1,2 HTP Engine - advantages / disadvantages, what to look for?

Probably few engines in our regions pump as much water as 1,2 HTP (perhaps only 1,9 TDi). The common public called him everywhere (from him .. does not pull, through the sale, to the hat). Sometimes you can hear incredible events about its properties, but often this is just nonsense, often caused by ignorance of the owners or participants in the discussion. It is true that the engine does have (had) many design flaws, if not equal to a design defect. On the other hand, many motorists did not understand what role they actually play in their small vehicle and some breakdowns or acceleration occurred for the same reason. The engine is designed for the smallest VW models. Not only in terms of volume, but also in terms of performance and especially design, the vehicle should be used mainly for urban traffic and commuting at a more relaxed pace. In other words, a Fabia, Polo or Ibiza with an HTP under the hood are not and never will be highway fighters.

Probably few engines in our regions pump as much water as 1,2 HTP (perhaps only 1,9 TDi). The common public called him everywhere (from him .. does not pull, through the sale, to the hat). Sometimes you can hear incredible events about its properties, but often this is just nonsense, often caused by ignorance of the owners or participants in the discussion. It is true that the engine does have (had) many design flaws, if not equal to a design defect. On the other hand, many motorists did not understand what role they actually play in their small vehicle and some breakdowns or acceleration occurred for the same reason. The engine is designed for the smallest VW models. Not only in terms of volume, but also in terms of performance and especially design, the vehicle should be used mainly for urban traffic and commuting at a more relaxed pace. In other words, a Fabia, Polo or Ibiza with an HTP under the hood are not and never will be highway fighters.

Many motorists wonder what motivates automakers to reduce the number of engine cylinders. The HTP is not the only three-cylinder engine on the market, Opel also has a three-cylinder unit in its Corse or Toyota in its Ayga for example. Fiat recently released a two-cylinder engine. The answer is relatively simple. Reducing production costs and striving for the lowest possible emissions.

A three-cylinder engine is cheaper to manufacture compared to a four-cylinder. With a volume of about one liter, the three-cylinder engine has the best surface area of the combustion chambers. In other words, it has lower heat losses and, in a steady state operation without frequent accelerations, it should theoretically have a higher efficiency, i.e. lower fuel consumption. Due to the smaller number of cylinders, there are also fewer moving parts and therefore, logically, its friction losses are also lower.

Likewise, engine torque is also dependent on the cylinder bore and therefore starts faster with HTP than with a comparable four-cylinder engine with the same gearbox. Thanks to the shorter escort, vehicles with an OEM engine start faster than those with a 1,4 16V company. Unfortunately, this only applies to starts and lower speeds. At higher speeds, there is already a lack of engine power, which is also emphasized by the significant weight of the small vehicle. So much for the pros.

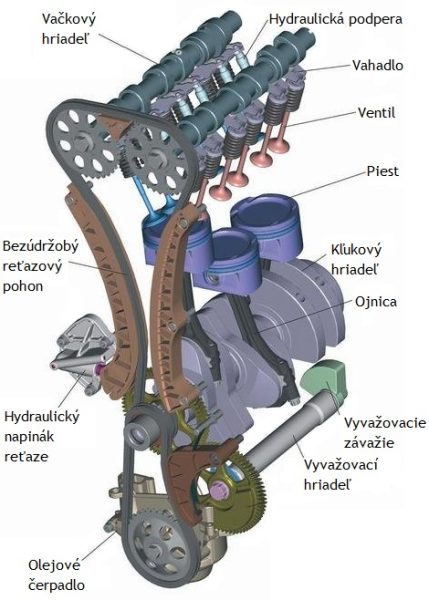

On the contrary, the disadvantages include the worst running culture and significant vibrations. Thus, a three-cylinder engine requires a larger and heavier flywheel for more regular operation and a balance shaft to suppress vibrations (more advanced work). In practice, this fact (extra weight) manifests itself in less readiness for faster acceleration and, on the other hand, in a slower decrease in the speed of the rotating engine when the foot is removed from the accelerator pedal. In addition, the need for rotation of the flywheel and an additional balance shaft in addition to each acceleration can reset this higher efficiency. In other words, with frequent acceleration, the resulting flow rate can be even higher than that of a comparable four-cylinder engine.

