Checking diesel engine injectors and how to clean them at home

Content

The diesel internal combustion engine (ICE) is a very reliable unit. Features of the diesel engine ensure the laying of a high margin of safety even during development. Practically, all its arising problems are connected exclusively with the fuel equipment. In particular, fuel injectors (injectors) become one of the bottlenecks.

What exactly might be wrong with them, we will figure it out in this article.

The principle of operation of diesel injectors

Their main task is the finest (dispersed) fuel atomization. Diesel runs on diesel fuel, unlike gasoline, it is a mixture of heavy fractions of oil refining. It is extremely reluctant to mix with air to form a consistency suitable for complete and rapid combustion.

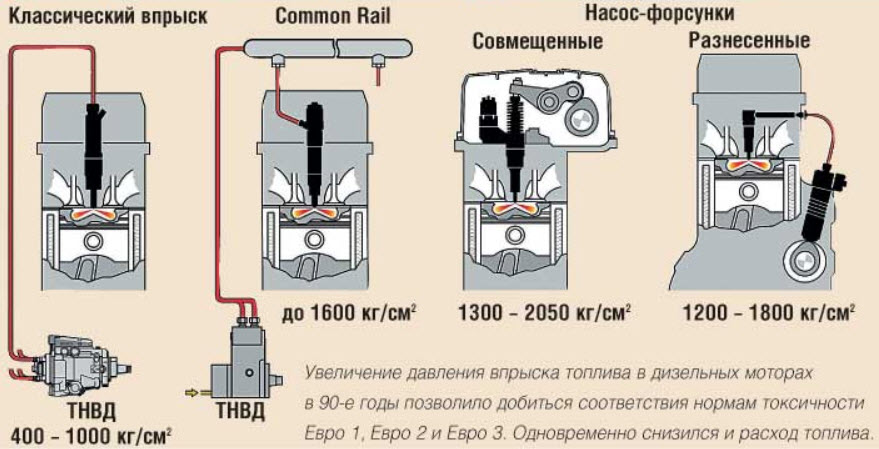

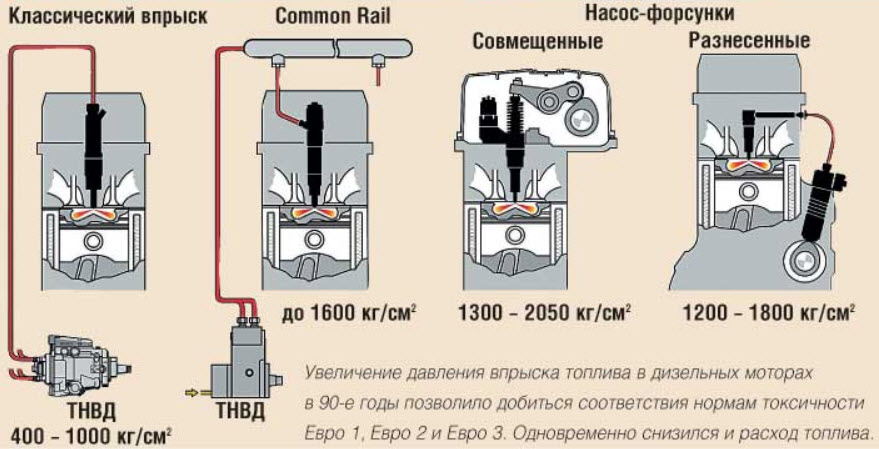

The simplest device has nozzles hydromechanical type. Diesel fuel comes to them separately from the individual sections of the high pressure fuel pump (TNVD). When a certain threshold pressure is reached at the right moment, the nozzle opens, and the fuel metered by the pump supercharger is injected into the combustion chamber, simultaneously spraying into tiny droplets.

After that, the pressure drops and the injector valve is closed by a return spring. A two-stage operation is possible, when a small pilot portion of diesel fuel is preliminarily supplied, after which the second spring is activated, and the main fuel charge is supplied to the atomizer. This improves engine performance.

A more advanced injection system has become its organization on the principle of a common high-pressure rail, the so-called Common Rail. Here, the high-pressure fuel pump creates the required pressure on all nozzles at the same time, and they are triggered at the right time by an electrical signal from the control unit.

