Self-diagnosis of clutch malfunctions VAZ 2107

Content

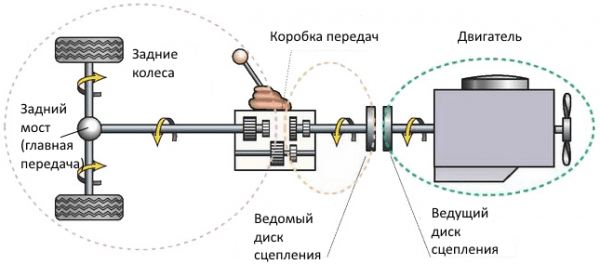

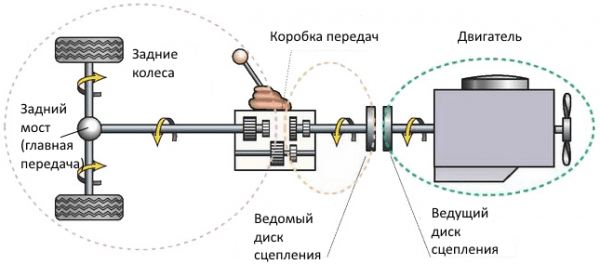

The VAZ 2107 clutch is a part of the transmission mechanism involved in the transmission of torque to the drive wheels of the car. All classic VAZ models are equipped with a single-plate clutch with a central spring. The failure of any clutch element can bring big trouble to the car owner. However, most problems can be solved on your own.

Clutch VAZ 2107

The controllability of the car largely depends on the serviceability of the VAZ 2107 clutch mechanism. How often this mechanism will have to be repaired is affected by the quality of the roads and the experience of the driver. For beginners, as a rule, the clutch fails quite quickly, and the repair and replacement of the assembly is quite labor-intensive.

Clutch assignment

The main task of the clutch is to transfer torque from the engine to the driving wheels of the car.

Initially, it was intended for short-term separation of the engine and final drive during smooth starting and gear changes. The VAZ 2107 clutch has the following characteristic properties:

- has the smallest allowable moment of inertia at the driven disk;

- removes heat from rubbing surfaces;

- protects transmission from dynamic overloads;

- does not require a lot of pressure on the pedal while controlling the clutch;

- has compactness, maintainability, low noise, ease of maintenance and care.

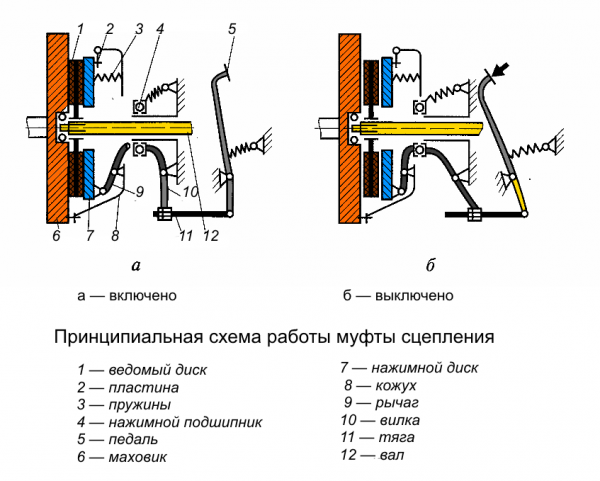

The device and principle of operation of the clutch VAZ 2107

Clutch VAZ 2107:

- mechanical (actuated by mechanical forces);

- frictional and dry (torque is transmitted due to dry friction);

- single disk (one slave disk is used);

- closed type (clutch is always on).

Clutch can be conditionally represented as four components:

- driving or active part (crankshaft flywheel 6, basket with casing 8 and pressure steel disk 7);

- slave or passive part (slave or passive disk 1);

- inclusion elements (springs 3);

- switching elements (levers 9, fork 10 and thrust bearing 4).

A casing 8 of the basket is bolted to the flywheel, connected by damper plates 2 to the pressure plate 7. This creates conditions for the transfer of constant torque from the flywheel through the casing to the pressure plate, and also ensures that the latter moves along the axis when the clutch is turned on and off. The driving part rotates constantly when the engine is running. The passive disk moves freely along the splines of the input shaft 12 of the gearbox. The hub is connected to the driven disk through damper springs 3 and due to this it has the possibility of a certain elastic rotation. Such a connection dampens the torsional vibrations that occur in the transmission due to the operation of the engine at different speeds and the corresponding dynamic loads.

