Laying the wiring harness in the car is a real headache

Content

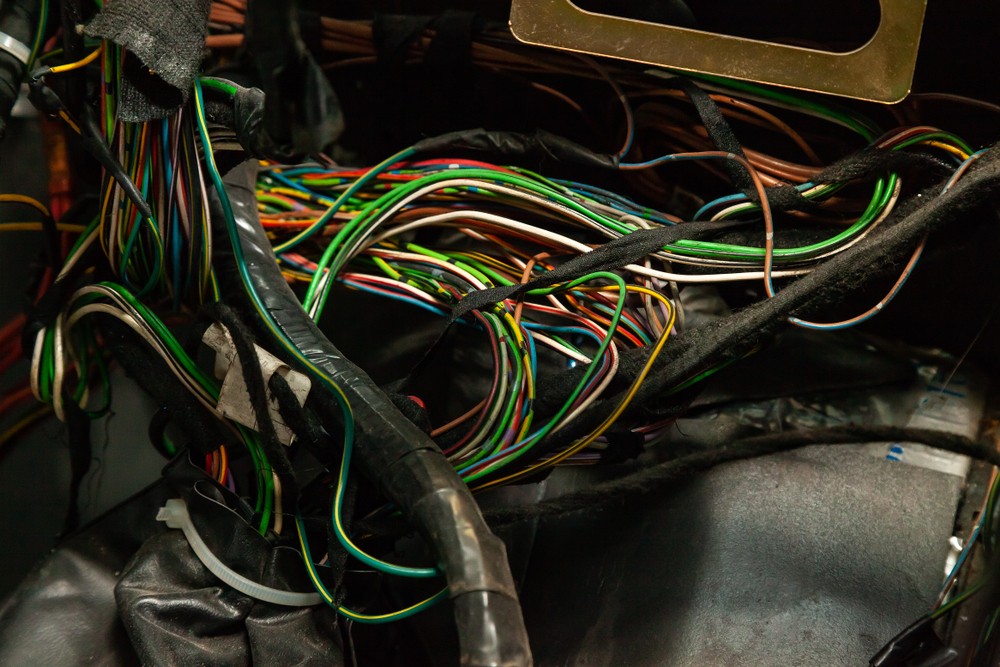

Running a car wiring harness is more than just connecting a car radio or subwoofer. The wiring harness is practically the nerve junction in the car, tying all the sensors, actuators, and consumers together. If mistakes are made when repairing or reinstalling the wiring harness, even the car may catch fire. Therefore: always know what you are doing and always make sure you are working cleanly.

When should the wiring harness be redone?

Replacing a complete wiring harness in a car is actually quite a rare repair. . Most often, this measure becomes necessary if your cable caught fire or an unknown short circuit simply cannot be found.

Moreover , the wiring harness is usually rerouted during a full restoration. Existing Classic Car Wiring usually already so brittle and oxidized that only a completely new harness can provide the necessary safety of operation.

Biting, rubbing, tearing are the enemies of cables

Wiring harness consists of power line and insulation . Electricity always flows in a circle, which is why it is called " chain ". The line must always run from the power source to the consumer and vice versa.

However, for cost reasons not every line is laid twice. Energy sources, i.e. alternator and battery connected to the car body on one side.

Thus, the metal sheet of the car is actually used as a return line - this is the famous "ground connection" . If a power line loses insulation due to a marten bite, crack, or abrasion, the current will complete the body.

The consumer is no longer supplied with power and fails . In this case, the cable heats up and expands at the point of damage. Thus, the damage continues and in the worst case can lead to a fire.

So test whoever binds himself forever...

Replacing the wiring harness - a very long and expensive repair . Is it true that a separate cable is very inexpensive . However, a complete, pre-assembled suspension can be very expensive.

You should refrain from buying used cars: the time it takes to tear the existing suspension off the old car is disproportionate to the benefit . And then you have a used part that you don't know how it has been used before.

Besides: Even wiring harnesses that have already been dismantled still have their price: you have to reckon with 200 – 1100 pounds for these spare parts .

