DIY repair of the VAZ 2107 clutch hydraulic drive

Content

- The principle of operation of the clutch drive VAZ 2107

- The device of the main elements of the hydraulic drive

- Malfunctions of the hydraulic clutch VAZ 2107

- Working fluid for hydraulic clutch VAZ 2107

- Bleeding the hydraulic clutch VAZ 2107

The main function of the hydraulic clutch is to provide a short-term separation of the flywheel and transmission when changing gears. If the VAZ 2107 clutch pedal is pressed very easily or immediately fails, you should think about pumping the release bearing drive hydraulic cylinder. To accurately identify the problem, check the fluid level in the master cylinder reservoir. You can repair the clutch without contacting a car service specialist.

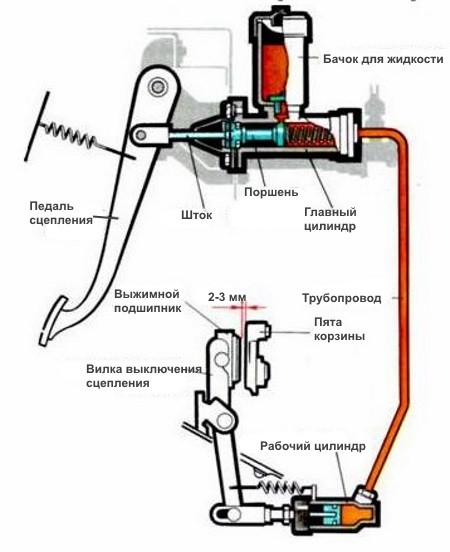

The principle of operation of the clutch drive VAZ 2107

The clutch is engaged and disengaged by the release bearing. He, moving forward, presses on the spring heel of the basket, which, in turn, retracts the pressure plate and thereby releases the driven disc. The release bearing is driven by the clutch on/off fork. This yoke can be pivoted on the swivel in a number of ways:

- using hydraulic drive;

- flexible, durable cable, the tension of which is automatically adjusted.

The clutch is engaged and disengaged by means of a release bearing, which presses on the spring foot of the basket, thereby retracting the pressure plate and releasing the driven disc.

The clutch is engaged and disengaged by means of a release bearing, which presses on the spring foot of the basket, thereby retracting the pressure plate and releasing the driven disc.

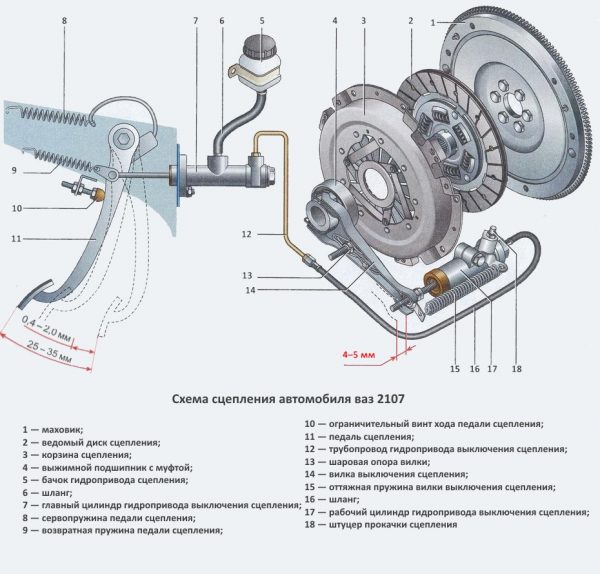

The principle of operation of the hydraulic clutch VAZ 2107 is quite simple. When the engine is running and the clutch pedal is in the up (depressed) position, the clutch and flywheel rotate as a unit. Pedal 11, when pressed, moves the rod with the piston of the main cylinder 7 and creates brake fluid pressure in the system, which is transmitted through the tube 12 and hose 16 to the piston in the working cylinder 17. The piston, in turn, presses on the rod connected to the end of the clutch fork 14 Turning on the hinge, the fork at the other end moves the release bearing 4, which presses on the spring heel of the basket 3. As a result, the pressure plate moves away from the driven disc 2, the latter is released and loses traction with the flywheel 1. As a result, the driven disc and the gearbox input shaft stop. This is how the rotating crankshaft is disconnected from the gearbox and conditions are created for switching speeds.

