The structure and principle of operation of the Easytronic transmission

Content

With the release of each new generation of cars, manufacturers are introducing more and more innovative technologies into their products. Some of them increase the reliability of certain car systems, others are designed to increase comfort while driving. And still others are being improved in order to provide maximum active and passive safety for everyone who is in the car while driving.

The car's transmission is also undergoing constant updates. Automakers are trying to improve gear shifting, reliability of the mechanism, and also increase its working life. Among the different modifications of the gearbox, there are mechanical and automatic (the difference between automatic types of transmissions is discussed in detail in a separate article).

The automatic type of gearboxes was primarily developed as an element of the comfort system, since the mechanical analogue still copes with its task perfectly. The main thing in this case is not to make mistakes when changing gears (this is described in detail in another review) and maintain it on time (for what is included in this procedure, read here).

The machine automatically shifts to an up / down gear (the electronic control unit is able to assess the condition of the car on the road based on a variety of sensors, the number of which depends on the car model). Thanks to this, the driver is not distracted from the road, although it is not a problem for a professional to enter a specific speed, despite the shift lever. For the car to start moving or slow down, the driver only needs to change the force exerted on the gas pedal. The activation / deactivation of a specific speed is electronically controlled.

The control of any automatic transmission is so simple that in some countries, when teaching a beginner to drive, a driving school puts a mark that a new driver is not allowed to drive vehicles equipped with a manual transmission.

A manual transmission, or a robotic box, was developed as a type of automatic transmission. But even among robots, there are several modifications. For example, one of the most common types is DSG, which was developed by the engineers of the VAG concern (about what cars this company produces, read separately). The device and features of this type of gearbox are described in another article... Another competitor of the considered robotic transmission option is Ford's PowerShift box, which is described in detail. here.

But now we will focus on an analogue developed in cooperation with Opel-Luk companies. This is Easytronic manual transmission. Consider its device, what is the principle of its operation, and also what makes the operation of this unit special.

What is Easytronic transmission

Like the DSG6 or DSG7 transmission, the Isitronic transmission is a kind of symbiosis between automatic and manual transmissions. Most of the parts that transmit torque from the power unit to the drive wheels have the same design as in classical mechanics.

The mechanism of operation itself is also almost identical to the operation of the manual transmission, only each gear is switched on / off mainly without the participation of the driver - he just needs to select the required mode (for this there is a function switch selector), and then only press the gas or brake. The rest of the work is done by electronics.

We will talk about the advantages and disadvantages of this transmission a little later. But in short, many motorists, who are allowed financial opportunities, opt for this type, because it combines the ease of operation of an automatic machine with the reliability and economy of mechanics.

The key difference between the robot and the mechanics is the absence of a clutch pedal (the driver only has gas and brakes, as in an automatic transmission). For this function (the clutch is squeezed out / released), an electrohydraulically operated drive will be responsible. And the electric motor, which is controlled by the ECU, is responsible for the movement of the gears and the selection of the necessary gears. Driver actions and traffic conditions are only input data that are processed by the microprocessor. Based on the programmed algorithms, the most effective gear shift moment is determined.

Principle of operation

Before considering what the work of Easytronic is, it is worth noting that the unit with the same name, but released in different years, may differ slightly from the older analogue. The reason is that technologies do not stand still - they are constantly evolving. The introduction of innovations allows automakers to increase the service life, reliability, or some of the subtleties of the operation of automatic systems, including transmissions.

Another reason why manufacturers are constantly making changes to the device or software of various units and mechanisms of cars is the competitiveness of products. The newer and better the product, the more likely it is to attract new customers. This is especially true for fans of various new products.

The robot differs from the classic automatic transmission by the rupture of traction forces (for a while, the torque ceases to flow from the motor to the gearbox shaft, as in mechanics when the clutch is squeezed out) during the selection and activation of the appropriate speeds, as well as the moment the drive is triggered. Many motorists are not satisfied with the operation of a conventional automatic machine, because it often works late or switches to an upshift when the engine has not yet reached the rpm range at which the best dynamics is observed (ideally, this parameter can only be controlled on the mechanics).

It is for this reason that a robotic transmission was developed to please both mechanics and automatic machine lovers. So, as we noticed, the robotic transmission independently determines the time when it is necessary to engage the appropriate gear. Let's consider how the system will work in two available modes: automatic and semi-automatic.

Automatic operation

In this case, the transmission is completely electronically controlled. The driver only chooses the route and, in accordance with the road situation, presses the appropriate pedal: gas / brake. During the manufacture of this transmission, the control unit is programmed at the factory. By the way, any automatic transmission is equipped with its own microprocessor. Each algorithm is activated when signals from different sensors enter the ECU (the exact list of these sensors depends on the vehicle model).

