Contactless ignition VAZ 2106: device, scheme of work, installation and configuration guide

Content

The electronic sparking system appeared only on the latest modifications of the rear-wheel drive "classic" VAZ 2106. Until the mid-90s, these cars were equipped with ignition with a mechanical interrupter, which was very unreliable in operation. The problem is solved relatively easily - the owners of outdated "sixes" can purchase a contactless ignition kit and install it on the car on their own, without turning to electricians.

Electronic ignition device VAZ 2106

The contactless system (abbreviated as BSZ) "Zhiguli" includes six devices and parts:

- the main distributor of ignition pulses is a distributor;

- a coil that generates high voltage for a spark;

- switch;

- connecting loop of wires with connectors;

- high voltage cables with reinforced insulation;

- spark plug.

From the contact circuit, the BSZ inherited only high-voltage cables and candles. Despite the outward resemblance to the old parts, the coil and the distributor are structurally different. New elements of the system are the control switch and the wiring harness.

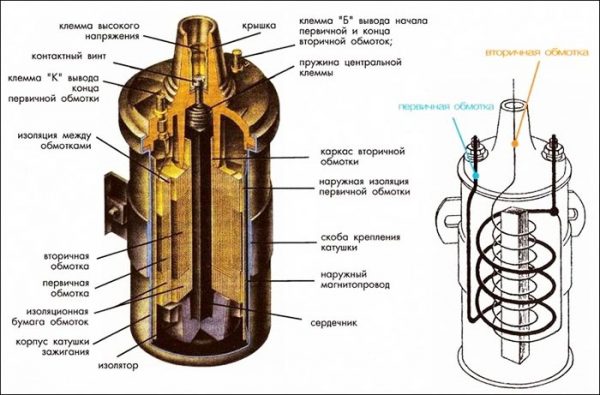

A coil operating as part of a non-contact circuit differs in the number of turns of the primary and secondary windings. Simply put, it is more powerful than the old version, since it is designed to create impulses of 22-24 thousand volts. The predecessor gave out a maximum of 18 kV to the electrodes of the candles.

A cable with connectors is used for reliable connection of the terminals of the ignition distributor and the switch. The device of these two elements should be considered separately.

