Automotive putty. How to apply?

Content

How to breed?

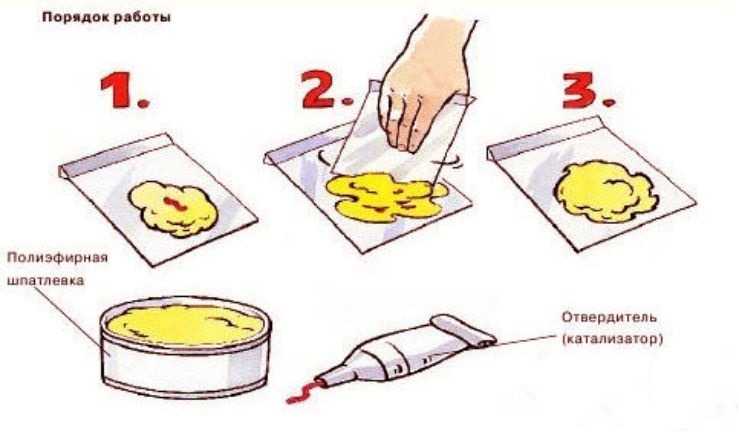

Automotive putties are sold in two-component form: putty mass (or base) and hardener. The base is a plastic substance that has good adhesion and pliability under external mechanical influence. The hardener is used to turn the liquid putty into a solid mass.

The vast majority of modern putties are diluted according to the same scheme: 2-4 grams of hardener per 100 grams of putty. In this case, the choice of the exact proportion depends on the weather conditions and the requirements for the speed of solidification. In dry hot weather, 2 grams is enough. If the weather is damp and cool, or accelerated curing is required, the proportion can be increased to 4-5 grams per 0,1 kg serving of base.

It is necessary to mix the base with the hardener slowly, with soft plastic movements and always by hand. It is impossible to beat automobile putty with mechanized means. This can saturate it with air, which loosens the hardened layer on the workpiece.

If, after adding the hardener and mixing, the putty has acquired a noticeable reddish tint, you should not use it. It is better to prepare a new portion. Too much hardener can cause a red tint to show through the paint.

How long does car putty with hardener dry?

The drying rate of automotive putty is influenced by many factors:

- brand of spatulas;

- amount of hardener;

- ambient temperature;

- air humidity;

- etc.

On average, one layer of putty dries for about 20 minutes to a set of strength sufficient for abrasive processing. However, when applying several layers, the drying time can be reduced. Finishing strength is gained in 2-6 hours.

You can also speed up the polymerization process of the putty with a hairdryer or an incandescent lamp. But there is one caveat here: it is categorically impossible to dry the first layer artificially, as this can subsequently lead to its cracking and peeling. And the subsequent layers should stand for at least 10 minutes after application without external influences. Only after the primary polymerization has passed, the putty is allowed to dry a little.

Watch this video on YouTube

How long does it take for fiberglass automotive putty to dry?

Fiberglass fillers are commonly used to fill deep uneven surfaces. They have high tensile strength and resist cracking well. Therefore, even a thick layer of putty with glass, unlike other types, is less likely to peel off the treated surface.

Due to the thicker layers, putty with glass requires a longer drying time. Different manufacturers report different curing rates for their products. But on average bodybuilders withstand fiberglass fillers 50% longer.

How to properly apply car putty?

There are simply no universal answers to the question of how to properly putty. Each master works in his own style. However, there are a few general recommendations that are mostly followed by bodybuilders.

- Work out in advance the question of which putty is better to eliminate the defect in your particular case.

- You need to cook as much putty at a time as is required to process one element or one defect. The hardener will turn the putty into a wax-like mass unsuitable for application in 5-7 minutes.

- Choose the appropriate spatula for the specific case. It makes no sense to stretch with a large wide spatula an area 3 times smaller than the spatula itself. The same applies to large areas of processing: do not try to pull them out with small spatulas.

- No need to try to immediately bring the surface to the ideal only with spatulas. The main thing is to fill the defective area well and accurately. And microroughness and "snot" will be removed with sandpaper.

Experienced bodybuilders work slowly, but without respite, within the framework of one defect.

What kind of sandpaper to rub putty for cars?

The first layer of automotive putty after drying is traditionally sanded with P80 sandpaper. This is a rather coarse-grained sandpaper, but it can be conveniently and quickly processed on a rough bottom layer.

Further, the grain with each subsequent processing increases by an average of 100 units. This is the so-called "rule of a hundred". That is, after the first rough grout, paper with a grain size of P180 or P200 is taken. After we increase to P300-400. You can already stop there. But if a perfectly smooth surface is required, then it will not be superfluous to walk with a finer-grained sandpaper.

After sanding, it is recommended to rinse the treated surface with water.

Watch this video on YouTube