1,2 HTP bol motor developed practically from zero. The block and cylinder head are made of aluminum alloy and, depending on the version, a two-valve or four-valve timing mechanism is used, driven by a ringing chain and later a toothed chain. In order to save production costs, several components (pistons, connecting rodvalves) is used from the 1598 cc four-cylinder engine group (AEE) from the 111 kW EA 55 series, which many motorists know from the first Octavia, Golf or Felicia.

The main reason for creating the engine was to compete with competitors, as Opel or Toyota have successfully marketed three-liter, three-cylinder (four-cylinder) models for many years. On the other hand, the VW Group, with its four-liter single-cylinder engine, did not get much water, as it did not surpass either in dynamics or in consumption. Unfortunately, during the development of the OEM, several design errors occurred, which led to a greater sensitivity of the engine to the method of use and, as a consequence, to an increased risk of technical problems.

The main moving parts are from a three-cylinder engine 1.2 12V (47 kW). The most significant difference from the 1.2 HTP (40 kW) engine is the four-valve gas distribution mechanism with two camshafts in the cylinder head (2 x OHC).

Irregular engine operation

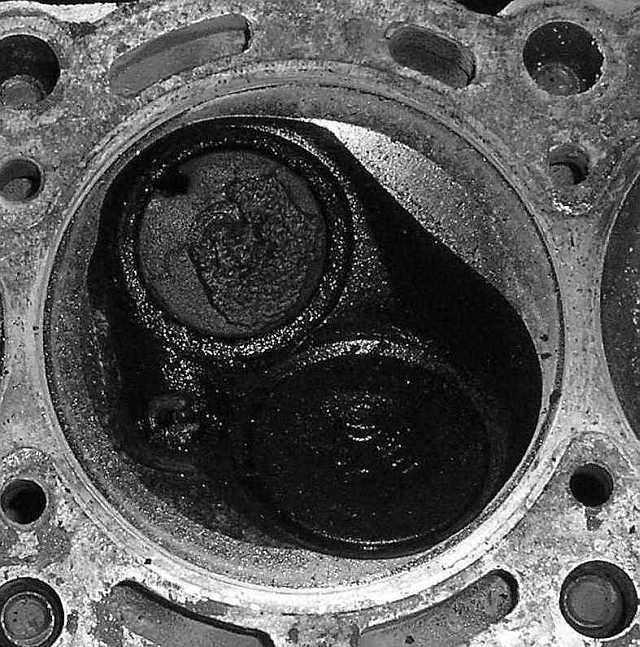

First of all, we can mention the complaints of motorists about irregular and unstable idling. A seemingly trivial question that can have costly consequences if not addressed in time. If we omit the breakdown of the ignition coil (a fairly common occurrence at the beginning of production), then the malfunction is hidden in the valve mechanism. Unstable idle is most often caused by loss of compression due to leaking (leaky) exhaust valves. This condition first manifests itself at low rpm, when the mixture has more time to exit through an imperfectly closed valve, and after gas is added, the operation is usually balanced. Later, the problem is compounded and the unevenness of the travel is noticeable in a much wider range of speeds.

The so-called "blowing" of the valve means an increased thermal stress on the valve itself and the environment, which, in turn, leads to ignition (deformation) of the valve and its seat. In case of minor breakdowns, repair will help (to repair the cylinder head seats and give new valves), but often it becomes necessary to replace the cylinder head along with the ignited valves. It should be added that this malfunction is much more common with a six-valve head (40 kW / 106 Nm or 44 kW / 108 Nm), which was not produced in Mlada Boleslav, but was purchased at other factories of the Volkswagen Group.

first The reason for mistrust may be a cylinder head made of less durable material, acc. material from which the valve guides are made. Like everything, valves gradually wear out (the clearance between the valve stem and its guide increases). Instead of a smooth sliding movement, the valve is said to vibrate, which leads to a delay in closing as well as excessive wear (increased backlash). A delay in closing leads to a decrease in the compression pressure and, as a result, to irregular engine operation.

second the problem is much more complicated. This is an excessive temperature of the engine oil, loss of its lubricating properties, etc. tappets carbonization (hydraulic valve clearance delimitation). This is because carbon can completely block the hydraulic tappets, which, together with the large backlash in the valve stem, causes it to vibrate during movement and thus be trapped.

