Do-it-yourself catalyst repair

Content

If a diagnosis of the catalyst was carried out, which showed that the element was clogged and the resistance to the passage of exhaust gases increased significantly, then the catalyst needs to be flushed. When washing with a catalyst cleaner is not possible (due to mechanical damage), then the part will have to be replaced. If it is not economically feasible to replace the catalyst, the catalyst will have to be removed.

The principle of operation and the role of the catalyst

Most modern cars are equipped with two converters: main and preliminary.

Exhaust system

base catalyst

A pre-converter is built into the exhaust manifold (so its warming up to operating temperature is significantly accelerated).

Theoretically, for internal combustion engines, catalytic converters are harmful, as the resistance of the exhaust tract increases significantly. In order to maintain the required temperature of the catalyst in some modes, it becomes necessary to enrich the mixture.

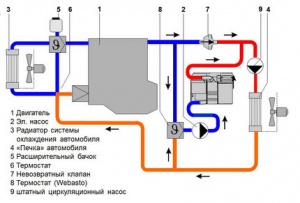

As a result, this leads to a noticeable decrease in engine performance in terms of fuel consumption and power. But sometimes simply removing the catalyst can make things worse, as the exhaust gas treatment system on most cars is tightly coupled to the engine control system. It is likely that the operation of the internal combustion engine will be carried out in emergency mode (CHECK ENGINE), which will undoubtedly lead to power limitation, as well as increased fuel consumption.

How to repair a catalyst

In the event that you still decide to remove the catalyst, then you first need to find out about the likely consequences and ways to help get around them. It is advisable to communicate with the owners of such cars (there are a huge number of clubs for car lovers of a certain brand on the Internet).

Condition of catalyst cells

In general, in the case indicated in the diagram above, the first oxygen sensor does not monitor the state of the catalysts, the removal of the latter will not affect its readings, the second temperature sensor will have to be deceived, for this we install a snag screw under the sensor, we do this in order to so that the readings of the sensor without a catalyst were equal or approximate to those that were with the catalyst installed. If the second sensor is also a lambda, you need to be more careful, since after removing the catalyst, you will most likely need to flash the ICE control unit (in some cases, you can make a correction).

In the case shown in the diagram above, the readings of the sensors are influenced by the state of the pre-catalyst. so, it would be more correct to remove the base catalyst and rinse the preliminary one.

As a result, we get the minimum resistance of the exhaust tract, these changes will not have any effect on the ICE control system, but when the screw is screwed in, the readings of the exhaust gas temperature sensor will be erroneous and this is not good. But this is all theory, but in practice it is necessary to take into account the state of the catalyst cells.

We draw up a work plan - we wash the preliminary catalyst and remove the base one, and that's it, you can start.

First you need to remove the exhaust manifold, the pre-catalyst is integrated in it:

An exhaust manifold. Manifold mounting bolts

An exhaust manifold. Preneutralizer

Remove the exhaust manifold. We end up with the following detail:

Cells are long, but rather thin channels, so we diagnose their condition carefully in the light, it is advisable to use a small but bright enough light source, the voltage of which does not exceed 12V (we follow safety rules).

External inspection:

The condition of the cells is almost perfect for a run of 200 thousand km.

When checking for light, a small defect was found, it does not pose danger and harm:

Flushing is carried out if there are no mechanical damages (these include subsidence, burnout, etc.), the presence of deposits, which significantly reduce the flow area. The honeycomb must be thoroughly blown with a carburetor spray or use a foam catalyst cleaner.

If there are a lot of deposits, then after blowing with a spray, the catalyst can be soaked overnight in a container with diesel fuel. After that, repeat the purge. Do not forget about the exhaust gas recirculation channel (another environmentalist trick):

If you nevertheless removed the preliminary catalyst, then the channel will have to be thoroughly washed, since the crumb formed during removal can get into the inlet, and from there into the cylinders (it is easy to guess that the cylinder mirror will not suffer slightly).

All operations that are carried out with the main catalyst are similar to those described for the example of the pre-catalyst. then we start the assembly, you need to assemble in the reverse order, the gaskets must be new or very well cleaned old ones, we assemble them carefully, do not forget anything.

Removing the base catalyst

In my case, it was enough to unscrew the two nuts securing the outlet pipe, as well as bend the line after the converter to the side.

Surprisingly Japanese catalyst, after 200 thousand kilometers is still full of energy.

Of course, a pitifully expensive catalyst, but it needs to be broken through, so we will make it easier for the internal combustion engine to breathe. Catalyst cells are very easy to punch with a puncher with a 23 mm drill.

I did not remove the entire catalyst cell, I punched two holes, the excess was removed.

The goal of only partial removal of the catalyst is simple - the cells that remain around the walls will reduce resonant vibrations, and the punched hole is enough to get rid of the increased resistance to the passage of exhaust gases in the catalyst area.

Looks like this up close:

After removing the honeycombs, we remove their fragments from the catalyst barrel. To do this, you need to start the car and run it well until the dust from the ceramics stops flowing. Then we put the outlet pipe in place and enjoy the result.

Advantages of Partial Catalyst Removal:

- noise level similar to stock;

- you can get rid of rattling in the area of \uXNUMXb\uXNUMXbthe catalyst barrel;

- increase in internal combustion engine power by approximately 3%;

- fuel consumption is reduced by 3%;

- ceramic dust will not enter the combustion chamber.

That's all, as you noticed, removing the catalyst will not present any difficulty. In the service, they tried to breed me for cutting the catalyst, cleaning and re-welding the body. Accordingly, they would have turned down the corresponding price for “such a complicated”, and moreover, useless work.

Source: http://avtogid4you.narod2.ru/In_the_garage/overhaul_catalytyc