This mode allows the box to work like a conventional automatic analogue. The only difference is the disconnection of the transmission from the motor. For this, a clutch basket is used (for details on the device of this mechanism, read in another review).

Here's how the manual transmission works in automatic mode:

- The number of engine revolutions decreases. This function is assigned to the crankshaft position sensor (for how this device works, read separately). In this case, the number of revolutions of the crankshaft is determined and the corresponding algorithm is activated in the control unit.

- The clutch basket is squeezed out. At this moment, the drive shaft is disconnected from the flywheel (for what functions the flywheel performs in the car, read here) so that the corresponding gear can be connected without damage.

- Based on the signals received by the control unit from the chassis, throttle or gas pedal position sensors and other sensors, it is determined which gear should be engaged. At this point, a suitable gear is selected.

- So that shock loads are not generated during the clutch engagement (the drive and driven shafts often have different rotational speeds, for example, when the machine is going uphill, after the clutch is released, the rotational speed of the driven shaft slows down), synchronizers are installed in the mechanism. For details on how they work, read in another article... These small mechanisms ensure synchronized rotation of the drive and driven shafts.

- The corresponding speed is activated.

- The clutch is released.

- The engine speed rises.

It is worth paying attention to the fact that some algorithms are triggered simultaneously. For example, if you first slow down the engine and then squeeze the clutch, then the engine will brake. On the other hand, when the clutch is disconnected at high revs due to the lack of load on the internal combustion engine, its revs will jump sharply to the maximum.

The same applies to the moment when the clutch disc is connected to the flywheel. This action and the increase in the speed of the power unit must occur synchronously. Only in this case, smooth gear shifting is possible. The mechanics have an identical principle of operation, only the driver performs all these stages.

If the car is on a long rise, and the box has not been transferred to semi-automatic mode, it is possible to overcome this obstacle, but it should be noted that the automatic switches speed not based on the load experienced by the engine, based on the crankshaft speed. Therefore, so that the control unit does not shift the transmission to an up / down gear, you should press the gas pedal two-thirds to keep the speed of the power unit at approximately the same level.

Semi-automatic operating mode

In semi-automatic mode, the transmission will operate in almost the same sequence. The only difference is that the driver himself chooses the moment of transition to a specific speed. The presence of a semi-automatic gearbox control is evidenced by a special niche on the mode selector.

Next to the main settings (drive, reverse speed, neutral mode, optional cruise control) there is a small window into which the gearshift lever moves. It has only two positions: "+" and "-". Accordingly, each of the positions up or down the gear. This mode functions according to the principle of the Tiptronic automatic transmission (read about this modification of the transmission in another review). To increase / decrease the speed, the driver needs to bring the vehicle to the required speed and move the lever to the desired position.

The driver does not take direct part in the movement of the gears, as in the case of a mechanical box. He only gives a command to the electronics when it is necessary to change to another gear. Until the control unit receives a signal from the lever in this mode, the car will continue to drive at the same speed.

The benefit of this mode is that the driver himself controls the increase / decrease in speed. For example, this function allows you to use engine braking when going downhill or during a long ascent. In order for the automation to independently adjust the operation of the transmission in accordance with such a road situation, the vehicle's package of options should include assistance when driving on slopes (in another article describes how this assistant works). The semi-automatic mode of the Isitronic robotic box enables the driver to forcibly not allow the mechanisms to switch.

So that, as a result of driver error, the transmission does not accidentally switch from high speed during acceleration to low speed (the driver accidentally hooked the gearshift lever in semiautomatic mode), the electronics still controls the operation of the transmission. If necessary, the device ignores some of the driver's commands, considering them as random.

In some models, other modes are additionally present. This is how they work:

- Winter... In this case, the start of the vehicle starts from the second speed at low revs of the internal combustion engine in order to avoid slipping of the driving wheels;

- Kick down... When the driver sharply presses the gas to the floor on the move to accelerate quickly, the electronics downshifts the transmission and activates the algorithm, according to which the engine spins up to higher revs;

- Sport... This mode is extremely rare. In theory, it activates faster gear changes, but when equipped with one clutch, this mode still works ineffectively.