When the pedal 5 is depressed, the passive disk 1 is clamped between the flywheel 3 and the pressure disk 6 with the help of springs 7. The clutch is turned on and rotates together with the crankshaft as a whole. The rotational force is transmitted from the active to the passive part due to the friction that occurs on the surface of the friction linings of the driven disk, flywheel and pressure disk.

When the pedal 5 is depressed, the hydraulic fork moves the clutch with the pressure bearing towards the crankshaft. The levers 9 are pressed inward and pull the pressure disc 7 away from the driven disc 1. The springs 3 are compressed. The active rotating part is disconnected from the passive one, the torque is not transmitted, and the clutch is disengaged.

When the clutch is engaged, the driven disc slips against the smooth surfaces of the flywheel and pressure plate, so the torque increases gradually. This allows the machine to move off smoothly and protects the transmission units during overloads.

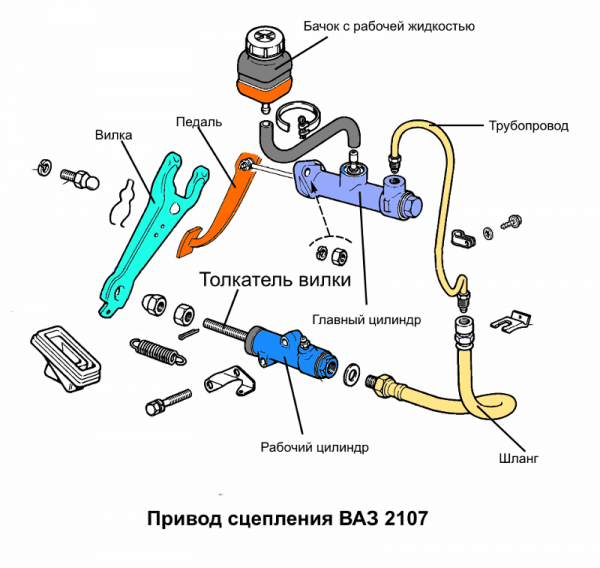

Clutch hydraulic drive device

The transmission of torque from the engine to the drive wheels is carried out using a hydraulic drive.

The hydraulic drive plays an important role in starting the car and changing gears. It consists of:

- pedal;

- main and working cylinders;

- pipeline and hose;

- pusher;

- fork on and off the clutch.

The hydraulic drive allows you to smoothly engage and disengage the clutch, without exerting much effort when pressing the pedal.

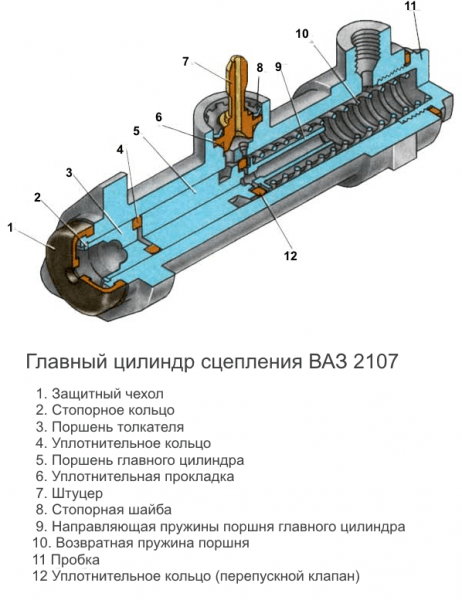

Clutch master cylinder

The clutch master cylinder (MCC) when you press the pedal increases the pressure of the working fluid. Due to this pressure, the rod of the fork on / off the clutch moves.

The pusher piston 3 and the master cylinder piston 5 are located in the GCC housing. The use of an additional pusher piston reduces the radial force on the GCC piston when the pedal is pressed. In this case, the sealing ring 4 is pressed against the walls of the cylinder mirror and improves the sealing of the pistons. To ensure tightness inside the cylinder, an o-ring 12 is located in the groove of the piston 5.

For additional sealing of the piston, an axial hole is drilled in its guide part 9, connected to the ring groove by 12 radial channels. With an increase in pressure in the working space of the GCC, it reaches the inner part of the ring 12 and bursts it. Due to this, the tightness of the master cylinder piston is increased. At the same time, ring 12 acts as a bypass valve through which the working part of the cylinder is connected to the reservoir with the working fluid. When the pistons reach the end position at the plug 11, the sealing ring 12 opens the compensation hole.

