The device, principle of operation and the procedure for self-replacing the clutch VAZ 2107

The VAZ 2107 clutch is the most important part of the transmission, which is involved in the transmission of torque to the wheels. It is located between the gearbox and the power unit, transferring rotation from the engine to the box. Knowledge of the design features of the entire unit and its constituent elements will allow, if necessary, to easily replace the clutch with your own hands.

Clutch device VAZ 2107

The clutch is operated by a pedal in the passenger compartment. When you press it, the clutch is disconnected from the gearbox, when released, it engages. This ensures a smooth start of the car from a place and noiseless gear shifting. The node itself consists of a large number of elements interacting with each other. VAZ 2107 is equipped with a single-plate clutch with a central spring.

Clutch basket

The clutch consists of two discs and a release bearing. The clutch used on the VAZ 2107 is simple and reliable. The pressure (drive disc) is mounted on the flywheel. Inside the basket there is a driven disk connected to the input shaft of the gearbox with special splines.

The clutch can be single-disc and multi-disc. The first is considered more reliable. The clutch functions as follows. When the pedal is depressed, the release bearing mounted on the input shaft pulls the basket petals towards the motor unit. As a result, the basket and the driven disc are disengaged, and it becomes possible to switch speeds.

For VAZ 2107, disks from VAZ 2103 (for engines up to 1,5 liters) and VAZ 2121 (for engines up to 1,7 liters) are suitable. Outwardly, they are very similar and have a diameter of 200 mm. These discs can be distinguished by the width of the linings (29 and 35 mm, respectively) and the presence of a 2121 mm mark in one of the grooves of the VAZ 6 damper.

Read about the diagnosis of an elastic coupling: https://bumper.guru/klassicheskie-modeli-vaz/zadnij-most/zamena-podvesnogo-podshipnika-na-vaz-2107.html

Clutch disc

The driven disc is sometimes called a drum. On both sides, overlays are glued to it. To increase the elasticity during the manufacturing process, special slots are made on the disc. In addition, the drum is equipped with eight springs located in the plane of the disc. These springs reduce the torsional vibration frequency and reduce dynamic loads.

The drum is connected to the gearbox and the basket is connected to the engine. During movement, they are tightly pressed against each other, rotating in one direction.

The single-disk scheme used on the VAZ 2107 is distinguished by its reliability, comparative cheapness and ease of maintenance. This clutch is easy to remove and repair.

The driven disc for a 1,5 liter engine has dimensions of 200x140 mm. It can also be installed on VAZ 2103, 2106. Sometimes a VAZ 2107 is equipped with a Niva drum (VAZ 2121), which differs in size (200x130 mm), a reinforced damper system and a large number of rivets.

Release bearing

The release bearing, being the most vulnerable element of the clutch, engages and disengages the transmission of rotation. It sits in the middle of the disc and is rigidly connected to the pedal via a fork. Each depression of the clutch pedal loads the bearing and shortens the bearing life. Do not keep the pedal depressed unnecessarily. The bearing is installed on the guide of the transmission drive shaft.

In the clutch kit, the release bearing is designated 2101. A bearing from the VAZ 2121, designed for high loads and having an increased resource, is also suitable. However, in this case, the basket will also need to be replaced, since it will take a lot of effort to press the pedal.

Clutch fork

The fork is designed to disengage the clutch when the clutch pedal is depressed. It moves the release bearing and, as a result, the inner edge of the spring.

Most often, with a faulty fork, the clutch becomes impossible to disengage. However, sometimes it continues to malfunction. If you do not replace the fork immediately, you will have to change the entire clutch assembly in the future.

Choice of grip

When buying a new clutch kit for a VAZ 2107, experts recommend being guided by the following criteria. When evaluating a driven disc:

- the surface of the linings should be smooth and uniform, without scoring, cracks and chips;

- all rivets on the disc must be the same size and be at an equal distance from each other;

- there should be no oil stains on the disc;

- there should be no backlash in the attachment points of the linings and springs;

- on the product in one way or another, the manufacturer's corporate logo must be applied.

When choosing a basket, you should pay attention to the following points:

- the casing must be stamped, without cuts and scratches;

- the surface of the disc must be even and uniform, without cracks and chips;

- the rivets must be uniform and strong.

The most popular are the following brands.