It became possible to more accurately distribute the mixture over the cylinders, smooth dosing due to multiple feeding within one cycle and high-quality combustion of diesel fuel with softer engine operation. This is ensured by the presence of an electromagnet in each injector, which controls the shut-off valve.

The next step was the appearance piezoelectric actuator for the spray needle. The effect of changing their geometric dimensions by some crystals when an electrical voltage is applied to them is used.

Unlike an electromagnetic drive, such an organization allows you to dramatically increase the speed of the valves. It became possible to increase the number of portions of fuel supplied per stroke of the cylinder. The measure was forced due to the ever-increasing requirements for the environmental friendliness of diesel engines. Such nozzles are characterized by high price and non-repairability.

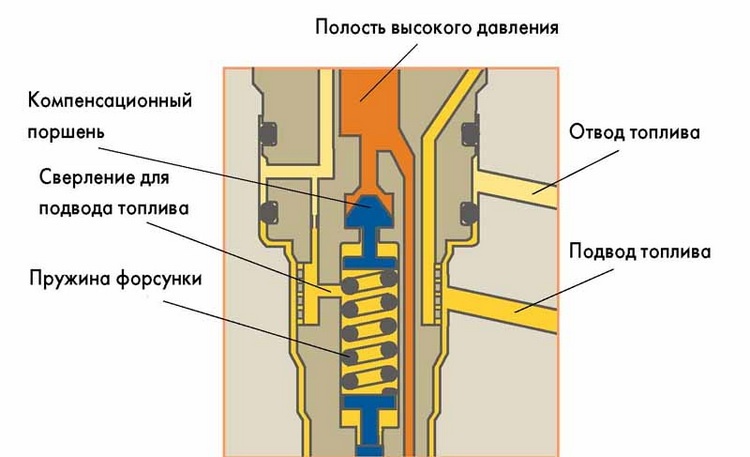

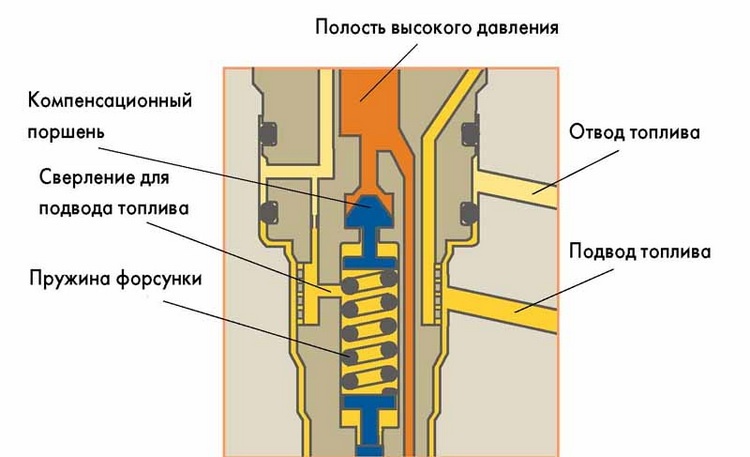

A separate class are the so-called pump injectors. They are distinguished by the absence of a high-pressure fuel pump in the system, its role is performed by the mechanical action of the camshaft cams on the plunger pair built into each fuel injector.

They are used relatively rarely due to a number of shortcomings. Of the advantages here, only the absence of a common high-pressure pump, which somewhat simplifies the equipment.

Symptoms of malfunctions

There are three common causes of failure:

- increased flow through the injector (overflow);

- reduction in the quality of fuel atomization;

- reduction in the performance of individual sprayers.

Outwardly, this will appear approximately the same, although a closer examination of each specific case will be able to indicate the approximate nature of the problem.

- The output of the engine changes, and its power can both fall and increase.

- The engine will start unstably and run rough at idle.

- In motion, clearly visible jerks and pickups may appear with the same position of the accelerator pedal.

- The sound of the engine will change, stiffness, vibrations and even knocks in the cylinders will appear.

- The engine will begin to smoke, the exhaust will turn black, which indicates the release of soot - unburned hydrocarbon fuel residues.