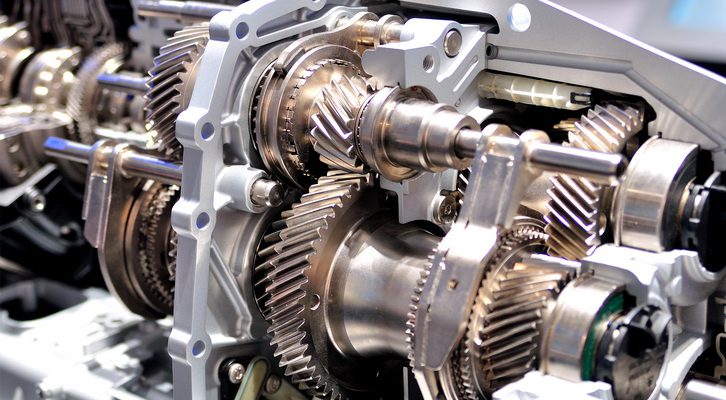

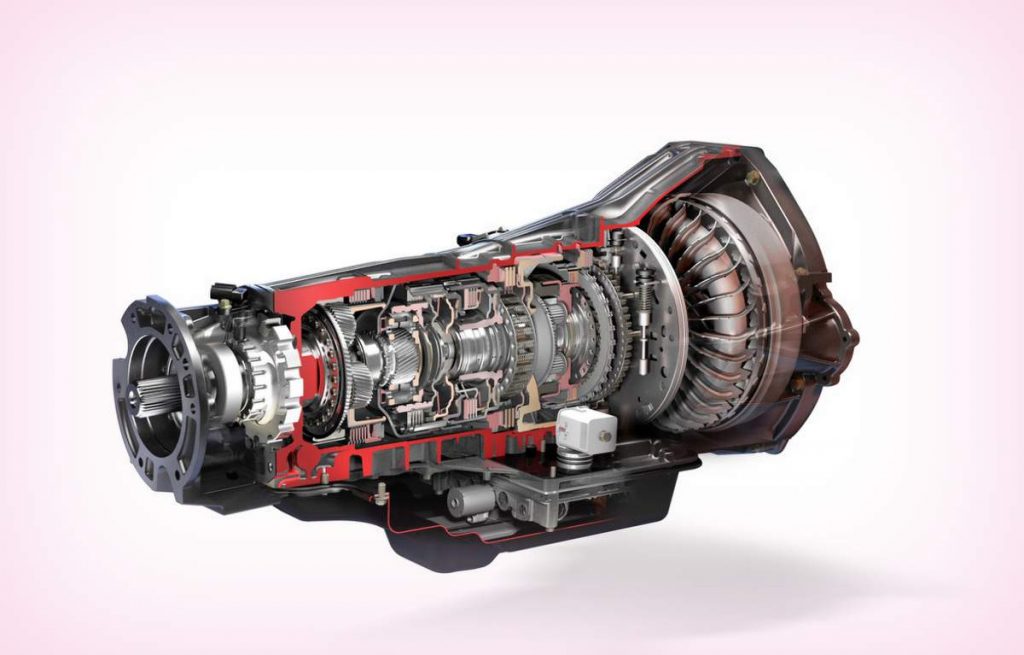

Easytronic box design

The design of the Easytronic manual transmission will include the following components:

- The mechanical box is the main one for this transmission;

- Clutch baskets;

- A drive that squeezes out the clutch friction disc;

- A drive with which the electronics is able to select and turn on speeds;

- Microprocessor control unit (all automatic and robotic gearboxes use an individual ECU).

So, the robot, which is installed in some Opel models, is based on the design of a five-speed manual transmission. Only this modification is supplemented with a clutch basket drive, as well as a gear shifter. Such a box works with one clutch. Details on how a robotic box with one clutch works are described here.

Other automakers have also developed a preselective type of robots. This modification is equipped with a double clutch basket. An example of such a modification is just the same DSG. Read about the structure and principle of operation of the dual-clutch transmission in another review.

Let's take a closer look at the structure of the main elements of the Easytronic transmission.

Clutch drive

The design of the clutch drive of the Izitronic box includes:

- Electric motor;

- Worm-type reducer;

- Eccentric mechanism.

The mechanism, equipped with an eccentric, is connected to a rod installed in the piston of the main cylinder head (clutch master cylinder). The degree of movement of this rod is fixed by a special sensor. The assembly plays the same role as the driver's foot when the clutch pedal is depressed. Among other things, the task of the mechanism includes:

- Force control to disengage the friction disc from the flywheel when the vehicle starts moving;

- Connection / disconnection of these elements during the movement of the machine for the transition to the optimal speed;

- Disconnecting the box from the flywheel to stop transport.

Self-adjusting clutch

The self-adjusting type of clutch is another feature of the Isitronic robotic gearbox. It will not be a secret for anyone that from time to time the basket drive in the mechanics needs to tighten the cable (in some cars a lever structure is used).

