What materials are used in the manufacture of car bodies?

Content

Materials for car bodies are diverse, these materials are used to obtain advantages, qualities or features that each of them can offer. Therefore, components, structures or car bodies are often found in which elements of a different nature are combined.

As a rule, the main reasons that determine the existence of various materials in the manufacture of the body are the goals to achieve weight reduction and increase the strength and safety of the collection through the use of lighter, but more durable materials.

Basic materials for car bodies

The materials that are mainly used in the production of bodywork over the past years are as follows:

- Iron alloys: steel and alloy steels

- Aluminum alloys

- Magnesium Alloys

- Plastics and their alloys, whether or not reinforced

- Thermosetting resins with fiberglass or carbon

- Glasses

Of the five materials for car bodies, steel is the most widely used, followed by plastic, aluminum and fiberglass, which is currently less commonly used on SUVs. In addition, for some high-end vehicles, magnesium and carbon fiber components are beginning to integrate.

Regarding the role of each material, it is worth noting that steel is present in most cars, especially in the middle and low grades. Also on mid-range cars, you can often find some aluminum parts like bonnet and so on. Conversely, when it comes to premium cars, aluminum parts take precedence. There are vehicles on the market with bodies made almost entirely of aluminum, such as the Audi TT, Audi Q7 or Range Rover Evoque.

It should also be noted that the rims can be forged steel, decorated with caps made of plastic or an alloy of aluminum or magnesium.

On the other hand, plastic is present to a very significant extent in modern cars (up to 50% of parts, in some cars - plastic), especially in the interior of the car. As for the materials for the car body, plastic can be found in the front and rear bumpers, body kits, body and rear-view mirror housings, as well as moldings and some other decorative elements. There are Renault Clio models that have plastic front fenders or another less common example, such as the Citroen C4 Coupe which is mounted on the rear door, synthetic material.

Glass is followed by plastics, usually used to reinforce plastic, forming a composite material for structural components such as front and rear bumpers. In addition, thermostable resins of polyester or epoxy are also used, thus forming composites. They are mainly used in accessories. for tuning although in some models of Renault Space the body is all made of this material. They can also be used in some parts of the car, such as the front fenders (Citroen C8 2004), or the rear (Citroen Xantia).

Technical characteristics and classification of the main materials used in the manufacture of bodies

Since various car body materials can be damaged and require repair in the workshop, it is necessary to know their characteristics in order to bring the repair, assembly and connection processes, in each specific situation.

Iron alloys

Iron, as such, is a soft metal, heavy and very sensitive to the effects of rust and corrosion. Despite this, the material is easy to form, forge and weld, and is economical. Iron used as a material for car bodies is alloyed with a small percentage of carbon (0,1% to 0,3%). These alloys are known as low carbon steels. In addition, silicon, manganese and phosphorus are also added to improve the mechanical properties, directly or indirectly. In other cases, additives have more specific purposes, the hardness of the steel is affected by alloys with a certain percentage of metals such as niobium, titanium, or boron, and special processing methods are used to improve characteristics, such as quenching or tempering to produce steels that are stronger or with specified collision behavior.

On the other hand, a decrease in sensitivity to oxidation or cosmetic improvements is achieved by adding a small percentage of aluminum, as well as galvanizing and galvanizing or aluminizing.

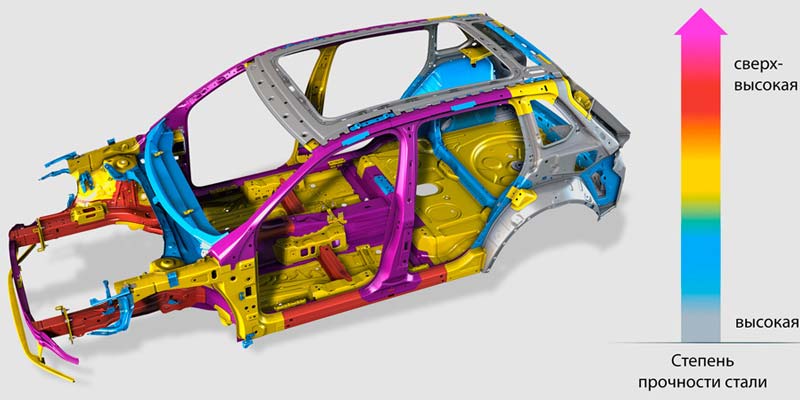

Therefore, according to the components included in the alloy, the steels are classified and subclassified as follows:

