Car racks: what is it, device, purpose

Content

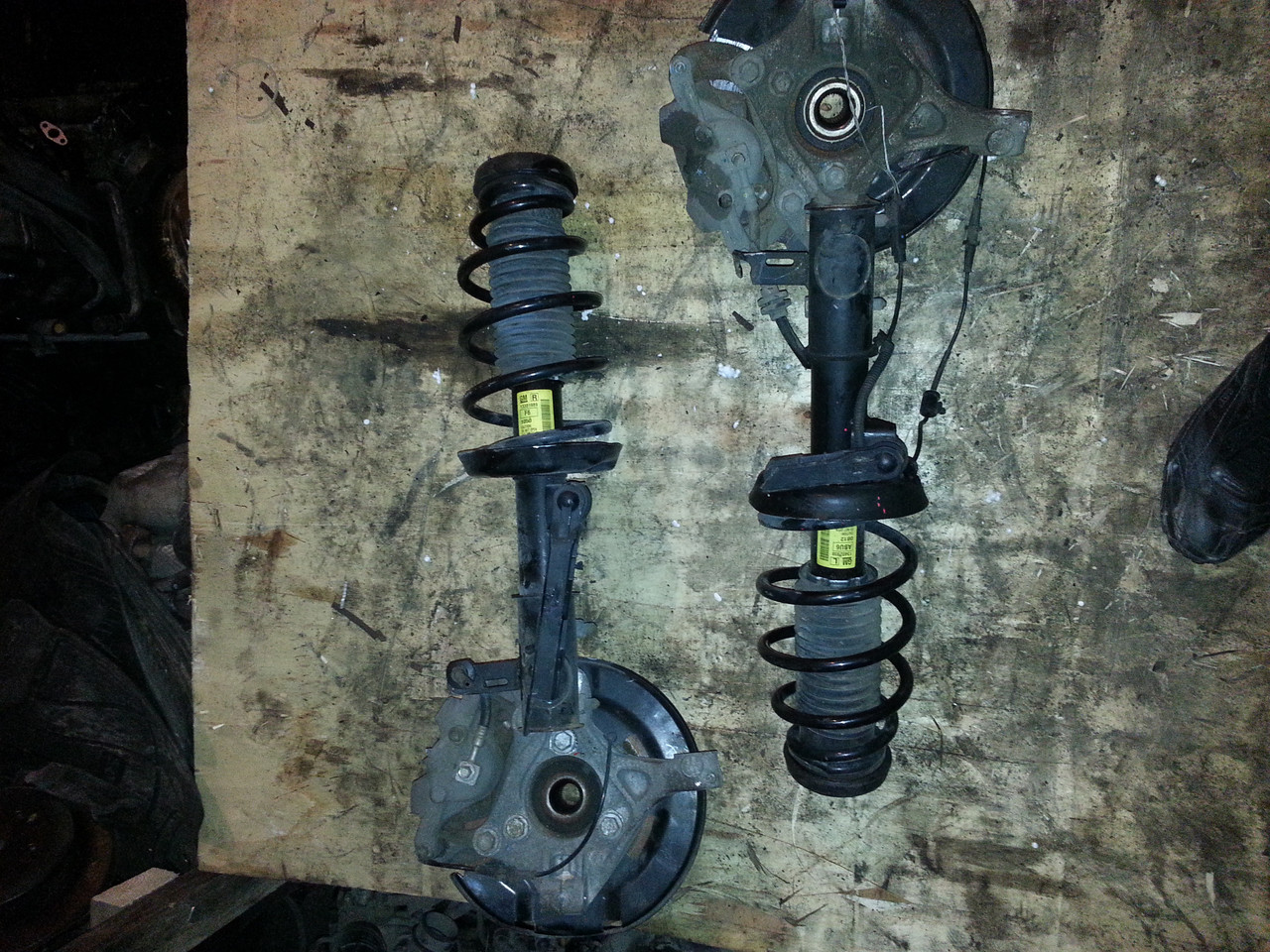

A shock absorber failure does not render the machine unusable. But it worsens comfort and controllability, as the duration and amplitude of body vibrations increase on bumps in the road. The struts of the car look quite powerful: they serve as a support, protect the suspension from shocks, and stabilize the wheels when cornering.

For safe and comfortable driving, special damping devices are responsible. Racks at the car are parts that provide stabilization during movement and maneuvers. The device should effectively protect cars and passengers from the effects of road roughness.

