Operation and types of automatic boxes

Content

Are you planning to switch to an automatic transmission in the near future or are you just looking to brush up on your knowledge in this area? Fiches-auto.fr reviews the technologies at your disposal for you.

Automatic converter box

TORQUE / HYDRAULIC CONVERTER

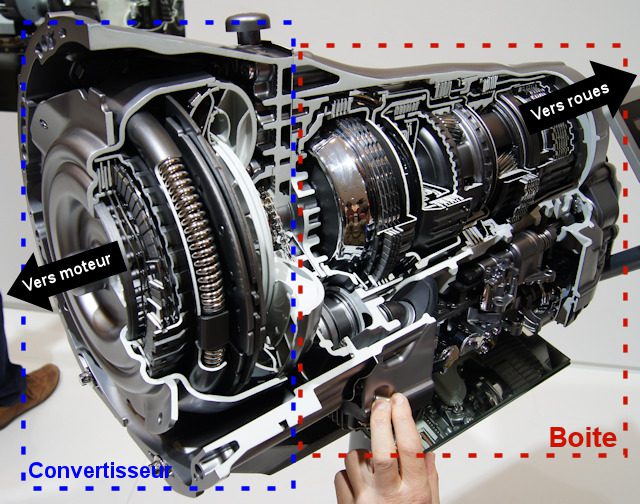

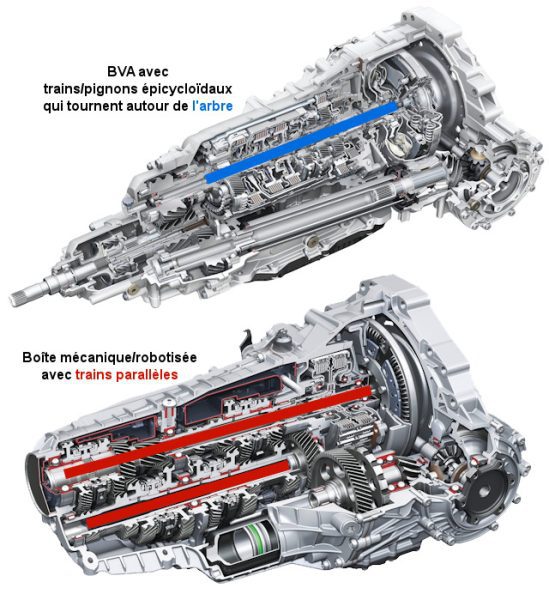

The grip is provided by the system hydraulic oil (converter) and the box consists of trains epicyclic as opposed to manual (parallel trains)

The automatic torque converter transmission, commonly referred to as "BVA", is perhaps the most well-known type of transmission after the manual transmission. For more information on how the converter works, go here.

Principle:

The disc clutch we know from manual transmissions has been replaced by a "torque converter" that transfers engine torque through fluid. With this design, the transducer can "slip" to provide a "clutch" function. It is this slippage that is the main reason for the excessive fuel consumption caused by the first BVA. To overcome this disadvantage, nowadays, a classic clutch (the so-called "bypass") is often added. This allows the transmitter to be short-circuited as soon as operating conditions permit, thereby reducing pressure losses and therefore consumption.

Gear shifting is automatic thanks to "planetary gears" which are connected to each other by friction discs (all hydraulically controlled), allowing more gear ratios to be used in a reduced volume (6 to 10 reports in total).

The device, controlled hydraulically and electronically, selects the best gear based on various information: accelerator pedal and gear selector position, vehicle speed, engine load, etc.

The selector allows you to choose from several operating modes (varying by manufacturer): normal, sporty, snowy, etc., as well as shift into reverse gear or go into parking mode.

Advantages:

- Choice of automatic or sequential mode (practical in the mountains / descents or towing)

- Driving comfort and smoothness: smooth to perfection and do not know the word jerk even from a standstill

- Increases engine torque at low revs precisely through "torque conversion". Hollow motor will appear smaller with BVA

- It easily accepts a lot of power, so some prestigious cars only offer an automatic in the most powerful versions (less often manual transmissions designed to produce more than 300 hp). And even if we exceed the allowable power (in the case of smart kids who reprogram beyond reason), we will have slippage, not twisting of the shafts in the case of manual control (although usually the clutch is released before slippage is also caused, which protects the box)

- Service life (less "sharp" mechanical links, gears are connected using couplings, not walkers) and ease of maintenance (no replacement clutch), only oil changes should be expected.