- Steels, plain or stamped.

- High strength steels.

- Steel of very high strength.

- Steel ultra-high strength: high strength and ductility (Fortiform), with boron, etc.

To accurately determine that the car element is made of steel, it is enough to conduct a test with a magnet, while a specific type of alloy can be found by referring to the manufacturer's technical documentation.

Aluminum alloys

Aluminum is a soft metal that is several levels lower in strength than most steels and is more expensive and difficult to repair and solder. However, it reduces weight compared to steel by up to 35%. and is not subject to oxidation, which steel alloys are susceptible to.

Aluminum is used as a material for car bodies, as well as its alloys with metals such as magnesium, zinc, silicon or copper, and may also contain other metals such as iron, manganese, zirconium, chromium or titanium to increase their mechanical properties . If necessary, to improve the behavior of this metal during welding, scandium is also added to it.

Aluminum alloys are classified according to the series to which they belong, so that all the most used alloys in the automotive industry are part of the 5000, 6000 and 7000 series.

Another way to classify these alloys is through the possibility of hardening. This is possible for the 6000 and 7000 alloy series, while the 5000 series is not.

Synthetic materials

The use of plastic has grown due to its low weight, the great design capabilities that it provides, their oxidation stability and low cost. On the contrary, its main problems are that it worsens performance over time, and there are also difficulties with the coating, which requires several meticulous processes of preparation, support and recovery.

The polymers used in the automotive industry are grouped as follows:

- Thermoplastics, such as Polycarbonate (PC), Polypropylene (PP), Polyamide (PA), Polyethylene (PE), Acrylonitrile Butadiene Styrene (ABS), or combinations.

- Thermosets like Resins, Epoxy resins (EP), fiberglass reinforced plastics (GRP) like PPGF30, or non-saturated polyester resins (UP).

- Elastomers

The type of plastic can be identified through its labeling code, technical documentation or certain tests.

Glasses

According to the position that they occupy the car glass are divided into:

- Rear windows

- Windshields

- Side windows

- Safety glass

Regarding the type of glass they differ:

- Laminated glass. Consist of two glasses glued together by a plastic Polivinil Butiral (PVB), which remains sandwiched between them. Using a film eliminates the risk of glass breaking, allows tinting or darkening, and promotes adhesion.

- Tempered glass. These are tempered glass during the manufacturing process, combined with strong compression. This significantly increases the break point, although after overcoming this limit, the glass breaks into many fragments.

Identification of the type of glass, as well as other information about it, is located on the silkscreen / marking on the glass itself. Finally, it should be noted that the windshields are a safety feature that directly affects the driver's view, therefore it is important to maintain them in good condition, repair or replace if necessary using the methods of dismantling, mounting and gluing the windows, certified by manufacturers.

Conclusion

The use of various materials for car bodies satisfies the need for manufacturers to adapt to the specific functions of each car part. On the other hand, strict regulatory requirements for environmental protection oblige to reduce the weight of the vehicle, so the number of new metal alloys and synthetic materials that are used in the automotive industry is growing.

4 comment

Sandra

Thank you for this document, it is not very bulky and contains essential information. Understanding is more fluid.

oath giver

Welcome

Perodua prosody

What is the backlight of the car?

Mohammed

What is the material used to make car logos?

And are the companies that manufacture the logo or other companies?