Contactless distributor

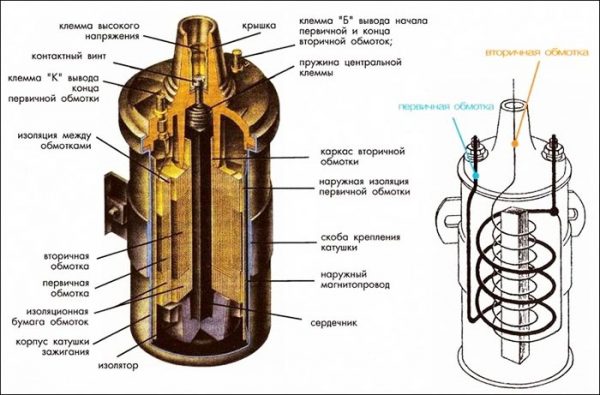

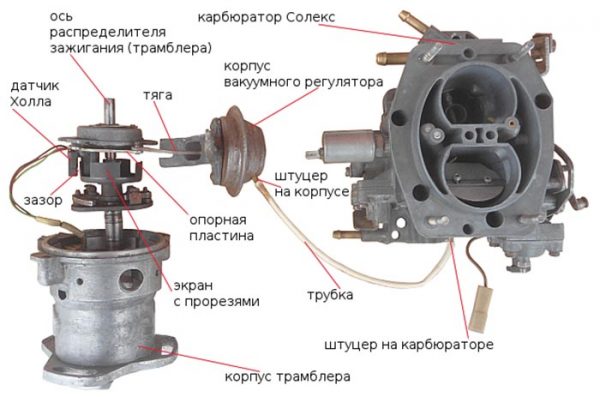

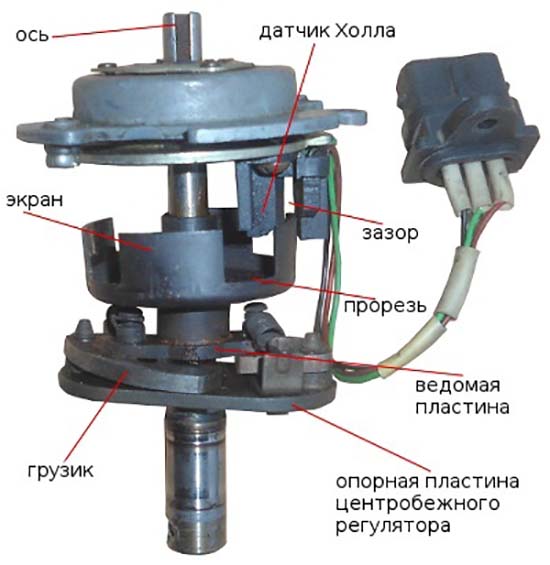

The following parts are located inside the distributor housing:

- a shaft with a platform and a slider at the end;

- base plate pivoting on a bearing;

- Hall magnetic sensor;

- a metal screen with gaps is fixed on the shaft, rotating inside the sensor gap.

Outside, on the side wall, a vacuum ignition timing unit is installed, connected to the support platform by means of a rod. A cover is fixed on top of the latches, where the cables from the candles are connected.

The main difference of this distributor is the absence of a mechanical contact group. The role of the interrupter here is played by an electromagnetic Hall sensor, which reacts to the passage of a metal screen through the gap.

When the plate covers the magnetic field between two elements, the device is inactive, but as soon as a gap opens in the gap, the sensor generates a direct current. How the distributor works as part of electronic ignition, read below.

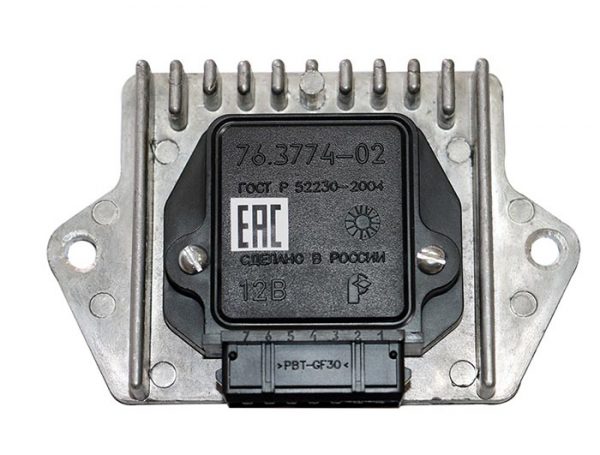

Control switch

The element is a control board protected by a plastic cover and attached to an aluminum cooling radiator. In the latter, 2 holes were made for mounting the part to the car body. On the VAZ 2106, the switch is located inside the engine compartment on the right side member (in the direction of the car), next to the coolant expansion tank.

The main functional details of an electronic circuit are a powerful transistor and a controller. The first solves 2 tasks: it amplifies the signal from the distributor and controls the operation of the primary winding of the coil. The microcircuit performs the following functions:

- instructs the transistor to break the coil circuit;

- creates a reference voltage in the electromagnetic sensor circuit;

- counts the engine speed;

- protects the circuit from high-voltage impulses (over 24 V);

- adjusts the ignition timing.

The switch is not afraid of changing polarity if the motorist mistakenly confuses the positive wire with the "ground". The circuit contains a diode that closes the line in such cases. The controller will not burn out, but simply cease to function - a spark will not appear on the candles.

Scheme and principle of operation of the BSZ

All elements of the system are interconnected and with the engine as follows:

- the distributor shaft rotates from the drive gear of the motor;

- the Hall sensor installed inside the distributor is connected to the switch;

- the coil is connected by a low voltage line to the controller, high - to the central electrode of the distributor cover;

- high-voltage wires from the spark plugs are connected to the side contacts of the main distributor cover.

The threaded clamp "K" on the coil is connected to the positive contact of the ignition lock relay and the terminal "4" of the switch. The second terminal marked "K" is connected to the "1" contact of the controller, the tachometer wire also comes here. Terminals "3", "5" and "6" of the switch are used to connect the Hall sensor.

The algorithm for the operation of the BSZ on the "six" looks like this:

- After turning the key in the lock voltage served on electromagnetic sensor и first winding transformer. A magnetic field develops around the steel core.