- Widely proven reliability, especially in North America where almost nothing is available

- A very complete box that combines impeccable comfort and undeniable dynamic qualities, more than those released after 2010.

Disadvantages:

- Excessive fuel consumption (no longer relevant since the 2010s)

- Higher cost than manual transmission

- Lower the engine brake (if not equipped with a bypass clutch, with even more clutch in manual / sequential mode)

- Slow gear shifting (responsiveness), which again becomes false on most modern versions (the ZF8 is neither clumsy nor slow)

- Motor converter that makes the engine / transmission link heavier. This is why Mercedes has allowed the eccentricity to put a multi-disc instead of a converter on large AMGs (I'm not talking about 43 and 53).

Here are some examples:

Almost all manufacturers offer at least one model of automatic transmission, although robotic gearboxes are now more popular: EAT6 / EAT8 from PSA, Tiptronic from Vw, Steptronic from BMW ...

Automatic transmission for 1 series since 2011

Robotic transmission with one clutch ("BVR").

SINGLE CLUTCH ROBOT

The clutch is provided by a conventional system with friction disc (the same mechanical) and the box consists of parallel trains (the same as on mechanics). If the specified arrangement is a longitudinal engine, we usually find this type of installation on vehicles with transverse engines (it is sufficient to install the engine + gearbox parallel to the chassis).

Differences between parallel planetary gears (images of Audi A4

Titpronic / epicyclic

et

S-Tronic / parallel

):

This is a very simple classic gearbox for which we have adapted a device that turns on, off and changes gears for you. This "robot" (actually there are two, one for the gears and the other for the clutch) most often consists of electro-hydraulic drives.

Everything is controlled by more and more sophisticated electronics taking into account many parameters.

Two operating modes are offered:

- Automatic: the computer selects the gear ratio most suitable for the situation, in accordance with self-adapting laws. Several operating modes may be available (city, sports, etc.).

- Sequential: You change gears yourself using the classic-style lever or paddle shifters. However, it is not necessary to control the clutch.

Please note that you can switch from one mode to another at your discretion in real time.

Advantages:

- Selectable automatic or sequential mode

- The automatic transmission, which conveys the best feeling of sportiness, is better than the dual-clutch transmission (I am obviously talking about good quality robotic transmissions). If I had to pick a high-end sports car, I would prefer a single-clutch robot, despite being slightly less efficient.

- Lighter than double clutch

- Consumption practically did not change compared to a manual transmission (and sometimes even slightly lower, since the robot does not make mistakes when using and slipping the clutch)

- Sometimes cheaper than the classic BVA because it is actually a simple manual transmission coupled to a robot (like the BMP and ETG from PSA).

Disadvantages:

- A wide variety of designs: there are good (sporty type SMG) or real disasters: ETG, ASG, Easy-R, etc. They are mostly very good for prestige cars, but make up the lower end of the range for general vehicles.

- Slow shifting and / or more or less noticeable jerking depending on the model (approval is not always at the top)

- Unlike a traditional automatic torque converter box, the clutch wears out and needs to be replaced like a manual one (with the exception of wet multi-disc engines, which extend the life of the vehicle).

- Increased reliability

Here are some examples:

BMP / ETG on Peugeot-Citroën (just not very good ...), Quick Shift on Renault, ASG on Volkswagen (on the rise!), SMG on BMW, as well as many of the gearboxes that supercars are equipped with ...

Here is BMP6 from PSA on DS5 Hybrid4. Becoming an ETG, however, is not very effective in terms of efficiency

Dual-clutch robotic transmission

DOUBLE CLUTCH BOX

The system consists of two-plate clutch, each of which is connected to a semi-box parallel trains... As in the previous diagram, this type of assembly is mostly found on transversely engineered vehicles rather than longitudinally as seen here.

Although there is an automatic mode and a sequential mode, as in the single-clutch transmission, the dual-clutch transmission has a completely different design. In fact, this is an assembly of two semi-gearboxes. Each has its own grip.

Thus, when the gear is engaged, the next gear is pre-engaged, which allows very fast gear changes (less than 10 milliseconds), because we do not need to wait for the change to take place between the clutches (one comes off and the other takes its place opposite the flywheel: therefore very quickly ( there is no need to wait for a report in the transmission).

In addition, the transmission of torque is continuous, which avoids sudden fluctuations.

In short, the dual-clutch BVR combines the advantages of an automatic transmission and a single-clutch BVR without their disadvantages.

This type of transmission is currently enjoying great success on small mechanical gears, and large ones still favor a converter box whose smoothness and reliability remain unsurpassed.

