Varieties of tuning the VAZ 2106 engine: block boring, turbine, 16-valve engine

Tuning a VAZ 2106 engine is an exciting, but at the same time expensive activity. Depending on the goals pursued and financial capabilities, the engine can be modified for specific purposes, from a simple increase in volume without fundamental changes in the design of the unit to the installation of a turbine.

VAZ 2106 engine tuning

The VAZ "six" began to be produced back in 1976. This model has long been outdated both in appearance and in technical characteristics. However, to this day there are many adherents of the operation of such cars. Some owners try to keep the car in its original form, others equip it with modern components and mechanisms. One of the primary units that undergoes tuning is the engine. It is on his improvements that we will dwell in more detail.

Cylinder block boring

The VAZ 2106 engine does not stand out for its power, because it ranges from 64 to 75 hp. With. with a volume of 1,3 to 1,6 liters, depending on the installed power unit. One of the most common engine modifications is the bore of the cylinder block, which allows you to increase the internal diameter of the cylinders and power. The boring process involves the removal of a layer of metal from the inner surface of the cylinders. However, you need to understand that excessive boring will lead to thinning of the walls and a decrease in the reliability and life of the motor. So, a stock power unit with a volume of 1,6 liters and a cylinder diameter of 79 mm can be bored up to 82 mm, obtaining a volume of 1,7 liters. With such changes, the reliability indicators will practically not worsen.

Extreme lovers can increase the cylinders to 84 mm at their own peril and risk, because no one knows how long such a motor will last.

The boring process is carried out on special equipment (boring machine), although there are craftsmen who carry out this procedure almost in garage conditions, while the accuracy remains doubtful.

At the end of the procedure, pistons are inserted into the block, which, according to their characteristics, correspond to the new cylinder sizes. In general, block boring consists of the following main stages:

- Dismantling the motor from the car.

- Complete disassembly of the power unit.

- Boring of the cylinder block according to the desired parameters.

- Assembly of the mechanism with the replacement of pistons.

- Installing the motor on a car.

Video: how to bore a cylinder block

Replacing the crankshaft

On the engine of the VAZ "six" there is a VAZ 2103 crankshaft with a piston stroke of 80 mm. In addition to increasing the diameter of the cylinders, you can increase the piston stroke, thereby forcing the engine. For the purposes under consideration, the motor is equipped with a VAZ 21213 crankshaft with a piston stroke of 84 mm. Thus, it will be possible to raise the volume to 1,65 liters (1646 cc). In addition, such a crankshaft has eight counterweights instead of four, which positively affects the dynamic characteristics.

Read more about crankshaft installation and repair: https://bumper.guru/klassicheskie-modeli-vaz/dvigatel/kolenval-vaz-2106.html

Refinement of the intake and exhaust system

Modernization of the cylinder head and manifolds, if desired, can be performed by anyone who owns the Six or another classic Zhiguli model. The main goal pursued is to increase power. It is achieved by reducing the resistance when supplying the fuel-air mixture at the inlet, i.e., by removing roughness. To carry out the procedure, the cylinder head must be dismantled from the car and disassembled. After that, the knot is recommended to be washed. For these purposes, you can use modern tools or ordinary kerosene, diesel fuel. From the required list of tools and materials you will need:

- drill with the ability to adjust the speed;

- drill;

- flexible rod;

- checkers;

- skins of different grain sizes;

- rags;

- calipers;

- exhaust valve and a set of washers for boring more than 32 mm;

- graphite grease;

- vise.

Intake manifold

It is better to start the procedure for finalizing the intake tract from the manifold, through which the channels in the cylinder head will then be bored. We work as follows:

- We clamp the collector in a vice, wrap a rag on a drill or a suitable nozzle, and on top of it - sandpaper with a grain size of 60–80 overlap.

For the convenience of work, we install the collector in a vice

For the convenience of work, we install the collector in a vice - We clamp the drill with sandpaper into the drill and insert it into the collector channel.

We wrap a drill or other suitable device with sandpaper, place it in a collector and bore

We wrap a drill or other suitable device with sandpaper, place it in a collector and bore - Having machined the first 5 cm, we measure the diameter with the exhaust valve.

