Device, malfunctions and repair of the VAZ 2106 engine

Content

- The main characteristics of the VAZ 2106 engine

- The device of the VAZ 2106 engine

- VAZ 2106 engine malfunctions and their symptoms

- Repair of the power unit VAZ 2106

The VAZ 2106 engine is rightfully considered the most successful of the entire line of Zhiguli power units. And it is to him that the “six” owes its popularity.

The main characteristics of the VAZ 2106 engine

The VAZ 2106 power plant is an improved version of the 2103 engine. By increasing the cylinder diameter, the developers managed to increase the engine power from 71 to 74 horsepower. The rest of the engine design has not changed.

Table: characteristics of the power unit VAZ 2106

| Positions | Features |

| Fuel type | Petrol |

| Fuel brand | AI-92 |

| injection mechanism | Carburetor/injector |

| Cylinder block material | Cast iron |

| BC head material | Aluminium alloy |

| Mass of the unit, kg | 121 |

| Position of cylinders | Inline |

| Number of cylinders, pcs | 4 |

| The diameter of the piston, mm | 79 |

| Piston stroke, mm | 80 |

| The working volume of all cylinders, cm3 | 1569 |

| Maximum power, hp With. | 74 |

| Torque, Nm | 87,3 |

| Compression ratio | 8,5 |

| Fuel consumption (highway/city, mixed), l/100 km | 7,8/12/9,2 |

| Engine resource declared by the manufacturer, thousand km. | 120000 |

| Real resource, thousand km. | 200000 |

| Camshaft location | Top |

| Width of gas distribution phases,0 | 232 |

| Exhaust valve advance angle,0 | 42 |

| intake valve lag,0 | 40 |

| Diameter of camshaft seals, mm | 40 and 56 |

| Width of camshaft seals, mm | 7 |

| crankshaft material | Cast iron (casting) |

| Neck diameter, mm | 50,795 – 50,775 Feet |

| Number of main bearings, pcs | 5 |

| Flywheel diameter, mm | 277,5 |

| Inner hole diameter, mm | 25,67 |

| Number of crown teeth, pcs | 129 |

| Flywheel weight, g | 620 |

| Recommended engine oil | 5W-30, 15W-40 |

| Engine oil volume, l | 3,75 |

| Maximum engine oil consumption per 1000 km, l | 0,7 |

| Recommended coolant | Antifreeze A-40 |

| Required amount of coolant, l | 9,85 |

| Timing drive | Chain |

| The order of the cylinders | 1–3–4–2 |

More about the VAZ-2106 device: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/gabarityi-vaz-2106.html

The device of the VAZ 2106 engine

The design of the power unit VAZ 2106 consists of four systems and two mechanisms.

Table: systems and mechanisms of the VAZ 2106 engine

| Системы | Devices |

| Power supply | Crank |

| Ignition | gas distribution |

| Lubricants | |

| Cooling |

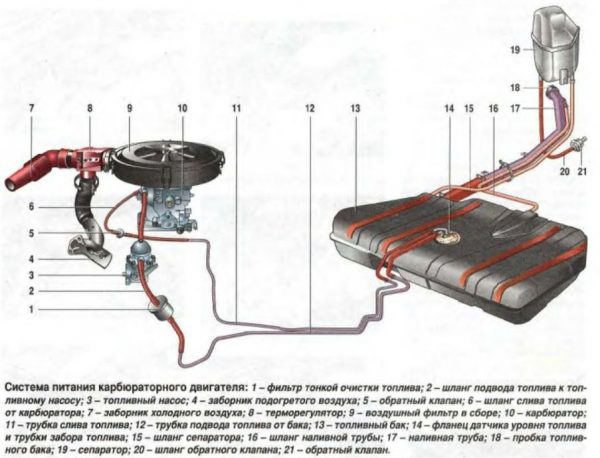

Power supply system VAZ 2106

The power supply system is designed to clean fuel and air, prepare a fuel-air mixture from them, supply it in time to the cylinders, and exhaust gases. In VAZ 2106, it consists of the following elements:

- tank with fuel level sensor;

- fuel filter;

- gasoline pump;

- carburetor;

- air purification filter;

- fuel and air lines;

- intake manifold;

- an exhaust manifold.

Fuel from the tank is supplied to the carburetor using a mechanical pump pump

Fuel from the tank is supplied to the carburetor using a mechanical pump pump

How the VAZ 2106 power system works

The fuel supply from the tank is carried out using a diaphragm-type gasoline pump. The device has a mechanical design and is driven by a pusher from the eccentric of the auxiliary drive shaft. There is a fine filter in front of the fuel pump, which traps the smallest particles of debris and moisture. From the gasoline pump, fuel is supplied to the carburetor, where it is mixed in a certain proportion with pre-cleaned air, and enters the intake manifold as a mixture. Exhaust gases are removed from the combustion chambers through the exhaust manifold, downpipe and muffler.

