Do-it-yourself repair of the working cylinder and adjustment of the clutch drive VAZ 2107

Content

Clutch problems can cause serious trouble for owners of vehicles with a manual transmission. VAZ 2107 is no exception. However, most of the faults can be easily eliminated with your own hands.

The device and principle of operation of the clutch VAZ 2107

VAZ 2107 is equipped with a single-disc dry-type clutch with a hydraulic drive. The drive design includes:

- a tank with a stopper and a built-in liquid damper;

- suspended pedal with a pusher;

- main and working cylinders;

- metal pipeline;

- the hose connecting the pipeline and the working cylinder.

When the pedal is pressed, the force is transmitted through the pusher to the piston of the clutch master cylinder (MCC). The GCC is filled with brake fluid coming from the hydraulic drive reservoir. The piston pushes out the working fluid, and it enters the clutch slave cylinder (RCS) under pressure through the pipeline and rubber hose. In the RCS, the pressure increases, and the fluid pushes the rod out of the device, which, in turn, actuates the clutch fork. The fork, in turn, moves the release bearing, disengaging the pressure and driven disks.

Clutch slave cylinder VAZ 2107

RCC is the final link of the clutch hydraulic drive. Its more frequent failure in comparison with other components of the mechanism is associated with increased loads resulting from high fluid pressure.

About replacing the clutch master cylinder VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/glavnyy-cilindr-scepleniya-vaz-2106.html

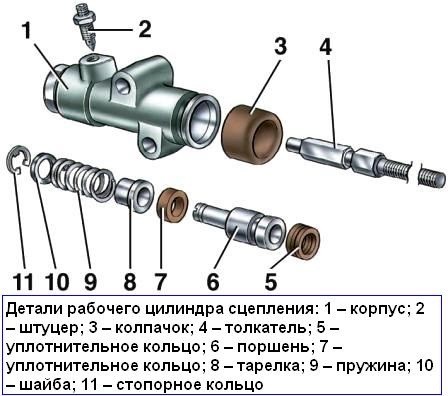

RCS device

The working cylinder of the VAZ 2107 consists of:

- housing;

- piston;

- rod (pusher);

- springs;

- protective cap (cover);

- two cuffs (o-rings);

- air bleed valves;

- retaining ring with washer.

The clutch slave cylinder has a fairly simple device.

The clutch slave cylinder has a fairly simple device.

Location of the RCS

Unlike the GTS, which is located in the VAZ 2107, the slave cylinder is located on the clutch housing and is bolted to the bottom of the “bell” with two bolts. You can only get to it from below, after removing the engine protection (if any). Therefore, all work is carried out on a viewing pit or overpass.

Check out engine tuning options: https://bumper.guru/klassicheskie-modeli-vaz/tyuning/tyuning-dvigatelya-vaz-2107.html

Signs of a malfunction of the RCS

The failure of the RCS is accompanied by the following symptoms:

- unusually soft travel of the clutch pedal;

- periodic or persistent clutch pedal failures;

- a sharp decrease in the level of the working fluid in the tank;

- the appearance of traces of liquid under the car in the area of the gearbox;

- Difficulty switching gears, accompanied by a crunch (grinding) in the checkpoint.

These signs may be the result of other malfunctions (the entire clutch mechanism, HCC, gearbox, etc.). Therefore, before starting work on the replacement or repair of the RCS, you need to make sure that it is he who is "to blame". To do this, it should be carefully examined. If traces of working fluid are found on the cylinder body, on its rod or hose, you can begin to dismantle the RCC.

The main malfunctions of the RCS

The main part of the RCS is made of durable steel, so it is completely changed only in case of serious mechanical damage. In other cases, you can limit yourself to repairs. Most often, the cylinder fails due to wear of the piston o-rings, protective cover, malfunction of the air release valve and damage to the hose connecting the cylinder and the pipeline.

Repair kit for RCS

Any defective part can be purchased separately. However, when replacing the cuffs, it is more advisable to buy a repair kit that includes three rubber seals and a protective cover. For classic VAZ models, repair kits are produced under the following catalog numbers:

- 2101-1602516;

- 2101-1605033;

- 2101-1602516.

The repair kit for the clutch slave cylinder VAZ 2107 includes a protective cover and three cuffs

The repair kit for the clutch slave cylinder VAZ 2107 includes a protective cover and three cuffs

The cost of such a set is about 50 rubles.