Why is carbon formed? The 1,2 HTP engine heats up the oil a lot and often heats up to 140–150 ° C under higher loads (with HTP it also runs at normal motorway speed). Conventional four-cylinder engines of the same capacity heat the oil up to a maximum of 110–120 ° C, even at high speed. Thus, in the case of a 1,2 HTP engine, the engine oil overheats, which causes a more rapid deterioration in the original properties. A large amount of carbon is generated in the engine, which deposits, for example, on valves or hydraulic jacks and limits their operation. The increased amount of carbon also increases the wear on the mechanical parts of the engine.

The engine oil temperature in a three-cylinder engine is in principle higher, since it is determined by the higher ratio of engine displacement to total heat exchange area. However, this physically based fact does not increase the temperature enough to reach such high temperatures compared to a comparable four-cylinder engine. The main reason for excessive oil heating is the location of the catalyst directly above the main oil passage in the block. Thus, the oil is heated not only from inside the engine, but also from the outside - due to the temperature of the exhaust gases. In addition, unlike other units of the concern, there is no oil cooler, the so-called. a water-to-oil heat exchanger, or at least a so-called cube, i.e. aluminum air-oil heat exchanger, which is part of the oil filter holder. Unfortunately, in the case of the 1,2 HTP engine, this is not possible due to lack of space, as it would not fit there. The somewhat unfortunate location of the catalytic converter housing next to the engine's aluminum block, where the main oil passage runs through the block, was addressed by the manufacturer in 2007 with a slight improvement. The engines received a protective heat shield between the catalytic converter and the cylinder block. Unfortunately, this still did not completely solve the problem of overheating.

Another significant problem with the valves can be caused by another reason, the cause of which must be searched again in the catalyst. Since it is located just behind the tailpipes, it gets very hot under increased load. Thus, the cooling of the catalyst is solved by enriching the mixture, which in turn means increased consumption. So not only the higher speeds, but the aftercooling of the catalyst means the 1,2 HTP is eating grass next to the highway road. Despite cooling with a richer mixture, the catalyst still overheated. Excessive overheating, as well as increased engine vibration, has led to the gradual release of small parts from the catalyst core. They then return to the engine during engine braking, where they can again damage the valves and valve guides. This problem was only fixed at the end of 2009/2010. (With the advent of Euro 5), when the manufacturer began to assemble a more heat-resistant catalyst, in which parts and sawdust did not escape from the core even at higher loads. The manufacturer also supplies a kit for old damaged engines, which, in addition to the cylinder head, valves, hydraulic jacks and bolts, also contains leads with a modified catalyst, from which excess sawdust no longer escapes.

Thirdly Carbon deposits can be caused by a clogged throttle valve. The first 12-valve models were equipped with an exhaust gas recirculation valve. However, the return of exhaust gases to the intake manifold occurred too close behind the throttle valve, so that the swirling of exhaust gases in these places led to the clogging of the muffler with carbon. Often, after several tens of thousands of kilometers, the throttle valve does not reach the idle position. This causes idle fluctuations, but unfortunately not only that. If the idle microswitch is not connected, the accelerator resistance potentiometer will remain energized, which can ultimately damage the output stage of the control unit. Therefore, in the case of the first years of operation, which contain an EGR valve, it is strongly recommended to dismantle and thoroughly clean the damper every 50 km. Engines 000, 40 and up with 44 kW no longer contain the problematic exhaust gas recirculation valve.