- Valeo (France), specializing in the production of elements of the brake system of excellent quality. The characteristic features of the Valeo clutch are soft work with a clear moment of switching on, reliability, high resource (more than 150 thousand km of run). However, such a clutch is not cheap.

Valeo clutch features smooth operation with a clear engagement moment

Valeo clutch features smooth operation with a clear engagement moment - Luk (Germany). In terms of quality, the Luk clutch is close to that of Valeo, but it costs a little less. The good damping properties of Luk products are noted.

- Kraft (Germany). However, production is concentrated in Turkey. The Craft clutch features smooth operation without overheating and reliable flywheel protection.

- Sachs (Germany). The company specializes in the production of transmission parts. The use of non-asbestos linings in the manufacture of clutch discs made Sachs very popular in Russia.

The choice of a clutch should be approached in a comprehensive manner and a choice should be made after inspection of the product and the advice of specialists.

Replacing the clutch

If the clutch starts to slip, it must be replaced. It is more convenient to do this on a lift or overpass. As a last resort, you can use a jack with the obligatory safety stops. Replacement will require:

- standard set of screwdrivers and wrenches;

- passages;

- clean rag;

- mount;

- mandrel.

Dismantling the gearbox

When replacing the clutch on a VAZ 2107, the gearbox can not be completely removed, but only moved so that the input shaft disengages from the basket. However, most often the box is completely dismantled. In addition to convenience, this allows you to check the condition of the crankcase and oil seals. The gearbox is removed as follows:

- The starter is removed.

Before dismantling the gearbox, the starter is removed

Before dismantling the gearbox, the starter is removed - Disconnect the shift lever.

Before dismantling the box, the gearshift lever is disconnected

Before dismantling the box, the gearshift lever is disconnected - The muffler mounts are dismantled.

- Remove the underbody traverses.

When removing the gearbox, the traverses are disconnected

When removing the gearbox, the traverses are disconnected

Learn more about the VAZ 2107 checkpoint: https://bumper.guru/klassicheskie-modeli-vaz/kpp/kpp-vaz-2107–5-stupka-ustroystvo.html

Removing the disc basket

After dismantling the gearbox, the basket with the disc is removed in the following order.

- The flywheel is secured against scrolling with a pry bar.

- With a 13 key, the basket fastening bolts are unscrewed

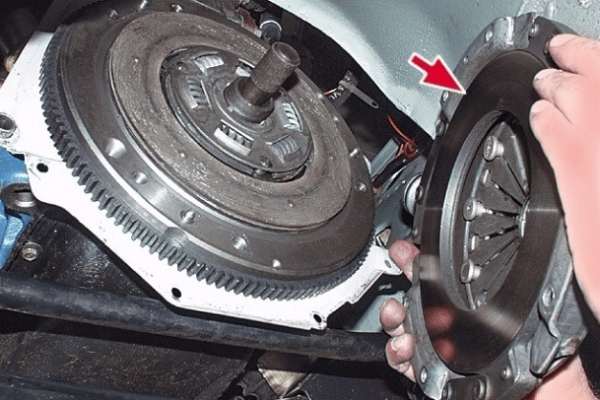

To remove the basket with a 13 key, the bolts of its fastening are unscrewed

To remove the basket with a 13 key, the bolts of its fastening are unscrewed.

- The basket is pushed back with a pry bar, and the disc is carefully removed.

- The basket is pressed slightly inward, then leveled and pulled out.

Removing the release bearing

After the basket, the release bearing is removed. This is done in the following way.

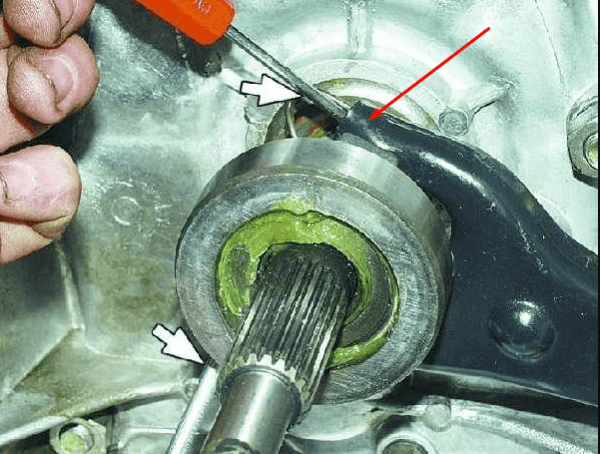

- With a screwdriver, press on the antennae of the fork that engages with the bearing.