- The oil level in the crankcase will begin to rise due to the ingress of excess diesel fuel there.

- A modern internal combustion engine will notice a malfunction by means of internal diagnostics and will light a control lamp on the instrument panel.

In any case, clarification of the causes will require individual diagnostics of injectors.

Diagnostics of injectors at home

With a certain degree of accuracy, it is possible to calculate a faulty device in a garage. First you need to determine the specific location of the suspicious injector.

The speed of an idling diesel engine is set and fixed in such a way that its uneven operation manifests itself as clearly as possible. Then, in one of the appropriate ways, the fuel pressure is removed from the nozzle, for which the fastening of the inlet fitting is loosened. A serviceable injector will cause a much more noticeable reaction from the engine than one that has deviations in operation.

Watch this video on YouTube

At an electromagnetic injector, you can measure the resistance of the solenoid winding with a multimeter. Its value can be from units of ohms to two tens, more precisely you can find out from the documentation for a particular device. In any case, a break will mean a complete coil failure.

On the simplest hydromechanical nozzles, you can measure the pressure at the beginning of the valve opening using a tee, a pressure gauge, and a known-good control part. Changes in spring calibrations are possible, which will cause the injection angle to deviate.

Overflow check (return drain)

In the Common Rail system, injection is controlled using a special check valve, the opening of which creates the necessary pressure drop on the main valve stem, as a result of which it also opens and supplies the cylinder.

Wear and contamination causes too much fuel to flow into the return line and rail pressure drops. The motor starts with great difficulty.

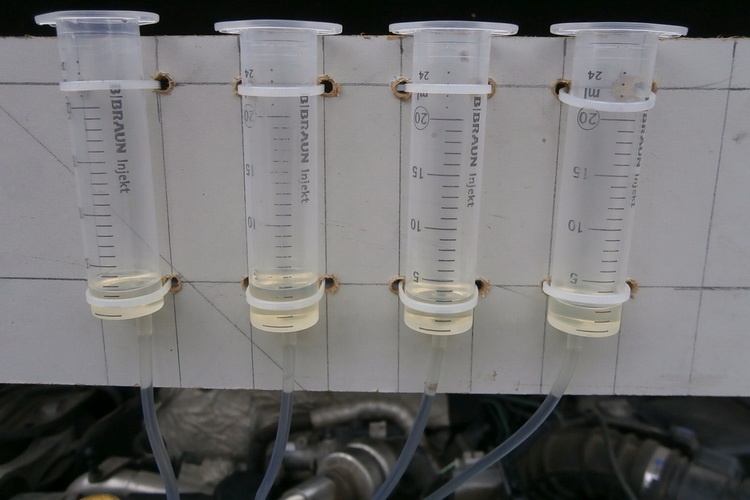

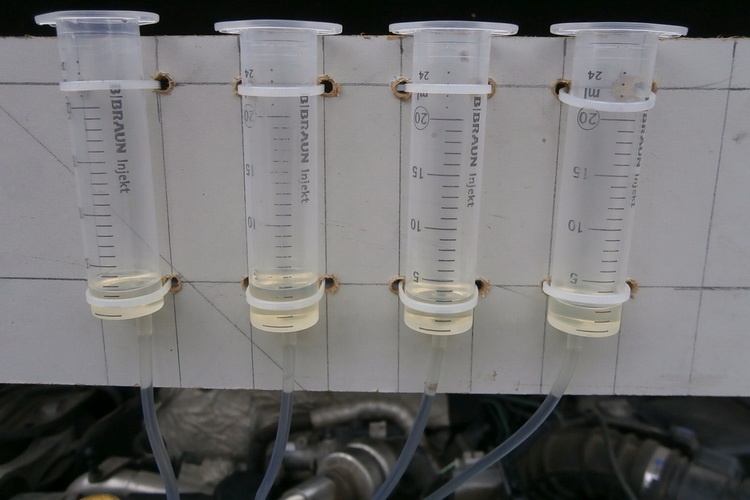

To check, return hoses are removed from all nozzles, and ordinary transparent flasks of medical syringes with tubes from dropper systems are installed instead. When the engine is idling, serviceable nozzles emit very little fuel into the return line, usually a few milliliters per minute.