Video: the principle of operation of the carburetor engine power system

Ignition system VAZ 2106

Initially, the "sixes" were equipped with a contact ignition system. It consisted of the following nodes:

- ignition switch (lock);

- battery;

- generator;

- ignition coil;

- voltage distributor with a breaker;

- high voltage wires;

- candles.

VAZ 2106 engines were equipped with contact and non-contact ignition systems

VAZ 2106 engines were equipped with contact and non-contact ignition systems

In the future, the ignition system was somewhat modernized. Instead of an interrupter, which was used to create an electrical impulse and required constant adjustment of the contacts, an electronic switch and a Hall sensor were used.

The principle of operation of contact and non-contact ignition systems VAZ 2106

In the contact system, when the ignition key is turned, voltage is applied from the battery to the coil, which acts as a transformer. Passing through its windings, the voltage rises several thousand times. Then it follows to the contacts of the breaker, where it turns into electrical impulses and enters the distributor slider, which “carries” the current through the contacts of the cover. Each contact has its own high-voltage wire that connects it to the spark plugs. Through it, the impulse voltage is transmitted to the electrodes of the candle.

The contactless system works a little differently. Here, a Hall sensor installed in the distributor housing reads the position of the crankshaft and sends a signal to the electronic switch. The switch, based on the received data, applies a low voltage electrical impulse to the coil. From it, the current again flows to the distributor, where it is “scattered” onto the candles by means of a slider, cover contacts and high-voltage wires.

Video: VAZ 2106 contact ignition system

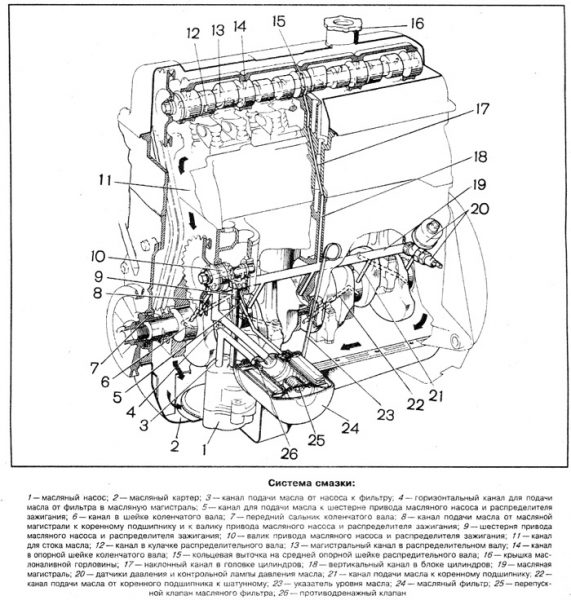

Lubrication system VAZ 2106

The lubrication system of the VAZ 2106 power plant is of a combined type: oil is supplied to some parts under pressure, and to others by spraying. Its design consists of:

- crankcase for storing lubricant;

- oil pump with oil receiver, pressure reducing valve and coarse filter;

- fine oil filter;

- oil channels located inside the cylinder block and cylinder head;

- emergency oil pressure sensor.

The VAZ 2106 lubrication system additionally performs the function of cooling

The VAZ 2106 lubrication system additionally performs the function of cooling

How the VAZ 2106 lubrication system works

The circulation of lubricant in the system is provided by an oil pump. It has a simple mechanical design based on two gears (driver and driven). Rotating, they create a vacuum at the inlet of the pump and a pressure at the outlet. The drive of the device is provided from the shaft of auxiliary units through its gear, which is engaged with the gear of the oil pump.

Leaving the pump, the lubricant is supplied through a special channel to the full-flow fine filter, and from it to the main oil line, from where it is carried to the moving and heating elements of the engine.

Video: operation of the VAZ 2106 lubrication system

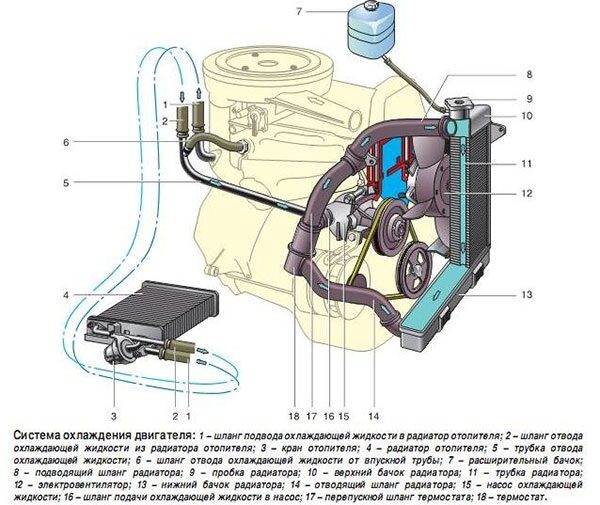

Cooling system

The cooling system of the VAZ 2106 power unit has a sealed design, where the refrigerant circulates under pressure. It serves both to cool the engine and to maintain its operating thermal conditions. The structure of the system is:

- liquid pump (pump);

- thermostat;

- radiator with electric fan;

- cooling fan activation sensor;

- temperature sensor;

- heater radiator;

- expansion tank;

- connecting pipes;

- engine cooling jacket.