Timing chain problems

Another technical problem, especially at the beginning of production, was the distribution chain drive. It's a paradox, because we read so many times that the toothed belt has been replaced by a maintenance-free chain. Surely the old "Škoda drivers" remember the phrase "gear train", which was part of the timing mechanism of the Škoda OHV engine. The only problem that arose was increased noise due to the tension of the chain itself. Perhaps there was no mention of a skip or break.

However, this does not happen with the 1,2 HTP engine, especially in the early years. The hydraulic timing chain tensioner runs too long and without oil pressure can create play that skips the chain when starting. And we are again in the quality of oil, because this happens especially when the oil deteriorates due to high temperatures, that is, it is thick, and the pump does not have time to supply it to the tensioner in time. The chain can be crossed even if the vehicle parked on the slope brakes only at the selected speed / quality or there have also been cases where the wheel bolts were tightened when the vehicle was jacked up and the wheels were braked only at the specified quality - if the vehicle is firmly planted on the ground . Timing chain problems can be manifested by increased noise - the so-called rattling or rattling sound when idling hard (engine spins at about 1000-2000 rpm) and then releases the accelerator pedal. If the chain skips 1 or 2 teeth, the engine can still be started, but it will run erratically and is usually accompanied by an illuminated engine light. If the chain bounces even more, the engine will not even start, resp. after a while it will go out, and if the chain accidentally slips while driving, a thud will usually be heard and the engine will go out. At this time, the damage is already fatal: bent connecting rods, bent valves, a cracked head or damaged pistons.

Also note the evaluation of the error messages. If, for example, the engine runs irregularly, the speed becomes worse and the diagnostics report a malfunction about an incorrect vacuum in the intake manifold, it is not a faulty sensor that is to blame, but simply a tooth or a missing circuit. If the sensor were only replaced and the car was running, there would be a high risk of a circuit skipping with fatal consequences for the engine.

Over time, the manufacturer began to modify the motors, for example by adjusting the tensioners to less travel or by lengthening the rails. For the 44 kW (108 Nm) and 51 kW (112 Nm) versions, the manufacturer modified the engine and the problem was significantly eliminated. However, it was possible to completely eliminate gaps only in July 2009, when the Škoda engine again modified the engine (the weight of the crankshaft was also reduced) and the assembly of the gear chain began. It replaces the problematic link chain, which has lower mechanical resistance, lower noise levels and, most importantly, higher operational reliability. It should be added that the timing of the timing chain was much more related to the more powerful version of 47 kW (significantly less than 51 kW).

What does this information lead to? Before purchasing a ticket with a 1,2 HTP engine, you must carefully listen to the engine operation. If possible, it is best to avoid the first year if you do not thoroughly know the owner, his work habits and driving style, respectively. engine not checked properly. During the production process, the units were gradually modernized, the reliability increased. The most significant improvements were made in July 2009 when the toothed chain was installed, in 2010 (Euro 5 emission standard) when a more robust catalytic converter was installed, and in November 2011 when the 6 kW single chamber engine was produced. ... The 44-valve version has ended. It was replaced by a 12-valve version with the same 44 kW output. Further improvements have also been made to the engine mechanics and control electronics (modified intake and exhaust pipes, crankshaft, new control unit, improved start assistant that smoothes the onset of clutch release torque, and a slight increase in idle speed) to improve performance. culture. The most powerful version with max. power of 55 kW and a torque of 112 Nm. Engines produced since November 2011 are already characterized by decent reliability and without any special remarks can be recommended for driving around the city and the surrounding area.

If you own or will own a 1,2 HTP engine, remember what job the HTP engine was designed for and use the vehicle as described in the introduction to this article. It is also recommended to reduce oil change intervals to a maximum of 10 km, and in the case of more frequent motorway trips, to 000 7500 km. No extra costs, since the engine oil is only 2,5 liters. Also, if the engine is more stressed, there is no need to change the oil recommended by the manufacturer according to the SAE standard (5W-30 al. 5W-40) to the 5W-50W-XNUMX viscosity grade. This oil is already thin enough to fill the fragile timing chain tensioner and hydraulic tappets quickly and in time, while at the same time withstanding excessive thermal stress.

Service - skipped timing chain 1,2 HTP 47 kW