Best idea: repair kits

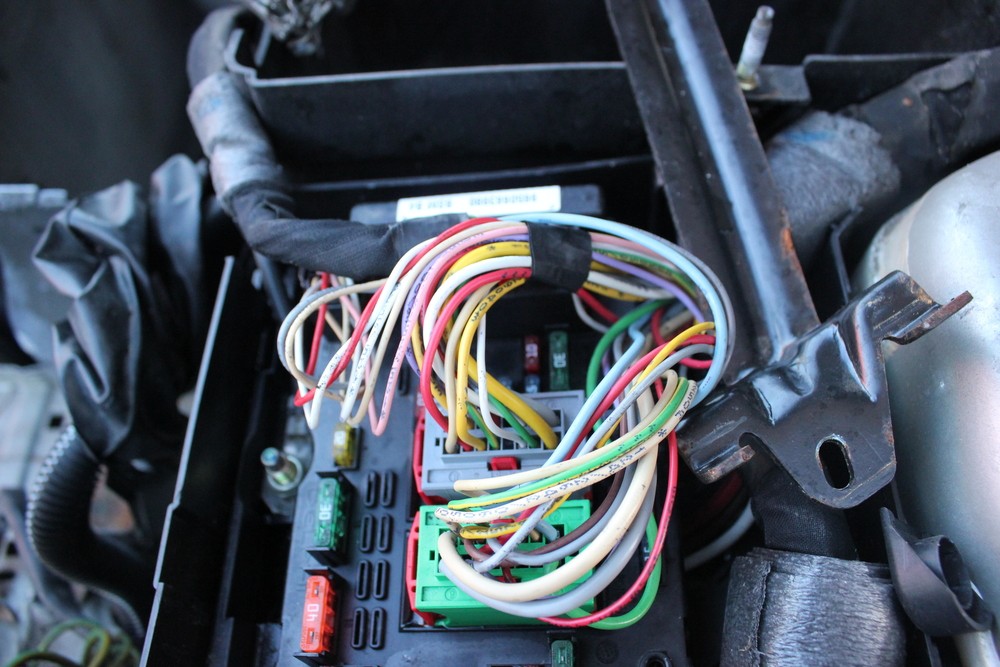

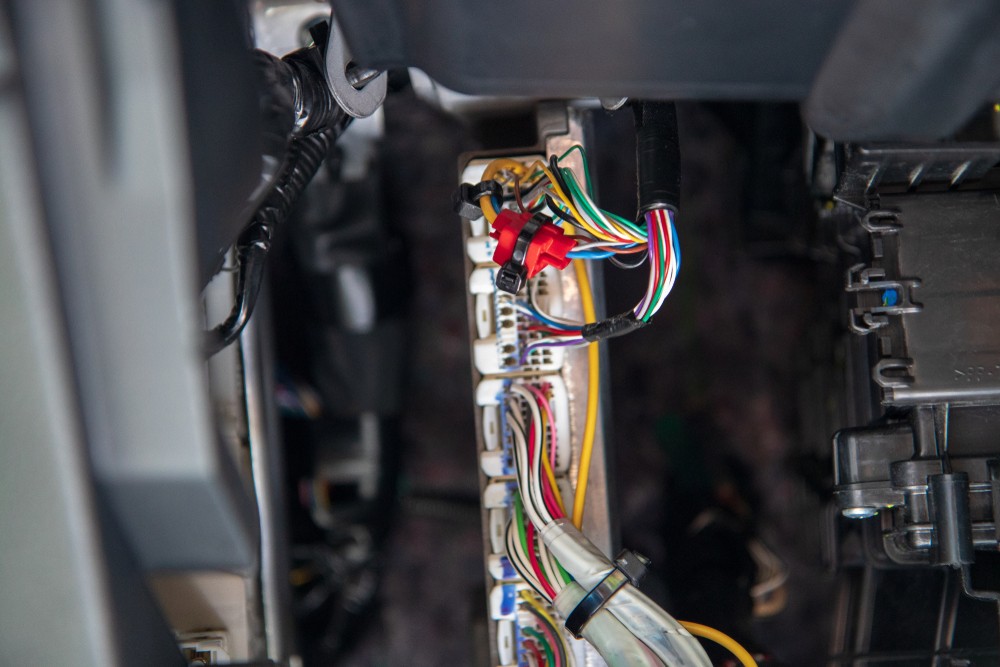

Fortunately, modern wiring harnesses are mostly modular. . This means that there is only one main harness, which is releasably connected to various secondary harnesses. Typical secondary harnesses are, for example, doors, tailgate or headlight battery .

It makes sense , because today there are many consumers in every corner of the car, and they all want to be supplied. For example, in the door you will find the power supply for the power windows, the corresponding switches, the electrically adjustable and heated rear-view mirror, which is also equipped with an indicator . It adds up pretty quickly.