Through this hole, when the clutch is engaged (when the RCS piston creates excess back pressure), part of the fluid passes into the reservoir. The pistons are returned to their original position by the spring 10, which with one end presses on the plug 11, and with the other end on the guide 9 of the piston 5. All internal parts of the GCC are fixed with a retaining ring 2. A protective cover is put on the mounting side of the GCC, which protects the working part of the cylinder from dirt .

Most often, the sealing rings wear out on the master cylinder. They can always be replaced from a repair kit. With more serious malfunctions, the GCC changes entirely.

If the compensation hole becomes clogged, excess pressure will be created inside the drive system, which will not allow the clutch to fully engage. She will wobble.

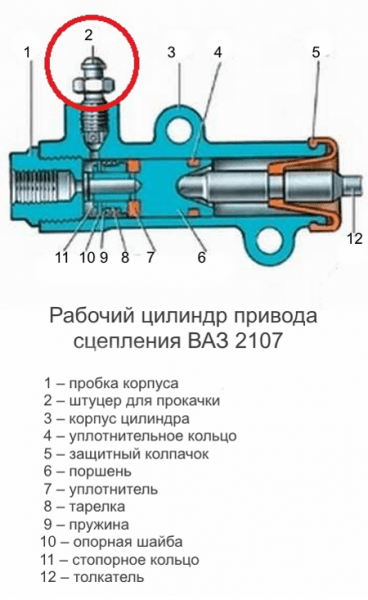

Clutch slave cylinder

The clutch slave cylinder (RCS) is attached with two bolts to the gearbox housing in the clutch housing area. Such an arrangement of the RCS leads to the fact that dirt, water, stones often get on it from the road. As a result, the protective cap is destroyed, and the wear of the sealing rings is accelerated.

When you press the pedal in the clutch hydraulic drive, pressure is created that is transmitted to the piston 6. The piston, moving inside the cylinder, moves the pusher 12, which, in turn, turns the clutch on and off fork on the ball bearing.

It is very important to observe the dimensions of the internal mirror of the main and working cylinders. When assembled at the factory, they are equal to each other - 19,05 + 0,025–0,015 mm. Therefore, the sealing rings on the pistons of both cylinders are completely interchangeable. If you need to make the clutch pedal softer, you need to buy a foreign analogue of the working cylinder with a smaller diameter of the working cavity. If the diameter is larger, then the pressure on it will be less. Therefore, in order to overcome the elastic force of the friction springs of the basket, it is necessary to apply a large force. Therefore, the pedal will be tighter.

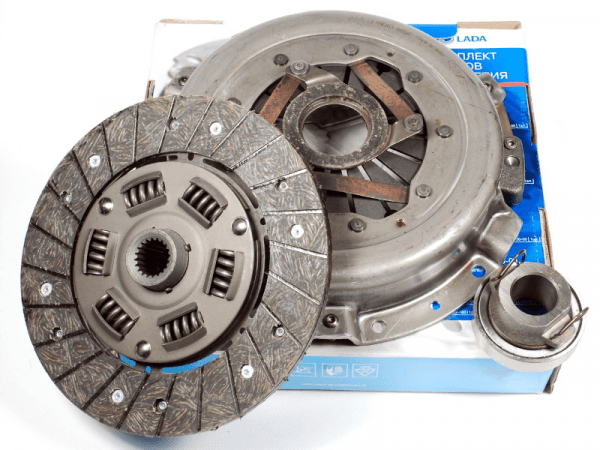

The composition of the clutch kit VAZ 2107

Clutch kit VAZ 2107 consists of:

- baskets;

- driven disk;

- pressure bearing.

According to the VAZ regulations, these elements are not repaired, but are immediately replaced with new ones.