- The starter rotates the engine crankshaft and the distributor drive. When a screen slit passes between the sensor elements, a pulse is generated that is sent to the switch. At this point, one of the pistons is close to the top point.

- The controller through the transistor opens the circuit of the primary winding of the coil. Then, in the secondary, a short-term pulse of up to 24 thousand volts is formed, which goes along the cable to the central electrode of the distributor cover.

- After passing through the movable contact - the slider directed towards the desired terminal, the current flows to the side electrode, and from there - through the cable to the candle. A flash is formed in the combustion chamber, the fuel mixture ignites and pushes the piston down. The engine starts.

- When the next piston reaches TDC, the cycle repeats, only the spark is transferred to another candle.

For optimal fuel combustion during engine operation, a flash in the cylinder should occur a fraction of a second before the piston reaches its maximum upper position. To do this, the BSZ provides for sparking ahead of a certain angle. Its value depends on the speed of the crankshaft and the load on the power unit.

The switch and the vacuum block of the distributor are engaged in adjusting the advance angle. The first reads the number of pulses from the sensor, the second acts mechanically from the vacuum supplied from the carburetor.

Video: BSZ differences from a mechanical breaker

Non-contact system faults

In terms of reliability, the BSZ significantly surpasses the outdated contact ignition of the "six", problems occur much less frequently and are easier to diagnose. Signs of a system malfunction:

- complete failure - the engine stalls and no longer starts;

- uneven idling, shots in the carburetor when the gas pedal is pressed sharply;

- interruptions and skipping cycles while driving.

The most common first symptom is an engine failure, accompanied by a lack of spark. Common causes of failure:

- The resistor built into the distributor slider burned out.

The burnout of the resistor installed in the slider leads to a break in the high-voltage circuit and the absence of a spark on the candles

The burnout of the resistor installed in the slider leads to a break in the high-voltage circuit and the absence of a spark on the candles - Hall sensor failed.

- A break in the wires connecting the switch to the coil or sensor.

- The switch burned out, more precisely, one of the parts of the electronic board.

The high-voltage coil becomes unusable extremely rarely. The symptoms are similar - the complete absence of a spark and a "dead" motor.

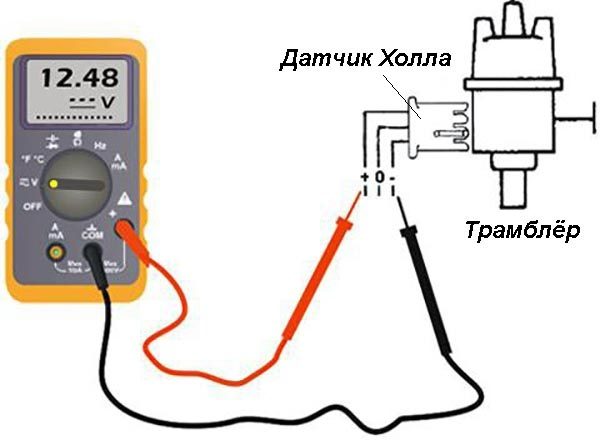

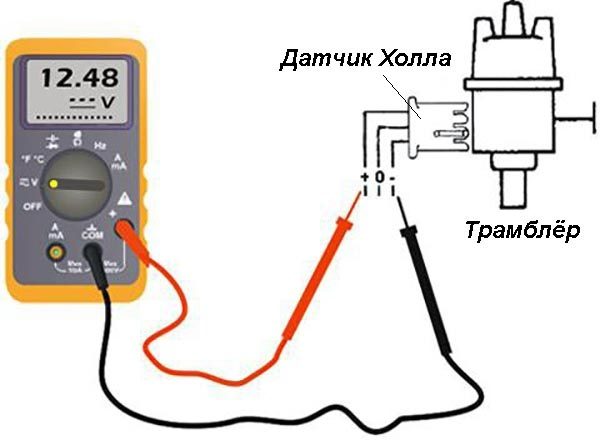

The search for the "culprit" is carried out by the method of successive measurements at different points. Turn on the ignition and use a voltmeter to check the voltage at the Hall sensor, transformer contacts and switch terminals. The current must be supplied to the primary winding and 2 extreme contacts of the electromagnetic sensor.