This happens due to the wear of the friction surface of the disc, which affects the forces that the driver will need to apply to disconnect the gearbox from the engine. If the cable tension is weak, the crunch of the gear teeth can be heard during the speed engagement.

The Easytronic box uses the SAC mechanism, which independently adjusts to the degree of disc wear. Also, this component provides constant and low force when depressing the clutch basket.

This function is extremely important for the serviceability not only of the friction surface of the clutch disc, but also of all transmission gears. Another feature of this system is that, due to the small effort on the basket, the manufacturer can use a low-power electric motor, which allows less electrical energy generated by the generator to be consumed. More details about the operation and device of the generator are described separately.

Electronic control unit

Since the operation of the Izitronic transmission is automatic (and even when the driver uses the semi-automatic mode, the system independently sets the actuators in motion), it needs a microprocessor that would process the signals from the sensors and activate the actuators.

The operation of the entire system as a whole is controlled by an electronic control unit. Someone thinks that this microprocessor is completely autonomous and not connected to the main ECU. In fact, this is not the case. These two elements of the onboard system are interconnected. Some of the data sent to the central unit is also used by the transmission microprocessor. Examples of this are signals about wheel speed and engine speed.

Some of the functions performed by the transmission control unit are:

- It captures and processes all signals from sensors that are associated with the efficient operation of the transmission. These sensors include the gearbox lever position sensor, wheel speed (this is part of the ABS system, which is described in detail in another review), position of the accelerator pedal, engine speed, etc .;

- In accordance with the information received, the corresponding algorithms are activated in the microprocessor, which form specific pulses;

- Sends impulses to the actuators to disengage the clutch and flywheel and select the appropriate gear.

Gear selection and engagement drive

The design of the drive for selecting and connecting gears of gears consists of two gearboxes. Each of them relies on one electric motor. These mechanisms replace the driver's hand when he moves the gearshift lever to the desired position (in this case, the forces are transmitted through the rocker and the cardan box).

In automatic mode, the electronics independently determines the moment when it is necessary to activate the fork drive, as well as the movement of the gears to the drive shaft.

Gear selector

The next component of the Isitronic robotic gearbox is the gear selector. This is the panel in which the lever is mounted. With its help, the driver selects the mode that is needed to perform a specific task. For ease of use, this panel is labeled to indicate where which mode is.

Despite its purpose, this element does not have a rigid physical connection with the gearbox mechanism. If in mechanics in emergency mode it is possible to perform some kind of manipulation with the mechanism, for example, to turn off the speed, then in this case this element is a kind of shift button stylized as a gearshift lever, which only sends a signal to the microprocessor.

Many automakers who equip their products with similar types of transmissions do not use the classic lever at all. Instead, a rotary washer is responsible for selecting the appropriate mode. A sensor is installed under the gearbox selector that determines the position of the lever. Accordingly, it sends the required signal to the control unit, which in turn activates the required functions.

Since gear shifting takes place in electronic mode, the driver can purchase a steering wheel with paddle shifters, with the help of which it will be easier for him to control the engagement of the corresponding gear in semi-automatic mode. But this rather belongs to the category of visual tuning. The reason is that the Izitronic lacks a truly sporty gear shifting, as in sports cars, so even a very fast movement of the lever to the plus or minus position will still be accompanied by a certain delay.

Tips for operating the gearbox Izitronic

The Easytronic robotic box is found in some trim levels of models such as Zafira, Meriva, Corsa, Vectra C and Astra, manufactured by Opel. Many motorists complain about the operation of this box. The main reason is that, according to the description of the mechanism of operation, the system is a more comfortable evolution of a manual transmission.

Since the unit operates in automatic mode, the same smoothness and softness is expected from it as from a classic automatic machine powered by a torque converter (for details on how this mechanism works, read here). But in life, a little bit different happens. The robot is distinguished by the rigidity of the clutch disc connection, as if the driver suddenly drops the pedal after turning on the speed. The reason is that electronics are not capable of ideally altering effort "feel" like a human.

The robot has the same disadvantages as in classical mechanics, with the exception of additional potential damage zones, for example, the electric drives of the basket or the box itself.

To extend the working life of the Easytronic manual transmission, the driver must comply with the following recommendations:

- When the car stops at a traffic light or a railway crossing, you should move the gear selector lever to neutral, and not hold the brake, as in the case of a machine. Although the machine will not move when the machine is at full stop and the brakes are applied, the clutch basket drive is operational and is subject to a great deal of stress. In neutral speed mode, the clutch disc is pressed against the flywheel, then the drive shaft of the box is not meshed with any gears. If you hold the brake for a long time, over time, the drive will no longer hold the spring-loaded disc, and subsequently the friction pad will begin to contact the flywheel, which will overheat and wear out.