Advantages:

- Comfortable driving thanks to passages without breaking the load and therefore quite smooth

- Selectable automatic or sequential mode

- Consumption growth

- Super-fast gear changes for improved efficiency in sporty driving. It is also the fastest technology in relation to automatic transmissions, although BVA converters are now almost equivalent (the effect obtained by the two clutches can also be obtained by the internal BVA clutches).

- No clutch wear with wet multi-discs

Disadvantages:

- At first, there may be jerks when starting off: the control of the clutch with the help of mechatronics may not always be perfect.

- More expensive to buy than BVA and BVR

- Heavy system weight

- If shifting between two gears is fast, it may be less if you want to downshift 2 gears at the same time and vice versa (up)

- Clutch wear on dry versions (clutches)

- Reliability is less preferable than on the BVA, here we move the forks and clutch electrohydraulically. Much more gas than just the inclusion of multi-plate clutches in the torque converter boxes.

Some examples: DSC for Peugeot, EDC for Renault, 7G-DCT for Mercedes, DSG / S-Tronic for Volskwagen and Audi ...

Here is the DSG gearbox fitted to a 2012 Passat AllTrack.

Continuously variable transmission

VARIATIONS CONTINUED / CVT

The system can benefit from hydrotransformer to start (it is not, for example, on Honda versions). The box consists of two dimmers tied with a belt or chain but no gears / gears, so one very long report (because it changes its gear all the time). Therefore, we cannot talk about an automatic transmission, even if it is usually called that.

Note that there are several methods for creating this changing effect, but the principle remains the same: continuously change the gearbox, because there are no fixed gear ratios determined by the pre-calibrated gears.

If you've ever driven a moped, you've already dealt with the principle of continuous change! The speed changes gradually, without changing gears.

The most common system consists of a metal belt and tapered pulleys, the winding diameter of which automatically changes depending on the engine speed (another version uses magnetism, but the principle remains the same).

Some models still offer sequential mode, which allows the driver to manually shift gears using a lever.

Advantages:

- Driving comfort (smooth driving, etc.)

- Completely jerk-free

- Large range of change / reduction (equivalent to at least 6 conventional gears), which allows you to save fuel at a stable speed (while the engine speed remains minimal even at high speeds)

- In some versions, automatic or sequential mode is available (then simulates reports by modifying them in stages rather than gradually)

- Reliability due to simplicity of design and low-aggressive mechanical contacts of the constituent elements.

Disadvantages:

- Excessive consumption during nervous driving (the engine literally growls when accelerating, and who speaks Braille, says consumption ...)

- The handling, which can be confusing, is even unpleasant for those who like dynamic driving (those who like good acceleration, and this is regular).

- Modeling reports for specific versions, which remains somewhat questionable ...

Some examples: Xtronic in Nissan, Autoronic Mercedes, CVT, etc., Multitronic in Audi ...

Which box and for whom?

The quiet father of the family will be completely satisfied with a BVA converter or even a continuously variable variator. The average driver (who likes to "send" from time to time) will need at least a version of the converter. The sports enthusiast will have to choose between a robot and a dual clutch. Feel free to give your opinion (experience reviews, etc.) to help internet users make their choice. Thanks everyone!

All comments and reactions

Dernier comment posted:

With (Date: 2021, 10:06:14)

I have a Nissan Tida 1.8 automatic 2008 release.

The problem is that when the reverse gear is engaged, it is difficult for the car to move in reverse.

If you can give me or advise me to solve this problem

Il I. 4 reaction (s) to this comment:

- Honda4 BEST PARTICIPANT (2021-10-07 20:08:44): Check the transmission oil level, you may have a leak.

When was the last bva oil change and how many kilometers?

- With (2021-10-08 12:04:53): Привет

I changed the oil and had some leaks that I fixed after replacing the timing chain, oil pump, water pump and I still have the same problem when my car is cold.

- Administrator SITE ADMINISTRATOR (2021-10-08 17:33:16): Careful, we're talking about tin oil ...

So it could be due to reversing solenoids (or their power / platinum), lack of oil (although this should be a concern in all gears), or brake / multi-disc connection (activated via solenoids).

Does the engine start to move when reversing? Skating?

- With (2021-10-09 02:52:27): No, the engine does not run away, but I accelerate a little to get the car moving, but with difficulty

(Your post will be visible under the comment after verification)

Comments continued (51 Ã 242) >> нажмите здесь

Write a comment

Which French brand do you like best?