The device and principle of operation of the throttle valve

Content

The throttle valve is one of the most important parts of the intake system of an internal combustion engine. In a car, it is located between the intake manifold and the air filter. In diesel engines, a throttle is not needed, however, it is still installed on modern engines in case of emergency operation. The situation is similar with gasoline engines with a valve lift control system. The main function of the throttle valve is to supply and regulate the air flow required to form the air-fuel mixture. Thus, the stability of the engine operating modes, the level of fuel consumption and the characteristics of the car as a whole depend on the correct operation of the damper.

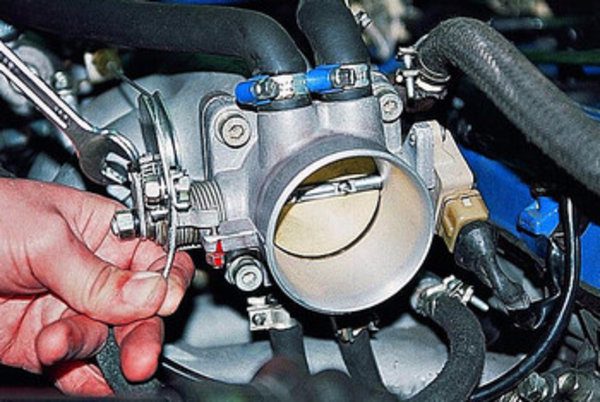

Choke device

In practical terms, the throttle valve is a wastegate. In the open position, the pressure in the intake system is equal to atmospheric. As it closes, it decreases, approaching the vacuum value (this happens because the engine is actually working as a pump). It is for this reason that the vacuum brake booster is connected to the intake manifold. Structurally, the damper itself is a round plate that can be rotated 90 degrees. One such revolution is a cycle from full opening to closing the valve.

The throttle body (module) includes the following elements:

- Housing equipped with multiple nozzles. They are connected to ventilation, fuel vapor recovery and coolant systems (to heat the damper).

- Actuator that sets the valve in motion by pressing the gas pedal by the driver.

- Position sensors, or potentiometers. They measure the opening angle of the throttle valve and send a signal to the engine control unit. In modern systems, two sensors for controlling the throttle position are installed, which can be with sliding contact (potentiometers) or magnetoresistive (non-contact).

- Idling regulator. It is necessary to maintain a given crankshaft speed in closed mode. That is, the minimum opening angle of the damper is provided when the gas pedal is not pressed.

Types and modes of operation of the throttle valve

The type of throttle drive determines its design, mode of operation and control. It can be mechanical or electrical (electronic).

Mechanical drive device

Old and budget car models have a mechanical valve drive, in which the gas pedal is directly connected to the bypass valve using a special cable. The mechanical drive for the throttle valve consists of the following elements:

- accelerator (gas pedal);

- rods and swing arms;

- steel rope.

Pressing the gas pedal sets in motion a mechanical system of levers, rods and cable, which forces the damper to rotate (open). As a result, air begins to flow into the system and an air-fuel mixture is formed. The more air is supplied, the more fuel will enter and, accordingly, the speed will increase. When the accelerator is in the inactive position, the throttle will return to the closed position. In addition to the basic mode, mechanical systems can also include manual control of the throttle position using a special handle.

The principle of operation of the electronic drive

The second and more modern type of dampers is an electronic throttle (electrically operated and electronically controlled). Its priority differences are:

- No direct mechanical interaction between the pedal and the damper. Instead, electronic control is used, which also allows the engine torque to be varied without the need to depress the pedal.

- The idle speed of the engine is automatically adjusted by moving the throttle.

The electronic system includes:

- gas pedal and throttle position sensors;

- electronic engine control unit (ECU);

- electric drive.

The electronic throttle control system also takes into account signals from the gearbox, climate control system, brake pedal position sensor, cruise control.

When you press the accelerator, the gas pedal position sensor, consisting of two independent potentiometers, changes the resistance in the circuit, which is a signal to the electronic control unit. The latter transmits the appropriate command to the electric drive (motor) and turns the throttle valve. Its position, in turn, is monitored by appropriate sensors. They send feedback information about the new valve position to the ECU.

The current throttle position sensor is a potentiometer with multidirectional signals and a total resistance of 8 kΩ. It is located on its body and reacts to the rotation of the axis, converting the valve opening angle into a DC voltage.

In the closed position of the valve, the voltage will be about 0,7V, and in the fully open position, it will be about 4V. This signal is received by the controller, thus learning about the percentage of throttle opening. Based on this, the amount of fuel supplied is calculated.

The output waveforms of the damper position sensors are multidirectional. The difference between the two values is taken as the control signal. This approach helps to cope with possible interference.

Throttle service and repair

If the throttle fails, its module completely changes, but in some cases it is enough to make an adjustment (adaptation) or cleaning. So, for a more accurate operation of systems with an electric drive, it is necessary to adapt or teach the throttle valve. This procedure involves storing data on the extreme valve positions (opening and closing) into the controller's memory.

The adaptation for the throttle valve is mandatory in the following cases:

- When replacing or reconfiguring the electronic control unit of the car engine.

- When replacing the damper.

- If unstable engine idling is noted.

The throttle body is trained at the service station using special equipment (scanners). Unprofessional intervention can lead to incorrect adaptation and deterioration of vehicle performance.

If a problem occurs on the sensor side, a problem light on the dashboard will illuminate. This may indicate both an incorrect setting and a broken contact. Another common malfunction is air leakage, which can be diagnosed by a sharp increase in engine speed.

Despite the simplicity of the design, it is best to entrust the diagnosis and repair of the throttle valve to an experienced specialist. This will ensure economical, comfortable, and most importantly, safe operation of the car and increase the engine's service life.