Learn how to diagnose the clutch yourself: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/stseplenie-vaz-2107.html

The device of the main elements of the hydraulic drive

The clutch on the VAZ 2107 is controlled by a hydraulic drive, the pressure in which is created using an outboard pedal mechanism. The main elements of the hydraulic drive are:

- clutch master cylinder (MCC);

- pipeline;

- hose;

- clutch slave cylinder (RCS).

The performance of the drive depends on the volume and technical characteristics of the operating fluid, which is usually used for the VAZ 2107 brake fluid (TF) DOT-3 or DOT-4. DOT is the designation for a system of requirements for the physicochemical properties of TF, developed by the Institute of the US Department of Transportation (DOT - Department of Transportation). Compliance with these requirements is a prerequisite for the production and certification of the liquid. The composition of TJ includes glycol, polyesters and additives. DOT-3 or DOT-4 fluids have a low price and are recommended for use in drum-type brake systems and hydraulic clutch drives.

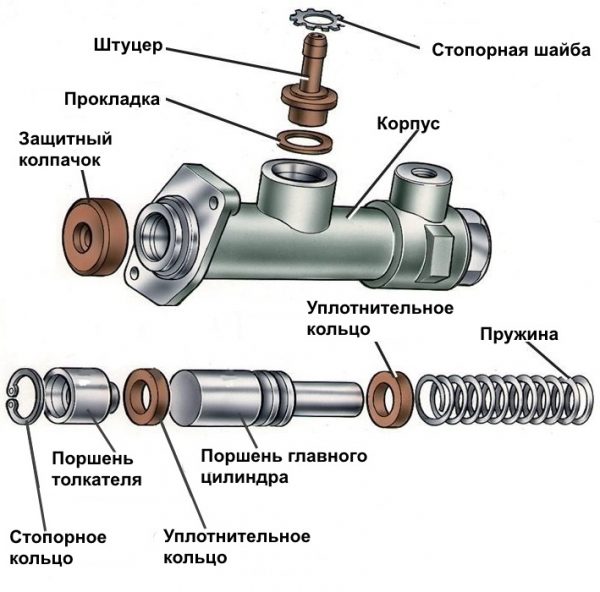

The device and purpose of the clutch master cylinder

GCC is designed to create pressure of the working fluid by moving the piston connected to the clutch pedal. It is installed in the engine compartment just below the pedal mechanism, mounted on two studs and connected to the working fluid reservoir with a flexible hose. The cylinder is arranged as follows. In its body there is a cavity in which a return spring, a working piston equipped with two sealing rings, and a floating piston are placed. The internal diameter of the GCC is 19,5 + 0,015–0,025 mm. Rust, scratches, chips are not allowed on the mirror surface of the cylinder and the outer surfaces of the pistons.

Replacing the master cylinder

Replacing the GCC is quite simple. This will require:

- a set of wrenches and heads;

- round-nose pliers for removing the retaining ring;

- a long thin screwdriver with a slot;

- disposable syringe for 10–22 ml;

- a small container for draining the working fluid.

The work is carried out in the following order:

- The working fluid is drained from the hydraulic clutch drive. To do this, you can use a medical syringe or simply pull off the sleeve from the GCS fitting.

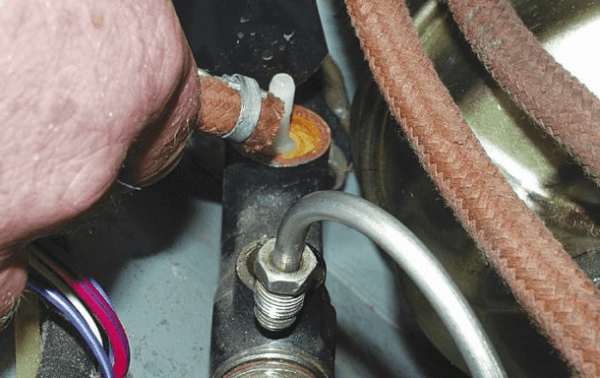

To remove the GCS, loosen the clamp with pliers and pull off the hose coming from the reservoir with the working fluid from the fitting

To remove the GCS, loosen the clamp with pliers and pull off the hose coming from the reservoir with the working fluid from the fitting - With a 10 open-end wrench, the fluid supply pipe to the working cylinder is unscrewed. In case of difficulty, you can use a special ring wrench with a slot for the tube and a clamping screw. With the help of such a key, the stuck nut of the fitting is turned off without any problems.

