Gearbox synchronizers - the most common breakdowns and repair costs

Content

- Synchronizer gearbox - what is it made of?

- How does a gearbox synchronizer work?

- Gearbox synchronizer wear - symptoms and causes

- Damaged gearbox synchronizer - symptoms

- Replacing the gearbox synchronizer - why is it necessary?

- Replacing the gearbox synchronizer - price

- Do you need to change the synchronizers in the gearbox?

In internal combustion engines, the best operating conditions for the unit can be obtained at certain rotation modes. Therefore, it is necessary to use several gear ratios in gearboxes. Transmission synchromesh helps shift gears on the move without annoying squealing or risk of component damage. How did it happen? Check and read also when the gearbox synchromesh needs to be replaced.

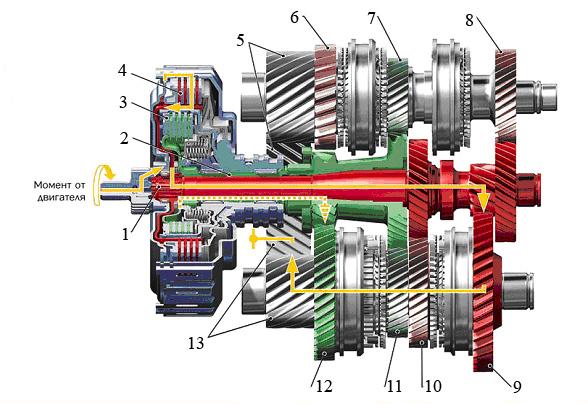

Synchronizer gearbox - what is it made of?

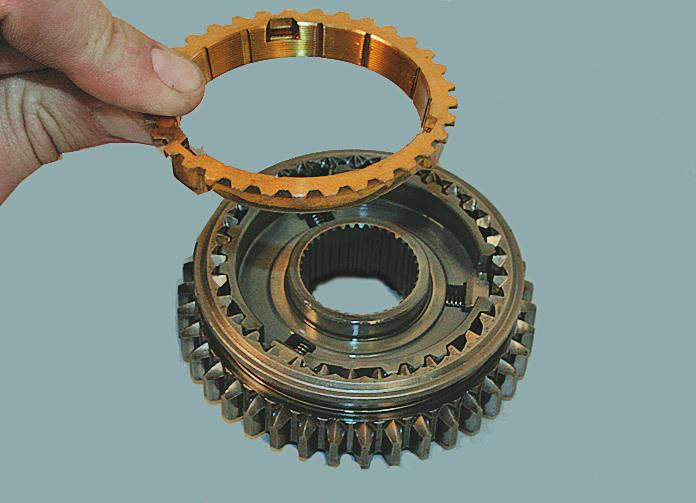

On the main shaft, which transmits torque from the engine to the gearbox, racks of individual gear ratios are installed. They are separated and there are synchronizers between them. These sprockets are equipped with special spring detents that allow the forks to work on a synchronizer and a certain gear ratio. Rings mounted inside the synchronizers and wheels play a key role in assembling the individual gears without collision.. The mechanisms used must be coordinated with each other so that when the elements approach each other, they can work in direct contact.

How does a gearbox synchronizer work?

For the driver, the most important advantage of having gearbox synchromesh is that it shifts gears without grinding. Everything is based on changing the position of the synchronizer sleeve towards the gear of the corresponding gear. This equalizes the speed. The rings inside the wheels take on the key task. They are contoured and allow you to synchronize their speeds just before connecting. In the next step, the gearing of the synchronizer sleeve is connected to the gear of this gear. The last step is to assemble the elements and transfer the drive.

Gearbox synchronizer wear - symptoms and causes

Let's start with the second case. The gearbox endures huge overloads and operates at high speeds. Its individual parts are made of metal, so the elements operate at high temperatures. This is why correct oil change intervals for gears that need it are critical. Transmission synchronizers usually fail due to misuse combined with careless maintenance.

Damaged gearbox synchronizer - symptoms

Symptoms of a damaged transmission synchronizer are usually:

- problems with switching to a specific gear;

- noise and metallic screeching.

A common sign that this element is damaged is difficulty shifting one or another gear. Each of them has its own separate “assistant” for shifting gears, so you can usually feel which one of them has serious problems. While driving, the gear can be engaged with noticeable resistance, so the driver needs to make more effort to shift it. In addition, a metallic screech can be heard. This is because the synchronizer rings are worn out and cannot lose transmission speed. As a result, they overlap each other at different speeds and fray.