A faulty one will give many times more, the specific value depends on the type of device and engine, but if at least the excess over the serviceable ones is three times or more, the nozzle must be repaired or replaced.

Diagnostic stand

A good professional injector test stand contains a set of routine tests that, in addition to express diagnostics, can identify more subtle malfunctions.

The simplest bench test is made to keep the nozzle working pressure, as well as its possible pollution and wear. The shape of the torch is visually assessed when spraying a calibrated liquid. The basic abilities of the device are determined, if they are not fulfilled, the injector is unambiguously rejected.

More complex tests determine whether the part under test is suitable for operation in all modes from idle to maximum power, check the valve response in the pre-injection modes, as well as the condition of the check valves.

This is the only way to assess the general condition and the ability to meet the current emission standards, as well as to predict the remaining resource. The result of the work of the professional stand will be the coding of the conditional state of the injector.

Special devices

The individual functions of the injectors can also be checked with specialized installations.

For example, hydro-mechanical injectors can be tested with a device that creates a fuel pressure at which the valve should open and make sure that it is within the specified limits. The device contains a hand pump and a pressure gauge.

There are also more complex designs, both included in diesel testers and autonomous. They are usually equipped with a manual or electric injection pump, a hydraulic accumulator, measuring equipment, and transparent flasks for visual control. Quite affordable for self-production.

Diesel injector cleaning

Having assessed the presence of a problem, in some cases it is possible to restore operability by cleaning or an intermediate repair in terms of complexity. It is allowed to remove pollution by chemical and mechanical methods.

Ultrasound

Exposure to high-frequency acoustic vibrations is quite effective, often even the inscriptions applied at the factory with special paints are often washed off from the parts.

The removed nozzle is placed in a bath filled with cleaning liquid, to which a powerful ultrasound emitter is connected. The cleaning process lasts about 20 minutes, after which the results are monitored on the stand.

The most modern nozzles, which contain a lot of delicate plastic parts, can start to work even worse than before cleaning, so they need to be checked for all parameters, and not just for the type of torch.

Cleaning at the stand

A special flushing liquid is poured under pressure through a contaminated injector, which is a very effective solvent.

This is the most reliable way of cleaning, since the part is not subjected to any destructive influences, and everything is focused on the dissolution of deposits and contaminants.

At the same time, using the same stand, the results of the work are monitored, after which it will be possible to make the most accurate decision on the possibility of further use of sprayers.

Use of additives

On sale there is a large number of various detergent additives for diesel equipment that work by simply adding them to the fuel.

The effectiveness of this method is rather doubtful, since such substances are already present in high-quality diesel fuel and, with constant use, do not allow the appearance of deposits. And it is difficult to wash off the existing ones due to the low concentration of detergent components.

In addition, you can get the opposite effect in the case of a heavily contaminated system, when large fractions separate and fall into bottlenecks, completely clogging them. However, a positive result is also not excluded.

Manual mode

It can be carried out both with disassembling the nozzle and by pouring a cleaning liquid through it. In the latter case, this is nothing but complexity, no different from washing at the stand.

Watch this video on YouTube

When disassembling the nozzle, where it is allowed by design, it is possible to clean and grind the valves, mechanically remove dirt from accessible parts, even clean the nozzle holes with a soft wire.

The main thing is to exercise sufficient care, taking into account the precision accuracy of all details. For flushing, the same liquid for cleaning injectors is used.

How to extend the life of fuel delivery devices

The fuel equipment of diesel engines, except for the most ancient ones, is designed for high-quality fuel.

- You should refuel only the best diesel fuel, specially designed for modern passenger car power systems.

- The ingress of water is strictly unacceptable, which will cause immediate corrosion of parts and require costly repairs.

- It is necessary to monitor the condition of filters and sedimentation tanks, change them in time and maintain them according to the instructions, and ideally, regular monitoring and preventive washing with removal in a specialized diesel service should be carried out.

Watch this video on YouTube

In addition, this will also help to avoid problems with the removal and installation of stuck connections, which can result in significant costs.