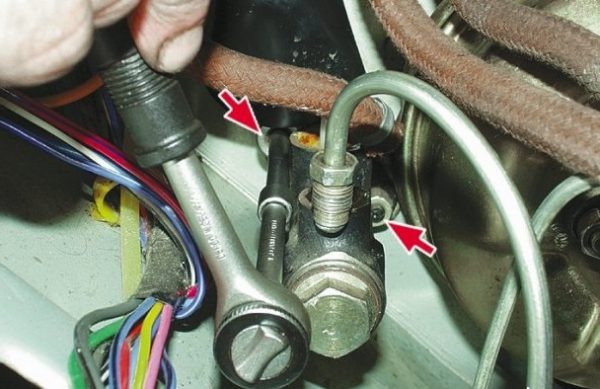

To dismantle the GCC, use the head and ratchet to unscrew the two nuts securing the clutch master cylinder

To dismantle the GCC, use the head and ratchet to unscrew the two nuts securing the clutch master cylinder - With a spanner wrench or a 13 head, the nuts securing the GCC to the front panel of the engine compartment are unscrewed. If you have difficulty, you can use the WD-40 liquid key.

- GCC is carefully removed. If it has become stuck, it can be moved from its place by carefully pressing the clutch pedal.

More about the device and replacement of the GCC: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/glavnyiy-tsilindr-stsepleniya-vaz-2107.html

Disassembly and assembly of the master cylinder

After carefully removing the GCC from the seat, you can begin to disassemble it. This is best done on a table or workbench with good lighting in the following order:

- Clean the outer surfaces of the housing from contamination.

- Carefully remove the protective rubber cover. Unscrew the fitting of the hose going to the tank with the working fluid.

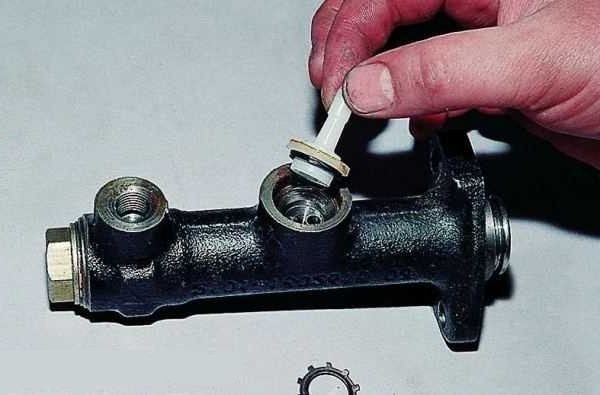

When disassembling the GCC, unscrew and remove the fitting, on which the hose from the brake fluid reservoir is put on.

When disassembling the GCC, unscrew and remove the fitting, on which the hose from the brake fluid reservoir is put on. - Use round-nose pliers to carefully squeeze and pull the circlip out of the groove.

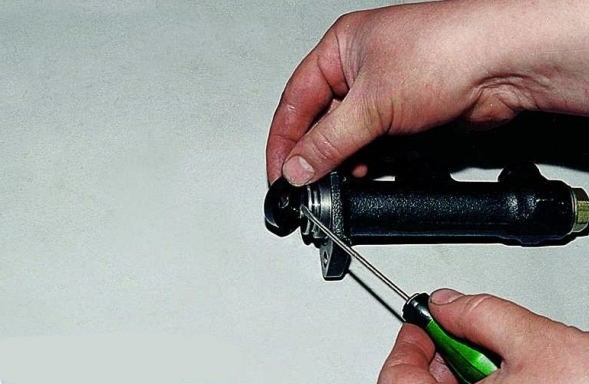

The retaining ring is removed from the GCC body using round-nose pliers

The retaining ring is removed from the GCC body using round-nose pliers - Unscrew the GCC plug.

- Using a screwdriver, carefully push the moving parts of the master cylinder out of the housing - the pusher piston, the master cylinder piston with o-rings and the spring.

- Carefully inspect all removed elements for mechanical damage, wear and corrosion.

- Replace parts unsuitable for further work with new parts from the repair kit.

- Replace all rubber products (rings, gaskets) regardless of their degree of wear.

- Before assembling, apply clean brake fluid to all moving parts and the mirror surface.

- When assembling, pay special attention to the correct installation of the spring, pistons and GCC pusher.

Assembly and installation of the assembled or new GCC is carried out in the reverse order.