- When parking, you should not leave the car at speed, as most motorists who have a manual gearbox do. For this, the parking brake and neutral gear are installed.

- The electronics of the box fixes many different signals, including the operation of the bulbs that light up when the brake is pressed. If one of these lights burns out, the circuit will not close, and the control unit may not fix the brake pedal pressure, so the drive may not turn on to disconnect the box from the flywheel.

- Routine transmission maintenance procedures should not be neglected. When changing the oil, follow the manufacturer's recommendations for the correct type of lubricant. In another review we have already considered what kind of oil is used in gearboxes.

- Change the brake fluid in the clutch circuit in a timely manner. This procedure should be carried out on average every 40 thousand km. mileage.

- When the car gets into a serious traffic jam or jam, do not use automatic mode, but switch to semi-automatic mode so that the electronics do not switch gears unnecessarily.

- Do not use the car to overcome off-road, and drive the car as accurately as possible on ice, without wheel slip, so that gears do not change when the car has an inappropriate speed.

- If the car stalls, in no case should you try to get out of the trap by swinging or slipping the driving wheels.

- The service of the unit directly depends on the driving style that the driver uses. For this reason, this transmission is simply contraindicated in a sporty driving style.

It is necessary to start the engine and start driving the car with isitronic in the following sequence:

- According to the vehicle operating instructions, it is necessary to start the internal combustion engine only when the neutral speed is on, although experience shows that the power unit will start at a different speed, but the brake pedal must be pressed. Of course, you should not do this, since violation of this recommendation not only exposes the engine to unnecessary load during start-up, but also wears out the clutch.

- Even if the car is in neutral, the engine will not start until the brake pedal is pressed (in this case, the N icon on the dashboard will light up).

- The start of the movement must be accompanied by a depressed brake pedal and moving the selector lever to position A. In summer, the first speed is switched on, and in winter, the second, if there is a corresponding mode in the on-board system.

- The brake is released and the car starts to move. If the driver does not press the brake, but immediately transfers the lever from neutral to mode A, it is necessary to smoothly press the gas, as in mechanics. Depending on the weight of the car, the engine may stall without filling.

- Further, the transmission works in automatic mode, depending on the number of revolutions of the internal combustion engine and the position of the gas pedal.

- Reverse speed is activated only when the car is completely stopped (this also applies to work on the mechanics). When the brake is pressed, the gearshift lever is moved to the R position. The brake is released and the car starts to move at the minimum engine speed. You can perform this procedure without pressing the brake pedal, only when switching to R, you need to add a little engine speed.

It should be borne in mind that the beginning of the movement, regardless of whether it is the first or reverse speed, should be carried out only with the brake pedal depressed. In this case, the clutch will last longer.

Advantages and disadvantages of the checkpoint

Any car system, no matter how long ago it was developed, has its advantages, but at the same time it is not without its disadvantages. The same applies to the Isitronic robotic checkpoint. Here are the advantages of this transmission:

- Compared to a classic machine, it costs less. The reason is that for the most part it is based on long-established mechanics. The design does not use a torque converter, which requires a large amount of oil, and more space for installation on a car;

- The new box provides the car with good dynamics (compared to the automatic, it is an order of magnitude higher);

- All in the same comparison with an automatic transmission, this box demonstrates the economy in terms of fuel consumption by the engine;

- Doesn't require a lot of oil - the movement uses the same volume as the related mechanics.

Despite its effectiveness, the robotic type unit has several significant disadvantages:

- At the moment of switching on the speeds, jerks are felt, as if the driver abruptly releases the clutch pedal, which affects the ride comfort with a dynamic set of speed;

- Even with careful operation, the box has a small working resource;

- Since the design uses a single clutch, the period between gear changes is palpable (work is accompanied by a delay);

- You have to spend much more money on the maintenance and repair of the device than with the same procedures in the case of classical mechanics;

- Since the gearshift occurs with a delay, the engine resource is not used with maximum efficiency;

- When installing this transmission from the Opel company into the car, the engine power is not fully used;

- With the exception of the semi-automatic mode, the driver has no freedom of action when driving the car - the box switches speeds only in the mode for which it is configured;

- You cannot perform chip tuning by installing a different firmware on the control unit in order to change the characteristics of the device. To do this, you will need to purchase another ECU with the appropriate firmware (separately read about why some car owners carry out chip tuning, and what characteristics are affected by this procedure).

At the end of our review, we offer a short video on how to get used to Easytronic after the machine: