shock absorbers. Construction, verification and cost

Content

The shock absorber is a key element in the suspension design of almost every car. Its job is to dampen vibrations, stabilize the track, and hold the springs in place. It is thanks to him that the wheel maintains constant contact with the surface. So let's check how it is built and what to do when it is developed?

The shock absorber is a key element in the suspension design of almost every car. Its job is to dampen vibrations, stabilize the track, and hold the springs in place. It is thanks to him that the wheel maintains constant contact with the surface. So let's check how it is built and what to do when it is developed?

shock absorbers. Operating principle

The shock absorber distributes the weight of the sprung mass to the wheels of our vehicle through appropriate punching and stamping damping. Shock absorbers and springs spring the body of the car in all conditions to achieve the best grip on the surface while maintaining comfort while driving. To solve this problem, engineers many years ago developed two types of shock absorbers: soft and hard (sports).

The shock absorber distributes the weight of the sprung mass to the wheels of our vehicle through appropriate punching and stamping damping. Shock absorbers and springs spring the body of the car in all conditions to achieve the best grip on the surface while maintaining comfort while driving. To solve this problem, engineers many years ago developed two types of shock absorbers: soft and hard (sports).

Soft, they transmit less vibration from unsprung masses to sprung masses and provide better driving comfort, which, unfortunately, translates into worse car handling when cornering. Therefore, to improve wheel traction in some cars, such as sports cars, rigid shock absorbers are used, which guarantee less body tilt, but, unfortunately, with reduced damping of bumps.

shock absorbers. Oil shock absorber

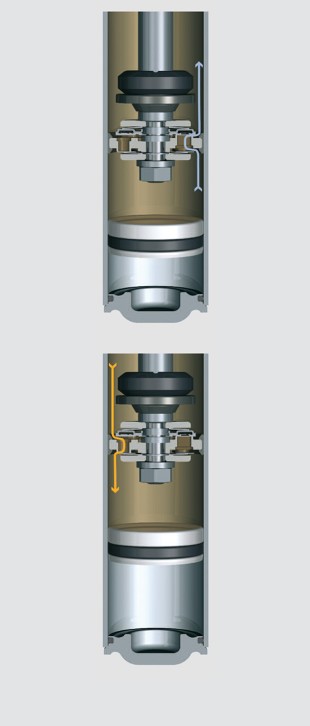

This is the first type of the element being described, i.e. a type of cylinder tightly filled with hydraulic oil. A piston is placed inside, which divides the space into two separate chambers and valves, thanks to which oil can flow between them, and they determine the speed of the piston. A properly selected valve ensures that the damping force is differentiated in compression and tension. The undoubted advantage of oil shock absorbers is their relatively easy regeneration and soft performance. The disadvantages include a large mass and a rather slow response when driving through bumps.

shock absorbers. Oil-gas shock absorber

Its structure resembles an oil shock absorber, but contains gas, nitrogen, to be exact, and hydraulic oil. In this configuration, the oil only compresses when the body is tilted significantly. When we overcome bumps, only gas works, which provides better traction. The oil/gas damper is lighter and offers the possibility of progressive action. Unfortunately, its regeneration is impossible. In addition, such a shock absorber is prone to damage, and even worse, a new part is not cheap.

shock absorbers. Signs of wear and check

Shock absorbers have a hard life on our roads. The most common signs of tire wear are increased body roll, the characteristic "diving" of the car when braking, hydraulic oil leakage, uneven tire wear, and excessive transmission of vibrations, knocking or squeaking when driving on uneven surfaces.

It is best to start the inspection by checking for shock absorber leaks or piston corrosion. If you see oil, this is a sign that damage can be suspected. However, it is best to contact a workshop or diagnostic station, where a specialist will determine the degree of wear and possibly qualify the part for replacement. Checking the effectiveness of shock absorbers can be carried out on a special machine, which, unfortunately, sometimes gives inaccurate results. Upon entering the station, the wheels are made to vibrate, followed by a measurement. The result is obtained as a percentage, more precisely, it is the adhesion force with the moving substrate. Percentages will not fully determine the effectiveness of a shock absorber, since the result depends on many components, such as vehicle load or mass distribution.

In this case, much depends on the degree of wear of other suspension elements, i.e. springs or metal-rubber elements, tire profile height and pressure. Tire pressures that are too low will increase performance, while tires that are too high will decrease performance. Thus, the effective damper can reach 40% as well as 70%. A value of more than 60% was taken as high efficiency. In short, the diagnostic station checks not so much the effectiveness of the shock absorbers as the difference between the wheels of a given axle.

The service life of both oil and gas-oil shock absorbers is estimated at a mileage of 60-100 thousand kilometers. km. However, the truth is that durability depends on how the vehicle is used, the quality of the road, and the driving style of the driver.

shock absorbers. Driver assistance systems

It is worth knowing that shock absorbers also have a big impact on the correct operation of electronic driving assistance systems such as ABS or ESP.

See also: What vehicles can be driven with a category B driver's license?

When the shock absorber is damaged and the wheel does not lift off the road properly, it can cause erroneous input signals to the controller. Which in an emergency will lead to an increase in the stopping distance and failure to receive adequate assistance in case of skidding.

shock absorbers. Exchange

The first and at the same time very important rule is to replace shock absorbers in pairs (in a given axis), which means that if, for example, the left front shock absorber is damaged, the right one must also be replaced. This is due to the specifics of their functioning. The new element has a different performance than the old part, resulting in a different ride and response to bumps. It is worth choosing completely new shock absorbers. The installation of used components is associated with a significant risk, since the suspension and brake system are components on which traffic safety directly depends. In addition, it is recommended to replace all types of pillows, bearings and covers along with shock absorbers. Before buying, you should read the opinions of users and workshops about the selected part. The cheapest substitutes, which very often have a much shorter lifespan, should be avoided.

The first and at the same time very important rule is to replace shock absorbers in pairs (in a given axis), which means that if, for example, the left front shock absorber is damaged, the right one must also be replaced. This is due to the specifics of their functioning. The new element has a different performance than the old part, resulting in a different ride and response to bumps. It is worth choosing completely new shock absorbers. The installation of used components is associated with a significant risk, since the suspension and brake system are components on which traffic safety directly depends. In addition, it is recommended to replace all types of pillows, bearings and covers along with shock absorbers. Before buying, you should read the opinions of users and workshops about the selected part. The cheapest substitutes, which very often have a much shorter lifespan, should be avoided.

shock absorbers. Expenses

The approximate cost of replacing two front shock absorbers (in a popular car) is about PLN 200, and rear shock absorbers - from PLN 100 to 200. Below are examples of prices for a set of front axle shock absorbers.

- Volkswagen Passat B5 1.9 TDI: PLN 320

- Audi A4 B7 1.8T: PLN 440

- Opel Astra G Estate 1.6: PLN 320

- Volkswagen Golf VI 2.0 TDI: PLN 430

- BMW 3 (e46) 320i: PLN 490

- Renault Laguna II 1.9 dCi: PLN 420

shock absorbers. Summary

A shock absorber is an element subject to natural wear and tear. The comfort and safety of travel directly depends on it, and this should not be forgotten. The first signs of its development should not be ignored, as the consequences of neglect can be deplorable. There is no shortage of spare parts, it is worth choosing a proven product, albeit a little more expensive.

See also: This is what the sixth generation Opel Corsa looks like.