Hall sensor failure is diagnosed as follows:

- Disconnect the high-voltage cable from the central socket on the distributor cover and fix the contact in close proximity to the body, at a distance of 5-10 mm.

- Disconnect the connector from the distributor, insert the bare end of the wire into its middle contact.

The test lead to test the sensor is inserted into the middle contact of the disconnected connector.

The test lead to test the sensor is inserted into the middle contact of the disconnected connector. - Touch the body with the other end of the conductor, after turning on the ignition. If there was no spark before, but now it appears, change the sensor.

When the engine runs intermittently, you need to check the integrity of the wiring, the contamination of the switch terminals or high-voltage wires for insulation breakdown. Sometimes there is a delay in the switch signal, causing dips and deterioration in overclocking dynamics. It is quite difficult for an ordinary owner of a VAZ 2106 to detect such a problem, it is better to contact a master electrician.

Modern controllers used on the contactless ignition of the "six" burn out quite rarely. But if the Hall sensor test gave a negative result, then try to replace the switch by elimination. Fortunately, the price of a new spare part does not exceed 400 rubles.

Video: how to check the health of the switch

Installation of BSZ on VAZ 2106

When choosing a contactless ignition kit, pay attention to the engine size of your "six". The distributor shaft for a 1,3-liter engine should be 7 mm shorter than for more powerful power units of 1,5 and 1,6 liters.

To install the BSZ on a VAZ 2106 car, you should prepare the following set of tools:

- open-end wrenches or spanners with dimensions of 7-13 mm;

- screwdrivers with flat and Phillips slots;

- pliers;

- drill with a 4 mm drill (to mount the electronic unit in the side member, you will have to make 2 holes for self-tapping screws).

First of all, you need to dismantle the old system - the main distributor and the coil:

- Remove the high-voltage wires from the sockets of the distributor cover and disconnect it from the body by unlocking the latches.

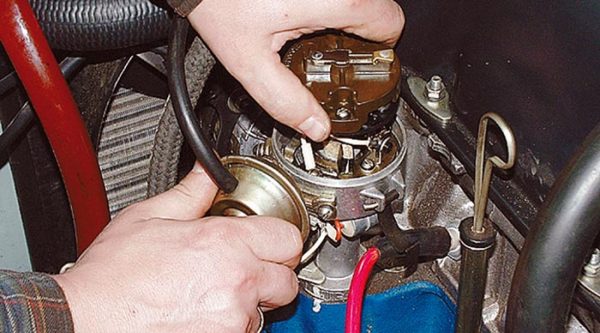

Dismantling of old equipment begins with disassembling the distributor - removing the cover and wires

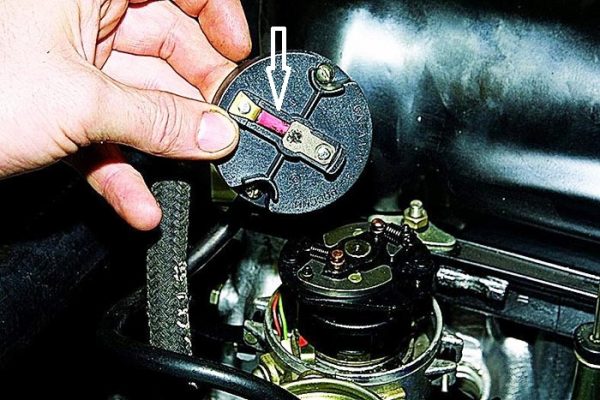

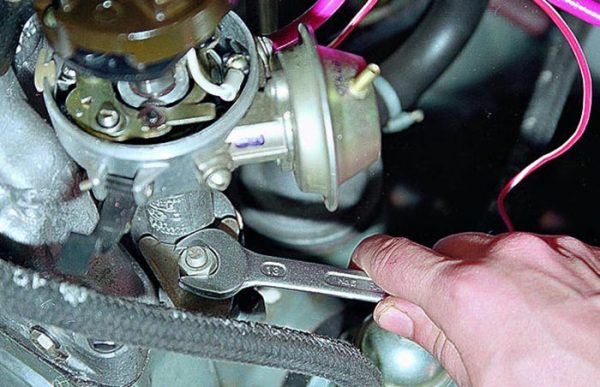

Dismantling of old equipment begins with disassembling the distributor - removing the cover and wires - Turning the crankshaft, set the slider at an angle of approximately 90 ° to the motor and put a mark on the valve cover opposite. Unscrew the 13 mm nut securing the distributor to the block.