Measuring the diameter of the channel using the exhaust valve

Measuring the diameter of the channel using the exhaust valve - Since the manifold channels are bent, it is necessary to use a flexible rod or fuel hose for turning, into which we insert a drill or a suitable tool with sandpaper.

A fuel hose can be used to drill channels at bends.

A fuel hose can be used to drill channels at bends. - We process the collector from the installation side of the carburetor. After sanding with 80 grit, use 100 grit paper and go through all the channels again.

The collector from the side of the carburetor installation is also processed with cutters or sandpaper

The collector from the side of the carburetor installation is also processed with cutters or sandpaper

Finalization of the cylinder head

In addition to the intake manifold, it is necessary to modify the channels in the head of the block itself, since there is a step between the manifold and the cylinder head that prevents the free passage of the fuel-air mixture into the cylinders. On classic heads, this transition can reach 3 mm. The finalization of the head is reduced to the following actions:

- To determine where to remove a part of the metal, we apply grease or plasticine to the plane of the head at the places where the collector fits. After that, it will be clearly visible where and how much to grind off.

After marking the cylinder head channels with plasticine or grease, we proceed to remove excess material

After marking the cylinder head channels with plasticine or grease, we proceed to remove excess material - First, we process a little so that the valve enters. Then we move deeper and grind down the guide bushing.

First we delve into the channel a little, then more

First we delve into the channel a little, then more - After passing through all the channels, we polish them from the side of the valve seats. We carry out this procedure carefully so as not to scratch the saddles themselves. For these purposes, it is convenient to use a cutter clamped in a drill. In addition, you need to make sure that the channel expands slightly towards the saddle.

We polish the channels from the side of the valve seats, making them slightly conical

We polish the channels from the side of the valve seats, making them slightly conical - At the end of the treatment, it should turn out so that the valve passes freely into the channel.

More about cylinder head diagnostics and repair: https://bumper.guru/klassicheskie-modeli-vaz/grm/poryadok-zatyazhki-golovki-bloka-cilindrov-vaz-2106.html

In addition to boring the channels, the cylinder head can be modified by installing a tuned camshaft. Most often, car owners install a shaft from the VAZ 21213, less often - sports elements of the Estonian type and the like.

Replacing the standard camshaft makes it possible to change the valve timing. As a result, the engine cylinders are better filled with a combustible mixture, and are also cleaned of exhaust gases, which increases the power of the power unit. The camshaft is changed in the same way as in a normal repair, i.e. no special tools are required.

Video: finalization of the cylinder head and intake manifold

Watch this video on YouTube

An exhaust manifold

The essence of finalizing the exhaust manifold is the same as at the intake. The only difference is that the channel needs to be sharpened by no more than 31 mm. Many do not pay attention to the exhaust manifold, because it is made of cast iron and is difficult to machine, but it is still possible. It should be borne in mind that the collector channel should be slightly larger in diameter than in the head. In the cylinder head itself, we perform grinding in the manner described above, and it is recommended to grind the bushings into a cone.

Ignition system

With a serious approach to finalizing the power unit, it is not possible to do without installing a contactless ignition system (BSZ) instead of the traditional contact one. BSZ has a number of undeniable advantages:

- more powerful spark;

- precise opening of the sparking circuit;

- high reliability and durability.

Equipping the VAZ 2106 with contactless ignition makes the engine more stable, eliminates the need for periodic adjustment of constantly burning contacts, since they simply do not exist in the BSZ. Instead of a contact group, a Hall sensor is used. An important point is that in winter, an engine with contactless ignition starts much easier. To install on the "six" BSZ, you will need to purchase a kit consisting of the following elements:

- trampler;

- spark plug;

- high voltage wires;

- ignition coil;

- switch;

- wiring.

Learn more about the contactless ignition system VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/elektrooborudovanie/zazhiganie/elektronnoe-zazhiganie-na-vaz-2106.html

The sequence of actions for replacing the contact ignition system with BSZ is as follows:

