Checking petrol injectors from A to Z

Content

The fuel injector plays an important role in the preparation of the working mixture of gasoline with air, both in terms of its quantitative composition, and in terms of an even more important property at the moment - high-quality atomization. This is what most of all affects the previously inaccessible ability of the engine in terms of efficiency and purity of exhaust.

The principle of operation of the injection nozzle

As a rule, electromagnetic injectors are used in gasoline engines, the operation of which is based on the control of the fuel supply by electrical impulses generated by the electronic engine control system (ECM).

An impulse in the form of a voltage jump enters the solenoid winding, which causes the magnetization of the rod located inside it and its movement inside the cylindrical winding.

The spray valve is mechanically connected to the stem. The fuel, which is in the rail under strictly controlled pressure, begins to flow through the valve to the outlets, is finely dispersed and mixed with the air entering the cylinder.

The amount of gasoline for one cycle of operation is determined by the total time of the cyclic opening of the valve.

total – because the valve can open and close several times per cycle. This is necessary to ensure finer operation of the engine on a very lean mixture.

For example, a small amount of a rich mixture can be applied to initiate combustion, and then a leaner mixture can be used to maintain combustion and provide the desired economy.

Thus, a good injector becomes a fairly technological unit, to which high and sometimes conflicting requirements are imposed.

- High speed requires low mass and inertia of parts, but at the same time it is necessary to ensure reliable closing of the valve, which will require a sufficiently powerful return spring. But in turn, to compress it, it is necessary to apply a significant effort, that is, to increase the size and power of the solenoid.

- From an electrical point of view, the need for power will increase the inductance of the coil, which will limit the speed.

- The compact design and low inductance will cause an increase in the current consumption of the coil, this will add problems with the electronic keys located in the ECM.

- High frequency of operation and dynamic loads on the valve complicate its design, conflicting with its compactness and durability. In this case, the hydrodynamic processes in the atomizer must provide the desired dispersion and stability over the entire temperature range.

The injectors have an accurate flow rate for a given pressure drop between the rail and the intake manifold. Since dosing is carried out only by the time spent in the open state, the amount of injected gasoline should not depend on anything else.

Although the required accuracy still cannot be achieved, and a feedback loop is used based on the signals of the oxygen sensor in the exhaust pipe. But it has a rather narrow operating range, upon exiting which the system is disrupted, and the ECM will display an error (Check) on the dashboard.

Signs of malfunctioning gasoline engine injectors

There are two common injector malfunctions - a violation of the quantitative composition of the mixture and a distortion of the shape of the spray jet. The latter also reduces the quality of mixture formation.

Since the qualitative observance of the composition of the mixture when starting a cold engine is of particular importance, the problems with the injectors most clearly manifest themselves in this mode.

The injector can “overflow” when the valve is unable to hold the pressure of gasoline and the over-rich mixture refuses to ignite, and the candles are thrown with gasoline in the liquid phase. Such an engine cannot be started without purging with additional air.

The designers even provide for a special mode for blowing candles, for which you need to completely drown the accelerator pedal and turn the engine over with the starter, while the fuel is completely blocked. But even this will not help when the closed nozzle does not hold pressure.

Poor atomization can result in a lean mixture. Engine power will drop, acceleration dynamics will decrease, misfires in individual cylinders are possible, which will cause the lamp on the instrument panel to light up.

Any deviations in the composition of the mixture, including due to its insufficient homogenization, will lead to a significant increase in fuel consumption. Not necessarily this will mean a too rich mixture, a poor one will affect the same way, since the overall efficiency of the engine will decrease.

Detonation may occur, it will exit the thermal regime and the catalytic converter will collapse, pops will appear in the intake manifold or muffler. The engine will require immediate diagnostics.

Injector test methods

The more complex the equipment used in diagnostics, the more accurately you can determine the causes of what happened and prescribe the necessary measures to eliminate the problem.

Power check

The easiest way to control the pulses arriving at the injector connector is to connect an LED indicator to its supply contact.

Watch this video on YouTube

When the shaft is rotated by the starter, the LED should blink, which indicates the approximate health of the ECM keys and the very fact of its attempts to open the valves, although the incoming pulses may not have sufficient power.

