided by the manufacturer. This is its main position at the same level as the gas pedal.

By clicking on the part, the driver should not feel jerks or dips, because the pedal is the first mechanism in a series of several nodes for braking efficiency. Pressing the pedal should not cause effort.

Brake lines

Due to the use of a special fluid in the brakes, all elements of the braking system must be hermetically interconnected. Even microscopic gaps or holes can cause the brakes to fail.

Pipelines and rubber hoses are used to connect all elements of the system. And for the reliability of their fixation to the mechanism cases, fasteners made of copper washers are provided. In places where the movement of units is provided, rubber hoses are installed to ensure the mobility of all parts. And in places where there is no movement of nodes relative to each other, rigid tubes are installed.

How to bleed the brake system

Pumping the brakes on the VAZ 2107 (that is, eliminating air jams) may be required in several cases:

- after pouring new fluid into the tank;

- in the process of repairing any node of the system;

- due to fluid leaks;

- due to a sharp decrease in braking efficiency.

Bleeding the system can restore the performance of the brakes and make driving a safer car. For work you will need:

- ring wrench for 8/10;

- open end wrench 8/10;

- thin transparent hose;

- basin or bucket for waste fluid.

Work is recommended to be done together: one person will depress the pedal in the cabin, the other will drain the fluid from the fittings.

Schedule:

- Fill with brake fluid up to the "maximum" mark on the reservoir.

Before starting work, make sure that the brake fluid is filled to the maximum

Before starting work, make sure that the brake fluid is filled to the maximum - Get the car up on a lift. Make sure the car is secure.

The work process involves actions in the lower part of the body, so it is more convenient to perform pumping on a flyover

The work process involves actions in the lower part of the body, so it is more convenient to perform pumping on a flyover - Pumping on the VAZ 2107 is carried out wheel by wheel according to the following scheme: right rear, left rear, then right front, then left front wheel. This regulation must be followed.

- Thus, you first need to dismantle the wheel, which is located behind and on the right.

- Remove the cap from the drum, unscrew the fitting halfway with a wrench.

After removing the cap, it is recommended to clean the fitting with a rag from adhering dirt

After removing the cap, it is recommended to clean the fitting with a rag from adhering dirt - Pull a hose onto the fitting body, the second end of which must be transferred to a basin.

The hose must be securely attached to the fitting so that the liquid does not flow past

The hose must be securely attached to the fitting so that the liquid does not flow past - In the cabin, the second person must press the brake pedal several times - at this time, fluid will be supplied through the hose.

The braking mode activates the system - the liquid begins to flow through the open fitting

The braking mode activates the system - the liquid begins to flow through the open fitting - Screw the fitting back half a turn. At the same time, fully depress the brake pedal and do not release pressure until fluid stops flowing out.

It is important to press the brake until all the fluid has flowed out of the fitting.

It is important to press the brake until all the fluid has flowed out of the fitting. - After that, remove the hose, screw the fitting to the end.

- The procedure is carried out until air bubbles appear in the flowing liquid. As soon as the liquid becomes dense and without bubbles, pumping of this wheel is considered complete. Consistently need to pump the remaining wheels.

Learn how to change a brake caliper: https://bumper.guru/klassicheskie-modeli-vaz/tormoza/support-vaz-2107.html

Video: the right way to bleed the brakes

Watch this video on YouTube

Thus, the braking system on the VAZ 2107 is available for self-study and minimal repairs. It is important to monitor the natural wear and tear of the main elements of the system in time and change them before they fail.