Video: replacing the clutch master cylinder VAZ 2101–07

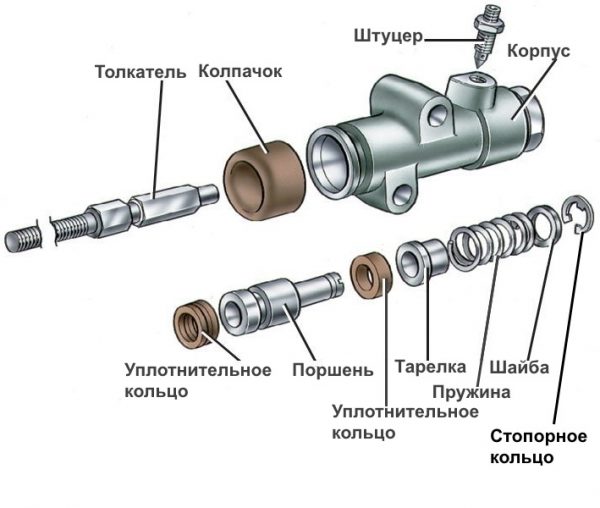

The device and purpose of the clutch slave cylinder

The RCS ensures the movement of the pusher due to the pressure of the TJ created by the main cylinder. The cylinder is located in a hard-to-reach place on the bottom of the gearbox and is fixed to the clutch housing with two bolts. The best way to get to it is from below.

Its design is slightly simpler than the design of the GCC. RCS is a housing, inside which there is a piston with two sealing rubber rings, a return spring and a pusher. Its working conditions are noticeably worse than those of the master cylinder. Dirt, impact from stones or road obstacles can cause the rubber protective cap to break and various contaminants enter the case. As a result, the wear of the sealing rings will accelerate, scratches will appear on the cylinder mirror and scoring on the piston. However, the designers provided for the possibility of repairing the main and working cylinders using repair kits.

Replacing the slave cylinder

It is more convenient to replace the RCS on a viewing hole, overpass or lift. This will require:

- set of wrenches;

- screwdriver;

- pliers;

- brake fluid DOT-3;

- preservation liquid;

- container for collecting operating fluid.

When dismantling the working cylinder, the following steps must be taken:

- Loosen the hydraulic hose fitting with a wrench for 17.

- Pull the end of the return spring out of the hole in the protruding end of the fork.

- Using pliers, pull out the cotter pin that locks the RCS pusher.

The pin is removed from the pusher hole using pliers

The pin is removed from the pusher hole using pliers - With a 13 head, unscrew the two screws securing the RCS on the clutch housing and pull them out together with the spring fastening bracket.

The bracket for fixing the return spring is removed together with the bolts

The bracket for fixing the return spring is removed together with the bolts - Remove the push rod from the slave cylinder and remove the slave cylinder itself.

- Unscrew the fitting of the brake fluid hose and drain it into a previously substituted container.

Care must be taken when disconnecting the hose fitting from the slave cylinder so as not to damage or lose the O-ring.

Dismantling and assembly of the working cylinder

The disassembly of the RCS is carried out in a certain sequence. For this you need:

- Carefully remove the protective rubber cap.

The protective rubber cap is removed from the working cylinder with a screwdriver

The protective rubber cap is removed from the working cylinder with a screwdriver - Clean the outer surfaces of the housing from dirt.

- Squeeze and pull out the retaining ring with round nose pliers.

- Unscrew the plug and carefully pry and remove the return spring with a screwdriver.

- Push out the piston with rubber seals.

- Carefully inspect all elements of the RCS for damage, wear and corrosion.

- Replace defective parts from the repair kit.

- Rinse the housing and all parts with a special preservation liquid.

- Before assembly, lower the piston with o-rings into a container with clean coolant. Apply the same liquid in a thin layer on the mirror of the cylinder.

- When assembling the RCS, take special care when installing the return spring and piston.

Installation of the RCS on its seat is carried out in the reverse order.

More about replacing the VAZ 2107 clutch: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/zamena-stsepleniya-vaz-2107.html

Video: replacing the clutch slave cylinder VAZ 2101–2107

Watch this video on YouTube

Malfunctions of the hydraulic clutch VAZ 2107

Incorrect operation of the hydraulic drive leads to a malfunction of the entire clutch mechanism.