Work only with the best quality

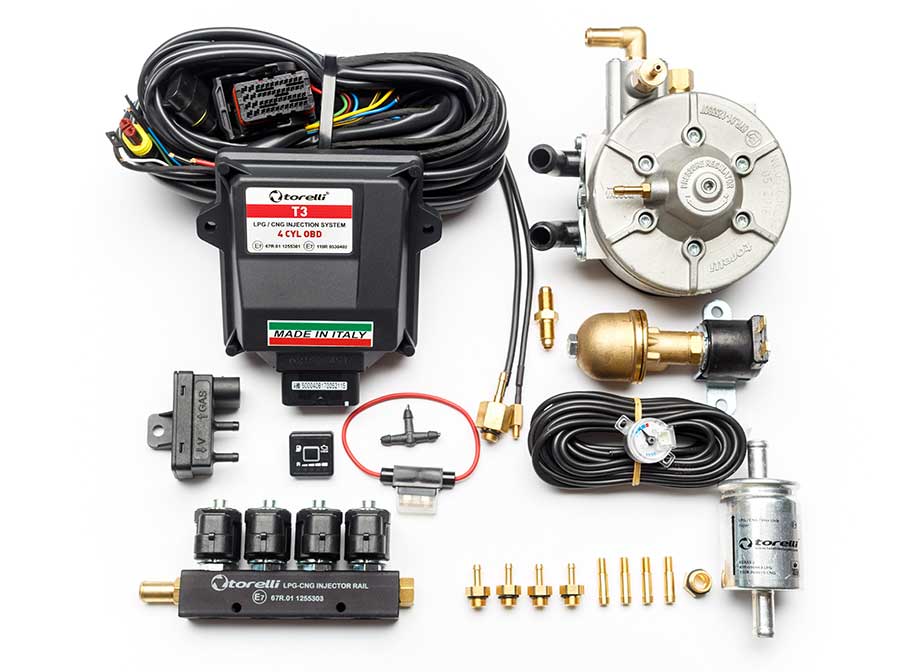

When working with a harness, the following applies: every pound invested in equipment, tools and spare parts pays off in time savings and better results. A good starter kit for a successful wiring harness repair consists of:

| - Multimeter – Wire stripper - Replaceable solid copper wire harness – Quality connectors – If necessary, high-quality insulating tape. |

Multimeter is the best way to save money. Models available today start at 8 pounds and offer usable quality.

Inform, inform, inform

The trick with electric current is that you can't see what it's doing from the outside. . At low voltages in a car, it is especially difficult to determine the appropriate direction of the currents.

Therefore, before repairing and replacing components in the wiring harness, you should study the electrical circuit of the car in detail. . Without information and accurate knowledge about which cable is responsible for which consumer, you should not even start.

Today, fiddling with stitched wires is no longer necessary. Control units sensitive to fluctuations in resistance. They quickly misinterpret sensor signals, if the wires are repaired unprofessionally.

Repair of the wiring harness is carried out by professional replacement of the submodule or replacement of a damaged cable with an identical or better one .

Always check connectors

The individual modules of a cable harness are usually connected to each other using several connectors. The factory no longer uses loose banana plugs or even shiny terminals. . If you find such temporary connectors on your car, you can be sure that a loser worked here .

Here the motto is: Be careful. Someone who repairs an automotive wiring harness with a luster terminal does other things as well. It is better to carefully inspect the component and replace the wiring harness if necessary.

Candles tend to rust . Since the contact surfaces are made of aluminum , finding a place of corrosion is not so easy. The combination of moisture and electrical stress causes even aluminum without rust to weather over time.

Unlike red iron rust, aluminum oxidizes to a white powder. . This layer of powder adheres to the corroded area and gradually seals it off. Therefore, when replacing submodules from the wiring harness, always check the connectors for corrosion and clean them thoroughly.

adapter plugs

You may have noticed that a multi-plug has a lot more slots than connections with . The reason for this is that these plugs can be converted.

But we recommend do not reuse plug tabs or flat plug sleeves that have been pulled out once . These components can be purchased for approximately 1 lb in packs of 100 . Do not break your fingers on a used part, but always use new connections.

Restoring a multi-plug is already troublesome enough . But with a little practice, you can do it. A pair of reliable and high-quality needle nose pliers will help you with this.

Work on the main culprit first

Many car wiring problems have a common cause: corroded ground wire . This is a particularly simple repair, and there isn't much you can do wrong.

Ground cable leads from the battery to the body . This is a thick black cable or open wire mesh. Severe corrosion can occur at the contact points between the battery and the body until the cable no longer conducts electricity reliably.

If the ground cable is not brittle, it is enough to cleanly grind the contact points on the cable and the body, and then reconnect them . A drop of battery grease prevents corrosion from recurring. In this way, " rotating electrical system » can be repaired in a few simple steps.