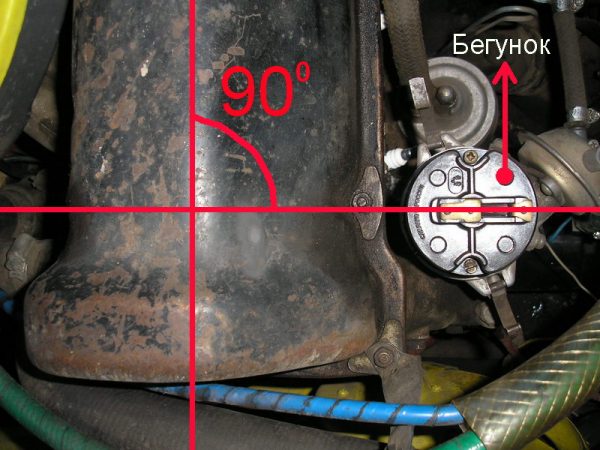

- We dismantle the old candle wires and the ignition distributor cover. By rotating the starter, we set the distributor slider perpendicular to the axis of the car so that it points to the first cylinder of the engine.

Before removing the old distributor, set the slider to a certain position

Before removing the old distributor, set the slider to a certain position - On the engine block at the place of installation of the distributor, we put a mark with a marker so that when installing a new distributor, at least approximately set the required ignition timing.

To make it easier to set the ignition on the new distributor, we make marks on the block

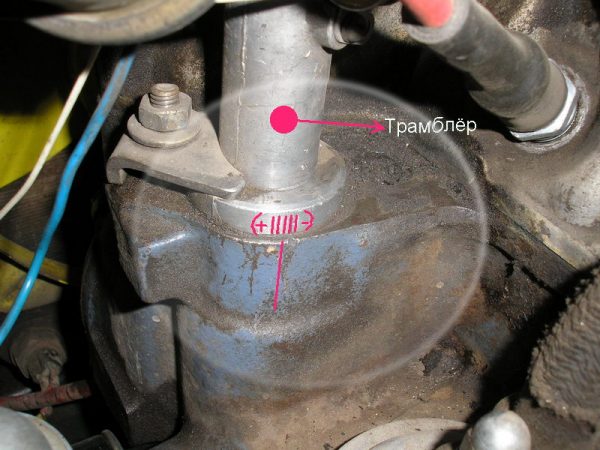

To make it easier to set the ignition on the new distributor, we make marks on the block - We remove the distributor and change it to a new one from the kit, setting the slider to the desired position, and the distributor itself - according to the marks on the block.

We change the old distributor to a new one by setting the slider to the desired position

We change the old distributor to a new one by setting the slider to the desired position - We unscrew the nuts of the wiring on the ignition coil, as well as the fastening of the coil itself, after which we replace the part with a new one.

Swapping ignition coils

Swapping ignition coils - We mount the switch, for example, near the left headlight. We connect the terminal with a black wire from the wiring bundle to ground, and insert the connector into the switch itself.

The switch is installed near the left headlight

The switch is installed near the left headlight - We insert the mating part of the wiring into the distributor.

- The remaining two wires are connected to the coil. Wires that were removed from the old element are also connected to the contacts of the new coil. As a result, it should turn out that on pin "B" there will be green and blue with a stripe, and on pin "K" - brown and lilac wires.

We connect the wires to the coil according to the instructions

We connect the wires to the coil according to the instructions - We change spark plugs.

- We install the distributor cap and connect new wires according to the cylinder numbers.

After installing the BSZ, you will need to adjust the ignition while the car is moving.

Carburetor

On the VAZ 2106, the Ozone carburetor was most often used. As a refinement of the power unit, many car owners equip it with a different device - DAAZ-21053 ("Solex"). This unit is economical and provides better vehicle dynamics. In order for the engine to develop maximum power, two carburetors are sometimes installed instead of one. Thus, it is possible to achieve a more uniform supply of a mixture of fuel and air into the cylinders, which affects the increase in torque and increase the power of the power plant. The main elements and nodes for such re-equipment are:

- two Solex or Ozone carburetors;

- a pair of intake manifolds from the Oka;

- hoses, tees, throttle controls.

All work comes down to dismantling the standard intake manifold and installing two new ones, while the latter are adjusted so that they fit snugly against the block head. Modification of the collectors consists in removing the protruding parts with the help of a cutter. After that, the carburetors are mounted and the same adjustment is performed, i.e., the adjusting screws are unscrewed by the same number of revolutions. To simultaneously open the dampers in both carburetors, a bracket is made that will be connected to the accelerator pedal.