The VAZ 2106 engine is equipped with a closed-type liquid cooling system

The VAZ 2106 engine is equipped with a closed-type liquid cooling system

How the cooling system of the VAZ 2106 works

The liquid cooling jacket is a network of channels located inside the cylinder head and cylinder block of the power unit. It is completely filled with coolant. During engine operation, the crankshaft rotates the fluid pump rotor drive pulley through a V-belt. At the other end of the rotor is an impeller that forces the refrigerant to circulate through the jacket. Thus, a pressure equal to 1,3–1,5 atmospheres is created in the system.

Read about the device and repair of the cylinder head system: https://bumper.guru/klassicheskie-modeli-vaz/grm/poryadok-zatyazhki-golovki-bloka-cilindrov-vaz-2106.html

Moving through the channels of the power unit, the refrigerant reduces its temperature, but heats up itself. When the liquid enters the cooling radiator, it gives off heat to the tubes and plates of the device. Thanks to the design of the heat exchanger and the constantly circulating air, its temperature is reduced. Then the refrigerant enters the engine again, repeating the cycle. When the coolant reaches critical temperatures, a special sensor is triggered, which turns on the fan. It performs forced cooling of the radiator, blowing it from the back with a stream of air.

In order for the engine to warm up faster in cold weather and not overheat in summer, a thermostat is included in the design of the system. Its role is to regulate the direction of the coolant. When the engine is cold, the device does not let the coolant into the radiator, forcing it to move only inside the engine. When the liquid is heated to a temperature of 80–850The thermostat is activated, and the refrigerant circulates already in a large circle, entering the heat exchanger for cooling.

When heated, the coolant expands in volume, and it needs to go somewhere. For these purposes, an expansion tank is used - a plastic tank where excess refrigerant and its vapor are collected.

In addition to lowering the temperature of the engine and maintaining its thermal regime, the cooling system also serves to heat the passenger compartment. This is achieved by an additional radiator installed in the heater module. When the refrigerant enters it, its body becomes hot, due to which the air that is in the module is heated. Heat enters the cabin thanks to an electric fan installed at the inlet of the "stove".

Video: VAZ 2106 cooling system diagram

Crankshaft mechanism VAZ 2106

The crank mechanism (KShM) is the main mechanism of the power plant. It serves to convert the reciprocating motion of each of the pistons into rotational motion of the crankshaft. The mechanism consists of:

- cylinder block;

- block heads;

- crankshaft;

- flywheel;

- elements of the piston group (rods, pistons, piston rings and pins).

The crank mechanism is used to convert the reciprocating motion of the pistons into the rotational motion of the crankshaft

The crank mechanism is used to convert the reciprocating motion of the pistons into the rotational motion of the crankshaft

The principle of operation of the KShM

The piston with its bottom receives the force created by the pressure of the burning combustible mixture. He passes it to the connecting rod, on which he himself is fixed with a finger. The latter, under the influence of pressure, moves down and pushes the crankshaft, with which its lower neck is articulated. Considering that there are four pistons in the VAZ 2106 engine, and each of them moves independently of each other, the crankshaft rotates in one direction, pushed by the pistons in turn. The end of the crankshaft is equipped with a flywheel, which is designed to dampen rotational vibrations, as well as increase the inertia of the shaft.

Each piston is equipped with three rings. Two of them serve to create pressure in the cylinder, the third - to clean the cylinder walls from oil.

Video: crank mechanism

Gas distribution mechanism VAZ 2106

The gas distribution mechanism (timing) of the engine is needed to ensure the timely entry of the fuel-air mixture into the combustion chambers, as well as the release of combustion products from them. In other words, he must close and open the valves in time. The design of the timing includes:

- camshaft;

- valves;

- pushers;

- push rods;

- rocker arms;

- drive elements (camshaft and crankshaft stars, drive chain with damper, tensioner, shoe).

The gas distribution mechanism of the VAZ 2106 is driven by a chain drive from the crankshaft

The gas distribution mechanism of the VAZ 2106 is driven by a chain drive from the crankshaft

How the VAZ 2106 timing works

The main element of the engine timing is the camshaft. It is he who, with the help of cams located along its entire length, through additional parts (pushers, rods and rocker arms) actuates the valves, opening and closing the corresponding windows in the combustion chambers.

The crankshaft rotates the camshaft by means of a tensioned chain. At the same time, the rotation speed of the latter, due to the difference in the sizes of the stars, is exactly two times less. During rotation, the camshaft cams act on the pushers, which transmit force to the rods. The latter press on the rocker arms, and they press on the valve stems.

In the operation of the mechanism, the synchronism of the rotation of the crankshaft and camshaft is very important. The slightest displacement of one of them leads to a violation of the gas distribution phases, which negatively affects the functionality of the power unit.