Before removing the ignition distributor, mark the position of the slider with chalk

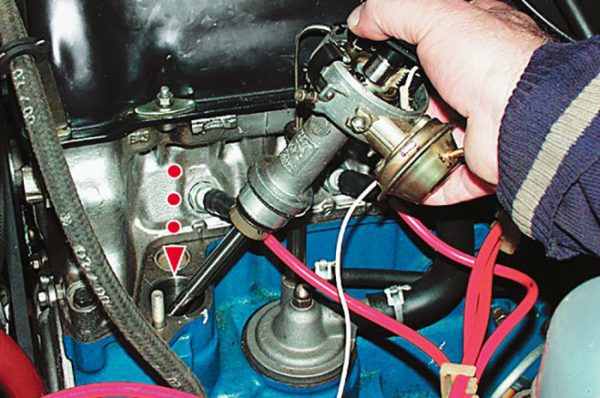

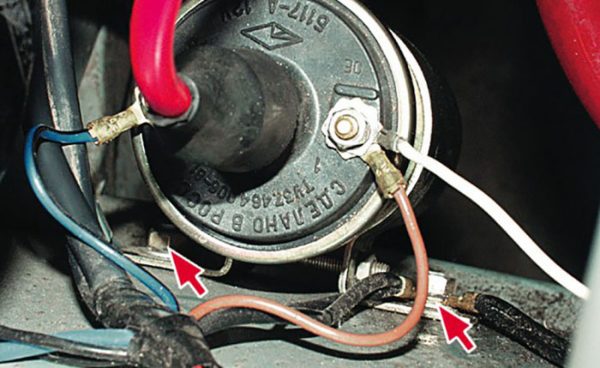

Before removing the ignition distributor, mark the position of the slider with chalk - Unscrew the clamps of the old coil and disconnect the wires. It is desirable to remember the pinout or sketch it.

Wire terminals are connected to the transformer contacts on threaded clamps

Wire terminals are connected to the transformer contacts on threaded clamps - Loosen and unscrew the clamp fastening nuts, remove the coil and distributor from the car.

The distributor housing is attached to the cylinder block with a single 13 mm wrench nut

The distributor housing is attached to the cylinder block with a single 13 mm wrench nut

When removing the ignition distributor, keep the gasket in the form of a washer installed between the part platform and the cylinder block. It can be useful for a contactless distributor.

Before installing the BSZ, it is worth checking the condition of the high voltage cables and candles. If you doubt the performance of these parts, it is better to change them immediately. Serviceable candles must be cleaned and set a gap of 0,8-0,9 mm.

Install the contactless kit according to the instructions:

- Remove the cover of the BSZ distributor, if necessary, rearrange the sealing washer from the old spare part. Turn the slider to the desired position and insert the distributor shaft into the socket, lightly press the platform with a nut.

Before installing the distributor in the socket, turn the slider towards the chalk marks drawn on the valve cover

Before installing the distributor in the socket, turn the slider towards the chalk marks drawn on the valve cover - Put on the cover, fixing the latches. Connect the spark plug cables according to the numbering (numbers are indicated on the cover).

- Screw the coil of the contactless system to the body of the VAZ 2106. In order for the terminals "B" and "K" to stand in their original position, first unfold the body of the product inside the mounting clamp.

When mounting the coil, connect the wires from the ignition relay and tachometer

When mounting the coil, connect the wires from the ignition relay and tachometer - Put the wires from the ignition switch and tachometer on the contacts according to the above diagram.

- Next to the side member, install the controller by drilling 2 holes. For convenience, remove the expansion tank.

The controller is attached to the holes in the side member using self-tapping screws.

The controller is attached to the holes in the side member using self-tapping screws. - Connect the wiring harness to the distributor, switch and transformer. The blue wire is connected to the “B” terminal of the coil, the brown wire is connected to the “K” contact. Place a high voltage cable between the distributor cover and the center electrode of the transformer.

