Inlet valve

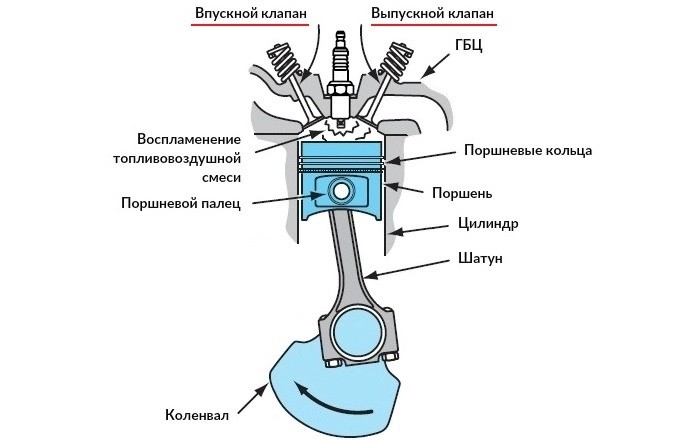

In this edition we will talk about intake and exhaust valves, however, before going into details, we will put these elements in context for a better understanding. The engine needs a means to distribute the intake and exhaust gases, to control and move them through the manifold to the intake manifold, combustion chamber and exhaust manifold. This is achieved through a series of mechanisms that form a system called distribution.

An internal combustion engine requires a fuel-air mixture, which, when burned, drives the mechanisms of the engine. In the manifold, the air is filtered and sent to the intake manifold, where the fuel mixture is metered through systems such as a carburetor or injection.

The finished mixture enters the combustion chamber, where this gas burns and, thus, converts thermal energy into mechanical energy. After the process is completed, it is necessary that the combustion products leave the chamber and allow the cycle to repeat. To develop this process, the engine must control the intake and exhaust of gas in each cylinder, this is achieved with the intake and exhaust valves, which will be responsible for opening and closing the channels at the right time.

ENGINE CYCLES

The operation of a four-stroke engine consists of four stages:

LOG

At this stage, the intake valve opens to let in air from outside, which causes the piston to drop, as well as the movement of the connecting rod and crankshaft.

COMPRESSION

At this stage, the intake and exhaust valves are closed. When the crankshaft rotates, the connecting rod and piston rise, this allows the air injected into the intake stage to increase its pressure several times, at the end of the compression stroke fuel and high pressure air are injected.

POWER

On the power stroke, the piston begins to descend as the compressed air/fuel mixture is ignited by the spark plug, causing an explosion inside the combustion chamber.

RELEASE

Finally, at this stage, the crankshaft turns to the right, thereby moving the connecting rod so that the piston can return up while the exhaust valve is open, and allows the combustion gases to escape through it.

WHAT IS INLET AND EXHAUST VALVES?

Inlet and outlet valves are elements whose function is to control the flow of a liquid or gas; those used in the intake and exhaust of a four-stroke engine are usually seated valves.

What is the role of these valves? Valves are precision parts of an engine and perform four very important tasks in engine operation:

- Blocking sections of the flow.

- Gas exchange control.

- Hermetically sealed cylinders.

- Dissipation of heat absorbed from the combustion of exhaust gases, transferring it to the valve seat inserts and valve guides. At temperatures up to 800ºC, each valve opens and closes up to 70 times per second and withstands an average of 300 million load changes over the life of the engine.

FEATURES

INLET VALVES

The intake valve performs the function of connecting the intake manifold to the cylinder depending on the distribution time. As a rule, they are made of only one metal, steel with chromium and silicon impurities, which provide good resistance to heat and work. Certain areas of the metal, such as the seat, stem, and head, are usually hardened to reduce wear. The cooling of this valve occurs due to its contact with the fuel-air mixture, which dissipates its temperature to a large extent, as a rule, upon contact with the stem, and its operating temperature reaches 200-300°C.

EXHAUST VALVES

The exhaust valve is in constant contact with the exhaust gases at very high temperatures, so they must be of a more robust design than the intake valves.

The heat accumulated in the valve is released through its seat by 75%, it is not surprising that it reaches a temperature of 800 ºC. Due to its unique function, this valve must be made of different materials, its head and stem are usually made of chromium and magnesium alloy steel, as it has excellent oxidation resistance and high temperature resistance properties. The top of the stem is usually made from silicon chrome. For thermal conductivity, hollow bottoms and rods filled with sodium are made, since this material has the function of quickly transferring heat to the cooling zone, reducing the temperature of the bottom to 100ºС.

TYPE OF VALVES

MONOMETALLIC VALVE

Produced rationally by hot extrusion or stamping.

BIMETALLIC VALVES

This makes a perfect combination of materials possible for both stem and head.

HOLLOW VALVES

This technology is used on the one hand for weight reduction, and on the other hand for cooling. Filled with sodium (melting point 97,5ºC), it can transfer heat from the valve head to the stem through the liquid sodium stirring effect, and achieve a temperature reduction of 80º to 150ºC.