Video: the principle of operation of the gas distribution mechanism

Watch this video on YouTube

VAZ 2106 engine malfunctions and their symptoms

No matter how reliable the engine of the "six" is, unfortunately, it also sometimes fails. There can be any number of reasons for the breakdown of the power unit, starting from a banal breakage of one of the wires and ending with the wear of parts of the piston group. To determine the cause of a malfunction, it is important to understand its symptoms.

Signs that the VAZ 2106 engine needs repair may be:

- inability to start (whether cold or hot);

- tripling, "floating" speed, unstable idling;

- power reduction at start, under load;

- overheat;

- the appearance of extraneous noise (knocking, clatter);

- exhaust color change (thick white or gray smoke).

It should be borne in mind here that any of these symptoms cannot directly indicate a malfunction of a particular node, mechanism or system, therefore, diagnostics should be approached comprehensively, rechecking your conclusions.

Engine won't start at all

If, with a charged battery and a normally working starter, the power unit does not start and does not “grab”, you need to check:

- ignition coil;

- interrupter (Hall sensor, switch);

- slider and contacts of the distributor cover;

- high-voltage wires with lugs;

- spark plug;

- gasoline pump;

- filter on the carburetor fuel intake fitting;

- idle valve.

The absence of signs of engine life is the result of a malfunction either in the ignition system or in the power system. It is better to start diagnostics with ignition, “ringing” the circuit with a tester, and checking if there is voltage on each element. As a result of such a check, you should make sure that there is a spark on the spark plugs during the rotation of the starter. If there is no spark, you should check each node of the system.

More details about the spark on the VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/elektrooborudovanie/zazhiganie/net-iskry-vaz-2106.html

The essence of checking the system is to understand whether the fuel reaches the carburetor and whether it enters the cylinders. To do this, you need to disconnect the outlet pipe of the fuel pump from the carburetor, insert it into some container, and scroll with the starter. If gasoline flows into the vessel, everything is in order with the pump and filter.

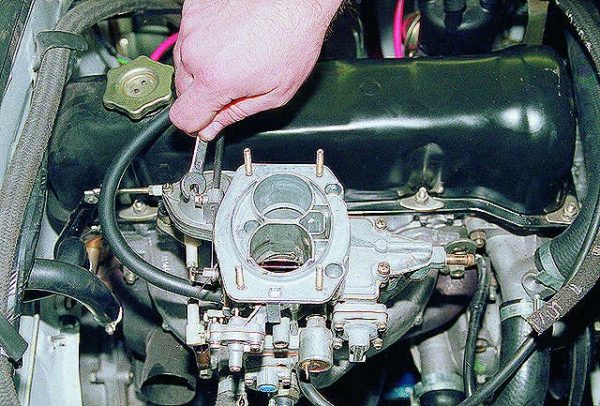

To check the carburetor, it is enough to remove the air filter and top cover from it. Next, you need to sharply pull the accelerator cable and look into the secondary chamber. At this point, you should be able to see a thin stream of fuel directed into the intake manifold. This means that the carburetor accelerator pump is operating normally. There is no trickle - the carburetor needs to be repaired or adjusted.

Worth checking the idle valve. If it fails, the engine will not start. To check it, you need to unscrew it from the carburetor cover and disconnect the power wire. Next, the valve must be connected directly to the battery terminals. During connection, a click characteristic of the operation of the electromagnet should be clearly audible, and the rod of the device should move back.

Video: why the car does not start

Watch this video on YouTube

The engine is troit, there is a violation of idling

Trouble of the power unit and a violation of idling can be caused by:

- failure of one or more spark plugs;

- breakdown of a high-voltage wire;

- burning contacts of the distributor cover;

- clogging of the fine fuel filter;

- obstruction of the filter on the inlet fitting of the carburetor;

- incorrect carburetor adjustment.

As in the previous case, here it is better to start the diagnosis with the ignition system. You should immediately check the spark on the electrodes of the candles and measure the resistance of each of the high-voltage wires. Then the distributor cover is removed and the condition of its contacts is assessed. In case of their burning, it is necessary to clean them from soot, or replace the cover.

Diagnostics of the fine filter is carried out by determining its throughput, as described above. But as for the carburetor filter, it must be unscrewed from the cover, and, if necessary, blown with compressed air.

If after these stages of diagnostics the symptoms remain, it is necessary to adjust the carburetor, namely the quality of the mixture and the fuel level in the float chamber.

Video: why the VAZ 2106 engine troit

Watch this video on YouTube

Reduced engine power

To the deterioration of the power qualities of the power unit lead to:

- clogging of fine filters or carburetor;

- malfunction of the fuel pump;

- incorrect adjustment of the quality of the combustible mixture;

- violation of the valve timing;

- incorrect adjustment of the ignition timing;

- wear of piston group parts.