Replacing the gearbox synchronizer - why is it necessary?

In order not to lead to the complete destruction of the gears, it is necessary to replace the gearbox synchronizers in time. Of course, you must remove this element and restore it or just replace it. And why such wear and tear? The main problem is negligence in work. Sometimes the driver hastily releases the clutch pedal before the gear is fully engaged. It is also considered a mistake to drive a car with your hand on the gear lever. Why? Even a slight pressure sets in motion the sliders responsible for moving the synchronizer rings.

Replacing the gearbox synchronizer - price

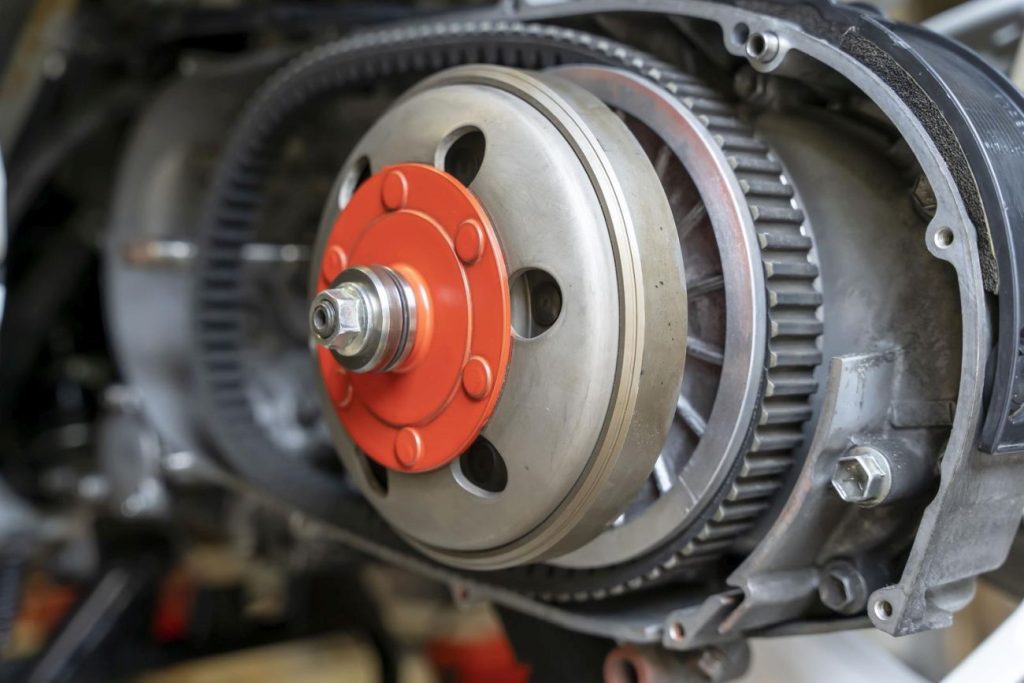

The cost of individual parts varies from 300 to 100 euros, much depends on the brand of car, year of manufacture and engine power. However, the cost of the components themselves is not the only problem for the car user. To replace synchronizers, you must:

- dismantling the gearbox;

- undressing her;

- replacement of damaged parts with new ones.

The solution is also to buy new seal kits and oil and put everything back together. After the gearbox synchronizers are installed, the gearbox still needs to be installed in its place. Therefore, the total cost is basically 1500-250 euros.

Do you need to change the synchronizers in the gearbox?

In the past, cars had gears without synchronizers. Appropriate handling of the accelerator pedal, double clutch disengagement and slow shifting were essential. Today, the matter is simple, because gearboxes are equipped with gearbox synchronizers. If you feel like your run is beginning to suffer from jerkiness, recovery may be needed. But it shouldn't be like that. Sometimes all you need is a slower shift into a certain gear. You can also use the method of putting the gear into neutral, disengaging and engaging the clutch, and engaging the next gear. But remember that gearbox synchronizers don't last forever. If they make themselves felt, it means that more and more sawdust appears in the chest. Consequently, overcoming the next thousand kilometers with such a defect may subsequently lead to the inevitable replacement of the gearbox. So take care of this element so as not to expose yourself to problems and expenses.