What is a stand

Engine torque is transmitted through the transmission to the wheels that are in contact with the road. All “bumps” and bumps at speed can respond with very strong blows for a car. To dampen vibrations in machines, special mechanisms are used, separately for each wheel. Such devices effectively reduce the amplitude of multidirectional vibrations of the car body.

The side struts of the car support the weight and the safe range of deflection of the center of gravity. They transfer the driving impulse from the wheels with little loss of energy to heat up the hydraulic fluid. Thus, the machine stand is a mechanism that provides the useful function of reducing the vibration of the support spring. A serviceable device affects the comfort and safety of a car on any road surface.

The racks of the car have differences in design, depending on the location on the car and the manufacturer. They differ in the type of hydraulic mixture in the cylinder body and the method of attachment to the car body and suspension.

Racks for cars

Rack device

The part connects the wheels of the car to the frame and body. And transfers the driving moment and direction to the design of the car.

Car racks consist of the following elements:

- A hollow cylinder with a piston inside. Filled with low compression material.

- Hydraulic mixture that transmits force to the piston. May be composed of liquids and gases.

- Push rod connected to the car body.

- The piston, which is located in the cylinder, is equipped with a valve and fits snugly against the walls.

- Sealing seals and glands to prevent liquid from escaping.

- A case that combines all parts into a single design

- Connecting elements for mounting the device.

Principle of operation

The main parts of the machine stand are the spring and shock absorber. The combined action of these elements provides good road holding, maneuverability and comfort:

- The spring is located on the axis of the rack, where it receives shocks when the car hits bumps and bumps. Rigid metal reduces the amplitude of vertical movement. It dampens the vibration effect of the roadway on the car body.

- The shock absorber of the machine rack, located on the longitudinal axis, reduces the return amplitude. And re allows the machine to sway in the vertical and horizontal direction. Together with the spring, it has the desired effect on reducing the vibrations that occur when hitting bumps in the road surface.

The functions of the car rack are:

- machine support;

- transmission of driving force from the wheels;

- body stabilization along the main axis;

- warning of a dangerous angle of inclination;

- side impact damping.

The design of the devices is different for different axles of the wheels. The front side pillars of the car are thin, long and with a thrust bearing. They can freely rotate around a vertical axis along with the wheel.

Varieties

The springs of the vehicle's shock-absorbing device are made of a special alloy that provides high elasticity. This detail in dimensions looks different for each brand of car.

Types of car strut shock absorbers:

- Mechanisms with oil shock absorbers for gentle operating conditions. On a bad road, they quickly heat up and lose their rigidity, but I have a small price.

- With a mixture of gases under pressure. Suspension with high rigidity effectively dampens vibrations and cools quickly. But the cost of this type of device is higher.

- With hydraulic fluid. A mixture of oil and gas under pressure. This type combines the advantages of the two previous ones - high efficiency on rough roads and good rigidity.

In automotive models of some companies, it is possible to adjust the operating mode of devices. The on-board computer controls the shock absorber bypass valve depending on the quality of the road surface. Types of operating modes:

- Sports.

- Comfort.

- Optimum.

These options correspond to a certain working pressure of the hydraulic mixture.

What is the difference between strut and shock absorber

The purpose of the device is to keep the machine in motion in a stable state. As well as protecting the car from multidirectional impacts on the elements of the suspension and bodywork.

Rear shock absorbers

The difference between a damping mechanism and a shock absorber:

- Attachment to ball joint and suspension arm.

- The action of loads from different directions.

- Higher cost and complexity.

- The machine cannot be operated with a defective device.

The car strut shock absorber usually acts as a structural element. But it can also be installed separately - it is attached to silent blocks and a loop on the car body.

A shock absorber failure does not render the machine unusable. But it worsens comfort and controllability, as the duration and amplitude of body vibrations increase on bumps in the road. The struts of the car look quite powerful: they serve as a support, protect the suspension from shocks, and stabilize the wheels when cornering.

A separate shock absorber is not a proper analogue of a damping mechanism. Therefore, in the event of a breakdown, it is necessary to replace the device with a new one.

Life time

The design of the damping mechanisms is quite reliable. But tough operation affects the durability of the elements.

More often the shock absorber as part of the car rack breaks. But there are breakdowns of other structural parts: fasteners, ball bearings, thrust bearings and springs. Shock-absorbing devices with a gas hydraulic mixture have a long service life.

The duration of the operation of the machine rack is affected by unpaired installation. If only one device is replaced, then the loads increase due to the different oscillation amplitudes. Due to asymmetrical impacts, suspension elements are likely to break.

When replacing, you need to install a new mechanism assembly. Old worn out elements cannot work effectively and will shorten the life of the entire device.