Clutch does not disengage completely (clutch "leads")

If it is difficult to turn on the first speed, and the reverse gear does not turn on or it is also difficult to turn on, it is necessary to adjust the stroke of the pedal and the stroke of the RCS. Since the gaps are increased, they need to be reduced.

Clutch does not fully engage (clutch slips)

If, with a sharp press on the gas pedal, the car accelerates with difficulty, loses power on climbs, fuel consumption increases, and the engine overheats, you need to check and adjust the pedal stroke and the distance of movement of the working cylinder rod. In this case, there are no gaps, so they need to be increased.

The clutch works "jerks"

If the car twitches when starting off, the cause of this may be a malfunction of the GCC or RCS return spring. The saturation of the working fluid with air bubbles can lead to the same consequences. The reasons for the unstable operation of the clutch control hydraulics should be found and eliminated.

Pedal fails and does not return

The cause of pedal failure is usually an insufficient volume of operating fluid in the reservoir due to leakage in the working (more often) or master cylinder. The main reason for this is damage to the protective cap and penetration of moisture and dirt into the cylinder. Rubber seals wear out and gaps form between them and the cylinder walls. Through these cracks, the liquid begins to flow out. It is necessary to replace the rubber elements, add liquid to the tank to the required level and remove air from the system by pumping.

Do not add used brake fluid to the hydraulic clutch control system, as it contains tiny air bubbles.

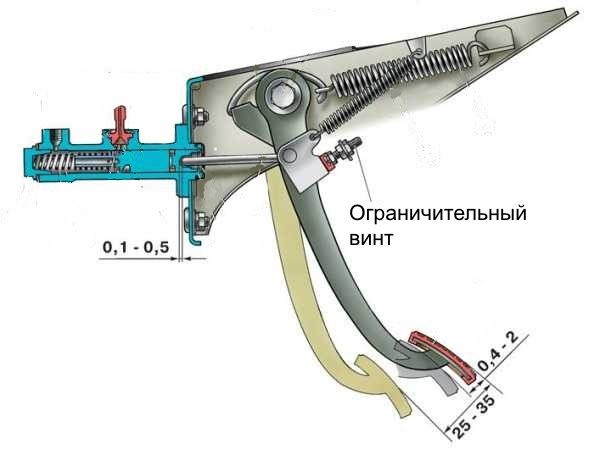

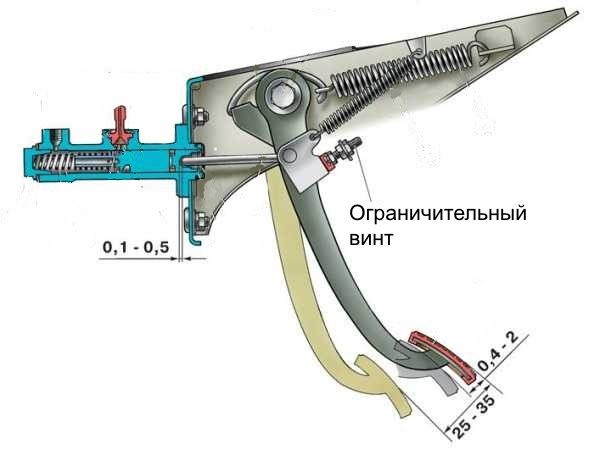

Adjustment of the pedal stroke and pusher of the working cylinder

The free play of the pedal is regulated by a limit screw and should be 0,4–2,0 mm (distance from the upper position to the stop of the pusher in the master cylinder piston). To set the required clearance, the screw lock nut is loosened with a wrench, and then the screw itself rotates. The working stroke of the pedal should be 25–35 mm. You can adjust it with the pusher of the working cylinder.