Clutch slave cylinder repair

To repair the RCS, you need to remove it from the car. This will require:

- round nose pliers or pliers;

- wrenches for 13 and 17;

- container for draining liquid;

- clean dry cloth.

Dismantling of the RCS

Dismantling of the RCS is carried out in the following order:

- We install the car on a viewing pit or overpass.

- From the inspection hole with a key of 17, we unscrew the tip of the connection between the hydraulic hose and the working cylinder.

The tip of the hydraulic drive hose is unscrewed with a 17 wrench

The tip of the hydraulic drive hose is unscrewed with a 17 wrench - At the end of the hose, we substitute the container and collect the liquid flowing from it.

- Disconnect the return spring from the clutch fork with pliers and remove it.

Coupling spring is removed with pliers

Coupling spring is removed with pliers - With pliers we pull out the cotter pin from the cylinder rod.

The pin is pulled out of the cylinder rod with pliers

The pin is pulled out of the cylinder rod with pliers - Using a 13 key, unscrew the two bolts securing the RCS to the crankcase.

The clutch slave cylinder is bolted to the crankcase with two bolts.

The clutch slave cylinder is bolted to the crankcase with two bolts. - Disconnect the spring clip and remove it.

The return spring bracket is mounted on the same bolts as the cylinder

The return spring bracket is mounted on the same bolts as the cylinder - We remove the rod of the working cylinder from engagement with the fork.

The rod of the working cylinder is connected to the fork

The rod of the working cylinder is connected to the fork - We remove the cylinder and with a rag remove traces of the working fluid and dirt from it.

Read also about the repair of the hydraulic clutch: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/kak-prokachat-stseplenie-na-vaz-2107.html

Dismantling and replacement of faulty parts of the RCS

To disassemble and repair the cylinder, you will need:

- a wrench on 8;

- slotted screwdriver;

- clean dry cloth;

- some brake fluid.

The working cylinder is disassembled in the following sequence:

- We clamp the cylinder in a vice.

- With an open-end wrench for 8, we unscrew the air bleed valve and inspect it for damage. If a malfunction is suspected, we purchase a new valve and prepare it for installation.

The fitting of the working cylinder is unscrewed with a key for 8

The fitting of the working cylinder is unscrewed with a key for 8 - Remove the protective cover with a thin slotted screwdriver.

The cover is detached with a thin screwdriver

The cover is detached with a thin screwdriver - We take out the pusher from the cylinder.

- Using a screwdriver, carefully pry the piston out of the cylinder.

To remove the piston, push it out of the cylinder with a screwdriver.

To remove the piston, push it out of the cylinder with a screwdriver. - Disconnect the retaining ring with a screwdriver.

To remove the retaining ring, you need to pry it with a screwdriver.

To remove the retaining ring, you need to pry it with a screwdriver. - Remove the spring and washer from the piston.

When disassembling the RCS, the spring is removed from the piston

When disassembling the RCS, the spring is removed from the piston - Remove the back cuff.

To detach the washer and the back cuff, it is enough to move them

To detach the washer and the back cuff, it is enough to move them - Remove the front cuff with a screwdriver.

To remove the front cuff, you need to pry it with a screwdriver.

To remove the front cuff, you need to pry it with a screwdriver. - We carefully inspect the inner surface of the cylinder (mirror) and the surface of the piston. If they are scored or dented, the entire cylinder should be replaced.

Before replacing the piston cuffs and the protective cover, the metal parts of the cylinder must be cleaned of dirt, dust, traces of moisture using brake fluid and a clean rag. New seals and a cover are installed during the RCS assembly process. First, the front cuff is put on the piston, then the back. In this case, the rear cuff is fixed with a washer. The protective cover is installed together with the pusher. The assembly of the device and its installation is carried out in the reverse order.

Video: repair of the clutch slave cylinder VAZ 2107

Bleeding the clutch hydraulic drive

After any work related to depressurization of the clutch mechanism, as well as when changing the fluid, the hydraulic drive must be pumped. For this you will need:

- brake fluid (0,3 l);

- rubber hose;

- key on 8;

- a container for collecting liquid (a plastic bottle with a volume of 0,5 liters is suitable).

In addition, an assistant is required for pumping. The procedure is as follows:

- After installing the RCS and connecting the hose to it, pour liquid into the reservoir of the hydraulic drive to a level corresponding to the lower edge of the neck.