Read how to pump the clutch on a VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/kak-prokachat-stseplenie-na-vaz-2106.html

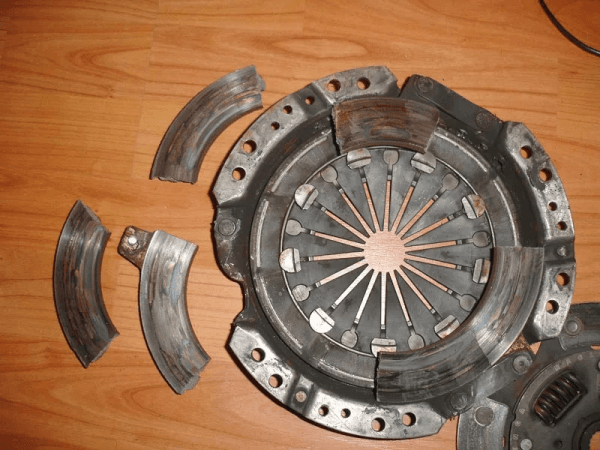

Cart

The basket has the most complex device of the clutch kit. It consists of many parts that require correct and precise assembly. They assemble the basket only in the factory and do not repair it even in specialized car services. When worn or serious defects are found, the basket is replaced with a new one. The main faults of the basket:

- loss of elasticity due to sagging of the springs;

- mechanical damage and fracture of damper plates;

- the appearance of wear marks on the surface of the pressure plate;

- kinks and cracks on the casing of the basket;

- another.

The service life of the clutch is determined by the resource of the basket, driven disk or thrust bearing. Therefore, to avoid the cost of repeated repairs, the coupling is always changed as a set.

Slave drive

The driven disk is designed to transmit torque from the engine flywheel to the gearbox input shaft and can briefly disconnect the gearbox from the engine. The manufacturing technology of such discs is rather complicated and involves the use of special equipment. Therefore, it is impossible to repair the disk yourself. It is replaced with a new one when:

- wear of friction linings;

- wear of the inner splines of the hub;

- detection of defects in damper springs;

- loosening nests under the springs.

Thrust bearing

The thrust bearing is designed to move the pressure plate away from the driven one and is activated when the clutch pedal is pressed. Its malfunctions are usually accompanied by whistling, knocking and other sounds. When the rollers are jammed, the supporting working surface or the seat in the cup are worn out, the pressure bearing assembly is changed.

Clutch malfunctions VAZ 2107

The main signs of a faulty VAZ 2107 clutch are:

- difficult to shift gears;

- the driven disk slips;

- vibration appears;

- thrust bearing whistles;

- the clutch is hard to disengage;

- the pedal does not return from the lower position.

Almost any malfunction is accompanied by extraneous sounds - noise, knocks, whistling, etc.

Find out why the car may jerk when starting off: https://bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/pri-troganii-s-mesta-mashina-dergaetsya.html

Gears are not shifting

If the gears are shifting with difficulty, an experienced driver will immediately tell that the clutch is leading. In other words, the clutch is not completely disengaged. As a result, when starting off, it is difficult to engage first gear, and when the pedal is depressed, the car moves slowly. The reasons for this situation may be:

- Increased distance between thrust bearing seat and basket heel. It must be set within 4–5 mm by changing the length of the working cylinder rod.

- The spring sectors of the driven disk warped. The disk needs to be replaced with a new one.

- The thickness of the driven disk has increased due to the stretching of the rivets that secure the friction linings. The disk needs to be replaced with a new one.

- Jamming of the driven disk on the splines of the drive shaft of the gearbox. Both parts are defective, if necessary, replaced with new ones.

- Lack of brake fluid in the master cylinder reservoir or accumulation of air bubbles in the hydraulic drive system. The working fluid is added to the required level, the clutch hydraulics are pumped.

Clutch slips

The clutch may begin to slip for the following reasons:

- there is no gap between the pressure bearing and the fifth basket;

- clutch drive not adjusted;

- oil has got on the rubbing surfaces;

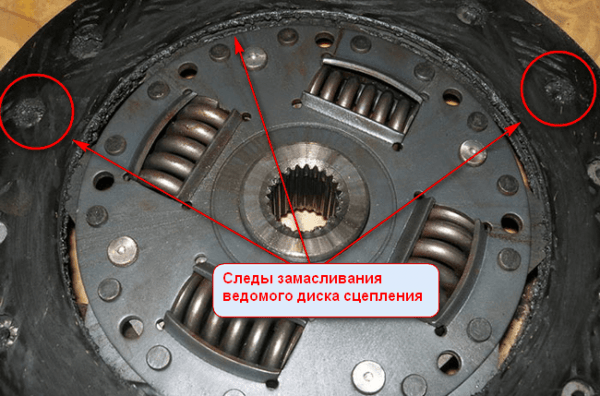

Oil on the driven disc can cause clutch slip and jerky operation.