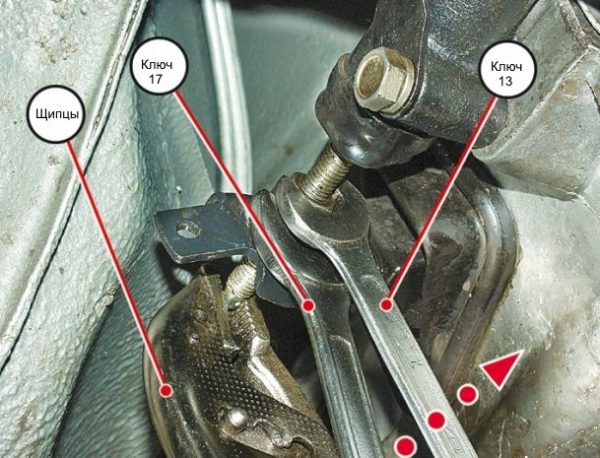

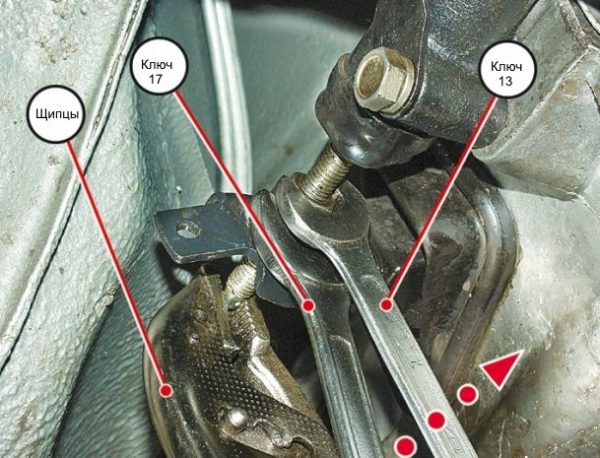

The length of the pusher of the working cylinder directly affects the gap between the end face of the release bearing and the fifth basket, which should be 4–5 mm. To determine the clearance, remove the return spring from the release bearing fork and move the fork itself by hand. The fork should move within 4–5 mm. To adjust the gap, use a 17 key to loosen the lock nut while holding the adjusting nut with a 13 key. During the adjustment, the pusher must be fixed. To do this, he has a turnkey flat of 8 mm, for which it is convenient to hook on with tongs. After setting the required clearance, the lock nut is tightened.

Working fluid for hydraulic clutch VAZ 2107

The clutch hydraulic drive uses a special fluid, which is also used in the brake system of classic VAZ models. In both cases, it is necessary to create a working environment that can withstand high pressure and does not destroy rubber products. For VAZ, it is recommended to use compositions such as ROSA DOT-3 and ROSA DOT-4 as such a liquid.

The most important characteristic of TJ is the boiling point. In ROSA it reaches 260оC. This characteristic directly affects the service life of the liquid and determines its hygroscopicity (ability to absorb water). The accumulation of water in the liquid liquid gradually leads to a decrease in the boiling point and the loss of the original properties of the liquid.

For the hydraulic clutch VAZ 2107, 0,18 liters of TJ will be required. It is poured into a special tank for the working fluid, which is located in the engine compartment near the left wing. There are two tanks: the far one is for the brake system, the near one is for the hydraulic clutch.

The service life of the working fluid in the hydraulic clutch VAZ 2107 regulated by the manufacturer is five years. That is, every five years the fluid must be changed to a new one. It's easy to do. You need to drive the car into a viewing hole or overpass and perform the following steps:

- unscrew the lid of the reservoir for the working fluid;

- clean the working cylinder from dirt;

- unscrew the fitting with the hose and insert the end of the hose into a previously prepared container;

- by pressing the clutch pedal, to completely drain the fluid from the system;

- screw the fitting into place;

- fill in fresh brake fluid;

- bleed the clutch hydraulic drive according to the algorithm described below.

Bleeding the hydraulic clutch VAZ 2107

The main purpose of bleeding the clutch hydraulic drive is to remove air from the TJ through a special fitting located on the working hydraulic cylinder of the release bearing drive. Air can get into the clutch hydraulic system in different ways:

- through the slots at the hose connection points;

- through loose threaded connections;

- when replacing the working fluid;

- when repairing or replacing the GCC or RCC.

It should be understood that clutch control using hydraulics refers to devices of frequent use during vehicle operation. The presence of air bubbles in the release bearing drive system will make it difficult for the lever to shift into low gear when pulling away. It's easier to say: the box will "growl". Driving becomes almost impossible.