To remove the release bearing, you need to press the antennae of the fork

To remove the release bearing, you need to press the antennae of the fork - The bearing is carefully pulled towards itself along the splines of the input shaft.

To remove the bearing, pull it towards you along the shaft.

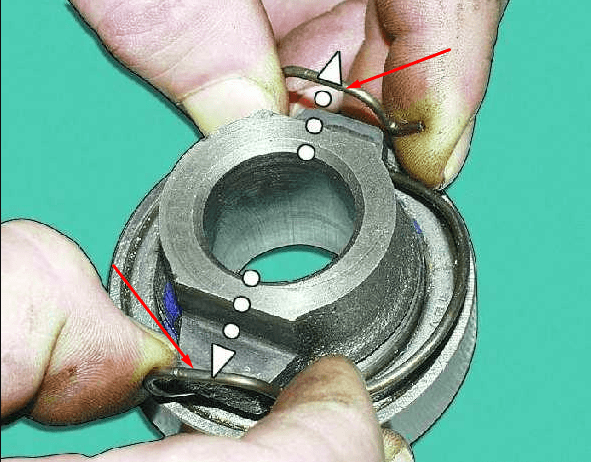

To remove the bearing, pull it towards you along the shaft. - Having pulled out the bearing, unclench the ends of the retaining ring of its fastening to the fork.

The release bearing is attached to the fork with a retaining ring.

The release bearing is attached to the fork with a retaining ring.

After removal, the circlip is checked for damage and, if necessary, replaced with a new one. If the ring, unlike the bearing, is in good condition, it can be reused with a new bearing.

Installing the disc cage

With the clutch and gearbox removed, they usually check the condition of all open units and parts. The mirrors of the disks and flywheel should be lubricated with a degreaser, and the SHRUS-4 grease should be applied to the shaft splines. When installing the basket, pay attention to the following points.

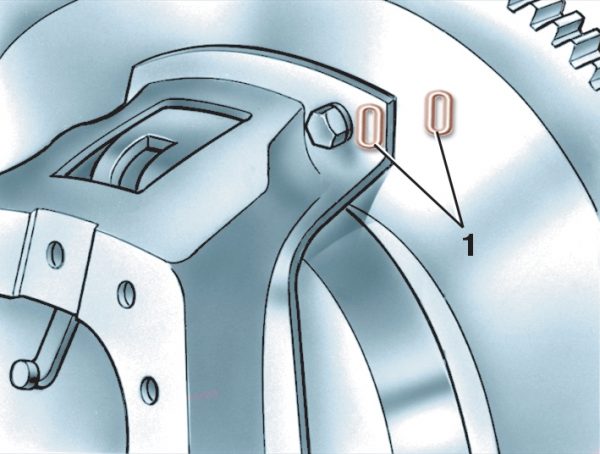

- When installing the basket on the flywheel, align the centering holes of the casing with the pins of the flywheel.

When installing the basket, the centering holes of the casing must match the pins of the flywheel

When installing the basket, the centering holes of the casing must match the pins of the flywheel - The fastening bolts should be tightened evenly in a circle, no more than one turn per pass. The tightening torque of the bolts should be between 19,1-30,9 Nm. The basket is properly secured if the frame can be easily removed after installation.

When installing a disc, it is inserted into the basket with the protruding part.

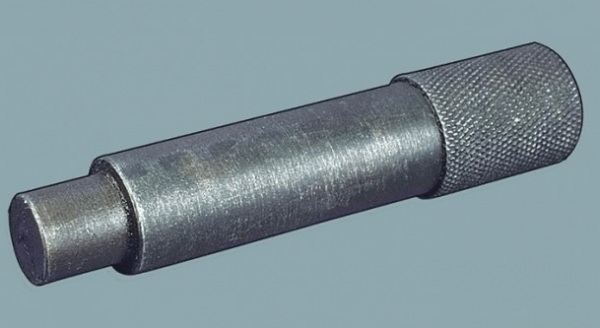

When mounting the disc, a special mandrel is used to center it to hold the disc in position.

The procedure for installing the cage with a disc is as follows.

- A mandrel is inserted into the flywheel hole.