Oil on the driven disc can cause clutch slip and jerky operation. - the bypass channel in the main cylinder body is clogged;

- the clutch pedal does not return to its original position.

Such malfunctions are eliminated by adjusting the drive, replacing oil seals, cleaning the channel with wire, detecting and correcting the causes of pedal jamming.

Clutch works jerky

If the clutch starts jerking, it may be caused by the following:

- the driven disk is jammed on the splines of the gearbox input shaft;

- oily areas formed on the friction linings;

- clutch hydraulic drive not adjusted;

- the steel disk of the basket is warped, some of the friction springs have lost their elasticity;

- drive disk defective.

In such situations, a complete replacement of the clutch is most often required.

Noise when engaging the clutch

The appearance of a rattle and rattle when the clutch pedal is released may be due to the following:

- thrust bearing jammed due to lack of lubrication;

- jammed gearbox input shaft bearing in the flywheel.

In both cases, the problem is solved by replacing the bearing.

Noise when disengaging the clutch

When you press the clutch pedal, a knock, clang, rattle is heard, vibration is felt on the gear lever. The reasons may be the following:

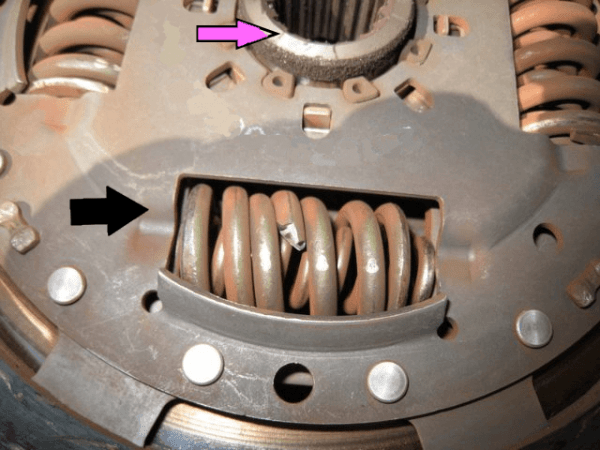

- the damper part of the driven disk is faulty (springs, sockets);

If the driven disk has worn splines, broken or loose damper springs, it must be replaced.

If the driven disk has worn splines, broken or loose damper springs, it must be replaced. - the spline connection of the driven disk and the gearbox input shaft is heavily worn;

- disconnected, lost elasticity or broken return spring of the clutch on/off fork.

In all cases, worn parts should be replaced with new ones.

Pedal returns but clutch does not work

Sometimes it happens that the clutch does not work, but the pedal returns to its original position. This may be due to the following situations:

- air ingress into the hydraulic drive system;

- wear of the sealing rings of the main and working cylinders;

- lack of working fluid in the tank.

In these cases, it is necessary to pump the hydraulic drive, replace the rubber rings with new ones and add the working fluid to the reservoir.

Find out when you need to change tires for summer: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/kogda-menyat-rezinu-na-letnyuyu-2019.html

tight grip

The softness of the clutch is determined by the force of pressure on the heel of the basket to retract the pressure plate. The amount of force depends on the elasticity of the damper springs. Baskets from many manufacturers, including foreign ones, are suitable for the VAZ 2107 clutch. A hard pedal signals to the driver that the life of the basket is coming to an end.

The pedal disengages the clutch at the start/end of its travel

When you press the pedal, the clutch may turn off at the very beginning or, conversely, at the very end. In such situations, it will be necessary to adjust the free travel and travel of the pedal. The free play is regulated by changing the length of the pedal limiting screw, and the working one is controlled by changing the length of the working cylinder rod. In addition, increased free play may be due to wear on the lining of the driven disk.

Video: main clutch problems and their solutions

Replacing the clutch VAZ 2107

Rapidly changing loads, high speeds, various angles of inclination - all these operating conditions impose special requirements on the quality of manufacture of the VAZ 2107 clutch and its individual parts, which are centered and balanced only in the factory. Clutch replacement is a rather complicated and time-consuming procedure performed on a viewing hole or overpass. For work you will need:

- a set of open-end, box wrenches and heads;

- slotted and Phillips screwdrivers;

- passages;

- clean rags;

- new clutch kit (preferably original version).