Tools and materials

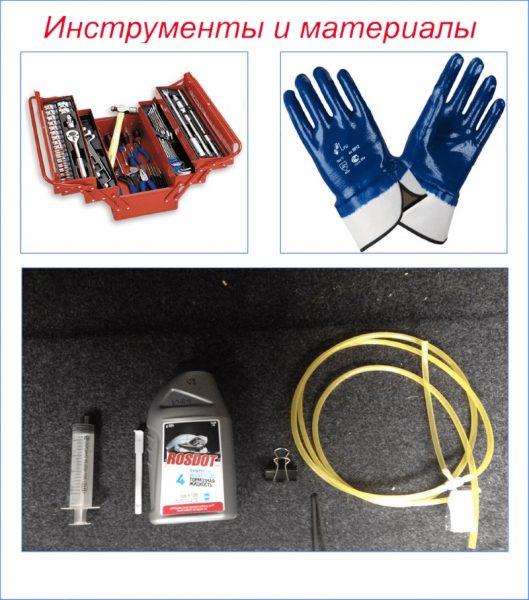

To remove air from the clutch hydraulic drive, you will need:

- a set of wrenches and spanners;

- a hammer;

- slotted and Phillips screwdrivers;

- pliers;

- measuring ruler, square;

- WD-40 or other rust remover;

- transparent rubber hose of the diameter corresponding to the fitting;

- a small container for collecting operating fluid;

- working fluid for topping up or replacing.

To bleed the VAZ 2107 clutch hydraulic drive, you will need a set of tools, rubber gloves to protect your hands, a rubber hose and a container of brake fluid

To bleed the VAZ 2107 clutch hydraulic drive, you will need a set of tools, rubber gloves to protect your hands, a rubber hose and a container of brake fluid

Bleeding of the clutch hydraulic drive can be started only after the elimination of all identified defects in the main and working cylinder, tube and hoses for supplying operating fluid. Work is carried out on a viewing hole, overpass or lift, and an assistant is required.

Clutch bleeding procedure

It's pretty easy to do the download. Actions are performed in the following order:

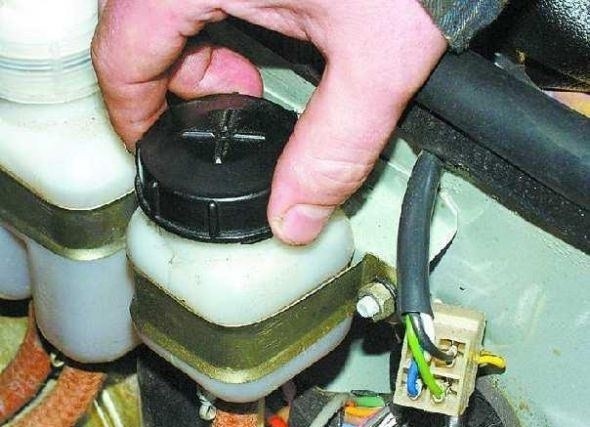

- We unscrew the cap on the tank with the GCS operating fluid.

To bleed the hydraulic clutch, you need to unscrew the cap of the reservoir with the working fluid

To bleed the hydraulic clutch, you need to unscrew the cap of the reservoir with the working fluid - Using a screwdriver, remove the protective cap on the drain fitting of the working cylinder and put a transparent tube on it, the other end of which is inserted into the container.

- The assistant vigorously presses the clutch pedal several times (from 2 to 5) and fixes it pressed.

When bleeding the clutch hydraulic drive, you need to press the clutch pedal hard several times, and then hold it down

When bleeding the clutch hydraulic drive, you need to press the clutch pedal hard several times, and then hold it down - With a key of 8, we turn the fitting to remove air half a turn counterclockwise and observe the appearance of bubbles.

To drain the brake fluid with air bubbles, turn the fitting counterclockwise by half a turn.

To drain the brake fluid with air bubbles, turn the fitting counterclockwise by half a turn. - The assistant presses the pedal again and keeps it depressed.

- We continue pumping until the air is completely removed from the system, that is, until gas bubbles stop coming out of the liquid.

- Remove the hose and tighten the fitting until it stops.

- We check the level of fluid in the tank and, if necessary, fill it up to the mark.

Video: clutch bleeding VAZ 2101–07

Since bleeding the hydraulics of the clutch drive is the final action, carried out after the elimination of all malfunctions in the clutch control system, it is necessary to perform it carefully, accurately, consistently. The working stroke of the clutch pedal should be free, not very difficult, with a mandatory return to its original position. The left foot is often used in driving, so it is important to properly adjust the free and working travel of the outboard clutch pedal.

Bleeding the hydraulic clutch drive of classic VAZ models does not require any special knowledge and skills. Nevertheless, this simple operation is very important for maintaining vehicle controllability. Bleeding the hydraulic clutch yourself is quite simple. This will require a standard set of tools, an assistant and careful following of the instructions of specialists.