The device and principle of operation of the main brake cylinder

Content

The central element of the vehicle's braking system is the brake master cylinder (abbreviated as GTZ). It converts the effort from the brake pedal into hydraulic pressure in the system. Let's consider the functions of the GTZ, its structure and principle of operation. Let us also pay attention to the peculiarities of the operation of the element in the event of failure of one of its contours.

Master cylinder: its purpose and function

In the process of braking, the driver directly acts on the brake pedal, which is transmitted to the pistons of the master cylinder. The pistons, acting on the brake fluid, activate the working brake cylinders. From them, in turn, the pistons are extended, pressing the brake pads against the drums or discs. The operation of the brake master cylinder is based on the property of the brake fluid not to be compressed under the action of external forces, but to transmit pressure.

The master cylinder has the following functions:

- transmission of mechanical force from the brake pedal using brake fluid to the working cylinders;

- ensuring effective braking of the vehicle.

In order to increase the level of safety and ensure maximum reliability of the system, the installation of two-section master cylinders is provided. Each of the sections serves its own hydraulic circuit. In rear-wheel drive vehicles, the first circuit is responsible for the brakes of the front wheels, the second for the rear wheels. In a front wheel drive vehicle, the brakes of the right front and left rear wheels are served by the first circuit. The second is responsible for the brakes of the left front and right rear wheels. This scheme is called diagonal and is most widely used.

The device of the main brake cylinder

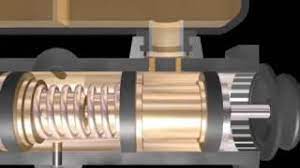

The master cylinder is located on the brake servo cover. The structural diagram of the main brake cylinder is as follows:

- the body;

- tank (reservoir) GTZ;

- piston (2 pcs.);

- return springs;

- sealing cuffs.

The master cylinder fluid reservoir is located directly above the cylinder and is connected to its sections through bypass and compensation holes. The reservoir is necessary to replenish the fluid in the brake system in the event of a leak or evaporation. The liquid level can be monitored visually due to the transparent walls of the tank, where the control marks are located.

In addition, a special sensor located in the tank monitors the liquid level. In the event that the liquid falls below the established rate, the warning lamp located on the instrument panel lights up.

The GTZ housing contains two pistons with return springs and rubber sealing cuffs. Cuffs are needed to seal the pistons in the housing, and the spring provides return and holding the pistons in their original position. The pistons provide the correct brake fluid pressure.

The brake master cylinder can be optionally equipped with a differential pressure sensor. The latter is necessary to warn the driver about a malfunction in one of the circuits due to loss of tightness. The pressure sensor can be located both in the brake master cylinder and in a separate housing.

The principle of operation of the brake master cylinder

At the moment the brake pedal is pressed, the vacuum booster rod begins to push the primary circuit piston. In the process of moving, it closes the expansion hole, due to which the pressure in this circuit begins to increase. Under the action of pressure, the second circuit begins its movement, the pressure in which also rises.

Through the bypass hole, the brake fluid enters the void formed during the movement of the pistons. The pistons move as long as the return spring and the stops in the housing allow them to do so. The brakes are applied due to the maximum pressure generated in the pistons.

After stopping the car, the pistons return to their original position. In this case, the pressure in the circuits gradually begins to correspond to atmospheric. The discharging in the working circuits is prevented by the brake fluid, which fills the voids behind the pistons. When the piston moves, the liquid returns to the tank through the bypass hole.

System operation in case of failure of one of the circuits

In the event of a brake fluid leak in one of the circuits, the second will continue to work. The first piston will move through the cylinder until it contacts the second piston. The latter will start moving, due to which the brakes of the second circuit will be activated.

If a leak occurs in the second circuit, the brake master cylinder will operate in a different way. The first valve, due to its movement, drives the second piston. The latter moves freely until the stop reaches the end of the cylinder body. Due to this, the pressure in the primary circuit begins to rise, and the vehicle is braked.

Even if the brake pedal travel is increased due to fluid leakage, the vehicle will remain in control. However, braking will not be as effective.