Dismantling the checkpoint

To gain access to the clutch, the gearbox must be removed. Dismantling the box consists of the following steps:

- In the engine compartment, the negative terminal is removed from the battery, the air filter and the top bolt of the starter is unscrewed.

- In the cabin, the gearshift lever is pulled out.

- From the inspection hole, the exhaust pipe of the exhaust system is unscrewed from the box and the cardan from the main gear. In this case, it is necessary to make chalk marks on the flanges of the universal joint and the rear axle gearbox.

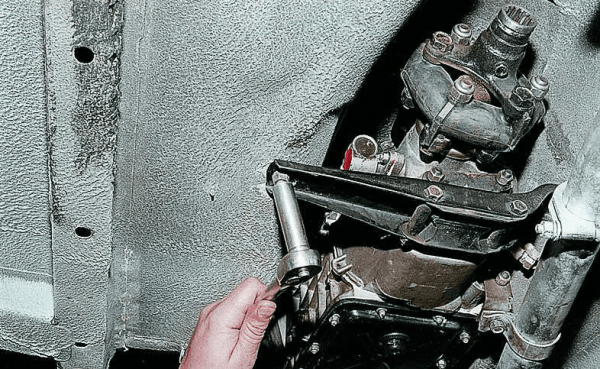

- From the inspection hole, the cross member of the rear gearbox support is unscrewed from the bottom.

When dismantling the gearbox, it is necessary to unscrew the bolts of the rear support cross member from the bottom

When dismantling the gearbox, it is necessary to unscrew the bolts of the rear support cross member from the bottom - The remaining starter bolts and four bolts securing the box to the rear of the block are unscrewed.

When dismantling the gearbox, it is necessary to remove the starter by unscrewing the four bolts

When dismantling the gearbox, it is necessary to remove the starter by unscrewing the four bolts - The wire is removed from the reverse gear sensor and the speedometer cable is unscrewed with pliers.

The speedometer cable is unscrewed with pliers

The speedometer cable is unscrewed with pliers - Unscrew the two bolts securing the working cylinder.

- The box is moved to such a distance that its drive shaft comes out of the clutch basket. An exhaust pipe can be used as a support for the box. If it is necessary to lower the box weighing 28 kg to the ground, it is necessary to unscrew the receiving pipe from the collector in advance and disconnect it from the resonator pipe.

Video: dismantling the gearbox VAZ 2107

Watch this video on YouTube

Removing the clutch

Dismantling the gearbox provides access to the VAZ 2107 clutch. To remove it, unscrew the six bolts securing the basket casing to the flywheel. In order not to damage the casing, all bolts are first loosened evenly by 1-2 turns. First, the basket is removed, and then the driven disk.

Inspection of clutch elements

After removing the clutch, carefully inspect the basket, driven disc and thrust bearing for damage and signs of wear. Particular attention should be paid to:

- at the driven disk - on the condition of the friction linings, damper springs and sockets, as well as the splines of the hub;

- at the basket - on the condition of the damper plates, springs, casing and pressure plate;

- at the pressure bearing - on the play of the rollers and the seat of the glass.

Separate clutch elements are not subject to repair, but are replaced as a set. If traces of oil are found on the working surfaces of the flywheel, driven and pressure disks, the condition of the crankshaft seals and the input shaft of the box should be checked. Worn and damaged rubber elements must be replaced. In addition, you should carefully inspect the fork on and off the clutch. If there are signs of wear on its ends, the fork must be replaced.

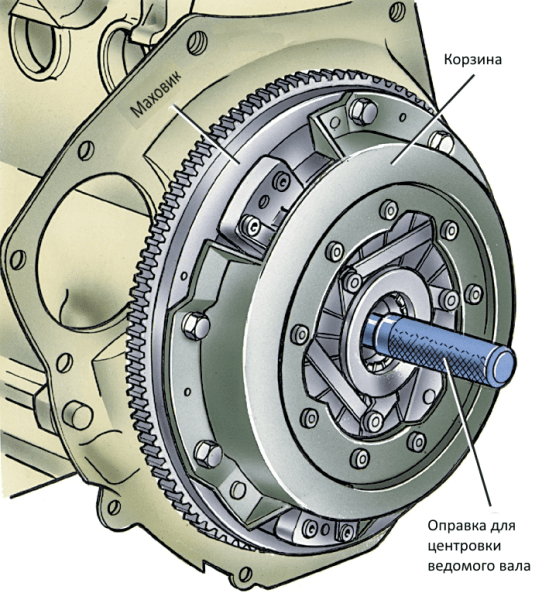

Installing the clutch

Installing the clutch on the VAZ 2107 is carried out in the following order.