Only an oscilloscope and a load simulator can provide accurate information.

How to measure resistance

The active nature of the load can be checked using an ohmmeter, which is part of a universal multimeter (tester). The resistance of the solenoid winding is indicated in the passport data of the injector, as well as its spread.

The ohmmeter reading should confirm the data match. The resistance is measured with the connector disconnected between the power contact and the case.

But in addition to resistance, the winding must provide the necessary quality factor and the absence of short-circuited turns, which cannot be determined by the simplest methods, but an open or complete circuit can be calculated.

Check on the ramp

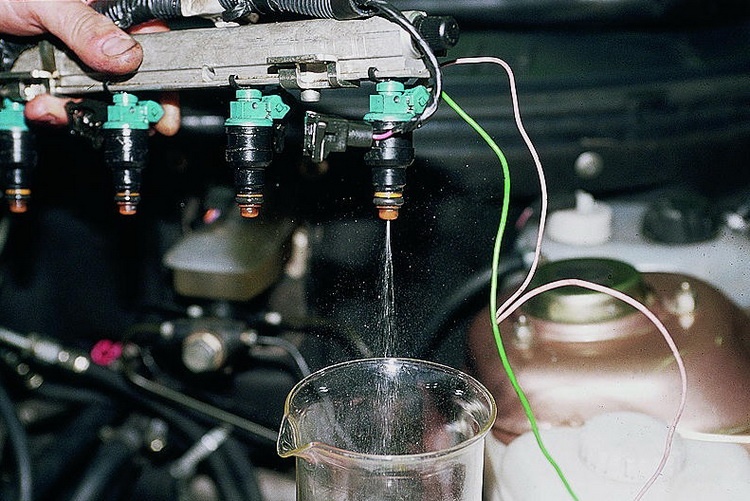

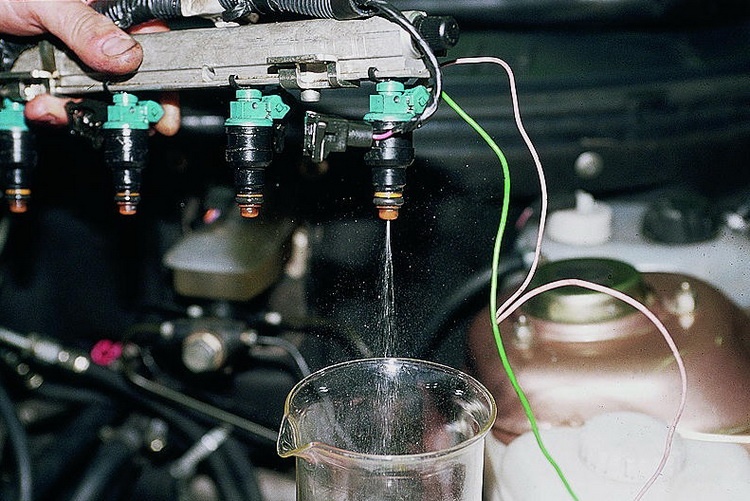

If you remove the rail assembly with nozzles from the manifold, you can assess the condition of the atomizers more accurately. By immersing each injector in a transparent test tube and turning on the starter, you can visually observe the fuel atomization.

Torches must have the correct conical shape, contain only individual droplets of gasoline that are indistinguishable to the eye, and most importantly, be the same for all connected nozzles. In the absence of control pulses, there should be no release of gasoline from the valves.

Checking injectors on the bench

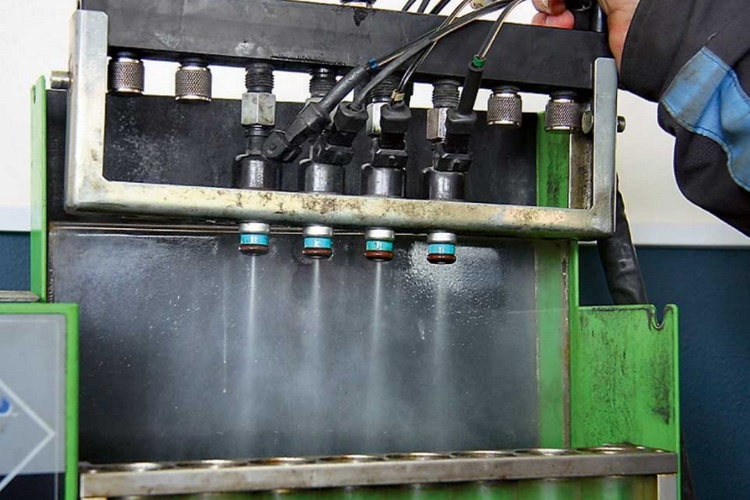

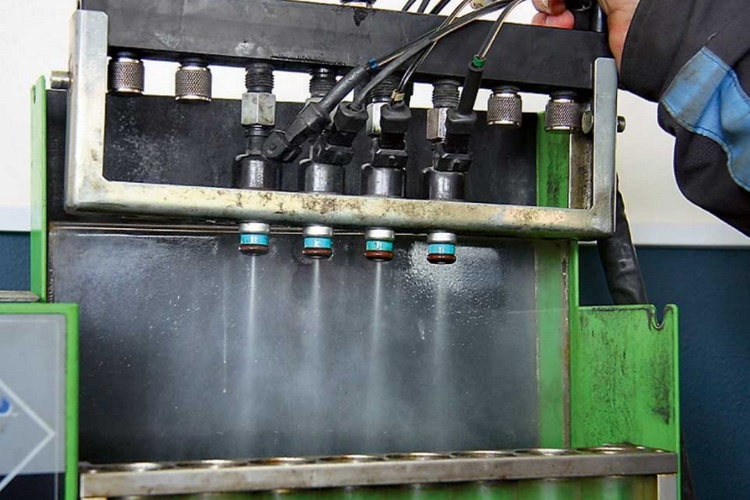

The most accurate and complete information about the condition of the atomizers can be given by a specialized installation. The injectors are removed from the engine and installed on the stand.

The device has several modes of operation, one of which is a test mode. The installation carries out cycling in various modes, collecting the allocated fuel and measuring its amount. In addition, the operation of the injectors is visible through the transparent walls of the cylinders; it is possible to evaluate the parameters of the torches.

The result will be the appearance of performance figures separately for each device, which must correspond to the passport data.

How to clean the fuel feeder yourself

The same stand has a nozzle cleaning function. But if desired, this can be done in the garage. A standard cleaning fluid and a simple device assembled from improvised means are used.

A home-made installation is an automobile electric fuel pump placed in a vessel with an injector cleaner. The hose from the pump is connected to the nozzle inlet, and its power connector is powered by a battery through a push-button microswitch.

By repeatedly driving a liquid containing powerful deposit solvents through the atomizer, it is possible to achieve a significant restoration of the spray properties of the device, which will become clear from the change in the shape of the torch.

Watch this video on YouTube

A nozzle that cannot be cleaned will have to be replaced, its defect is not always associated with contamination, corrosion or mechanical wear is possible.

Cleaning the injector without removing it from the engine

It is quite possible to clean the injectors without completely disassembling the injection units. At the same time, the cleaning fluid (solvent) allows the engine to work during the flushing process.

The sediment solvent is supplied from a separate installation, industrial or home-made, to the pressure line of the ramp. Excess mixture is returned to the supply tank through the return pipeline.

Watch this video on YouTube

This method has both advantages and disadvantages. The advantage will be savings on assembly and disassembly procedures, as well as the inevitable costs of consumables and parts. At the same time, other elements will also be cleaned, such as gas distribution valves, a rail and a pressure regulator. Soot will also be removed from the pistons and combustion chamber.

The disadvantage will be the insufficient effectiveness of the solution, which is forced to combine cleaning properties with fuel functions, as well as some riskiness of the procedure, when the washed slag travels through the elements of the fuel system and enters the oil. It will not be easy for the catalyst either.

An additional inconvenience will also be the lack of visual control over the cleaning effect. The results can be judged only by indirect signs. Thus, this method can only be recommended as a preventive procedure with a mandatory oil change in the engine.