With a noticeable decrease in engine power, the first step is to evaluate the performance of the fuel system by checking the filters, the fuel pump and adjust the quality of the mixture. Next, you need to determine whether the timing marks on the crankshaft and camshaft stars match the marks on the engine and camshaft covers. If everything is in order with them, adjust the ignition timing by turning the distributor housing in one direction or another.

As for the piston group, when its parts are worn, the loss of power does not appear so clearly and quickly. To determine what exactly the piston is to blame for the loss of power, compression measurement in each of the cylinders can help. For VAZ 2106, indicators in the range of 10–12,5 kgf / cm are considered normal2. It is allowed to operate the engine with a compression of 9-10 kgf / cm2, although such figures indicate a clear wear of the elements of the piston group.

Video: why engine power is reduced

Watch this video on YouTube

Engine overheating

Violation of the thermal regime of the power plant can be determined by the coolant temperature gauge. If the arrow of the device constantly or periodically changes into the red sector, this is a clear sign of overheating. It is not recommended to continue driving a car whose engine is prone to overheating, as this can lead to burning of the cylinder head gasket, as well as jamming of the moving parts of the power unit.

Violation of the thermal regime of the motor may be the result of:

- insufficient refrigerant level in the system;

- jamming the thermostat;

- obstruction (clogging) of the cooling radiator;

- breakdown of the cooling fan;

- fluid pump failure.

If signs of overheating are found, the first thing to do is to pay attention to the level of coolant in the expansion tank, and top up coolant if necessary. You can determine the performance of the thermostat by the temperature of the radiator pipes. When the engine is warm, they should both be hot. If the lower pipe is hot and the upper pipe is cold, then the thermostat valve is stuck in the closed position, and the refrigerant moves in a small circle, bypassing the radiator. In this case, the device must be replaced, since it cannot be repaired. The patency of the radiator is also checked by the temperature of the nozzles. If it is clogged, the top outlet will be hot and the bottom outlet warm or cold.

The cooling fan on the VAZ 2106 usually turns on at a coolant temperature of 97–990C. His work is accompanied by a characteristic buzz that the impeller emits. It can fail for several reasons, including poor contact in the connector, a broken sensor, and a malfunction of the electric motor itself. To test the device, just connect its contacts directly to the battery.

It is quite difficult to diagnose a breakdown of a liquid pump without dismantling it, so it is checked last. Most often, its malfunction is associated with damage to the impeller and wear of the rotor bearing.

Video: why the engine overheats

Watch this video on YouTube

Extraneous sounds

The operation of any power unit is accompanied by a lot of sounds, so only a specialist can tell by ear where extraneous noise is and where it is not, and even then not everyone. To determine the "extra" knocks, there are special car phonendoscopes that allow you to more or less accurately determine the place where they come from. As for the VAZ 2106 engine, extraneous sounds can be emitted by:

- valves;

- main and connecting rod bearings;

- piston pins;

- timing chain drive.

The valves make a high-frequency knock that comes from the valve cover. They knock due to improper adjustment of thermal clearances, wear of the camshaft cams, and weakening of the valve springs.

Main and connecting rod bearings make similar sounds. The reason for this is their wear, as a result of which the play between them and the connecting rod journals increases. In addition, knocking can also be caused by low oil pressure.

The piston pins usually ring. This phenomenon is often caused by detonation inside the cylinders. It occurs due to incorrect adjustment of the ignition timing. A similar problem is solved by setting a later ignition.

The noise of the timing chain is like a loud rustling or clanging, caused by its weak tension or problems with the damper. Replacing the damper or its shoe will help get rid of such sounds.

Video: engine knock

Watch this video on YouTube

Exhaust color change

By the color, consistency and smell of exhaust gases, one can generally judge the condition of the engine. A serviceable power unit has a white, light, translucent exhaust. It smells exclusively of burnt gasoline. A change in these criteria indicates that the motor has problems.

Thick white smoke from the exhaust pipe under load indicates the combustion of oil in the cylinders of the power plant. And this is a sign of worn piston rings. You can make sure that the rings have become unusable, or "lie down", by inspecting the air filter housing. If grease enters the cylinders, it will be squeezed out through the breather into the "pan", where it will settle in the form of an emulsion. A similar malfunction is treated by replacing the piston rings.

But thick white exhaust may be the result of other problems. So, in the event of a breakdown (burnout) of the cylinder head gasket, the coolant enters the cylinders, where it turns into white vapor during combustion. In this case, the exhaust will have an inherent smell of coolant.

Video: why white smoke comes out of the exhaust pipe

Watch this video on YouTube

Repair of the power unit VAZ 2106

Repair of the "six" motor, which involves the replacement of parts of the piston group, is best done after it is dismantled from the car. In this case, the gearbox can not be removed.

Dismantling the VAZ 2106 engine

Even after removing all attachments, manually pulling the engine out of the engine compartment will not work. Therefore, to complete this task, you will need a garage with a viewing hole and an electric hoist. In addition to it, you will need:

- a set of screwdrivers and wrenches;

- containers for collecting coolant and oil;

- marker;

- a few old blankets (to protect the car's paintwork while the engine is being removed).