- We put one end of the pre-prepared hose on the valve fitting to bleed air, and lower the other end into a container to collect liquid.

One end of the hose is put on the fitting, the other is lowered into a container to collect liquid

One end of the hose is put on the fitting, the other is lowered into a container to collect liquid - We ask the assistant to press the clutch pedal 4–5 times and hold it down.

- With a key 8, unscrew the air bleed valve fitting by about three quarters of a turn. We are waiting for the air to come out of the cylinder together with the liquid.

- We twist the fitting into place and ask the assistant to repeat pressing the pedal. Then we bleed the air again. Bleeding cycles are repeated until all the air is out of the system, and fluid without bubbles starts to flow out of the nozzle.

It is necessary to bleed air until fluid without bubbles comes out of the hose

It is necessary to bleed air until fluid without bubbles comes out of the hose - We check the work of the clutch. The pedal should be squeezed out with effort and without failures.

- Add brake fluid to the reservoir to the required level.

Clutch drive adjustment

After bleeding, it is recommended to adjust the clutch actuator. For this you will need:

- a caliper or (in extreme cases) a ruler;

- wrenches on 8, 10, 13, 17;

- round nose pliers or pliers.

The procedure for adjusting the clutch on the carburetor and injection models of the VAZ 2107 is different. In the first case, the clutch pedal free travel setting is adjusted, in the second - the amplitude of movement of the working cylinder rod.

For carburetor VAZ 2107, the drive is configured as follows:

- We measure the magnitude of the free travel (backlash) of the clutch pedal using a vernier caliper. It should be 0,5–2,0 mm.

- If the amplitude is outside the specified limits, with a 10 key, unscrew the lock nut on the stroke limiter stud and, turning the limiter in one direction or another, set the required backlash.

The working stroke of the clutch pedal is regulated by a limiter

The working stroke of the clutch pedal is regulated by a limiter - Tighten the lock nut with a 10 key.

- We check the full pedal travel (from the upper position to the lower one) - it should be 25–35 mm.

For injection VAZ 2107, the drive is adjusted in the following order:

- We install the car on a viewing pit or overpass.

- From below, using pliers, remove the tension spring from the clutch fork.

- Determine the backlash of the slave cylinder pusher by pushing the clutch fork all the way back. It should be 4–5 mm.

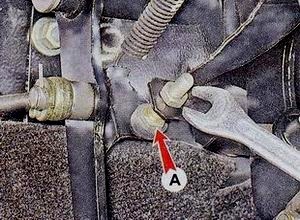

- If the backlash does not fall within the specified interval, with a 17 key we hold the stem adjustment nut, and with a 13 key we unscrew the fixing nut.

To unscrew the adjusting and fixing nuts, you need wrenches for 13 and 17

To unscrew the adjusting and fixing nuts, you need wrenches for 13 and 17 - With a key of 8 we fix the stem from turning by grabbing it by the shoulder, and with a key of 17 we rotate the stem adjustment nut until its backlash becomes 4–5 mm.

The backlash of the stem is adjusted with an adjusting nut

The backlash of the stem is adjusted with an adjusting nut - Having fixed the adjusting nut in the desired position with a 17 key, tighten the lock nut with a 13 key.

- We check the value of the full pedal travel. It should be 25–35 mm.

Slave cylinder hose

The hose connecting the pipeline and the slave cylinder must be replaced if:

- visible damage accompanied by leakage of brake fluid;

- detection of cracks, swellings (cones) on its surfaces;

- wear of the threaded connections of the tips.

The hoses produced by domestic enterprises have the catalog number 2101-1602590 and cost about 100 rubles.

To replace the hose you need:

- Place the machine on an overpass or inspection pit.

- Raise the hood and locate the junction of the hydraulic line and the slave cylinder hose in the engine compartment.

- Using a 17 key, fix the hose tip, and with a 13 key, unscrew the fitting on the pipeline. Place a container at the end of the pipeline and collect the liquid flowing out of it.

- Using a 17 wrench, unscrew the tip of the other end of the hose from the RCS housing. A rubber O-ring is installed in the cylinder seat, which must also be replaced.

- Install a new hose in reverse order.

Thus, diagnostics, repair and replacement of the VAZ 2107 clutch slave cylinder is not very difficult even for an inexperienced motorist. The minimum set of tools and the recommendations of professionals will allow you to complete all work with a minimum investment of time and money.