Compressor or turbine on the "six"

You can increase engine power by installing a compressor or turbine, but first you need to figure out what this will require. First of all, you need to understand that, due to its design features, a turbine can be installed on a carburetor engine, but it is rather problematic. The nuances lie in both large material and time costs. The most important points to think about when equipping a car with a turbine are:

- Mandatory installation of an intercooler. This part is a kind of radiator, only the air is cooled in it. Since the turbine creates high pressure and the air is heated, it must be cooled to get the effect of the installation. If the intercooler is not used, the effect will be, but much less.

When equipping the machine with a turbine, an intercooler will also be required.

When equipping the machine with a turbine, an intercooler will also be required. - Equipping a carburetor engine with a turbine is a dangerous undertaking. According to the experience of car owners who are engaged in such modifications, the exhaust manifold can “bang”, which will fly off the hood. Since the intake has a different principle on an injection engine, a turbine for this engine is a more preferable option, albeit expensive.

- Based on the second point, the third follows - you will need to remake the engine into an injection one or install one.

If you are not such an avid race car driver, then you should look towards the compressor, which has the following differences from the turbine:

- Does not develop high blood pressure.

- There is no need to install an intercooler.

- You can equip the VAZ carburetor engine.

To equip the VAZ 2106 with the unit in question, you will need a compressor kit - a kit that includes everything you need to re-equip the motor (pipes, fasteners, supercharger, etc.).

The product is installed according to the manufacturer's instructions.

Video: installing a compressor on the example of the "five"

Watch this video on YouTube

16-valve engine on the VAZ 2106

One of the options for tuning the "six" is to replace the 8-valve engine with a 16-valve one, for example, from the VAZ 2112. However, the whole process does not end with a banal replacement of motors. There is a rather serious, painstaking and expensive work ahead. The main stages of such improvements are:

- For a 16-valve engine, we install an injection power system.

- We customize the mount on the engine mounts (classic supports are used).

- We change the crown on the flywheel, for which we knock down the old one, and in its place we put a part from the VAZ 2101 with preheating. Then, from the side of the engine on the flywheel, we grind off the shoulder (you will have to contact the turner). This is necessary in order for the starter to fall into place. At the end of work with the flywheel, we carry out its balancing.

We finalize the flywheel by installing a crown from the VAZ 2101

We finalize the flywheel by installing a crown from the VAZ 2101 - We cut the bearing from the VAZ 16 crankshaft onto the crankshaft of the 2101-valve engine, since this element is a support for the gearbox input shaft. Without replacement, the bearing will quickly fail.

On the crankshaft, it is necessary to replace the bearing with a "penny"

On the crankshaft, it is necessary to replace the bearing with a "penny" - The pallet is also subject to refinement: we crush the stiffeners on the right side so that the engine does not rest against the beam.

The pallet needs to be adjusted so that it does not rest against the beam

The pallet needs to be adjusted so that it does not rest against the beam - We adjust the motor shield under the new block with a hammer and a sledgehammer.

The engine shield needs to be straightened so that the new engine becomes normal and does not rest against the body

The engine shield needs to be straightened so that the new engine becomes normal and does not rest against the body - We install the clutch from the VAZ 2112 through an adapter with a release bearing from the “tens”. The fork with the clutch slave cylinder remains native.

- We install the cooling system at our discretion, since it still needs to be modified. The radiator can be supplied, for example, from the VAZ 2110 with the selection of the appropriate pipes from the VAZ 2121 and 2108, the thermostat - from the "penny".

When installing a 16-valve engine, you will have to install a different design of the cooling system

When installing a 16-valve engine, you will have to install a different design of the cooling system - According to the exhaust system, we remake the standard exhaust manifold or manufacture the exhaust from scratch.

- We install the hitch, connect the wiring.

After installing the engine, we mount the hitch and connect the wiring

After installing the engine, we mount the hitch and connect the wiring

From the listed points for installing a 16-valve unit, you can understand and preliminarily evaluate your capabilities both financially and technically. In the absence of the necessary components and knowledge, you will have to seek outside help and “pour” additional funds into this type of hobby.

Video: installing a 16-valve engine on a "classic"

Watch this video on YouTube

The engine of the "six" lends itself well to forcing, and it is not necessary to be a specialist with extensive experience to increase the volume of the unit. Gradually improving your car, as a result, you can get a rather “peppy” car that will make you feel more confident on the road.