To dismantle the motor:

- Drive the car into the inspection pit.

- Raise the hood, draw around the canopies along the contour with a marker. This is necessary so that when installing the hood, you do not have to set the gaps.

In order not to have to set gaps when installing the hood, you need to circle the canopies with a marker

In order not to have to set gaps when installing the hood, you need to circle the canopies with a marker - Loosen the nuts securing the hood, remove it.

- Drain coolant completely.

The coolant must be drained from both the radiator and the cylinder block.

The coolant must be drained from both the radiator and the cylinder block. - Using a screwdriver, loosen the clamps of the pipes of the cooling system. Remove all pipes.

To remove the pipes, you need to loosen the clamps

To remove the pipes, you need to loosen the clamps - Remove the fuel lines in the same way.

The hoses are also secured with clamps.

The hoses are also secured with clamps. - Disconnect high voltage wires from spark plugs and distributor cap.

- After unscrewing the two nuts, disconnect the exhaust pipe from the exhaust manifold.

To disconnect the pipe, unscrew the two nuts

To disconnect the pipe, unscrew the two nuts - Disconnect the battery, remove it and put it aside.

- Unscrew the three nuts securing the starter, disconnect the wires. Remove starter.

The starter is attached with three nuts

The starter is attached with three nuts - Unscrew the upper gearbox mounting bolts (3 pcs).

The gearbox is held on top with three bolts.

The gearbox is held on top with three bolts. - Disconnect the air and throttle actuators from the carburetor.

From the carburetor, you need to disconnect the air and throttle actuators

From the carburetor, you need to disconnect the air and throttle actuators - Having descended into the inspection hole, dismantle the clutch slave cylinder.

To remove the cylinder, you need to dismantle the spring

To remove the cylinder, you need to dismantle the spring - Remove the two lower gearbox-to-engine bolts.

The bottom of the gearbox is secured with two bolts.

The bottom of the gearbox is secured with two bolts. - Unscrew the nuts securing the protective cover (4 pcs).

The casing is fixed on four nuts

The casing is fixed on four nuts - Unscrew the three nuts securing the power plant to the supports.

The engine is mounted on three supports

The engine is mounted on three supports - Securely fasten the mounting chains (belts) of the hoist to the engine.

- Cover the front fenders of the car with old blankets (so as not to scratch the paintwork).

- Carefully lift the engine with a hoist.

Before removing the engine, you need to make sure that the fasteners are secure.

Before removing the engine, you need to make sure that the fasteners are secure. - Take the motor aside and place it on the floor or table.

How to replace earbuds

When the engine is removed from the car, you can begin to repair it. Let's start with inserts. To replace them, you must:

- Unscrew the drain plug on the oil pan with a hex wrench.

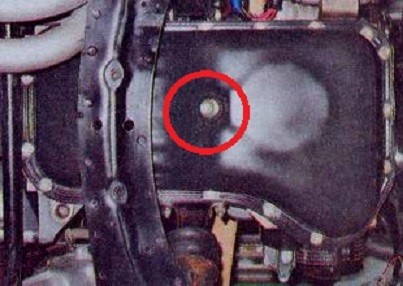

The plug is unscrewed with a hexagon

The plug is unscrewed with a hexagon - Using a 10 key, unscrew all twelve bolts around the perimeter of the pallet. Remove pan with gasket.

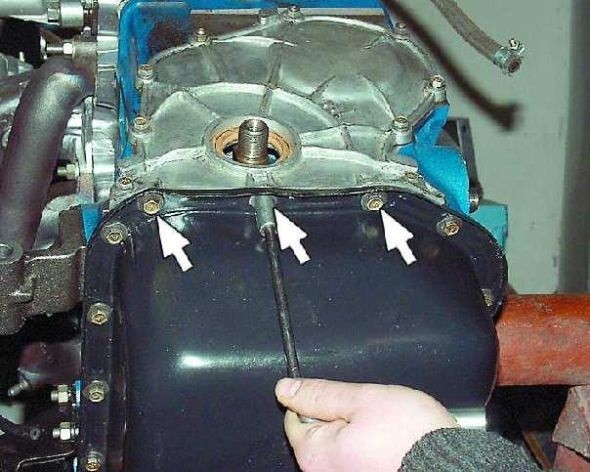

The pallet is fixed with 10 bolts

The pallet is fixed with 10 bolts - Remove the carburetor and ignition distributor.

- Using a 10mm wrench, remove the eight valve cover nuts. Remove cover with gasket.

The valve cover is fixed with eight nuts.

The valve cover is fixed with eight nuts. - Using a spudger or chisel, bend the washer that secures the camshaft star mounting bolt.