A mandrel is inserted into the flywheel hole to center the disc

A mandrel is inserted into the flywheel hole to center the disc - A new driven disc is put on.

- The basket is installed, the bolts are attached.

- The bolts are tightened evenly and gradually in a circle.

Installing the release bearing

When installing a new release bearing, proceed as follows.

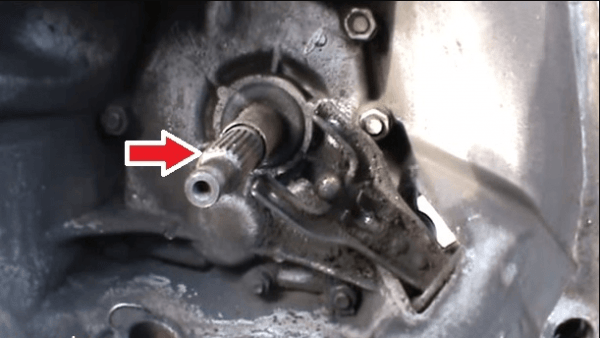

- Litol-24 grease is applied to the splined surface of the input shaft.

The splined part of the input shaft is lubricated with "Litol-24"

The splined part of the input shaft is lubricated with "Litol-24" - With one hand, the bearing is put on the shaft, with the other hand, the clutch fork is exposed.

- The bearing is pushed all the way until it locks into the fork barbs.

A properly installed release bearing will move the clutch fork when pressed by hand.

Video: installing the release bearing

Installing the checkpoint

Before installing the gearbox, you need to remove the mandrel and move the crankcase towards the engine. Then:

- The lower bolts are tightened.

- The front suspension arm is installed in place.

- Tightening with a torque wrench.

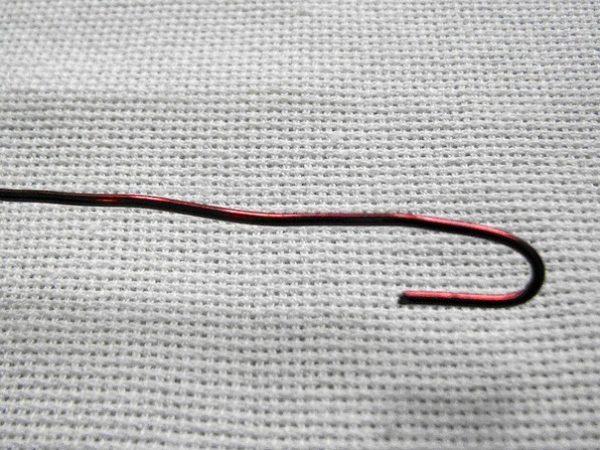

Installing the clutch fork

The fork must fit under the pressure spring on the release bearing hub. When installing, it is recommended to use a hook bent at the end no more than 5 mm. With such a tool, it is easy to pry the fork from above and direct its movement to fit under the release bearing retaining ring. As a result, the fork legs should be between this ring and the hub.

Read about adjusting the VAZ-2107 hub bearing: https://bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/zamena-stupichnogo-podshipnika-vaz-2107.html

Replacing the clutch hose

A worn or damaged clutch hose leads to fluid leakage from the hydraulic drive system, making it difficult to change gears. Replacing it is very easy.

- All fluid is drained from the clutch hydraulic system.

- The expansion tank is detached and moved to the side.

- With keys 13 and 17, the connecting nut of the clutch pipeline at the rubber hose is unscrewed.

The pipeline nut is turned off with keys 13 and 17

The pipeline nut is turned off with keys 13 and 17 - The bracket is removed from the bracket and the end of the hose is thrown off.

- With a 17 key under the car, the hose retainer is unscrewed from the working cylinder. The hose is completely removable.

- Installing a new hose is done upside-down.

- New fluid is poured into the clutch reservoir, then the hydraulic actuator is pumped.

Clutch hose damage or wear can be identified by the following symptoms.

- When the clutch pedal is fully depressed, the vehicle starts to shake.

- The clutch pedal does not return to its original position after being released.

- Traces of fluid appear at the ends of the clutch hose.

- After parking, a wet spot or a small puddle forms under the car.

Thus, replacing the clutch of a VAZ 2107 car is quite simple. This will require a new clutch kit, a standard set of tools, and consistently following professional instructions.