- The driven disk with the protruding part of the hub is applied to the flywheel.

The position of the driven disc is first centered with a mandrel and then the basket is screwed onto the flywheel

The position of the driven disc is first centered with a mandrel and then the basket is screwed onto the flywheel - A mandrel is inserted into the flywheel bearing in such a way that the splined part of the driven disk goes to the appropriate diameter. The disc position is centered.

When installing a new driven disk, it must be centered using a special mandrel

When installing a new driven disk, it must be centered using a special mandrel - The basket is mounted on guide pins. In this case, the holes for the tightening bolts in the flywheel and casing must match.

- Tighten the six bolts securing the basket to the flywheel evenly.

- A mandrel is removed from the centered driven disk by hand.

Installing the checkpoint

The gearbox is installed in the reverse order of dismantling. Before this, it is necessary to lubricate the smooth and splined part of the input shaft of the CV joint box 4 or grease. If the driven disk is centered correctly, the gearbox will easily be installed in its place.

Clutch selection

On different models of the VAZ 2107, the manufacturer installed carburetor (2103 with a volume of 1,5 liters) and injection (2106 with a volume of 1,6 liters) engines. Despite the external similarity, the clutch of these models has certain differences. The diameter of the pressure plate of the basket in both cases is 200 mm. But for the basket for 2103, the width of the pressure plate is 29 mm, and for 2106 - 35 mm. Accordingly, the diameter of the driven disk for 2103 is 140 mm, and for 2106 - 130 mm.

Some car owners install a clutch from the VAZ 2107 on the VAZ 2121, which is noticeably stiffer and more reliable than the native one.

Clutch kits from classic cars of well-known brands are suitable for all VAZ models with rear-wheel drive.

Table: clutch manufacturers for VAZ 2107

| Country | Manufacturer brand | Advantages and disadvantages of clutch | Weight, kg | Price, rub |

| Germany | sachs | Reinforced, so a little stiff. Reviews are great | 4,982 | 2600 |

| France | VALEO | Excellent reviews, very popular | 4,322 | 2710 |

| Russia, Togliatti | VazInterService | Put on the conveyor, good reviews | 4,200 | 1940 |

| Germany | LUK | There are dampers on the pressure and driven disks. Reviews are good | 5,503 | 2180 |

| Netherlands | HELLO | Noisy, short-lived, many negative reviews | 4,810 | 2060 |

| Germany | KRAFT | Soft, reliable. Reviews are good (many fakes) | 4, 684 | 1740 |

| Russia | TRIAL | Too hard. Reviews 50/50 | 4,790 | 1670 |

| Belarus | FENOX | Heavy, bad reviews | 6, 376 | 1910 |

| Turkey | MAP | Medium hardness, reviews 60/40 | 5,370 | 1640 |

| China | CAR TECHNOLOGY | Heavy, not very good reviews | 7,196 | 2060 |

Clutch adjustment

Clutch adjustment is necessary after its repair or replacement, as well as after bleeding the hydraulic drive. This will require:

- open-end wrenches for 8, 10, 13 and 17;

- ruler with divisions;

- passatizhi.

Pedal free travel adjustment

The pedal free play should be 0,5-2,0 mm. Its value is measured in the passenger compartment with a ruler and, if necessary, adjusted by changing the length of the pedal travel limit screw.

Adjustment of a rod of the working cylinder

The rod of the working cylinder is adjusted from the inspection hole or on the overpass. In this case, it is necessary to achieve the value of the clutch play (the distance between the end face of the thrust bearing and the fifth basket) within 4–5 mm. Adjustment is carried out by changing the length of the rod of the working cylinder.

After both adjustments are made, the operation of the clutch is checked. To do this, on a warm engine with the pedal depressed, try to turn on all gears, including reverse speed. There should be no noise, the gear lever should move easily, without sticking. Starting off must be smooth.

Video: clutch bleeding VAZ 2101–07

Despite the laboriousness, work on replacing and adjusting the VAZ 2107 clutch is quite simple and does not require any special equipment, skills and knowledge. Even a novice car enthusiast, having a standard set of locksmith tools and expert recommendations, will be able to perform all operations without any problems.