To unscrew the bolt, you need to bend the washer

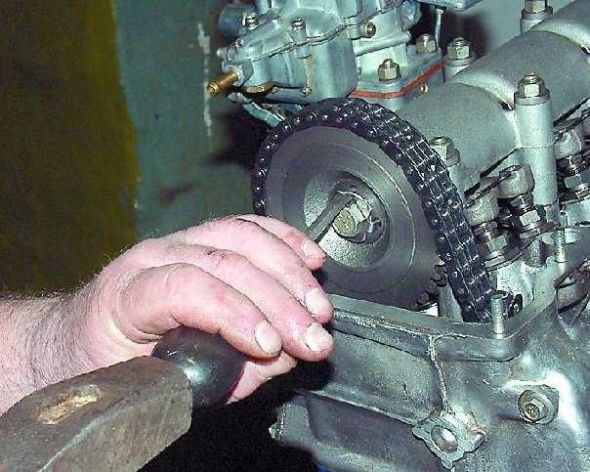

To unscrew the bolt, you need to bend the washer - Using a 17 wrench, unscrew the camshaft star bolt. Remove star and chain.

- Unscrew the two nuts securing the chain tensioner with a 10 wrench.

The tensioner is secured with two nuts

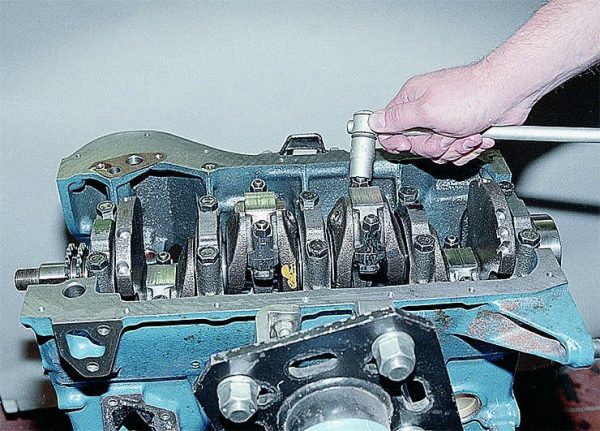

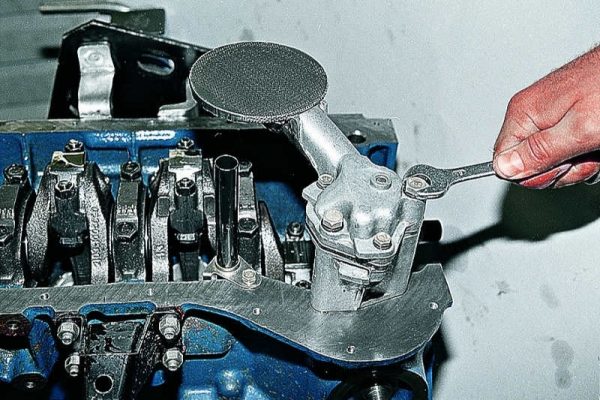

The tensioner is secured with two nuts - Using a 13 socket wrench, unscrew the nine nuts securing the camshaft bed. Take off the bed.

To remove the bed, you need to unscrew nine nuts

To remove the bed, you need to unscrew nine nuts - Using a 14 wrench, unscrew the nuts securing the connecting rod caps. Remove the covers with inserts.

Each cover is secured with two nuts.

Each cover is secured with two nuts. - Dismantle the connecting rods, remove the liners from them.

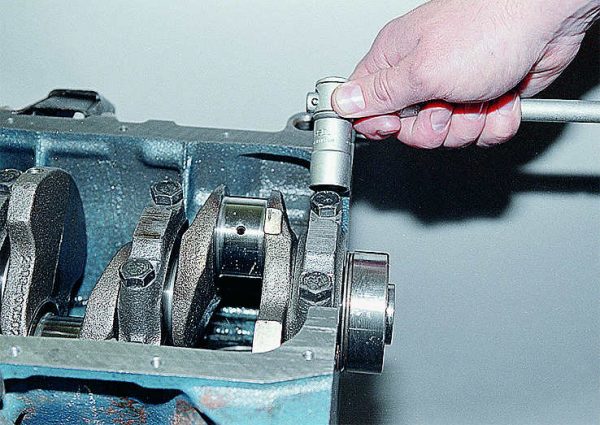

- Using a 17 wrench, unscrew the bolts on the main bearing caps.

The cover is attached with two screws.

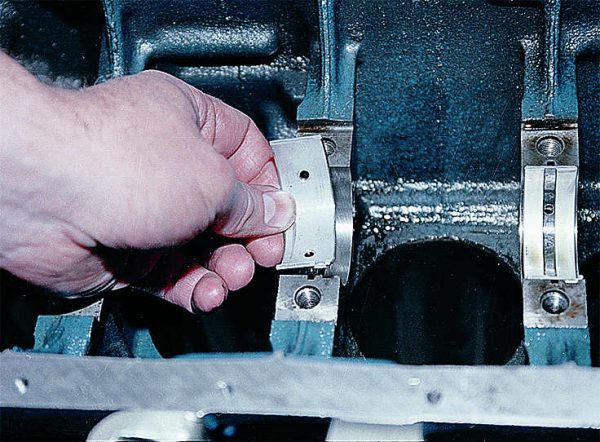

The cover is attached with two screws. - Disconnect covers, remove thrust rings

- Remove the main bearing shells from the covers and cylinder block.