Candle cables are connected according to the numbering on the cover, the central wire is connected to the coil electrode

Candle cables are connected according to the numbering on the cover, the central wire is connected to the coil electrode

If during the installation process there were no annoying errors, the car will start immediately. The ignition can be adjusted "by ear" by releasing the distributor nut and slowly turning the body at idle engine speed. Achieve the most stable operation of the motor and tighten the nut. Installation completed.

Video: instructions for installing non-contact equipment

Watch this video on YouTube

Setting the ignition timing

If you forgot to put a risk on the valve cover before disassembly or did not align the marks, the moment of sparking will have to be adjusted again:

- Turn out the candle of the first cylinder and reset the cover of the main distributor.

To track the piston stroke, you need to unscrew the candle of the first cylinder

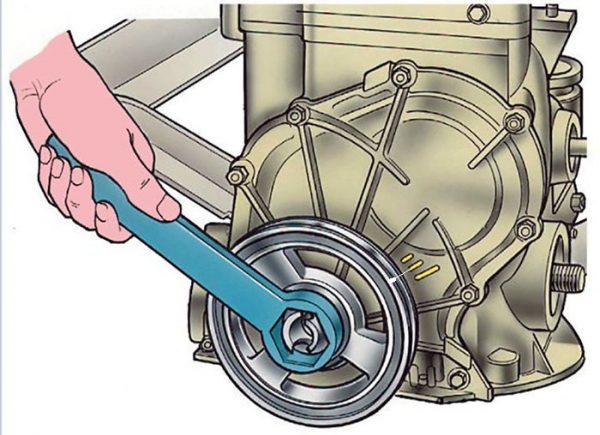

To track the piston stroke, you need to unscrew the candle of the first cylinder - Insert a long screwdriver into the spark plug well and turn the crankshaft by the ratchet clockwise with a wrench (when viewed from the front of the machine). The goal is to find the TDC of the piston, which will push the screwdriver out of the well as much as possible.

The mark on the pulley is set opposite the long line on the motor housing

The mark on the pulley is set opposite the long line on the motor housing - Loosen the nut holding the distributor to the block. By rotating the case, make sure that one of the slots of the screen is in the gap of the Hall sensor. In this case, the movable contact of the slider must be clearly aligned with the side contact "1" on the cover of the distributor.

The distributor body should be rotated to the desired position and fixed with a nut

The distributor body should be rotated to the desired position and fixed with a nut - Tighten the distributor mounting nut, install the cap and spark plug, then start the engine. When it warms up to 50-60 degrees, adjust the ignition "by ear" or by strobe.

Attention! When the piston of cylinder 1 reaches its upper position, the notch of the crankshaft pulley should coincide with the first long risk on the cover of the timing unit. Initially, you need to provide a lead angle of 5 °, so set the pulley mark opposite the second risk.

In the same way, tuning is carried out using a light bulb connected to the mass of the car and the low-voltage winding of the coil. The moment of ignition is determined by the flash of the lamp when the Hall sensor is activated, and the switch transistor opens the circuit.

Video: ignition adjustment "by ear"

Watch this video on YouTube

Candles for electronic ignition

When installing a BSZ on a VAZ 2106 model car, it is advisable to select and install candles that are optimally suited for electronic ignition. Along with Russian spare parts, it is allowed to use imported analogues from well-known brands:

- original candles recommended by the manufacturer - A17DVR (M);

- NGK — BCPR6ES-9, BPR6ES-9;

- Bosch—FR7DCU, WR7DC;

- Brisk — DR15YC, LR15YC;

- I take — 14FR-7DU, 14R-7DU.

The letter M in the marking of a domestic part indicates copper plating of the electrodes. On sale there are A17DVR kits without copper coating, quite suitable for BSZ.

The gap between the working electrodes of the candle is set within 0,8-0,9 mm using a flat probe. Exceeding or decreasing the recommended clearance leads to a drop in engine power and an increase in gasoline consumption.

The installation of a non-contact sparking system significantly improves the performance of carburetor Zhiguli equipped with rear-wheel drive. Unreliable, always burning contacts brought a lot of trouble to the owners of the "sixes". At the most inopportune moments, the breaker had to be cleaned, getting your hands dirty. The first electronic ignition appeared on the front-wheel drive models of the "eighth" family, and then migrated to the VAZ 2101-2107.