Inserts are made of steel and aluminum alloy

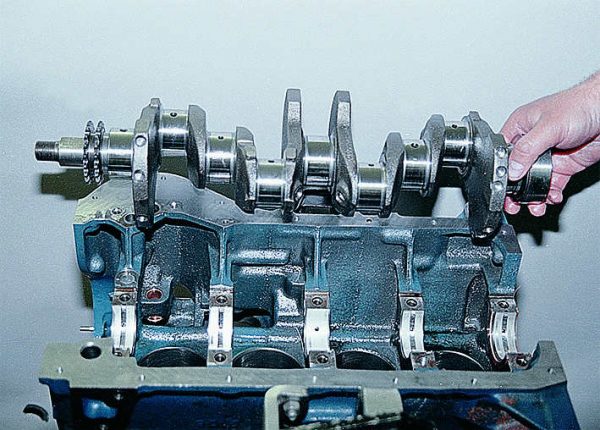

Inserts are made of steel and aluminum alloy - Dismantle the crankshaft.

The shaft must be cleaned of oil by washing in kerosene

The shaft must be cleaned of oil by washing in kerosene - Rinse the shaft in kerosene, wipe with a dry clean cloth.

- Install new bearings and thrust washers.

- Lubricate the main and connecting rod journals of the crankshaft with engine oil, then install the shaft into the cylinder block.

- Install main bearing caps and secure with screws. Tighten the bolts with a torque wrench to 68,3–83,3 Nm.

- Install the connecting rods with new bearings on the crankshaft. Fix them with nuts. Tighten nuts to 43,3–53,3 Nm.

- Assemble the engine in reverse order.

Replacement of compression and oil scraper rings of pistons

To replace the piston rings, you will need the same tools, as well as a vise and a special mandrel for crimping the pistons. Repair work should be carried out in the following order:

- Dismantle the engine in accordance with p.p. 1-10 of the previous instruction.

- Push the pistons one by one out of the cylinder block together with the connecting rods.

Pistons must be removed along with connecting rods.

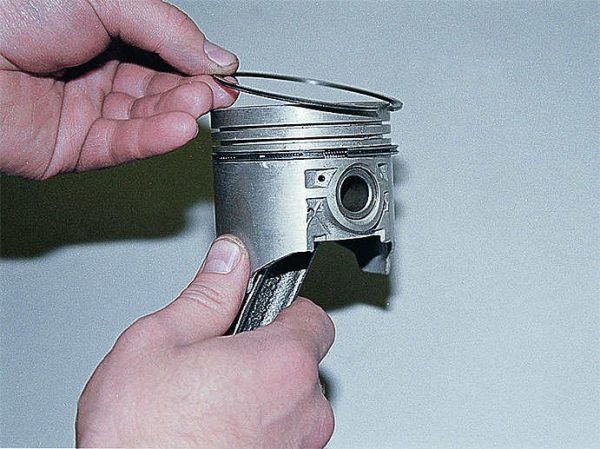

Pistons must be removed along with connecting rods. - Clamp the connecting rod in a vice, and use a thin screwdriver to remove two compression and one oil scraper rings from the piston. Do this procedure for all pistons.

Each piston has three rings

Each piston has three rings - Clean the pistons from soot.

- Install new rings, orienting their locks to the protrusions in the grooves.

- Using a mandrel, install the pistons with rings into the cylinder.

It is more convenient to install pistons using a mandrel

It is more convenient to install pistons using a mandrel - Assemble the engine in reverse order.

Oil pump repair

To remove and repair the oil pump, you must:

- Using a 13 wrench, unscrew the two pump mounting bolts.

The pump is held on by two bolts.

The pump is held on by two bolts. - Dismantle the device together with the gasket.

- Using a 10 wrench, unscrew the three bolts securing the oil intake pipe.

The pipe is attached with three bolts

The pipe is attached with three bolts - Disconnect the pressure reducing valve.

The valve is used to maintain pressure in the system

The valve is used to maintain pressure in the system - Remove pump cover.

- Remove the drive and driven gears.

Gears must not show signs of wear or damage.

Gears must not show signs of wear or damage. - Inspect the pump parts, assess their condition. If the housing, cover or gears have signs of wear or mechanical damage, replace the defective elements.

- Clean the oil pickup screen.

If the mesh is dirty, it must be cleaned or replaced.

If the mesh is dirty, it must be cleaned or replaced. - Assemble the device in reverse order.

Self-repair of the engine is a rather complicated process, but not so much that it is not to be dealt with. The main thing is to start, and then you yourself will figure out what's what.